Clutch drive design

The clutch is an important part of a car with a manual transmission. It consists directly of the clutch basket and drive. Let us dwell in more detail on such an element as the clutch drive, which plays an important role in the clutch assembly. It is when it malfunctions that the clutch loses its performance. We will analyze the design of the drive, its types, as well as the advantages and disadvantages of each.

Clutch drive types

The drive device is designed for remote control of the clutch directly by the driver in the car. Depressing the clutch pedal directly affects the pressure plate.

The following drive types are known:

- mechanical;

- hydraulic;

- electrohydraulic;

- pneumohydraulic.

The first two types are the most common. Trucks and buses use a pneumatic-hydraulic drive. Electrohydraulics are installed on machines with a robotic gearbox.

Some vehicles use a pneumatic or vacuum booster for relief.

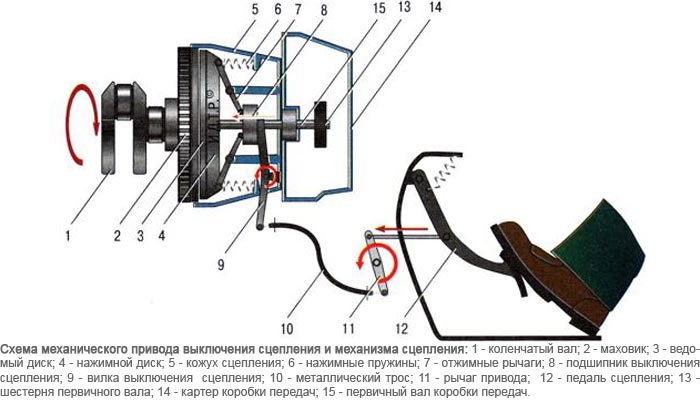

Mechanical drive

A mechanical or cable drive is characterized by a simple design and low cost. It is unpretentious in maintenance and consists of a minimum number of elements. The mechanical drive is installed in cars and light trucks.

Mechanical drive components include:

- clutch cable;

- clutch pedal;

- unlock plug;

- release bearing;

- adjustment mechanism.

The coated clutch cable is the main drive element. The clutch cable is attached to the fork as well as to the pedal in the cabin. At that moment, when the driver presses the pedal, the action is transmitted through the cable to the fork and release bearing. As a result, the flywheel is disconnected from the transmission and, consequently, the clutch is disengaged.

An adjustment mechanism is provided at the connection of the cable and the drive lever, which guarantees the free movement of the clutch pedal.

The clutch pedal travel is free until the actuator is activated. The distance traveled by the pedal without much effort on the part of the driver when it is depressed is free.

If the gear shifts are noisy and there is slight shaking of the vehicle at the beginning of the movement, it will be necessary to adjust the pedal travel.

Clutch clearance should be between 35 and 50 mm pedal free play. The norms of these indicators are indicated in the technical documentation for the car. The pedal stroke is adjusted by changing the length of the rod using the adjusting nut.

The trucks do not use a cable, but a mechanical lever drive.

The advantages of a mechanical drive include:

- simplicity of the device;

- low cost;

- operational reliability.

The main disadvantage is the lower efficiency than the hydraulic drive.

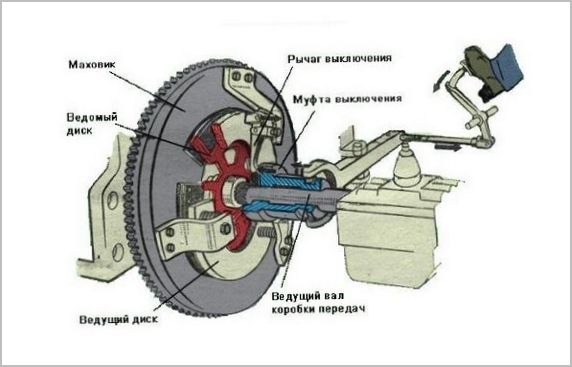

Hydraulic clutch drive

The hydraulic drive is more complex. Its components, in addition to the release bearing, forks and pedals, also have a hydraulic line that replaces the clutch cable.

In fact, this line is similar to the hydraulic brake system and consists of the following components:

- clutch master cylinder;

- clutch slave cylinder;

- reservoir and brake fluid line.

The clutch master cylinder is similar to the brake master cylinder. The clutch master cylinder consists of a piston with a pusher located in the crankcase. It also includes a fluid reservoir and o-rings.

The clutch slave cylinder, similar in design to the master cylinder, is additionally equipped with a valve to remove air from the system.

The mechanism of action of the hydraulic actuator is the same as that of the mechanical one, only the force is transmitted by the liquid in the pipeline, and not by the cable.

When the driver presses the pedal, the force is transmitted through the rod to the clutch master cylinder. Then, due to the incompressibility of the fluid, the clutch slave cylinder and the release bearing control lever are actuated.

The advantages of hydraulic drive include the following features:

- hydraulic clutch allows you to transfer force over long distances with high efficiency;

- resistance to overflow of fluid into the hydraulic components contributes to the smooth engagement of the clutch.

The main disadvantage of the hydraulic drive is a more complicated repair compared to the mechanical one. Fluid leaks and air in the hydraulic drive system are perhaps the most common malfunctions that occur in the clutch master and slave cylinders.

The hydraulic drive is used in cars and trucks with a folding cab.

The nuances of the clutch

Often, drivers tend to associate bumps and jerks when driving a car with clutch failure. This logic is wrong in most cases.

For example, when a car changes speed from first to second, it suddenly slows down. It's not the clutch itself that's to blame, but the clutch pedal position sensor. It is located behind the clutch pedal itself. The sensor malfunction is eliminated by a simple repair, after which the clutch resumes operation smoothly and without shock.

Another situation: when shifting gears, the car twitches slightly and may stop when starting off. What is the possible reason? The most common culprit is the clutch delay valve. This valve provides a certain speed at which the flywheel can engage, no matter how fast the clutch pedal is depressed. For novice drivers, this feature is essential because the clutch delay valve prevents excessive wear on the clutch disc surface.