Do-it-yourself reverse hammer: manufacturing instructions

Content

First you need to deal with the design. In the classic version, a mechanical reverse hammer is a pin 50 cm long and 15-20 mm in diameter. A handle is fixed on one side, and a fixing device (hook, suction cups, threaded bolt) on the other.

For body repair, straightening, removing “stuck on” parts, you need a rare hand tool - a reverse hammer. The design is made from improvised materials: anchors, shaped pipes. One option is a do-it-yourself reverse hammer from a shock absorber. The benefit is obvious: you will give a second life to a used spare part and make an exclusive mechanism that will come in handy more than once in servicing a car.

How to make your own reverse hammer from an old shock absorber

VAZ shock absorber struts are best suited. After dismantling the old car, do not rush to scrap the old parts. With some effort and ingenuity, it is easy to make a reverse hammer out of a shock absorber.

Device design

First you need to deal with the design. In the classic version, a mechanical reverse hammer is a pin 50 cm long and 15-20 mm in diameter. A handle is fixed on one side, and a fixing device (hook, suction cups, threaded bolt) on the other. A steel bushing - a weight - slides freely between them.

Device design

Necessary materials and tools

After properly disassembling the rack, you will have the necessary material to build a do-it-yourself reverse hammer from a shock absorber.

List of tools for work:

- Bulgarian;

- electric welding;

- locksmith vice;

- standard set of keys;

- gas-burner.

Prepare a container for grease flowing out of the pipe cavity during cutting.

Disassembly of the shock absorber strut

To create a useful puller, you need the top of the old part and the stock.

Clamp the part in a vise, substitute the dishes under the place where you will make the cut. Saw off the pipe to the plate with the spring. Work carefully, do not hook the stem.

Disassembled shock absorber

Remove fasteners and other parts from the rack. You are left with a stem and a top cap. Take out from the last an epiploon and the plug.

Reverse hammer manufacturing

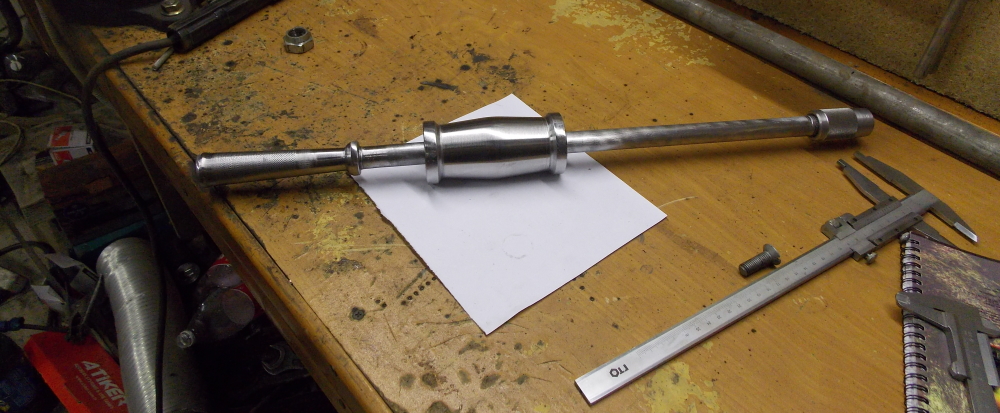

The released rod will serve as the basis from which a functional reverse hammer from the shock absorber will be obtained. It remains to supply the pin with three parts: a handle, a weight-weight and a nozzle.

Further instruction:

- From one end of the rod - where the thread is - attach the handle. Fix it by welding nuts on both sides. Process the welds according to the rules: remove the grinder with sagging and bumps, grind.

- From a piece of a shock absorber strut and a tube of the desired diameter matched to it, make a movable weight. Mount the element on the main pin.

- Attach the nozzles to the end of the rod opposite the handle.

The latter can be changed as needed: perhaps these will be hooks for leveling dents on the car body, or you want to knock out soured grenades, hubs, nozzles. Vacuum suction cups, hooks can be used at the end of the device.

How to make a handle

For convenient use of the device, find and fasten rubberized side handles from power tools at one end of the main working rod. If there are no suitable parts, attach any clamp that fits comfortably in your hand.

Reverse hammer handle made of silicone hose

Alternatively, use a piece of fuel hose. Secure it on both sides with nuts.

How to make a moving kettlebell

The rest of the pipe from the shock absorber strut will go to this important detail. The reverse hammer from the shock absorber rod is useless without a weight-weight: its weight must be at least 1 kg.

How to make weights:

- Pick up a pipe of a smaller section than a piece from the rack, but larger than the diameter of the rod (the weight should slide freely along the rod).

- Insert one tube into another so that they do not touch the walls.

- Center the parts, weld one end, leave the other open.

- Melt the lead, pour it into the gap between the pipes. After the metal hardens, the weight is ready for work.

Give the cooled weight an aesthetic look (cut off the welds from welding, go over with sandpaper), put a beautiful heavy element on the rod. Do-it-yourself reverse hammer from a shock absorber is ready.