Oxygen sensors UDC and DDC on Priora

Content

- Purpose and features of oxygen sensors

- Design features and principle of operation of oxygen sensors: interesting and very useful information

- What happens to the car when the oxygen sensor malfunctions: error codes

- How to properly check the oxygen sensor for Priora's serviceability: instructions

- Features of removing and replacing the oxygen sensor on the VAZ-2170: articles and models from different manufacturers for Priora

- Lambda repair on Priore: how to fix it and features of proper cleaning

- Is it worth putting a trick instead of a lambda on Priora: we reveal all the secrets of using tricks

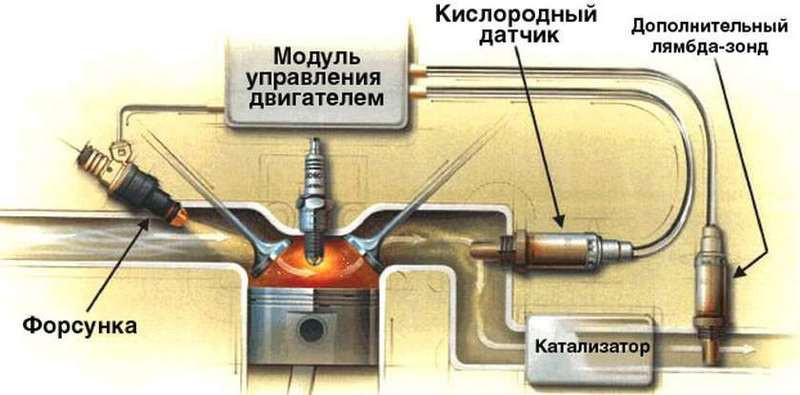

VAZ-2170 cars and their modifications are equipped with devices called oxygen sensors. They are installed in the design of the exhaust system and perform very important functions. Its breakdowns affect not only the increase in harmful emissions into the atmosphere, but also worsen the operation of the engine. Priora is equipped with 2 such devices, which are also called lambda probes (scientifically). It is with these elements that we will get acquainted in more detail and find out their purpose, varieties, signs of malfunctions and features of the correct replacement in Prior.

material content

- Purpose and characteristics of oxygen sensors

- Design features and principle of operation of oxygen sensors: interesting and very useful information

- What happens to the car if the oxygen sensor malfunctions: error codes

- How to properly check the oxygen sensor for serviceability Priors: instructions

- Features of removing and replacing the oxygen sensor on the VAZ-2170: articles and models from different manufacturers on Priora

- Lambda repair on prior: how to fix it and features of proper cleaning

- Should I give Priora a cheat instead of a lambda?: we reveal all the secrets of using cheats

Purpose and features of oxygen sensors

An oxygen sensor is a device that measures the amount of oxygen in the exhaust system. Several such devices are installed on the Priors, which are located immediately before and after the catalytic converter. The lambda probe performs important functions, and its correct operation affects not only the reduction of harmful emissions into the atmosphere, but also increases the efficiency of the power unit. However, not all car owners agree with this opinion. And to understand why this is so, a detailed analysis of such devices should be carried out.

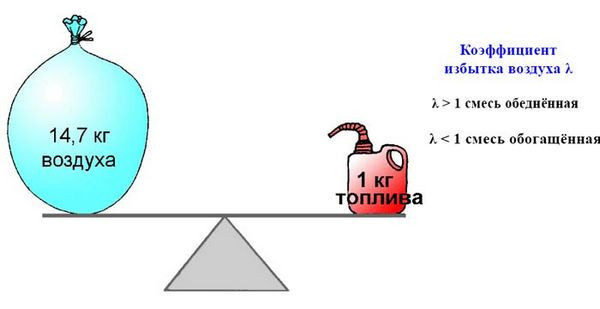

Interesting! The lambda probe sensor got this name for a reason. The Greek letter "λ" is called lambda, and in the automotive industry it represents the ratio of excess air in an air-fuel mixture.

First, let's pay attention to the oxygen sensor on the Priore, which is located after the catalyst. In the photo below, it is indicated by an arrow. It is called a Diagnostic Oxygen Sensor, or DDK for short.

Oxygen sensor No. 2 in Prior

Oxygen sensor No. 2 in Prior

The main purpose of the second (it is also called additional) sensor is to control the operation of the exhaust gas catalyst. If this element is responsible for the correct operation of the exhaust gas filter, then why do we need the first sensor, which is listed below.

Priora control oxygen sensor

A sensor located just before the catalytic converter is used to determine the amount of oxygen in the exhaust gases. He is called a manager or UDC for short. Engine efficiency depends on the amount of oxygen in the exhaust vapors. Thanks to this element, the most efficient combustion of fuel cells is guaranteed and the harmfulness of exhaust gases is reduced due to the absence of unburned gasoline components in its composition.

