Metal conditioner ER. How to beat friction?

What is an ER additive and how does it work?

ER additive is popularly referred to as the "friction winner". The abbreviation ER stands for Energy Release and translated into Russian means "released energy".

Manufacturers themselves prefer not to use the word "additive" in relation to their product. This is due to the fact that, by definition (if we are meticulous in technical terms), the additive should directly affect the properties of its carrier, that is, motor, transmission oil or fuel. For example, increase extreme pressure properties, or reduce the coefficient of friction by changing the physical properties of the lubricant. However, the composition of ER is an independent substance that does not affect the working properties of its carrier in any way. And oil or fuel only acts as a carrier of the active component.

The ER additive belongs to the class of metal conditioners, that is, it contains special compounds of soft metal particles and activating additives. These compounds circulate with the engine or transmission oil through the system without affecting the performance of the engine until it reaches operating temperature.

After reaching the operating temperature, the components of the composition begin to settle on metal surfaces and become fixed in the microrelief. A thin layer is formed, usually not exceeding a few microns. This layer has high tensile strength and securely adheres to metal surfaces. But most importantly, the formed protective film has an unprecedentedly low coefficient of friction.

Due to the partial restoration of damaged working surfaces, as well as due to the abnormally low coefficient of friction, the formed film has several positive effects:

- extending the life of the engine;

- noise reduction;

- increase in power and injectivity;

- a decrease in the "appetite" of the motor for fuel and oil;

- facilitating cold start in cold weather;

- partial equalization of compression in the cylinders.

However, it should be understood that the manifestation of the above effects for each individual engine is individual. It all depends on the design features of the motor and the defects present in it at the time of using the composition of the defects.

Watch this video on YouTube

Instructions for use

As mentioned above, the ER metal conditioner is an independent product in terms of the way it works. Other technological fluids (or fuel) act only as its transporters to loaded contact patches.

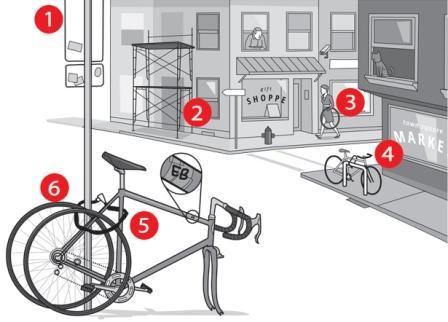

Therefore, the ER composition can be added to various media that come into contact with friction surfaces during operation.

Let's look at a few usage examples.

- Oil for four-stroke engines. The tribotechnical composition ER is poured into fresh oil. You can first add the additive to the canister and then pour the oil into the engine, or pour the agent directly into the engine immediately after maintenance. The first option is more correct, since the additive will immediately be evenly distributed throughout the entire volume of the lubricant. During the first processing, the following proportions should be observed:

- mineral oil - 60 grams per 1 liter;

- synthetic - 30 grams per 1 liter.

With the second and subsequent filling for mineral oil, the proportion is halved, that is, up to 30 grams per 1 liter, and for synthetic lubricants it remains the same.

- In oil for two-stroke engines. Everything is easier here. For 1 liter of two-stroke oil, regardless of its origin, 60 grams of additive is poured.

- Transmission oil. In mechanics, when using lubricants with a viscosity up to 80W inclusive - 60 grams with each oil change, with a viscosity above 80W - 30 grams with each change. In automatic transmission, you can add up to 15 grams of the composition. However, in the case of automatic transmissions, one should be careful, as modern automatic transmissions can fail after using the product.

- Power steering. For passenger cars with a small volume of fluid - 60 grams for the entire system, for trucks - 90 grams.

- Differentials and other transmission units with separate crankcases that use liquid lubricants - 60 grams per 1 liter of oil.

- Diesel fuel. 80 grams of additive is poured into 30 liters of diesel fuel.

- Wheel bearings - 7 grams per bearing. Thoroughly clean the bearing and hub seat before use. Then mix the agent with the recommended amount of grease per bearing and drive the resulting mixture into the hub. It is recommended to use only in those cars where open-type bearings are installed, and with the possibility of dismantling them. Hubs that are assembled with a bearing are not recommended to be treated with an ER additive.

It is always better to use a little less than the recommended amount of lubricant than to use too much. Practice has shown that the rule “you can’t spoil porridge with butter” does not work regarding the composition of ER.

Reviews car owners

Motorists speak of the “friction winner” in more than 90% of cases positively or neutrally, but with a little skepticism. That is, they say that there is an effect, and it is noticeable. But expectations were much higher.

Most of the reviews come down to the mark by car owners of several improvements in the operation of the motor:

- the engine really becomes quieter, vibrates less and, in general, one gets the impression of a certain “normalization” of its operation;

- subjectively, a decrease in fuel consumption is noticed, small and much less than declared by the manufacturer, but by 2-3% the engine becomes less voracious;

- oil consumption for waste is slightly reduced, especially in the case of worn engines.

Negative reviews are almost always associated with the misuse of the product or the violation of proportions. For example, there is one detailed review on the network in which a motorist wanted to revive a completely “dead” motor with a tribological composition. Naturally, he didn't succeed. And on the basis of this, a peremptory verdict was issued on the uselessness of this composition.

There are also cases when the composition precipitated and clogged the motor. This is the result of an incorrect concentration of the additive in the oil.

In general, the ER additive, if we analyze the reviews of motorists, works in almost all cases. It is important not to expect a miracle from her and adequately understand that this tool only partially eliminates the effects of engine wear, saves fuel and lubricants a little and helps to drive several additional thousand kilometers before a major overhaul.

Watch this video on YouTube