Models of gearboxes MAZ

Content

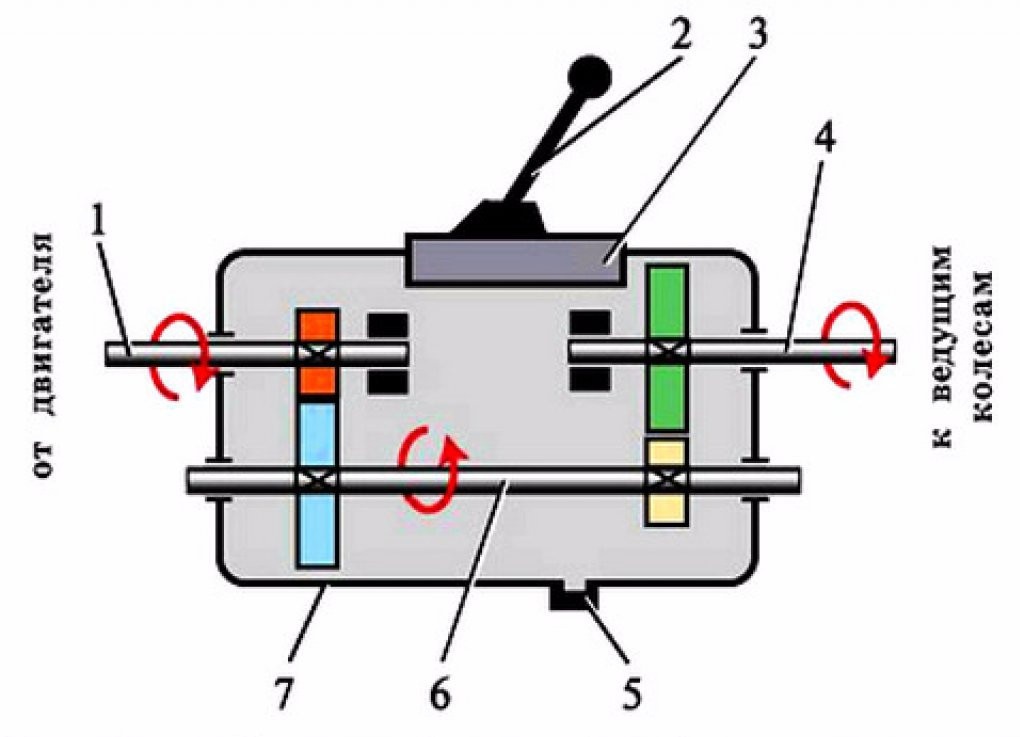

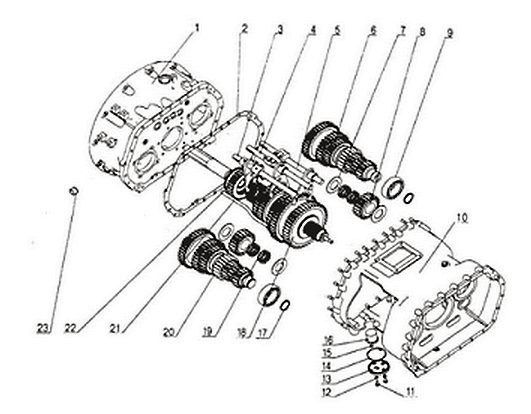

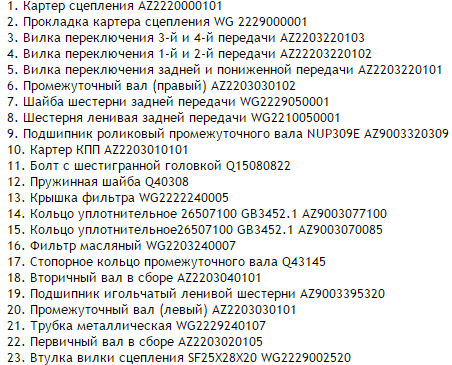

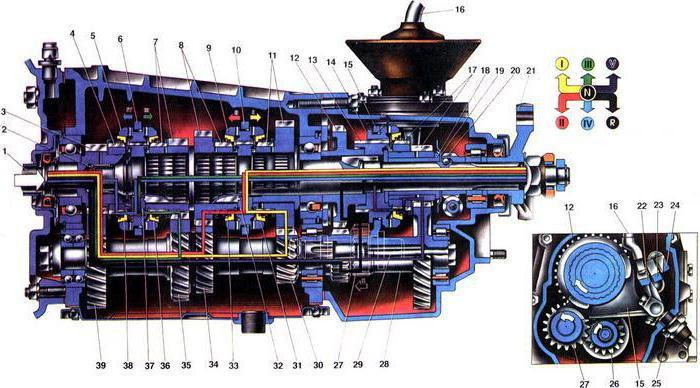

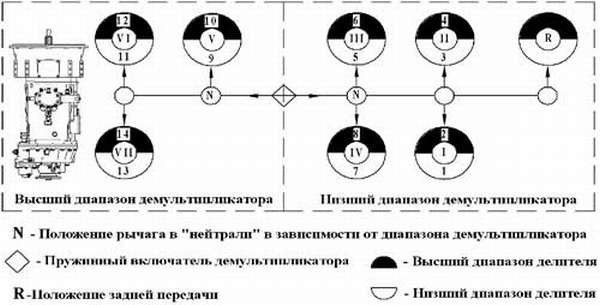

MAZ vehicles are equipped with an eight-speed YaMZ-238A dual-range gearbox with synchronizers in all gears except reverse. The gearbox consists of a two-speed main gearbox and an additional two-speed gearbox (downshift). The gearbox device is shown in Fig.44. Installation of all parts of the gearbox is carried out in the crankcases of the main and additional boxes, which are interconnected and then assembled in the clutch housing; a single power unit is formed as part of the engine, clutch and gearbox. The input shaft 1 of the main box is mounted on two ball bearings; the driven clutch discs are mounted on a splined front end, and the rear end is made in the form of a ring gear of the main crankcase constant gear. The output shaft of the main crankcase 5 rests in front on a cylindrical roller bearing mounted in the bore of the gear rim of the drive shaft, and in the back on a ball bearing mounted on the front wall of the additional crankcase. The rear end of the secondary shaft is made in the form of a crown, which is a permanent engagement of the additional housing. The gears of the second and fourth gears of the output shaft of the main box are mounted on plain bearings made in the form of steel bushings with a special coating and impregnation, and the gears of the first and reverse gears are mounted on roll bearings. The intermediate shaft 26 of the main box in front rests on a roller bearing mounted on the front wall of the main box crankcase, and at the rear - on a double-row spherical bearing placed in a glass installed in the rear wall of the main crankcase housing. In the crankcase tides of the main box, an additional shaft of the intermediate reverse gear is installed. Reverse gear is engaged by moving the reverse carriage 24 forward until it engages with the reverse gear ring gear 25 which is in constant engagement with the reverse idler gear. The output shaft 15 of the additional box rests at the front on a cylindrical roller bearing located in the hole of the gear rim of the output shaft of the main box, at the back - on two bearings: a cylindrical roller bearing and a ball bearing, respectively, are installed in the rear wall of the additional box housing and the output shaft bearing cover. In the splines of the middle part of the output shaft of the additional box, gear shift synchronizers are installed, and at the splined rear end there is a flange for attaching the cardan shaft. In the central cylindrical part of the shaft, the gear 11 of the additional box is installed on cylindrical roller bearings. The intermediate shaft 19 of the additional box rests at the front on a cylindrical roller bearing installed in the front wall of the additional box housing, and at the rear - on a double-row spherical bearing placed in a glass installed on the rear wall of the additional sump box. The reduction gear 22 is mounted on the front splined end of the auxiliary crankcase countershaft. In the rear part of the intermediate shaft, a ring gear is made, which is engaged with the reduction gear of the secondary shaft of the additional box.

Other details

The MAZ semi-trailer in the gearbox system is equipped with a front roller that controls the second lever inserted into the head of the movable link of the support. The outer part of the movable rod is connected to the intermediate control mechanism by means of an elongated cardan rod. The mounting bracket is attached to the vehicle frame.

The lower edge of the gear lever is connected to the same node. Mounting method: similar to the previous method. Part of the arm goes through the cabin floor, ensuring the integrity of all other connections. This design allows you to tilt the cab without the need for separation and deformation of existing elements and assemblies.