Delving into the topic of the purpose of a lambda probe in cars, you should know that such a device does not determine the amount of harmful impurities in the exhaust, but the amount of oxygen. Its value is equal to "1" when the optimal composition of the mixture is reached (the optimal value is considered when 1 kg of air falls on 14,7 kg of fuel).

Interesting! By the way, the values of the air-gas ratio are 15,5 to 1, and for a diesel engine 14,6 to 1.

To achieve ideal parameters, an oxygen sensor is used.

If there is a large amount of oxygen in the exhaust gases, the sensor will transmit this information to the ECU (electronic control unit), which, in turn, will adjust the fuel assembly. You can learn more about the purpose of oxygen sensors from the video below.

Design features and principle of operation of oxygen sensors: interesting and very useful information

The design and principle of operation of the oxygen sensor is information that will be useful not only to previous owners, but also to other cars. After all, such information will be key and will play a significant role in troubleshooting a car with various breakdowns. Having convinced of the importance of this information, let's proceed to its consideration.

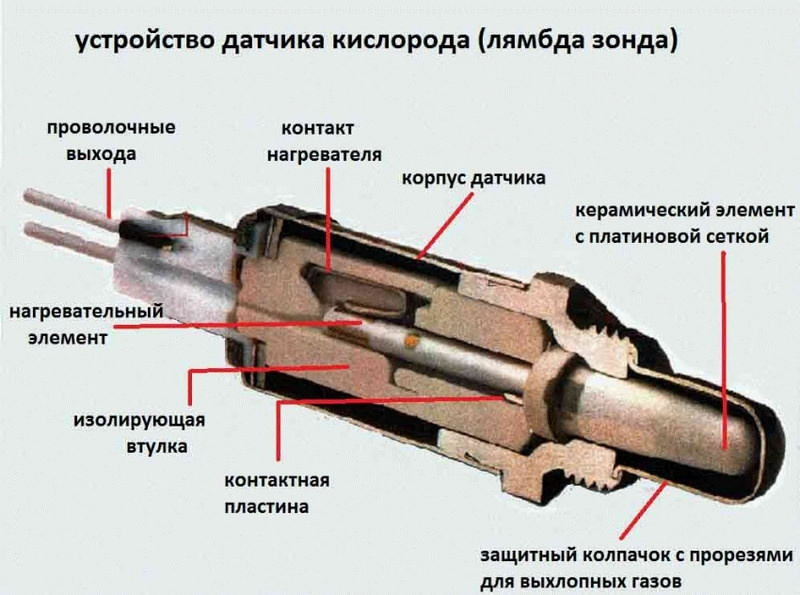

To date, there is a lot of information about the principle of operation of oxygen sensors and their design, but not always enough attention is paid to this issue. It should immediately be noted that oxygen sensors are divided into types depending on the type of materials from which they are made. However, this does not affect how you work, but is directly reflected in the work resource and quality of work. They are of the following varieties:

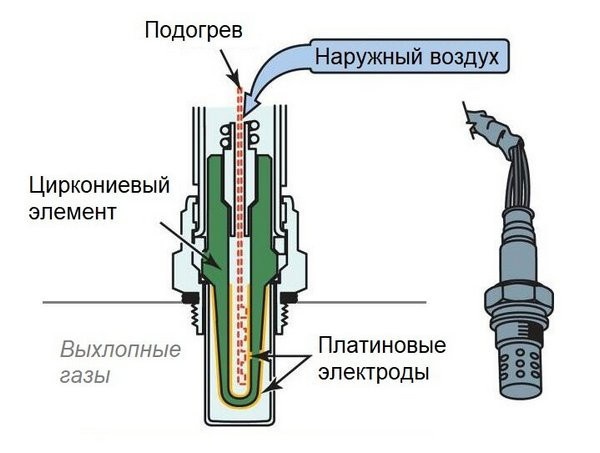

- Zirconium. These are the simplest types of products, the body of which is made of steel, and inside there is a ceramic element (a solid electrolyte of zirconium dioxide). Outside and inside the ceramic material is covered with thin plates, thanks to which an electric current is generated. Normal operation of such products occurs only when they reach temperature values of 300-350 degrees.

- Titanium. They are completely similar to zirconium-type devices, only differing from them in that the ceramic element is made of titanium dioxide. They have a longer service life, but their most important advantage is that due to the refractoriness of titanium, these sensors are equipped with a heating function. The heating elements are integrated, so the device heats up quickly, which means more accurate mixture values \uXNUMXb\uXNUMXbare obtained, which is important when starting a cold engine.

