Wheel Tightening Torque: Everything You Need to Know

Content

Tightening torque comes into play when you need to install one or more wheels on your car. They are held onto the rim by bolts, each of which requires precise rotational force. It is this phenomenon that is designated by the term tightening torque.

⚙️ What is the tightening torque of the wheels?

When replacing a wheel, it is necessary to secure the new wheel to its hub. This is done through bolted connection consisting of hairpin or screw and nut... Thanks to this system, the wheel can be stationary and there will be no backlash.

Depending on the model, we can find 4 to 5 wheel bolts... Since the bolt relies on the application of force to bring two elements together between them, this tension must be accurately calculated so that the parts do not move due to friction.

This pulling force that is applied to the bolt is related to the force applied to the nut, which is why we are talking about the tightening torque. Therefore this applied to the axis and expressed in Newton meters (Nm)... For example, 10 Nm = 1 kg rotating force for a 1 meter arm.

Thus, this tightening torque will vary from vehicle to vehicle, but also depends on the type of wheel. It usually varies depending on the following:

- Rim material;

- Diameters of nut and screw or stud;

- Screw or stud pitch;

- Coefficients of friction at thread and nut level.

🔎 What is the tightening torque for an aluminum wheel?

If your car has wheels with aluminum alloy rims, you will need to adjust the tightening torque because it will be different from the steel rim... Typically, the following bolt sizes are most common for aluminum discs:

- Bolt with a diameter of 10 mm. : tightening torque approx. 72 Nm;

- Bolt with a diameter of 12 mm. : approx. 96 Nm;

- Bolt with a diameter of 14 mm. : it should be about 132 Nm

For steel discs, the tightening torque is usually 20% lower to the values of the aluminum rim.

If in doubt, always contact recommendations from your manufacturer specified in your vehicle's maintenance log.

This way, you have access to the torque values recommended by the manufacturer to ensure optimal performance of your vehicle.

🔧 Can the wheel be tightened without a torque wrench?

Not all motorists wishing to change a wheel are equipped with a torque wrench to perform this maneuver. However, she necessary to facilitate disassembly et observe the recommended tightening torques by the manufacturer without damaging the wheels or their fixing pins.

In addition, without a torque wrench, you have no there is no way to be sure that the tightening is even for all nuts and bolts. Thus, you may be in danger while traveling.

If this is not done with a torque wrench, you have to go to a professional in a workshop so that the latter can check the tightening torque of the wheels.

We must also consider bolt assembly and disassembly procedure which differ depending on their number. So, when you start this intervention, be sure to follow the order shown in the diagram above.

💡 Where can I find a torque table for a car wheel?

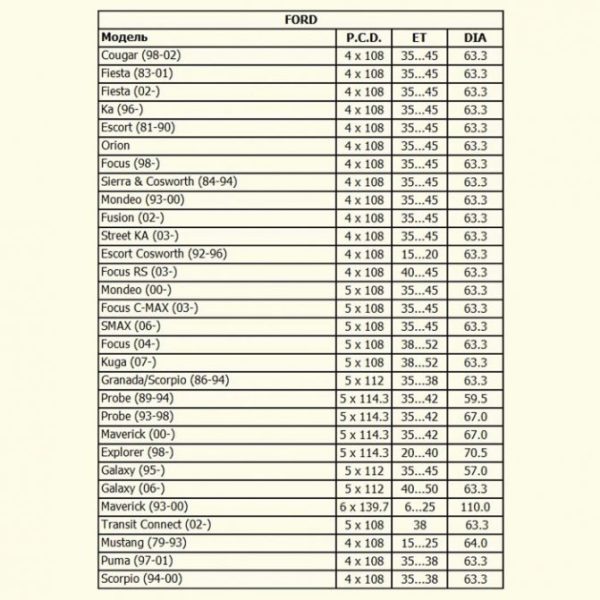

The tightening torques table can be found in your vehicle's service book. If you don't have one, you can find the most common recommendations in the table below.

These values are indicative, they can vary significantly depending on the characteristics of the axle, whether it is smooth or spline.

Wheel torque is a value that needs to be known and should not be approximated due to the risk of serious wheel geometry problems and lack of traction when traveling.