Устройство

MAZ-5551 without a berth is much more spacious than KamAZ vehicles. Thanks to well-placed handrails and steps, climbing into the cab of the dump truck is extremely easy. True, the ergonomics of the cab is not the strongest side of the truck. Although the seat cushion moves and the steering column is adjustable in two planes, there is no need to talk about driver comfort. The interior of the car has good visibility, but discomfort causes increased fatigue, which is especially evident on long trips. The huge steering wheel does not add comfort, as small drivers have to lean forward to turn it.

The MAZ-5551 instrument panel is quite informative and convenient. However, there are also disadvantages. The light indication has a low brightness, so it is hard to see during the day.

However, in the cab of a dump truck, there are much more successful solutions. The location of the fuse and relay box behind the dashboard is very convenient and easy to get to. An efficient heating system, a sunroof and a dome light inside the cab enhance driving comfort.

Thanks to the large rear-view mirrors, the visibility and safety of the MAZ-5551 control are increased.

The driver's seat has a suspension system and is adjustable in several directions. However, the cabin is still not very comfortable, since the car does not have a depreciation system. The passenger seat is attached directly to the floor.

Cabin

What interesting things did the designers do to improve the ergonomics and handling of the MAZ? There are many changes, and all of them are very pleasant. The cabin is comfortable and spacious. Even without a bed, two passengers can easily accommodate here, not counting the driver himself.

Well-designed handrails and steps make it quick and easy to get into the cab. The seat can be moved and adjusted; Unfortunately, only the passenger seat. In the 90s, not all cars had an adjustable steering wheel, but the MAZ-5551 has it. The first drawback was also noted in the cabin - the steering wheel is too large. If you are short, you need to lean forward a little with each turn. It is unlikely that such an innovation can be considered a convenience.

The dashboard leaves a double impression. On the one hand, it is quite informative, on the other hand, it has a weak glow, due to which individual elements are practically invisible during the day. A well-located safe is, of course, a plus for the MAZ-5551. However, as well as efficient heating, which does an excellent job even in severe frost. Between the passenger and the driver there is a small compartment in which you can hide various little things: documents, keys, a bottle of water, etc.

The MAZ-5551 truck has been produced by the Minsk Automobile Plant for three decades, since 1985. Despite its non-innovative design (its immediate predecessor MAZ-503 first hit the roads in 1958), the MAZ-5551 dump truck remains one of the most popular eight-ton trucks in the vastness of Russia. Read about the Kamaz 500 series in this article.

Manual

The instruction manual contains the following sections:

Safety requirements when working with this vehicle

All precautions and emergency procedures are listed here.

Motor. This section contains engine specifications, design and maintenance recommendations.

Transmission of infection

The operation of the transmission is described and a brief description of its main elements is given.

Transport chassis. This section describes the design of the front axle and tie rod.

Steering, brake systems.

Electrical equipment.

Transport marking. Where to find the vehicle identification number is described here, the decoding of the number is given.

The rules of samsval.

Features of operation and maintenance. Explains when and how to perform maintenance, what types of maintenance they are.

Conditions for storage of vehicles, rules for their transportation.

Warranty period and transport ticket.