The cost of sensors depends not only on the type of material from which they are made, but also on factors such as quality, number of bands (narrowband and wideband), and who the manufacturer is.

Lambda probe device Interesting! Conventional narrowband devices are described above, while wideband devices are characterized by the presence of additional cells, thereby improving the quality, efficiency and durability of the devices. When choosing between narrowband and wideband elements, preference should be given to the second type.

Lambda probe device Interesting! Conventional narrowband devices are described above, while wideband devices are characterized by the presence of additional cells, thereby improving the quality, efficiency and durability of the devices. When choosing between narrowband and wideband elements, preference should be given to the second type.

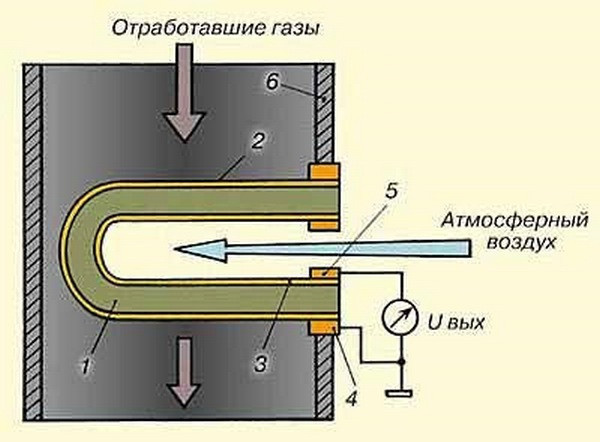

Knowing what oxygen sensors are, you can begin to study the process of their work. Below is a photo, on the basis of which you can understand the design and principle of operation of oxygen sensors.

This diagram shows the following important structural parts:

- 1 - ceramic element made of zirconium dioxide or titanium;

- 2 and 3 - outer and inner lining of the inner casing (screen), consisting of a layer of yttrium oxide coated with conductive porous platinum electrodes;

- 4 - grounding contacts that are connected to external electrodes;

- 5 - signal contacts connected to internal electrodes;

- 6 - imitation of the exhaust pipe in which the sensor is installed.

The operation of the device occurs only after it has been heated to high temperatures. This is achieved by passing hot exhaust gases. The warm-up time is approximately 5 minutes, depending on the engine and ambient temperature. If the sensor has built-in heating elements, then when the engine is turned on, the inner case of the sensor is additionally heated, which allows it to start working faster. The photo below shows this type of sensor in section.

Interesting! On Priors, the first and second lambda probes are used with heating elements.

After the sensor is heated, the zirconium (or titanium) electrolyte begins to create a current due to the difference in the composition of oxygen in the atmosphere and inside the exhaust, thus forming an EMF or voltage. The magnitude of this voltage depends on the amount of oxygen contained in the exhaust. It varies from 0,1 to 0,9 volts. Based on these voltage values, the ECU determines the amount of oxygen in the exhaust and adjusts the composition of the fuel cells.

Now let's move on to studying the principle of operation of the second oxygen sensor on the Priore. If the first element is responsible for the correct preparation of fuel cells, then the second is necessary to control the efficient operation of the catalyst. It has a similar principle of operation and design. The ECU compares the readings of the first and second sensors, and if they differ (the second device will show a lower value), then this indicates a malfunction of the catalytic converter (in particular, its contamination).

Differences between Priory UDC and DDC oxygen sensors Interesting! The use of two oxygen sensors indicates that Priora vehicles comply with Euro-3 and Euro-4 environmental standards. In modern cars, more than 2 sensors can be installed.

Differences between Priory UDC and DDC oxygen sensors Interesting! The use of two oxygen sensors indicates that Priora vehicles comply with Euro-3 and Euro-4 environmental standards. In modern cars, more than 2 sensors can be installed.

What happens to the car when the oxygen sensor malfunctions: error codes

The failure of the oxygen sensor in Priora cars and other cars (we are talking about the first lambda probe) leads to a disruption in the stable operation of the internal combustion engine. The ECU, in the absence of information from the sensor, puts the engine into an operating mode called emergency. It continues to operate, but only the preparation of fuel elements takes place according to average values, which manifests itself in the form of unstable operation of the internal combustion engine, increased fuel consumption, reduced power and increased harmful emissions into the atmosphere.

