freewheel generator

Content

The technical progress of the last decades has made significant changes in the design of a modern car. Engineers manage to improve the technical and operational properties of the car through the introduction of new parts, assemblies and assemblies. Serious design changes have undergone a converter of mechanical energy into electrical energy - a generator.

Until relatively recently, all generators were equipped with a common pulley and belt, the distinguishing feature of which was a relatively small resource - no more than 30 thousand km. The generators of modern machines, in addition to all this, also received a special overrunning clutch that allows you to smoothly transfer torque from the internal combustion engine. In this article, we will talk about why a freewheel is needed, how to check it and how to remove it.

Purpose and principle of operation of the overrunning clutch

As you know, the transmission of torque from the power unit to all its working bodies is transmitted unevenly. The transmission of rotation is more cyclic, which begins at the moment of combustion of fuel in the cylinders and continues for two complete revolutions of the crankshaft. Also, these elements have their own cyclic indicators that are different from the values of the crankshaft.

The consequence of this is that the most important parts in the operation of the power unit are subjected to uneven loads, which leads to their premature wear. And given that the motor operates in different modes, the loads can become critical.

Structure

The freewheel mechanism is built into the pulley itself to compensate for the negative effects of torque fluctuation. A fairly simple but effective design reduces the level of inertial loads on the generator bearings. Structurally, this element is a double cylindrical cage formed by rollers.

Complete freewheel structure:

- Indoor and outdoor cage;

- Two inner bushings;

- slotted profile;

- Plastic cover and elastomer gasket.

These clamps are exactly the same as roller bearings. The inner row of rollers with special mechanical plates acts as a locking mechanism, and the outer ones act as bearings.

Operating principle

By its principle of operation, the device resembles a boot bendix. At the moment of ignition of the fuel mixture in the cylinders of the power unit, the speed of rotation of the outer clip increases, to which power is supplied from the crankshaft. The outer part is connected to the inner one, which ensures the extension of the armature and the generator pulley. At the end of the cycle, the speed of rotation of the crankshaft decreases significantly, the inner ring exceeds the outer one, they diverge, after which the cycle repeats again.

Diesel power plants were in dire need of such a mechanism, but over time, the device began to make its way into the design of its gasoline counterparts. The Ford Tranist is perhaps the most famous car equipped with a flywheel alternator. Today, many car models receive such a system due to the fact that reliable power supply and uninterrupted operation of electronics are becoming increasingly important. Once you have figured out what the overrunning generator clutch is for, you can proceed to the next step - its maintenance and replacement.

Signs of a malfunctioning mechanism

Extensive testing by various independent car companies has proven the flywheel to be highly efficient. The design will reduce the load on important engine components, reduce noise and vibration. But you need to understand that this mechanism also has its own resource - a little more than 100 thousand kilometers. Structurally, the overrunning clutch has much in common with the bearing, malfunctions and symptoms, respectively, are also identical. It can fail due to jamming.

The main symptoms of a malfunction:

- The appearance of noise when starting the engine;

- Monitoring tensioner clicks;

- Belt drive failure.

Failure can be caused by various factors: mechanical damage, dirt ingress, improper installation of the generator, natural destruction. Subsequent operation of the vehicle will lead to accelerated wear of the alternator belt and other related elements. It is important to respond in time to the first signs of failure in order to quickly and with minimal financial costs eliminate the consequences of the failure of the inertial pulley.

Removing and replacing the overrunning clutch of the generator

Despite the fact that in appearance a conventional generator set is not much different from an improved one, the method of dismantling them is somewhat different. On some models, the freewheel mechanism is extremely difficult to remove due to the fact that the distance between the housing and the generator is so small that it is simply impossible to get close with a key. There are frequent cases of problems with fasteners, often even WD-40 does not help. To solve this kind of problem, professional car mechanics recommend using a special key, which consists of two removable parts.

Replacement mechanism of SsangYong Kyron 2.0

To disassemble the overrunning clutch of an SUV SsangYong Kyron with a 2.0 engine, you need to arm yourself with a special Force 674 T50x110mm wrench. The key consists of a Torx-type slot, convenient for removing rollers, and a socket with an external polyhedron. On the other hand, there is a hexagon for an additional key to release the fasteners.

It is recommended to follow the following workflow:

- At the first stage, it is necessary to disassemble the engine protection and remove the fan casing.

- The Torx 8 sleeve must rest against the body and, using a socket wrench bent to "17", unscrew the coupling.

- After loosening the part, lubricate the threads and the seat.

- Lubricate bearings, tensioner bushings and roller.

- Assemble the knot in reverse order.

After finishing work, it is important to replace the protective cap.

Removal and installation of the overrunning clutch on the Volvo XC70

The appearance of strange sounds and vibrations in the Volvo XC70 at low speeds is the first symptom indicating the need for a flywheel diagnosis and, possibly, its replacement. To quickly and efficiently remove and replace a structural element on this machine, follow these steps:

- arm yourself with a special ATA-0415 head.

- Remove drive belt, remove alternator.

- A hard-to-reach bolt is easily unscrewed with a head and a pneumatic wrench.

- New part installed (INA-LUK 535012110).

- Lubricate parts, assemble in reverse order.

At this point, the disassembly and subsequent installation of the new mechanism can be considered completed. If necessary, the bearings are also changed at the same time.

Mechanism replacement on Kia Sorento 2.5

As a new copy of the freewheel for the Kia Sorento 2.5, a pulley from one of the most famous auto parts companies INA is suitable. The price of one part ranges from 2000 to 2500 thousand rubles. It is also important to arm yourself with a special key - Auto Link 1427 worth 300 rubles.

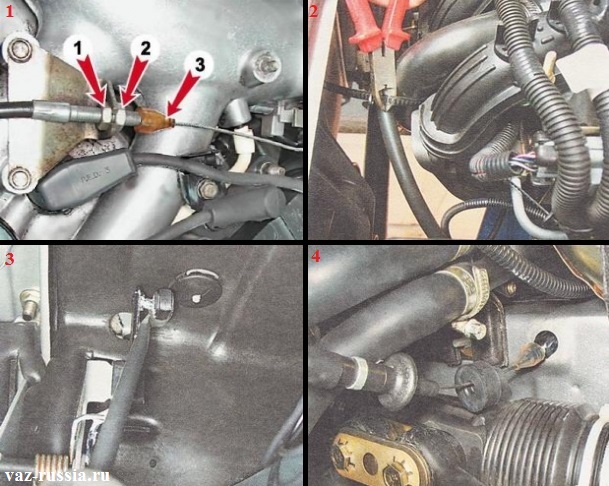

After all the necessary tools and auxiliary materials are at hand, you can get to work:

- Loosen the engine cover bracket.

- Unmount the "chip" and remove the positive terminal.

- Disconnect all types of tubes: vacuum, oil supply and drain.

- Loosen the two alternator fastening bolts with the key to "14".

- Loosen all clamping screws.

- Clamp the rotor in a vise, having previously prepared the gaskets.

- Using a socket and a long wrench, remove the pulley from the shaft.

After that, the failed mechanism is replaced. Next, you need to collect everything and reinstall it in its place. But spring-loaded brushes can interfere with this. To do this, unscrew the vacuum pump and find the hole in front of the brush assembly. The brushes are pressed and fixed in the hole with a characteristic sound.