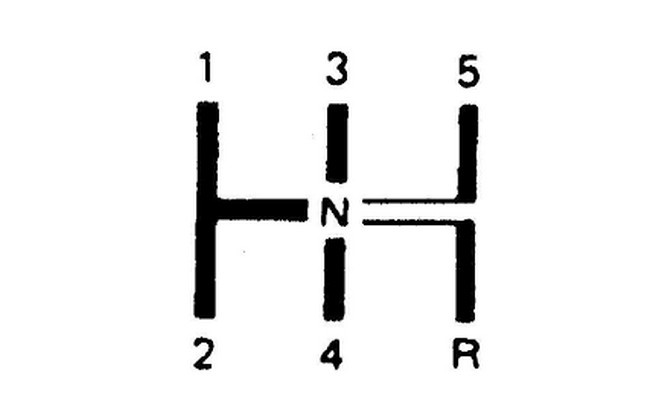

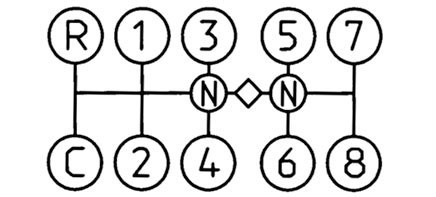

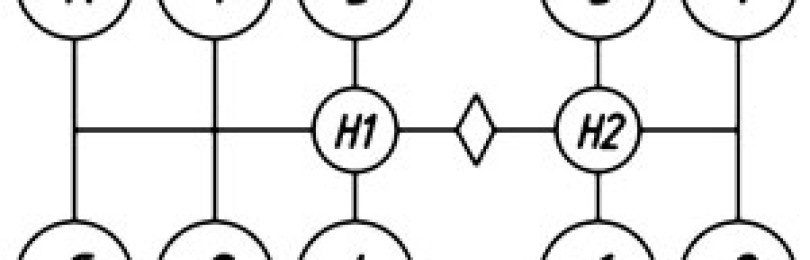

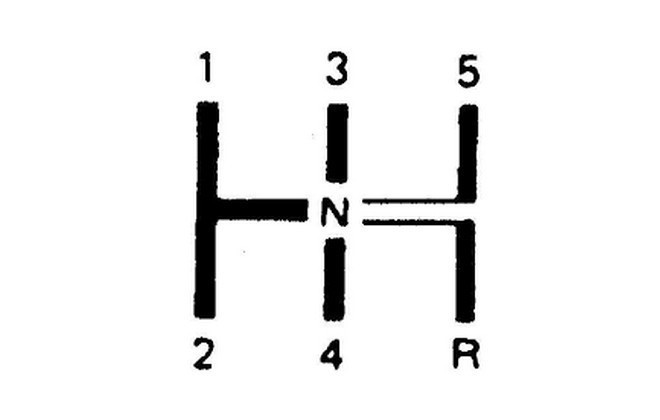

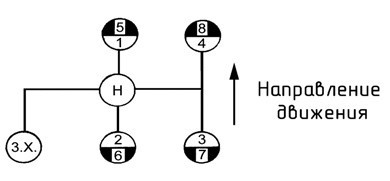

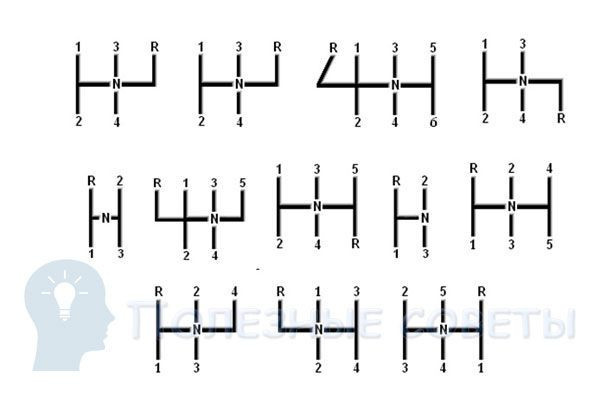

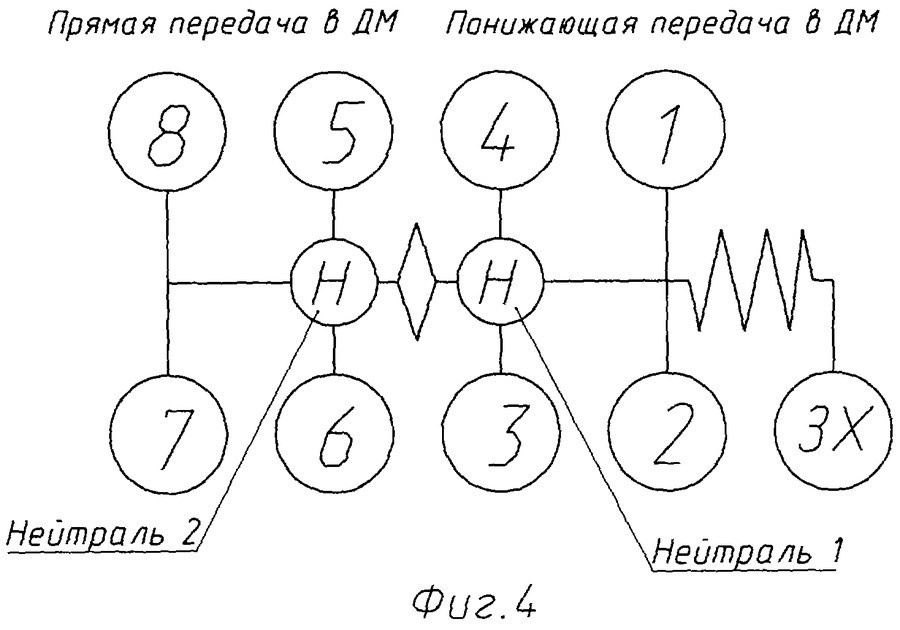

Gear shift diagram

The gearshift diagram is in the dump truck owner's manual. The change happens like this:

- Using the clutch mechanism, the power unit is disconnected from the vehicle's transmission. This allows you to shift gears without reducing engine speed.

