Car fender liner treatment: how to avoid corrosion

Content

Protecting the fender liner of a car includes a number of measures that will vary depending on what material the element is made of.

Among all body elements, sills and wheel arches remain the most vulnerable parts that are the first to suffer from corrosion. A new car, off the assembly line, has standard rust protection that will keep moisture and salt out for the first 12 months.

Properly processing the fender liner of a car means protecting the body from premature wear and creating additional sound insulation for the cabin. Cars such as Kia Rio, Lifan and Renault Logan are produced with minimal anti-gravel coating. Therefore, it is better to process car fenders immediately after purchase. If the car is used, you must first carefully check the entire body for rust. And only then do anti-corrosion protection.

What is fender processing

Protecting the fender liner of a car includes a number of measures that will vary depending on what material the element is made of. Today, car fender liner protection is made from:

- steel or aluminum;

- polyethylene, ABC plastic, fiberglass;

- liquid formulations ("liquid fender liner");

- films.

Each of the types has advantages and disadvantages, is used in certain cases. Before you cover the fenders of the car with a protective film or anticorrosive, it is necessary to remove the part and process the wheel arch. For plastic and fiberglass elements, anticorrosive and anti-gravel are not used: the material is not subject to corrosion and does not react with salt reagents. The only thing that can ruin a plastic element is a crack from gravel. You can strengthen the structure with armored film.