Usually, the transition of the engine into emergency mode is accompanied by the “Check Engine” indication, which in English means “check the engine” (and not an error). The causes of a sensor malfunction may be the following factors:

- wear Lambda probes have a certain resource, which depends on various factors. Priors are installed from the factory with ordinary narrow-band zirconium-type sensors, the resource of which does not exceed 80 km of run (this does not mean at all that the product needs to be changed at such a run);

- mechanical damage - the products are installed in the exhaust pipe, and if the first sensor practically does not come into contact with various obstacles that may affect it while driving, then the second one is highly susceptible to them in the absence of engine protection. Electrical contacts are often damaged, which contributes to the transfer of incorrect data to the computer;

- housing leakage. This usually happens when non-original products are used. With such a failure, the computer may fail, since an excess amount of oxygen contributes to the supply of a negative signal to the unit, which, in turn, is simply not designed for this. That is why it is not recommended to choose cheap non-original analogues of lambda probes from unknown manufacturers;

- use of low-quality fuel, oil, etc. If the exhaust is characterized by the presence of black smoke, carbon deposits form on the sensor, which leads to its unstable and incorrect operation. In this case, the problem is solved by cleaning the protective screen.

The characteristic signs of failure of the oxygen sensor on the Prior are the following manifestations:

- The "Check Engine" indicator lights up on the instrument panel.

- Unstable operation of the engine, both at idle and during operation.

- Increased fuel consumption.

- Increased exhaust emissions.

- The emergence of engine tuning.

- The occurrence of faults.

- Carbon deposits on spark plug electrodes.

- Corresponding error codes appear on the BC. Their respective codes and reasons are listed below.

A malfunction of the oxygen sensors can be determined by the presence of the corresponding error codes displayed on the BC screen (if available) or on the ELM327 scan.

ELM327

ELM327

Here is a list of these lambda probe error codes (DC - oxygen sensor) on Priore:

- P0130 - Incorrect lambda probe signal n. No. 1;

- P0131 - Low DC signal #1;

- P0132 - High level DC signal No. 1;

- P0133 - slow reaction of DC No. 1 to enrichment or depletion of the mixture;

- P0134 - open circuit DC No. 1;

- P0135 - Malfunction of the DC heater circuit No. 1;

- P0136 - short to ground DC circuit No. 2;

- P0137 - Low DC signal #2;

- P0138 - High level DC signal No. 2;

- P0140 - Open circuit DC No. 2;

- P0141 - DC heater circuit malfunction #2.

When the above signs appear, you should not immediately rush to change the DC on the Priora car. Check the cause of device failure by corresponding errors or by checking it.

How to properly check the oxygen sensor for Priora's serviceability: instructions

If there is a suspicion of a malfunction of the lambda probe itself, and not its circuit, it is not recommended to rush to change it without first checking it. The check is made as follows:

- In the KC installed in the car, it is necessary to disconnect its connector. This should change the sound of the engine. The engine should go into emergency mode, which is a sign that the sensor is working. If this does not happen, then the motor is already in emergency mode and the DC current does not correspond with 100% certainty. However, if the engine goes into emergency mode when the sensor is disconnected, this is not yet a guarantee of the product's full operability.

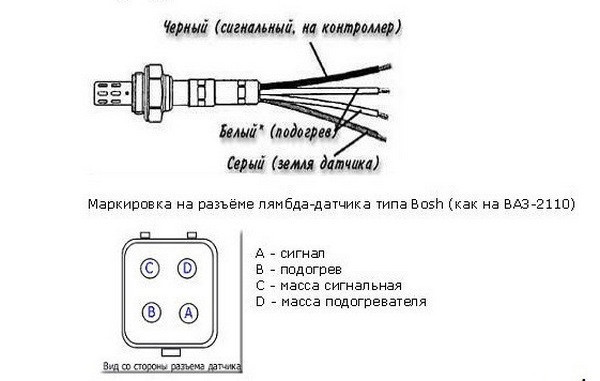

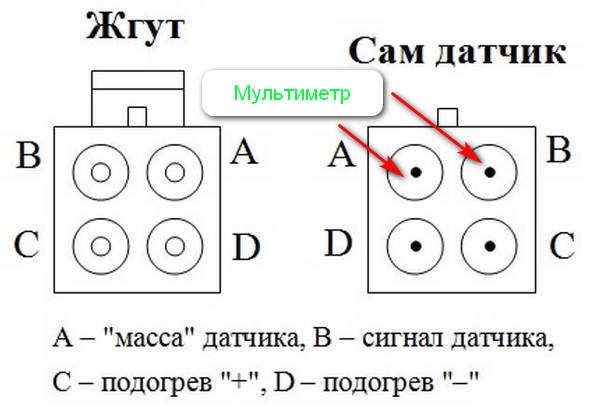

- Switch the tester to voltage measurement mode (minimum up to 1V).

- Connect the tester probes to the following contacts: the red probe to the black wire terminal of the DC (it is responsible for the signal sent to the computer), and the black probe of the multimeter to the gray wire terminal.