- The torque passes through the clutch block.

- The gears are arranged parallel to the shaft axis of the device.

- The first axle is connected to the clutch mechanism, on the surface of which there are splines. A drive disk moves along them.

- From the shaft, the rotating action is transmitted to the intermediate shaft, combined with the gear of the input shaft mechanism.

- When the neutral mode is activated, the gears begin to rotate freely, and the synchronizer clutches come to the open position.

- When the clutch is depressed, the fork moves the clutch to the engaged position with torque located at the end of the gear.

- The gear is fixed together with the shaft and stops rotating on it, which ensures the transmission of action and rotational force.

Electroscheme

The electrical circuit diagram includes such elements as:

- Batteries Their voltage is 12 V. Before starting work, it is necessary to correct the density of the batteries.

- Generator. Such an installation is equipped with a built-in voltage regulator and a rectifier unit. The generator design includes bearings, the condition of which is recommended to be checked every 50 km.

- Start off. This device is necessary to start the power unit. It consists of a relay cover, contacts, plugs for lubrication channels, an anchor rod, a glass, brush holder springs, fasteners, a handle, a protective tape.

- Electrical device. Its task is to facilitate starting the engine at low temperatures.

- Battery ground switch. Batteries must be connected and disconnected from the mass of the vehicle.

- Lighting system and light signaling. Control of headlights, searchlights, fog lights, interior lighting.

Essential elements

The MAZ gearbox includes a primary shaft with a gear mounted in the crankcase on ball bearings. There is also an intermediate shaft. From the front, it looks like a device on a cylindrical roller bearing, and from the back, like a ball counterpart. The rear element compartment is protected by a cast-iron casing, the first and rear gearboxes are cut directly on the shaft, and the remaining ranges and PTO are through keyed drives.

The MAZ gearbox with a reduction gear is equipped with an intermediate shaft drive gear with a damping damper. This allows you to reduce the vibrations that are transformed from the power unit to the transmission housing. In addition, this solution allows you to reduce the noise of the gearbox at idle. The need to install a shock absorber is due to the insufficient uniformity of the operation of the YaMZ-236 type engine.

The gear tooth is made separately from the hub. It is disengaged by six coil springs. Residual vibrations are damped by deformation of the spring elements and friction in the damper assembly.

URAL 4320 wiring diagram

The electrical circuit URAL 4320 is single-wire, where the negative potential of the voltage source of the equipment and devices is connected to the vehicle ground. The negative terminal of the battery is connected to the "mass" of the URAL 4320 using a remote switch. Below is a large resolution diagram of the URAL 4320 electrical equipment.

URAL 4320 wiring diagram

On the URAL 4320 electrical equipment diagram, the connections between cables and devices are made using plugs and connectors. For convenience, the colors of the wires on the URAL 4320 electrical equipment diagram are presented in color.

Repair of checkpoint YaMZ-238A MAZ

Transmission care consists of checking the oil level and replacing it in the crankcase. The oil level in the crankcase must match the control hole. The oil must run hot through all drain holes. After draining the oil, you need to remove the cover at the bottom of the crankcase, into which the oil pump oil separator with a magnet is placed, rinse them well and install them in place

When doing this, make sure that the oil line is not blocked by the cap or its gasket.

| rice one |

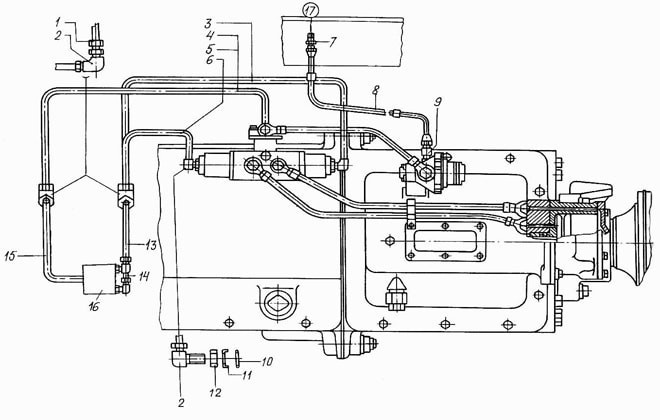

To flush the gearbox, it is recommended to use 2,5 - 3 liters of industrial oil I-12A or I-20A in accordance with GOST 20799-75. With the gearbox control lever in neutral position, the engine is started for 7-8 minutes, then it is stopped, the flushing oil is drained and the oil provided by the lubrication map is poured into the gearbox. It is unacceptable to wash the gearbox with kerosene or diesel fuel.

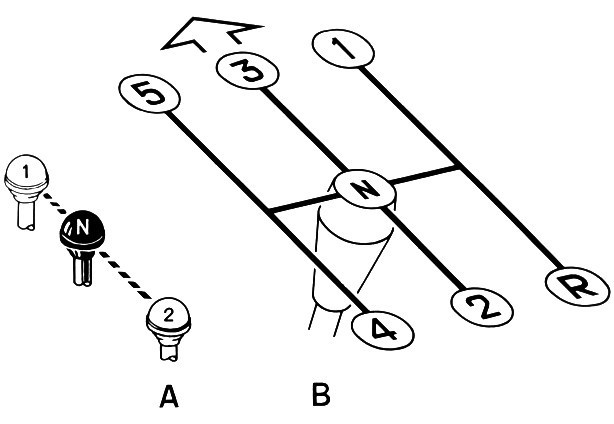

When the gearbox is running, the following settings are possible:

- the position of the lever 3 (see Fig. 1) shifting gears in the longitudinal direction;

- the position of the gear lever in the transverse direction;

- a locking device for the longitudinal thrust of the telescopic elements.