Liquid liners Solid

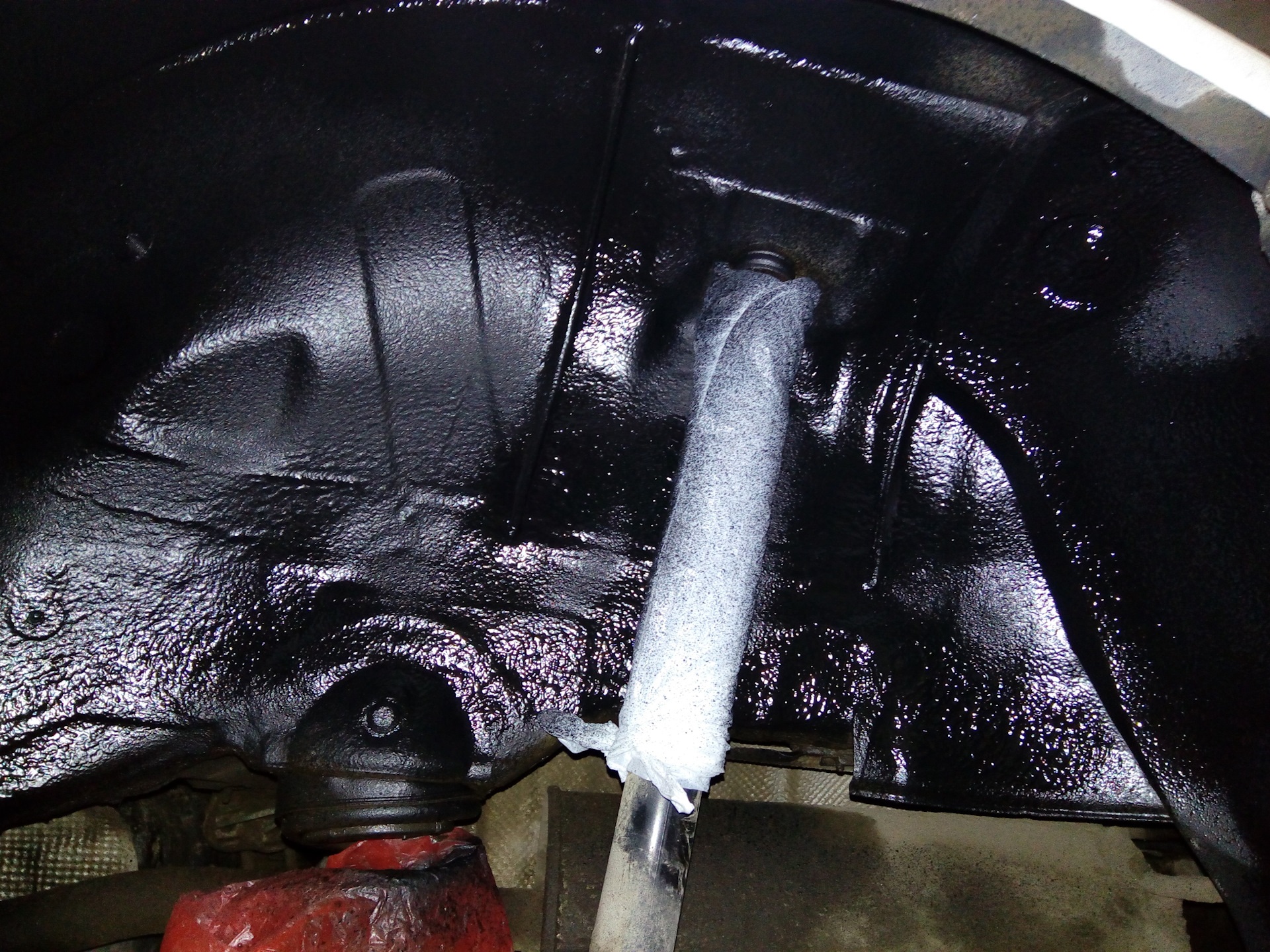

Technologically, the processing of steel parts is reduced to cleaning the part, degreasing, coating with anticorrosive or antigravel.

Processing methods

In car services, the processing of fender liner on a car is offered:

- liquid anticorrosives on wax, oil bases (sprayed);

- mastic (applied in several layers with a brush).

Regardless of the material chosen, the sequence of work will always be the same:

- Cleaning the wheel arch, dismantling the old fender liner (on some Mazda and Priora models, steel parts with a rubber edging are installed at the factory).

- Removal of foci of corrosion (preservatives are used).

- Degreasing the surface.

- Spraying (application) of anticorrosive in several layers. The thickness of the anti-corrosion protection depends on the selected material. So, wax and mastic are applied in 2 layers.

Processing fender liner on a car with your own hands does not require special. tool. All you need is quality ingredients and time.

mastic

Painting the fender liner with mastic is the easiest option for anti-corrosion protection of wheel arches. In most cases, the material is used to treat the bottom, since it has a high density and is inconvenient to spray into the hidden cavities of the wheel arch.

Mastic for fender liner

Apply the mastic with a brush (after thoroughly cleaning the fender liner), in 2 layers. After hardening, the material forms an elastic hermetic layer that traps flying gravel and prevents rusting.

Factory processing of wheel arches with mastic is included in the work on soundproofing the cabin.

wax mixture

Wax anticorrosive agents are liquid compositions with the addition of wax and resins for the treatment of hidden cavities (an example is the aerosol anticorrosive agent for fender liner from LIQUI MOLY). They are easy to apply: the work can be done independently.

Wax anticorrosives

After thoroughly cleaning the arch, the aerosol is sprayed 3-4 times, allowing each layer to dry completely. This forms a thin film.

Wax compositions withstand sub-zero temperatures well, the coating does not crack, wax does not flow in the heat (unlike Movil). An elastic and sealed film up to 1 mm thick protects car fenders for up to 1 year, then the composition must be renewed.

Oil-based products

The main advantage of oil-based anticorrosive agents is their high penetrating power. For the treatment of the fender liner on a car older than 5 years, it is recommended to choose products that contain corrosion inhibitors and zinc. The inhibitor stops rust pockets (and it is almost always present on an old car), zinc creates a protective layer.

Oil-based anticorrosives

For arches, anticorrosive agents are chosen in aerosol cans (one is enough to process the front arches). If the product is in cans, you will need a special spray gun.

Which is better: liquid or plastic fender liner

“Liquid fender liner” is a wheel arch coating with a special compound. After surface treatment with a locker, the protective layer has a thickness of up to 2 mm (depending on how many times the product has been sprayed). Main advantages:

- in the form of an aerosol or mastic, the “liquid fender liner” penetrates into all hidden cavities of the wheel arch;

- preserves a possible source of corrosion;

- forms a sufficiently strong film to protect the body from stones and gravel.

A plastic fender liner is a removable part that is installed in the arch, attached to the body with self-tapping screws or glued. Advantages of plastic:

- not subject to corrosion;

- low cost;

- large assortment for all models.

Do-it-yourself anti-corrosion treatment

Experienced drivers cook their compositions for anti-corrosion treatment of the body. The recipes have been tested over the years and are used to support metal that has almost exhausted its resource. This treatment allows you to delay the moment of natural destruction of iron as much as possible and serves as a reliable barrier against moisture and aggressive components.

Bituminous mastic for the car

A good tool is a composition based on bituminous mastic. It is necessary to take in equal parts anti-gravel "Cordon", mastic for the bottom of Body-950. Heat up and mix thoroughly. Process the fender liner in 2 layers with the finished paste.

The disadvantages of the method include the fact that the anticorrosive agent will have to be applied with a brush. This is inconvenient, there is no guarantee that it will be possible to penetrate into all hidden places.