- Below is the pinout of the lambda probe on the Priore and which contacts to connect the multimeter to.

- Next, you need to look at the readings from the device. As the engine warms up, they should change by 0,9 V and decrease to 0,05 V. On a cold engine, the output voltage values \u0,3b\u0,6brange from 5 to XNUMX V. If the values do not change, this indicates a malfunction of the lambda. The device needs to be replaced. Despite the fact that the device has a built-in heating element, after starting a cold engine, it is possible to take readings and determine the correct operation of the element only after it has warmed up (about XNUMX minutes).

However, it is possible that the heating element of the sensor has failed. In this case, the device will also not work properly. To check the health of the heating element, you will need to check its resistance. The multimeter switches to resistance measurement mode, and its probes should touch the other two pins (red and blue wires). The resistance should be from 5 to 10 ohms, which indicates the health of the heating element.

Important! The colors of the sensor wires from different manufacturers may vary, so be guided by the pinout of the plug.

Based on simple measurements, the suitability of direct current can be judged.

Interesting! If there is a suspicion of a DC malfunction, then after the verification procedure, the working part should be disassembled and cleaned. Then repeat the measurements.

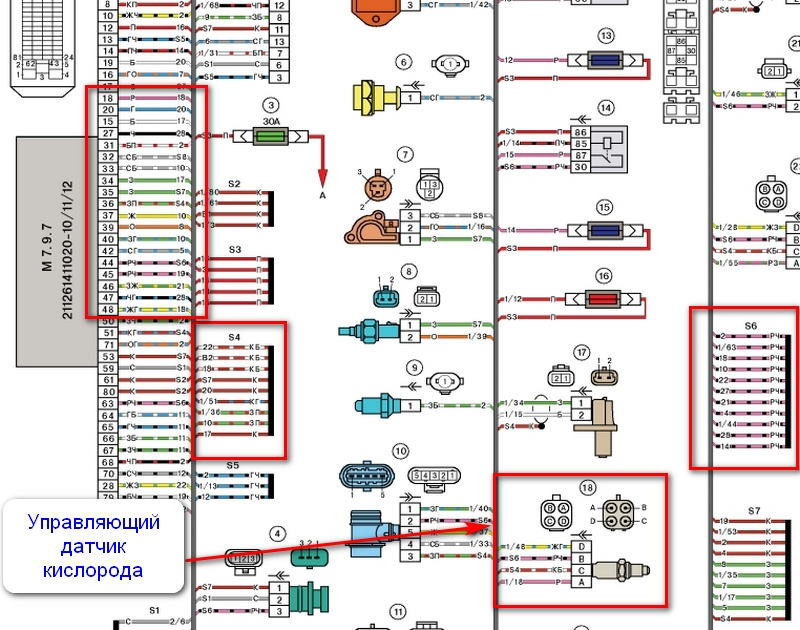

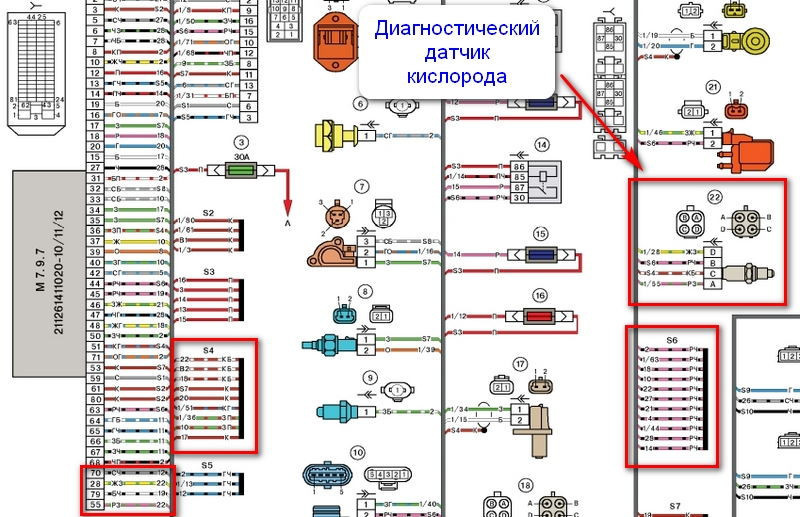

If the Priora lambda probe is working, it will not be superfluous to check the condition of the circuit. The power supply of the heater is checked with a multimeter, measuring the voltage at the contacts of the socket to which the device is connected. Checking the signal circuit is done by checking the wiring. For this, a basic electrical connection diagram is provided to help.