To adjust the angle of inclination of the lever З in the longitudinal direction, it is necessary to loosen the nuts on the bolts 6 and, moving the rod 4 in the axial direction, adjust the angle of the lever to approximately 85 ° (see Fig. 1) in the neutral position of the gearbox.

The adjustment of the position of the lever in the transverse direction is carried out by changing the length of the transverse link 17, for which it is necessary to disconnect one of the tips 16 and, having unscrewed the nuts, adjust the length of the link so that the gearbox control lever, being in the neutral position, against gears 6 - 2 and 5 - 1 had an angle of approximately 90˚ with the horizontal plane of the cab (in the transverse plane of the vehicle).

Adjustment of the gearshift locking device should be made as follows:

- raise the cab;

— disconnect pin 23 and disconnect rod 4 from fork 22;

- clean the earring 25 and the inner rod from old grease and dirt;

— push the inner rod until the stop sleeve 15 clicks;

— unlock the nut of the earring 25 and, inserting a screwdriver into the groove of the rod of the inner link, unscrew it until the angular play of the earring disappears;

- preventing the rod 24 from turning, tighten the locknut;

- check the quality of the fit. When the lock sleeve 21 moves towards the spring 19, the inner rod must extend without sticking to its full length, and when the rod is pressed all the way into the grooves, the lock sleeve must move clearly with a “click” until the sleeve rests against the lower protrusion of the earring.

When adjusting the drive, the following requirements must be taken into account:

- make adjustments with the cab raised and the engine turned off;

- avoid kinks and kinks of external and internal movable rods;

— in order to avoid breakage, connect the stem 4 with the fork 22 so that the hole in the earring for the pin 23 is above the longitudinal axis of the stem 4;

- check the neutral position of the gearbox with the cab raised by free movement of the lever 18 of the gear change mechanism in the transverse direction (relative to the longitudinal axis of the vehicle). Roller 12 in the neutral position of the box has an axial movement of 30 - 35 mm, while the compression of the spring is felt.

The gearbox drive adjustments described above must be made when removing and installing the engine and cab.

MAZ gearbox device: varieties and principle of operation

In this article, we will tell you what functions the gearbox on the MAZ engine performs, give some recommendations for repair, and also indicate the MAZ gear shift scheme with a divider, which you can study and study in detail.

The purpose of the checkpoint

In the gearbox there is such an element as a gear, usually there are several of them, they are connected to the gear lever and it is due to them that the gear changes. Gear shifting controls the speed of the car.

So, in other words, gears are gears. They have different sizes and different rotation speeds. In the course of work, one clings to the other. The system of such work is due to the fact that a large gear sticks to a smaller one, increases the rotation, and at the same time the speed of the MAZ vehicle. In cases where a small gear sticks to a large one, the speed, on the contrary, drops. The box has 4 speeds plus reverse. The first is considered the lowest and with the addition of each gear, the car starts to move faster.

The box is located on the MAZ car between the crankshaft and the cardan shaft. The first comes directly from the engine. The second is directly connected to the wheels and drives their work. List of works leading to speed control:

- The engine drives the transmission and crankshaft.

- The gears in the gearbox receive a signal and start moving.

- Using the gear lever, the driver selects the desired speed.

- The speed selected by the driver is transmitted to the propeller shaft, which drives the wheels.

- The car continues to move at the selected speed.

Device layout

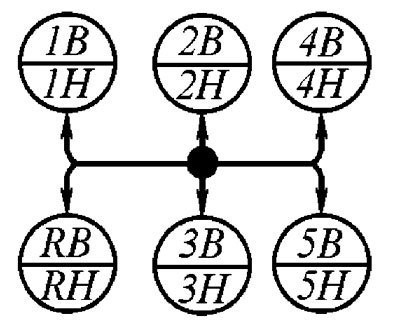

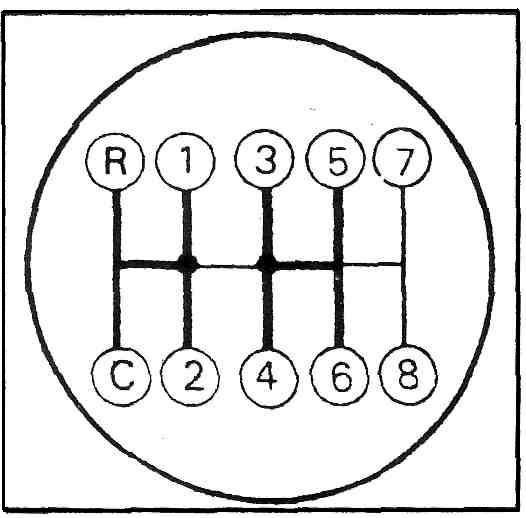

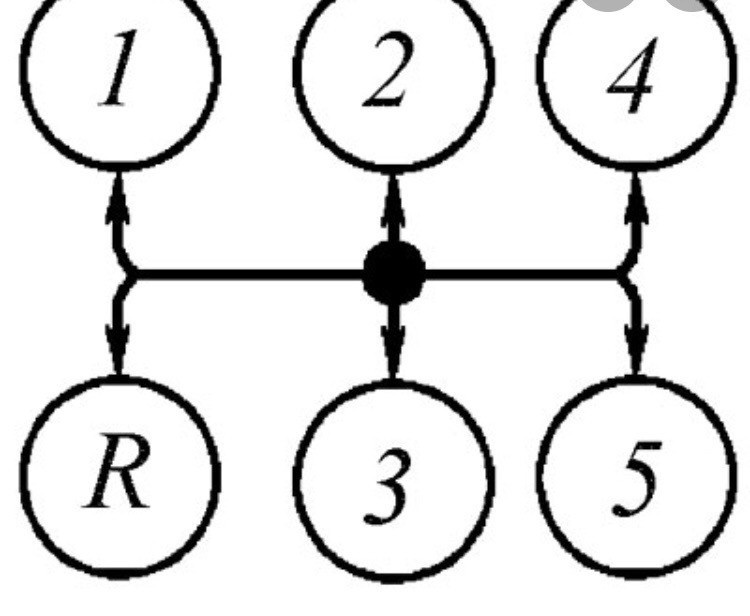

The scheme of the gearshift device of the gearbox with a divider on the MAZ is not simple, but it will help you a lot when carrying out repairs. The step gearbox on the MAZ consists of such elements as the crankcase, shafts, mortar, synchronizers, gears and other equally important elements.

