Throttle valve sensor VAZ 2107

Initially, the VAZ-2107 models were produced with carburetors, and only in the early 2000s, cars began to be equipped with nozzles with an electronic control unit (ECU). This required the additional installation of measuring instruments for various purposes, including the throttle position sensor (TPDZ) of the VAZ-2107 injector).

Car VAZ 2107:

What does the DPS do?

The function of the throttle valve is to regulate the amount of air entering the fuel rail. The more the “gas” pedal is pressed, the greater the gap in the bypass valve (accelerator), and, accordingly, the fuel in the injectors is enriched with oxygen with greater force.

TPS fixes the position of the accelerator pedal, which is "reported" by the ECU. The block controller, when the throttle gap is opened by 75%, switches on the engine full purge mode. When the throttle valve is closed, the ECU puts the engine in idle mode - additional air is sucked in through the throttle valve. Also, the amount of fuel actually entering the combustion chambers of the engine depends on the sensor. The full operation of the engine depends on the serviceability of this small part.

TPS:

Устройство

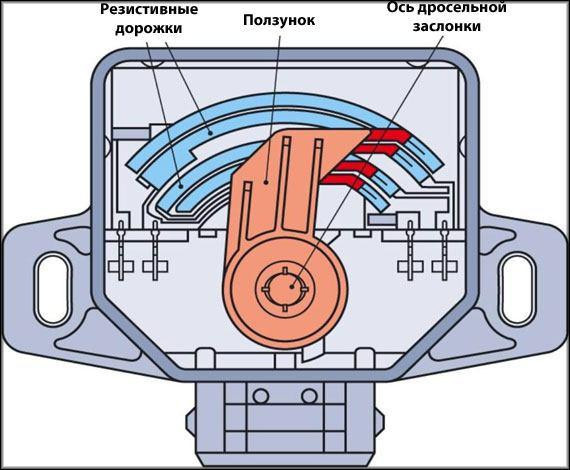

Throttle position devices VAZ-2107 are of two types. These are sensors of contact (resistive) and non-contact type. The first type of device is an almost mechanical voltmeter. The coaxial connection with the rotary gate ensures the movement of the contactor along the metallized track. From how the angle of rotation of the shaft changes, the characteristic of the current passing through the device along the cable from the electronic control unit (ECU) of the engine changes).

Resistive sensor circuit:

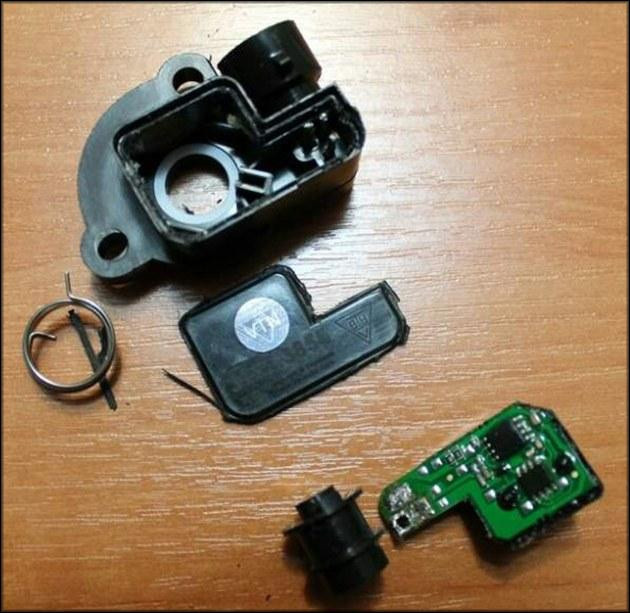

In the second version of the non-contact design, the ellipsoidal permanent magnet is located very close to the front face of the damper shaft. Its rotation causes a change in the magnetic flux of the device to which the integrated circuit responds (the Hall effect). The built-in plate instantly sets the angle of rotation of the throttle shaft, as reported by the ECU. Magnetoresistive devices are more expensive than their mechanical counterparts, but more reliable and durable.

TPS integrated circuit:

The device is enclosed in a plastic case. Two holes are made at the entrance for fastening with screws. The cylindrical protrusion from the throttle body fits into the socket of the device. The ECU cable terminal block is located in the side connector.

Malfunctions

Symptoms of a malfunction can manifest themselves in different ways, but mainly it affects the throttle response of the engine.

Signs of malfunction of the TPS, indicating its breakdown:

- difficulty starting a cold engine;

- unstable idling up to a complete stop of the engine;

- forcing "gas" causes malfunctions in the engine, followed by a sharp increase in speed;

- idling is accompanied by increased speed;

- fuel consumption is unreasonably increased;

- the temperature gauge tends to go into the red zone;

- from time to time the inscription "Check Engine" appears on the dashboard.

Worn contact path of the resistive sensor:

Diagnostics

All of the above signs of a malfunction of the throttle position sensor may be associated with the failure of other sensors in the computer. To accurately determine the breakdown of the TPS, you need to diagnose it.

Proceed as follows:

- Remove the cover from the sensor connector block.

- The ignition is on but the engine does not start.

- The multimeter lever is in the ohmmeter position.

- The probes measure the voltage between the extreme contacts (the central wire transmits a signal to the computer). The voltage should be around 0,7V.

- The accelerator pedal is pressed all the way down and the multimeter is removed again. This time the voltage should be 4V.

If the multimeter shows different values \uXNUMXb\uXNUMXband does not respond at all, then the TPS is out of order and needs to be replaced.

Replacement of DPDZ

It should be noted right away that the repair of a spare part can only concern resistive (mechanical) sensors, since electronic devices cannot be repaired. Restoring a worn contact track at home is quite troublesome and obviously not worth it. Therefore, in the event of failure, the best option would be to replace it with a new TPS.

It is not difficult to replace a damaged device with a new acceleration sensor. Minimum experience with a screwdriver and instrument connectors required.

This is done like this:

- the car is installed on a flat area, raising the handbrake lever;

- remove the negative terminal of the battery;

- remove the wire terminal block from the TPS plug;

- wipe the sensor mounting points with a rag;

- unscrew the fixing screws with a Phillips screwdriver and remove the counter;

- install a new device, tighten the screws and insert the block into the sensor connector.

Experts advise buying a new throttle position sensor only from branded manufacturers. In an effort to save money, drivers become victims of sellers of cheap fakes. By doing this, they run the risk of suddenly getting stuck on the road or "waggling" around the highway, wasting large amounts of fuel to the nearest gas station.