Oxygen Sensor Diagram #1

Oxygen Sensor Diagram #1  Oxygen Sensor Diagram #2

Oxygen Sensor Diagram #2

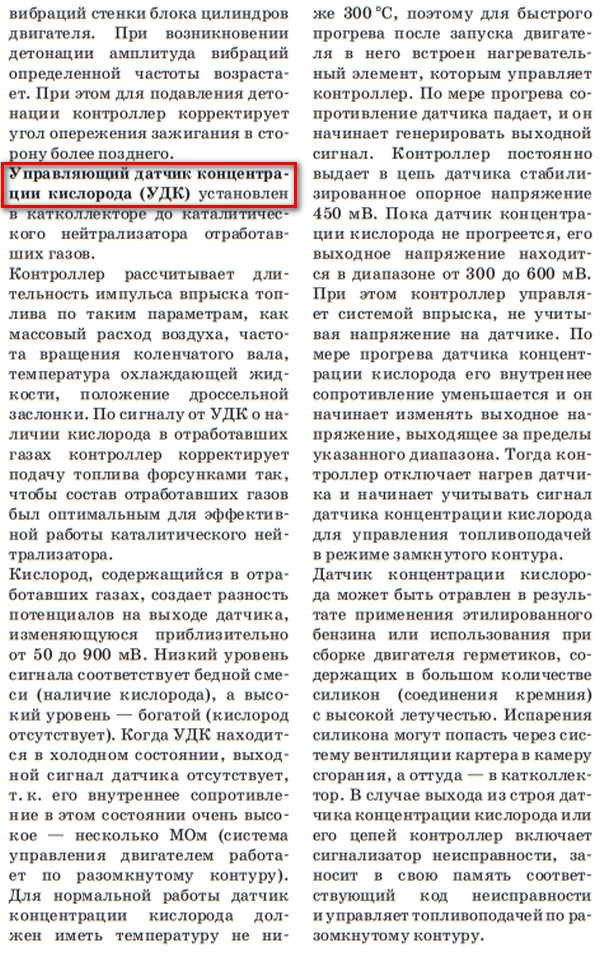

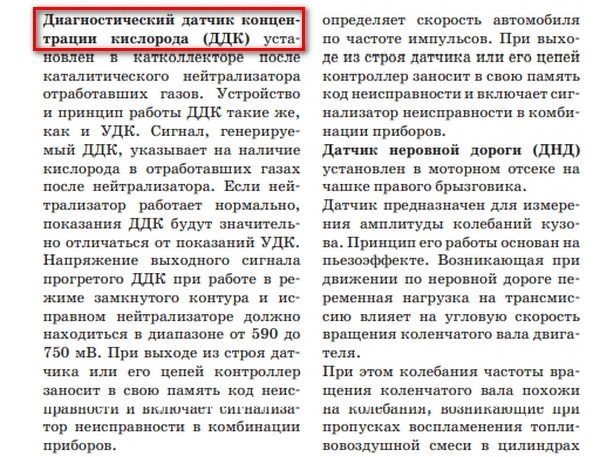

A defective sensor must be replaced. The test of both sensors is identical. Below is a description of the principle of operation of devices from the instructions for Priora cars.

Description of UDC Priora

Description of UDC Priora  Description of DDC Priora

Description of DDC Priora

It is important to understand that when checking the lambda by the output voltage, low readings indicate an excess of oxygen, that is, a lean mixture is supplied to the cylinders. If the readings are high, then the fuel assembly is enriched and does not contain oxygen. When starting a cold motor, there is no DC signal due to high internal resistance.

Features of removing and replacing the oxygen sensor on the VAZ-2170: articles and models from different manufacturers for Priora