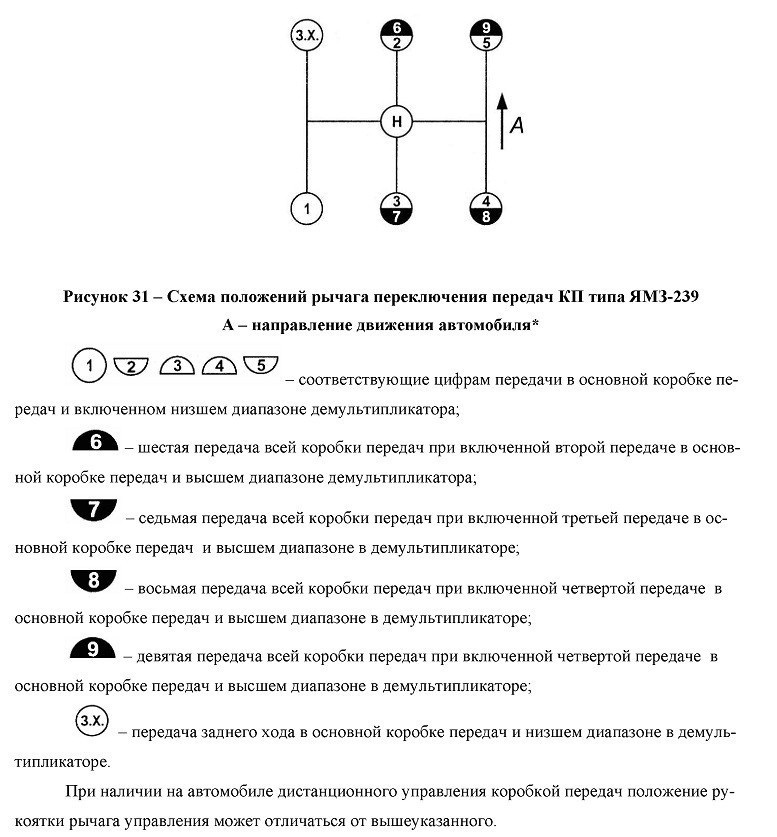

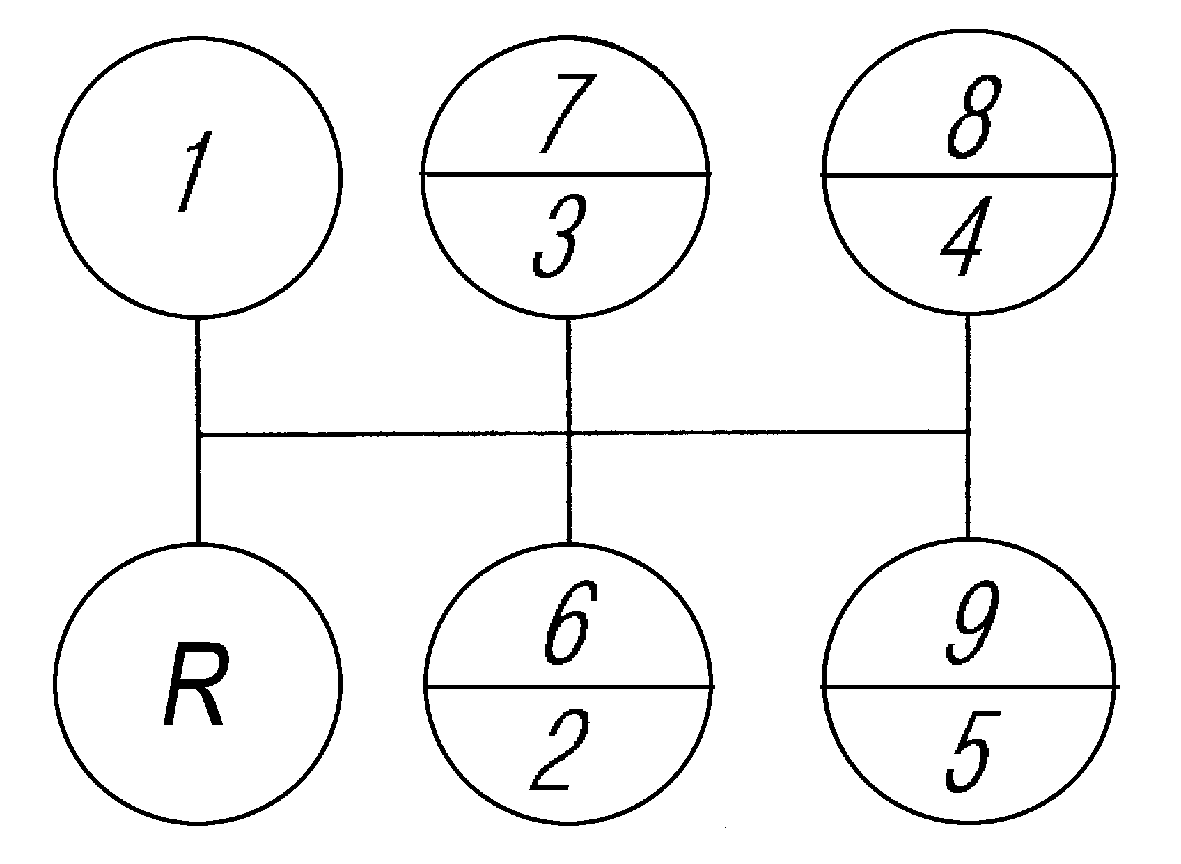

9 step

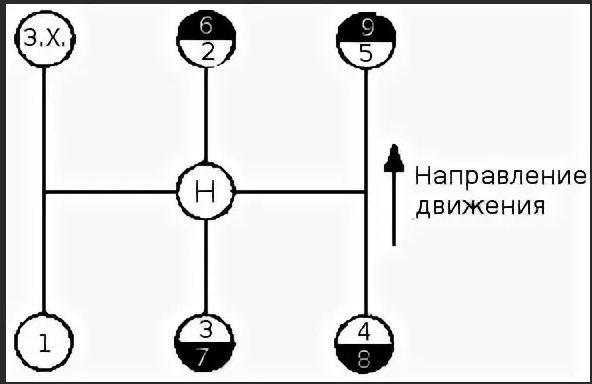

Such a unit is installed, in most cases, on trucks or cars that will be subjected to high traffic.

