Malfunctions of the MAZ middle axle gearbox

Noise on the bridge, more like a howl, is the first sign of a gearbox malfunction. On modern MAZ vehicles, the central shaft gearbox is installed vertically. Structurally similar to the rear axle gearbox. Spare parts of the central and rear units are replaceable, they are regulated according to the same principle.

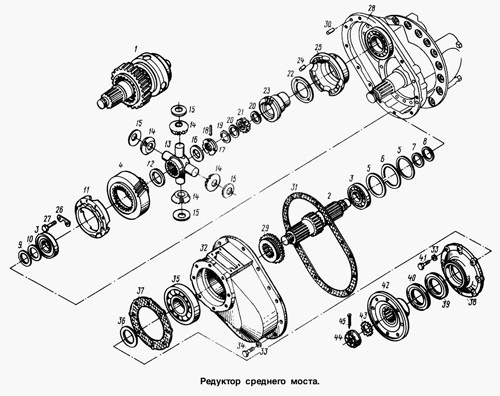

Design

It is worth noting that the MAZ 5440 gearbox consists of:

- the main pair (driving and driven gears);

- steelite axes;

- satellites;

- housings of differentials;

- Aspects;

- adjusting washer;

- crankcase.

Each of these mechanisms has a certain operational resource. Sometimes they wear out sooner. The need to repair or replace the gearbox or components is evidenced by kinks, chips on the surface, extraneous noise, as mentioned above.

The exact cause of the malfunction can only be determined after removing and inspecting the gearbox. Without this, one can only guess what caused the breakdown.

Common malfunctions

Bearing wear is one of the most common causes. This happens due to insufficient oil level in the gearbox housing, poor-quality bearing or significant wear. The malfunction is eliminated by replacing the bearing.

If the bearing falls apart while the vehicle is moving, its rollers may crack inside the gearbox. The situation is dangerous because the gearbox itself can jam. In this case, the amount of repair increases significantly. You need to do this at specialized service stations.

Satellite gears are also a weak point in the gearbox. They fall apart if the car is regularly operated under a load that is much higher than the permissible one. The gears also need to be replaced.

To avoid the problems described above, gears and bearings must be changed periodically, within the time limits set by the manufacturer in the regulations. Also, you should not save on the quality of components, since repairs in case of their premature failure will cost many times more.

Diagnostics

The gearbox is disassembled in stages, after which all components and parts are thoroughly washed. Then it is necessary to inspect the surfaces for the presence of chips, cracks, metal fragments, traces of friction, burrs on the gear teeth.

With strong signs of wear on the driven or driving gear, the entire main pair should be replaced. If the parts are in good condition, then they do not need to be replaced.