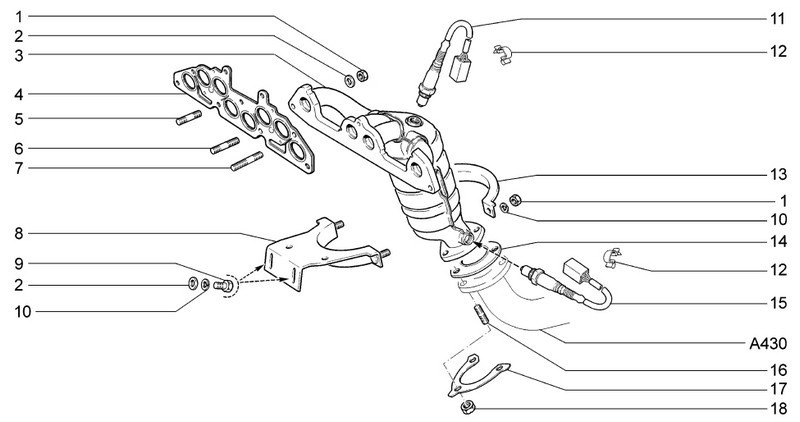

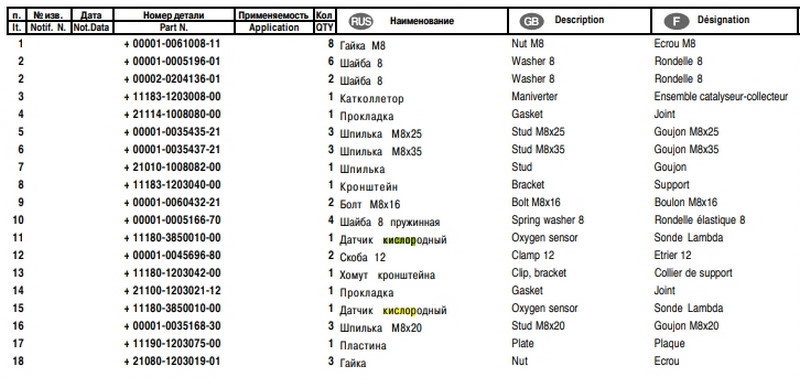

If Priora has a faulty CD (both primary and secondary), it should be replaced. The replacement process is not difficult, but this is due to access to the products, as well as the difficulty of unscrewing them, as they stick to the exhaust system over time. Below is a diagram of a catalytic device with oxygen sensors UDC and DDC installed on the Priore.

And the designations of the constituent elements of the catalyst and its constituent devices in the Priora car.

Important! Priora has absolutely identical lambda probes, which have the original number 11180-3850010-00. Outwardly, they have only a slight difference.

The cost of the original oxygen sensor on the Priora is about 3000 rubles, depending on the region.

Priora original oxygen sensor

However, there are cheaper analogues, the purchase of which is not always justified. Alternatively, you can use the universal device from Bosch, part number 0-258-006-537.

Priory offers lambdas from other manufacturers:

- Hensel K28122177;

- Denso DOX-0150 - you will need to solder the plug, since the lambda is supplied without it;

- Stellox 20-00022-SX - You will also need to solder the plug.

Let's move on to the direct process of replacing this important element in the design of a modern car. And right away it’s worth making a small digression and raising such a topic as replacing the ECU firmware to reduce the level of compatibility with the Euro-2 environment. The first lambda must be installed on modern vehicles and must be in good condition. After all, the correct, stable and economical operation of the engine depends on this. The second element can be removed so as not to change it, which is usually done due to the rather high cost of the product. It is important to understand this, so let's move on to the process of removing and replacing the oxygen sensor on the Priore:

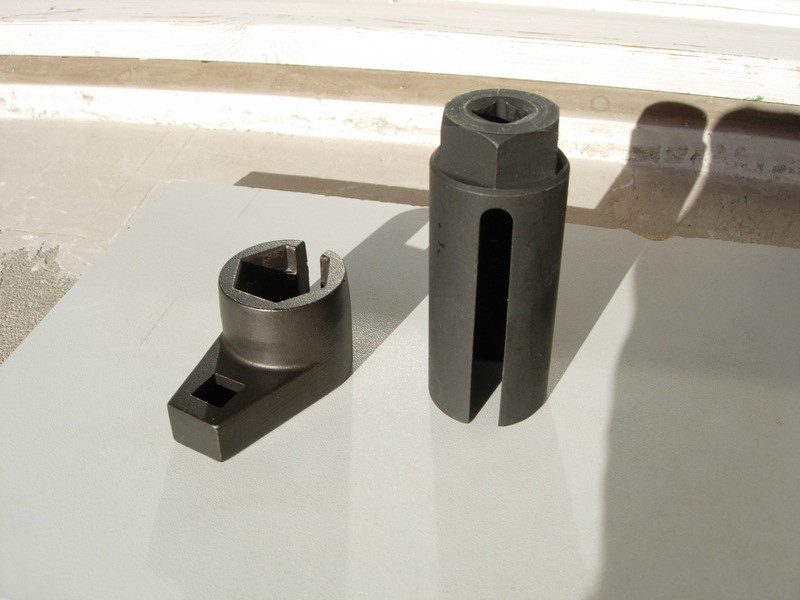

- The disassembly process is carried out from the engine compartment. To work, you need a ring wrench for "22" or a special head for oxygen sensors.

- It is better to work on disassembling the device after warming up the internal combustion engine, since it will be problematic to unscrew the device when it is cold. In order not to get burned, it is recommended to wait for the exhaust system to cool down to a temperature of 60 degrees. Work must be done with gloves.

- Before unscrewing, be sure to treat the sensor with WD-40 fluid (you can use brake fluid) and wait at least 10 minutes.