9-speed gearbox

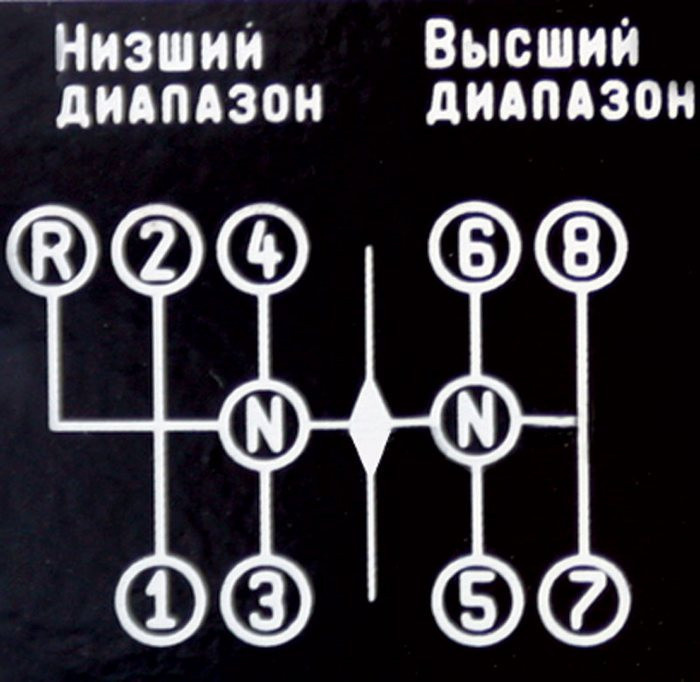

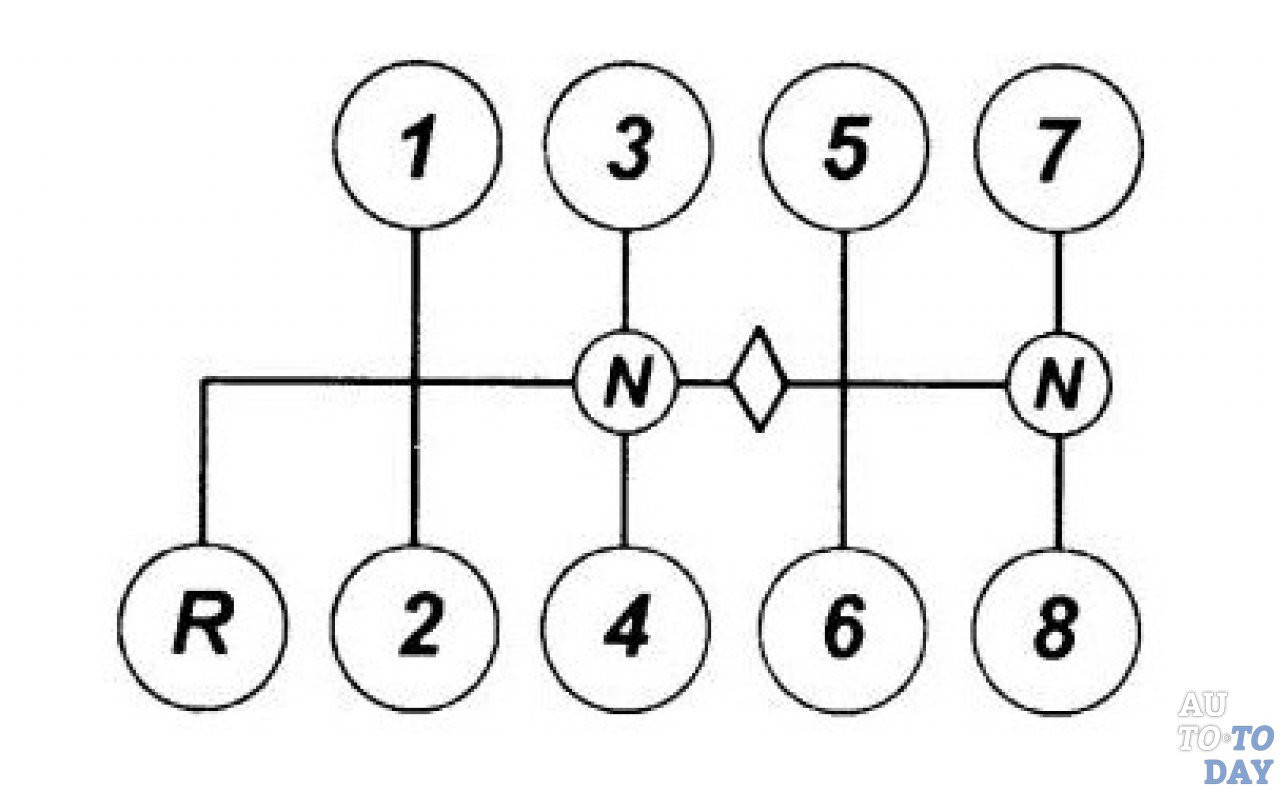

8 step

This unit, like its predecessor, is popular with machines with a large payload.

