Purpose of the CVVT system in the engine

Content

Modern environmental legislation obliges car manufacturers to develop better engines, improve their efficiency and reduce emissions of harmful substances in exhaust gases. Designers learn to control previously accepted processes with average trade-off parameters. One such development is the Variable Valve Timing (CVVT) system.

CVVT system design

CVVT (Continuous Variable Valve Timing) is a continuous variable valve timing system that allows you to more efficiently fill the cylinders with fresh charge. This is achieved by varying the opening and closing times of the intake valve.

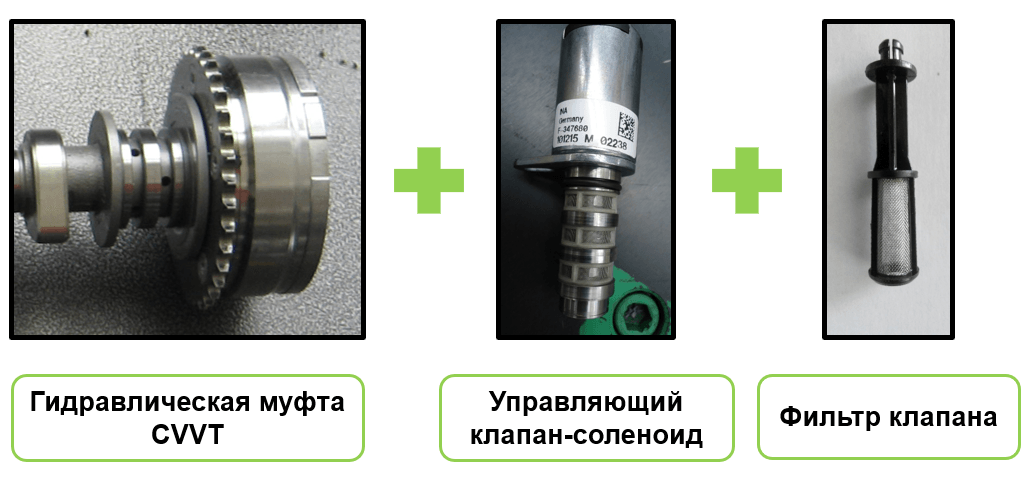

The system includes a hydraulic circuit consisting of:

- Control solenoid valve;

- valve filter;

- The drive is a hydraulic clutch.

All components of the system are installed in the engine cylinder head. The filter should be cleaned or replaced periodically.

CVVT hydraulic couplings can be installed on both intake and both shafts of an internal combustion engine.

If phase shifters are installed on the intake and exhaust camshafts, this valve timing system will be called DVVT (Dual Variable Valve Timing).

Additional system components also include sensors:

- Position and speed of the crankshaft;

- Camshaft positions.

These elements send a signal to the engine ECU (control unit). The latter processes the information and sends a signal to the solenoid valve, which regulates the oil supply to the CVVT clutch.

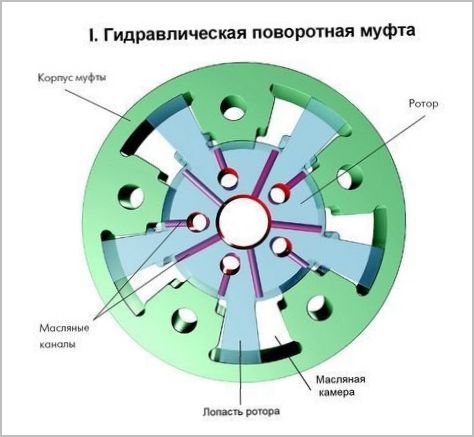

CVVT clutch device

The hydraulic clutch (phase shifter) has an asterisk on the body. It is driven by a timing belt or chain. The camshaft is rigidly connected to the fluid coupling rotor. The oil chambers are located between the rotor and the clutch housing. Due to the oil pressure generated by the oil pump, the rotor and crankcase can move relative to each other.

The clutch consists of:

- rotor;

- stator;

- stop pin.

The locking pin is required for the operation of the phase shifters in emergency mode. For example, when the oil pressure drops. It slides forward, allowing the hydraulic clutch housing and rotor to lock into the middle position.

VVT control solenoid valve operation

This mechanism is used to adjust the oil supply to delay and advance the opening of the valves. The device consists of the following components:

- Plunger;

- connector;

- Spring;

- Housing;

- Valve;

- Openings for supply, supply and drain of oil;

- Winding.

The engine control unit issues a signal, after which the electromagnet moves the spool through the plunger. This allows the oil to flow in different directions.

How the CVVT system works

The principle of operation of the system is to change the position of the camshafts relative to the crankshaft pulley.

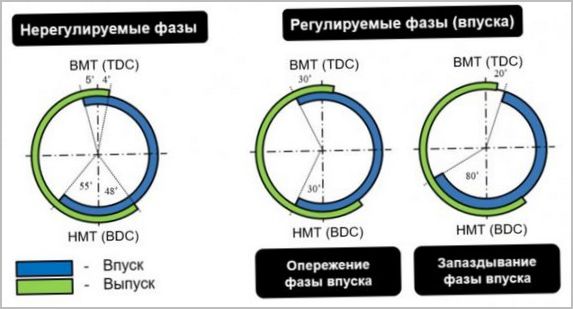

The system has two areas of work:

- valve opening advance;

- Valve opening delay.

Advance

The oil pump during the operation of the internal combustion engine creates pressure that is applied to the CVVT solenoid valve. The ECU uses pulse width modulation (PWM) to control the position of the VVT valve. When the actuator needs to be set to the maximum advance angle, the valve moves and opens an oil passage into the advance chamber of the CVVT hydraulic clutch. In this case, the liquid begins to drain from the lag chamber. This makes it possible to move the rotor with the camshaft relative to the housing in the direction opposite to the rotation of the crankshaft.

For example, the CVVT clutch angle at idle is 8 degrees. And since the mechanical valve opening angle of an internal combustion engine is 5 degrees, it actually opens 13.

Lag

The principle is similar to that described above, however, the solenoid valve, at maximum delay, opens the oil channel leading to the delay chamber. . At this point, the CVVT rotor moves in the direction of rotation of the crankshaft.

CVVT logic

The CVVT system operates throughout the entire engine speed range. Depending on the manufacturer, the logic of work may differ, but on average it looks like this:

- Idling. The task of the system is to rotate the intake shaft so that the intake valves open later. This position increases the stability of the engine.

- Average engine speed. The system creates an intermediate position of the camshaft, which reduces fuel consumption and emissions of harmful substances with exhaust gases.

- High engine speed. The system is working to generate maximum power. To do this, the intake shaft rotates to allow the valves to open early. Thus, the system provides a better filling of the cylinders, which improves the performance of the internal combustion engine.

How to maintain the system

Since there is a filter in the system, it is recommended to replace it periodically. This is an average of 30 kilometers. You can also clean the old filter. A car enthusiast can handle this procedure on their own. The main difficulty in this case will be finding the filter itself. Most designers put it in the oil line from the pump to the solenoid valve. After the CVVT filter has been disassembled and thoroughly cleaned, it should be inspected. The main condition is the integrity of the grid and the body.

It should be remembered that the filter is quite fragile.

Without a doubt, the CVVT system aims to improve engine performance in all operating modes. Due to the presence of a system of advancing and delaying the opening of intake valves, the engine is more economical and reduces emissions of harmful substances. It also allows you to minimize idle speed without compromising stability. Therefore, this system is used by all major car manufacturers without exception.