- Plug Disabled

- The cable holder is detachable.

- The device is unscrewed.

- Replacement is carried out in the reverse order of removal. When installing new products, it is recommended to pre-lubricate their threads with graphite grease. It is important to note that sensors No. 1 and No. 2 can be swapped with each other in case the first one starts to work. The first element is much more important, since it is he who is responsible for the process of preparing fuel elements. However, the second sensor should not be replaced either, since its failure will also lead to unstable operation of the internal combustion engine. In order not to buy a second sensor, you can upgrade the “brains” to Euro-2, but this service will also cost money.

The difference between the lambda replacement processes at Priore 8 valve and 16 valve in access to devices. In 8-valve Priors, getting to both types of products is much easier than in 16-valve ones. Removing the second lambda probe can be done both from the engine compartment and from below from the inspection hole. To get to the second RC from the engine compartment on the Priore 16 valves, you will need a ratchet with an extension, as shown in the photo below.

If the car's catalytic converter is working, then you should not turn on the "brains" on Euro-2 again in order to get rid of the oxygen sensor (second). This will adversely affect the condition of the engine and its parameters. Make only well-considered and balanced decisions before you decide on major modifications to the car, including the exhaust system.

Lambda repair on Priore: how to fix it and features of proper cleaning

It makes no sense to repair the oxygen sensor if it has already served more than 100 thousand kilometers. Products rarely meet these deadlines, and problems with them often occur at a run of 50 thousand km. If the product is malfunctioning due to poor response, you can try to repair it. The repair process involves cleaning the surface from soot. However, it is not so easy to remove carbon deposits, and it is impossible to carry out such an operation with a metal brush. The reason for this is the design of the product, since the outer surface contains a platinum coating. Mechanical impact will mean its removal.

A simple trick can be used to clean up the lambda. To do this, you will need orthophosphoric acid, in which the sensor should be placed. The recommended residence time of the product in acid is 20-30 minutes. For best results, remove the outer part of the sensor. This is best done on a lathe. After acid cleaning, the device must be dried. The cover is returned by welding it with argon welding. In order not to remove the protective screen, you can make small holes in it and clean them.

When returning the part to its place, do not forget to treat the threaded part with graphite grease, which will prevent it from sticking to the catalyst housing (exhaust manifold).

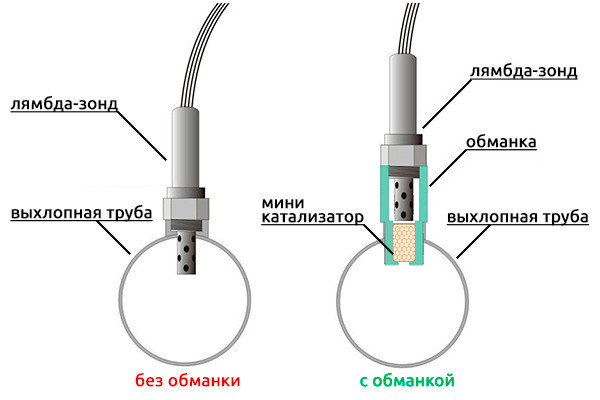

Is it worth putting a trick instead of a lambda on Priora: we reveal all the secrets of using tricks

It should be noted right away that the disadvantage of the lambda probe is a special insert into which the sensor is screwed. This is necessary so that in the event of a catalytic converter failure (or lack of it), the diagnostic oxygen sensor transmits the necessary readings to the ECU. Putting a snag instead of lambda control is not recommended, as in this case the motor will not work correctly. The spacer is placed only and exclusively in the event that the computer is misleading about the real state of affairs in the exhaust system.

It is not recommended to operate the vehicle with a defective catalytic converter as this will lead to other problems. That is why tricks are usually installed on the second CC to show the ECU that the catalyst is theoretically working correctly (in fact, it may be faulty or missing). In this case, you do not need to change the firmware to Euro-2. It is also important to understand that firmware does not fix the problem if the oxygen sensor is defective. This device must work properly, and only in this case the engine will work properly.

It's a lot less of an inconvenience than a new catalytic converter or ECU firmware. The installation process takes no more than 15 minutes.

In conclusion, it is necessary to summarize and point out the fact that many car owners consider the lambda probe an insignificant element in the car and are often simply removed along with catalytic converters, 4-2-1 spiders and other types of installations. However, this approach is fundamentally wrong. After that, there are complaints about high consumption, low dynamics and unstable operation of the internal combustion engine. This petty indignation (at first glance, an incomprehensible face) is to blame for everything. It is important to responsibly approach the repair of your car, because any alteration contributes not only to the deterioration of its functionality, but also to a decrease in its service life.