8-speed gearbox

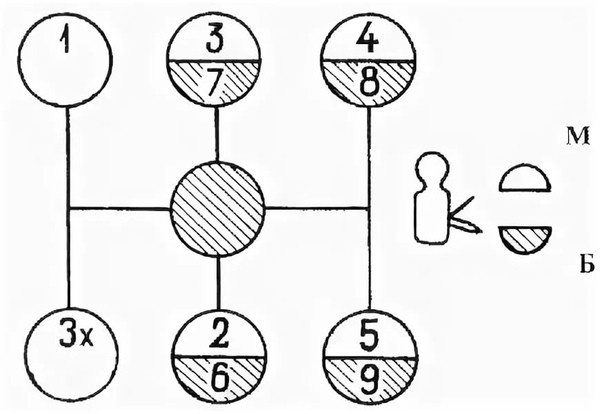

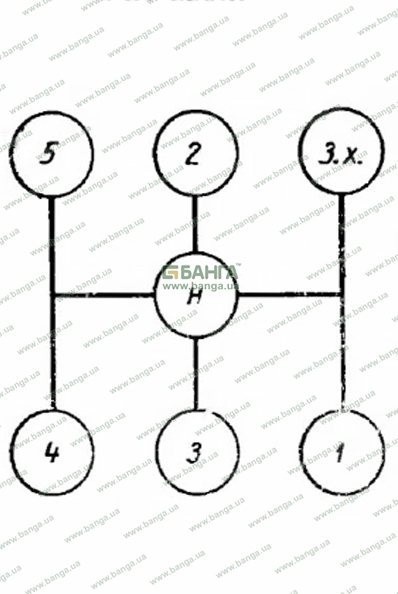

5 step

The most popular among cars.

5-speed gearbox

Repair recommendations

Want to keep your divider box in good condition for years to come? Then you need basic care and control. It is necessary to monitor the work of such elements as gears, mortar, control lever itself, etc. Has it ever happened that a breakdown is inevitable? We will give you the following recommendations for self-repair:

familiarize yourself with the diagram and instructions for your mechanism;

to carry out repairs, you must first completely remove the box and only after that you can proceed with the repair;

after removal, do not rush to disassemble it completely, sometimes the problem lies on the surface, pay special attention to all the details, if you see suspicious "behavior", then most likely the problem is in this element;

if you still have to disassemble the box completely, put all the parts in the order of disassembly so as not to get confused when lifting it.

In this article, the gear shifting scheme of MAZ of all types was considered. We hope that the information was useful to you in the repair. May your box serve you for years to come!

autozam. com

Possible damage

Transmission malfunctions at YaMZ 236 can be of the following plan:

- the appearance of extraneous noise;

- reducing the amount of oil poured into the box;

- difficult inclusion of speeds;

- spontaneous shutdown of high-speed modes;

- crankcase fluid is leaking.

With any of these manifestations, it is advisable to independently check the oil level in the box, how tightly all the mounting screws and nuts are tightened. If this is not a problem, the car should be sent to a service center for diagnosis. Here, the craftsmen must, using special equipment, check the integrity of the gearbox components (couplings, bearings, bushings, etc.), evaluate the performance of the oil pump.

..160 161 ..

MAINTENANCE OF GEARBOX YaMZ-236

During maintenance, check the connection of the gearbox with the engine and the condition of its suspension, maintain a normal oil level in the gearbox and replace it with TO-2 in a timely manner.

The oil level in the gearbox must not fall below the lower edge of the control hole 3 (Fig. 122). Drain the oil from the gearbox housing while it is hot through the drain plug 4. After draining the oil, clean the magnet on the drain plug. After draining the oil, unscrew the screws and remove cover 2 from the oil pump inlet, clean and flush the screen, then replace the cover

When installing the intake cover, be careful not to block the oil line with the cover or its gasket.

Rice. 122. Plugs of the YaMZ-236P gearbox: 1 oil filler hole; 2-cover of the oil pump intake; 3-hole for checking the oil level; 4 drainage holes

Rinse the gearbox with industrial oil I-12A or I-20A according to GOST 20199 - 88; Pour 2,5 - 3 liters into the crankcase, move the gear lever to neutral, start the engine for 1 ... 8 minutes, then turn it off, drain the flushing oil and refill. It is strictly forbidden to flush the gearbox with kerosene or diesel fuel in order to avoid failure of the oil pump due to insufficient suction vacuum and, as a result, failure of the gearbox. In the case of a gearbox overhaul, lubricate the oil pump with the oil used in the gearbox before installation.

When towing a car with the engine running at idle, the input and intermediate shafts of the gearbox do not rotate, the oil pump in this case does not work and does not supply lubricant to the toothed bearings of the secondary shaft and to the conical surfaces of the synchronizer shaft, which will lead to scratches on the sliding surfaces, wear of the synchronizer rings and failure of the entire gearbox. To tow, disengage the clutch and engage the transmission in direct (fourth) gear, or disconnect the transmission from the transmission.

It is not allowed to tow the car for a distance of more than 20 km without disengaging the cardan or disengaging the clutch with the direct gear engaged.

To avoid premature wear of friction pairs, it is recommended to warm up the gearbox before starting the engine at an ambient temperature below -30°C. If this is not possible, when the engine is stopped for a long time, drain the oil from the crankcase and, before starting the engine, heat up this oil and fill it into the crankcase through the hole in the top cover.

For smooth and easy shifting and to protect the countershaft teeth and the first and rear gears from wear on the axles, as well as to protect the synchronizer rings from wear to properly adjust the clutch and prevent "drive".

The MAZ gearbox is a gearshift mechanism that is part of the transmission device along with a divider.