The general device of the Hydractive hydropneumatic suspension, the principle of operation and the price of repair

Content

Any car suspension contains elastic elements, damping and guides. Manufacturers strive to bring the properties of each node as close as possible to the theoretical ideal. This is where the organic shortcomings of commonly used solutions, such as springs, springs and oil hydraulic shock absorbers, emerge. As a result, some firms decide to take a radical step, using hydropneumatics in the suspension.

How Hydractive Suspension Came to Be

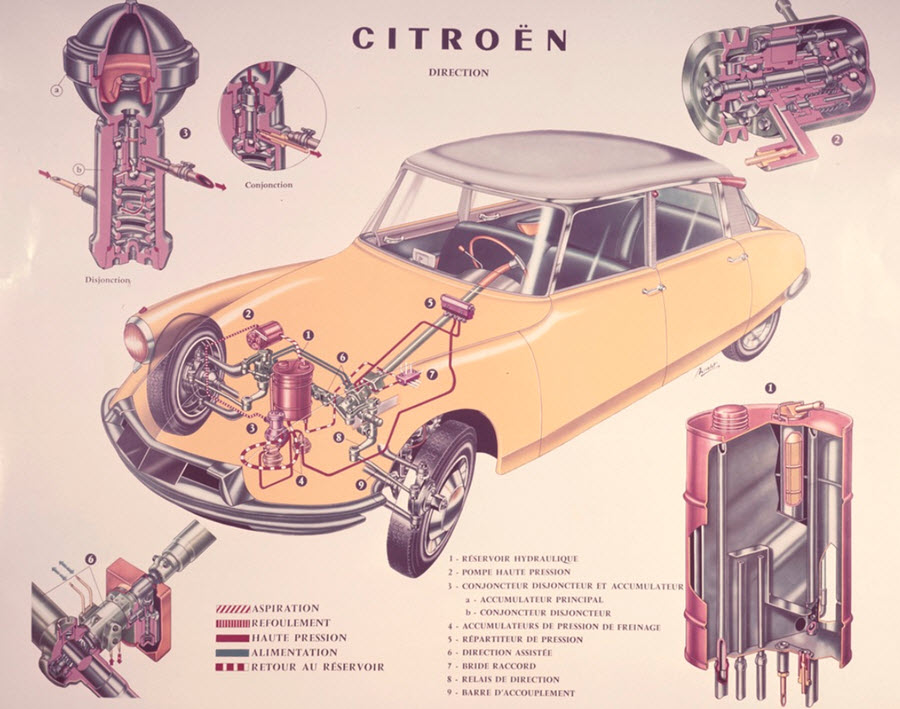

After numerous experiments with the suspension of heavy equipment, including tanks, a new type of hydromechanics was tested on Citroen passenger cars.

Having achieved good results with an experienced rear suspension on machines already known by that time for their revolutionary design with a monocoque body and front-wheel drive. Traction Avant, the new system was serially installed on the promising Citroen DS19.

The success was beyond all expectations. The car has become extremely popular, including due to the unusually smooth suspension with adjustable height of the body.

Elements, nodes and mechanisms

The hydropneumatic suspension incorporates elastic elements operating on nitrogen compressed to high pressure, and it is pumped for the entire service life of the air spring.

However, this is not a simple replacement of metal with compressed gas; a second important element is also separated from nitrogen through a flexible membrane - a working fluid in the form of a special hydraulic oil.

The composition of the suspension elements is roughly divided into:

- hydropneumatic wheel struts (working spheres);

- a pressure accumulator that stores energy to regulate the suspension as a whole (main sphere);

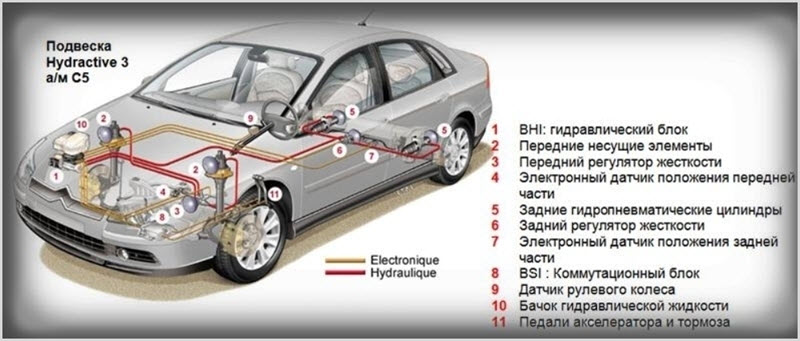

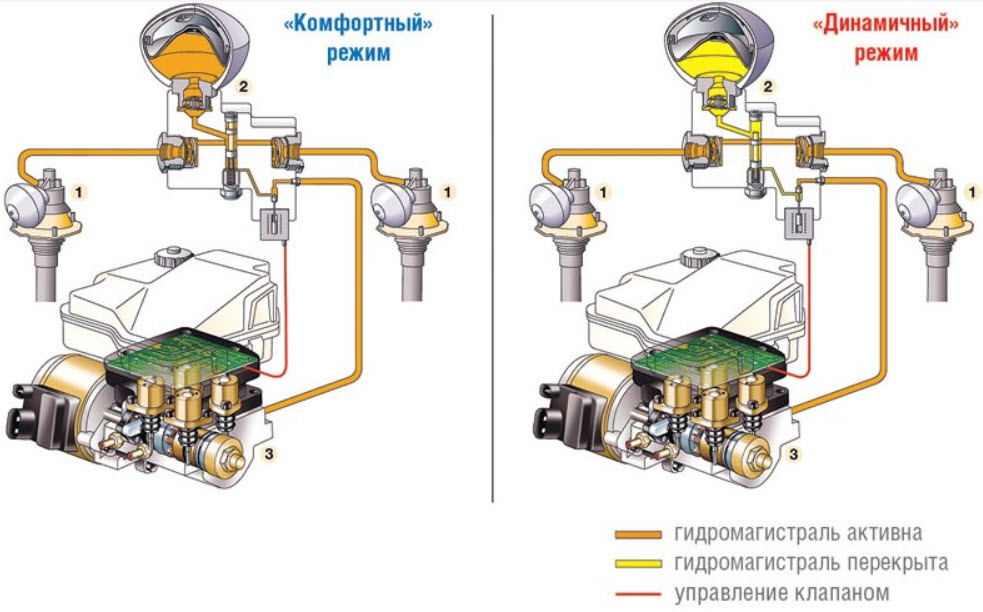

- additional areas of stiffness adjustment to give the suspension properties of adaptation;

- pump for pumping the working fluid, first mechanically driven by the engine, and then electric;

- a system of valves and regulators for controlling the height of the car, combined into so-called platforms, one for each axle;

- high-pressure hydraulic lines connecting all nodes and elements of the system;

- the valves and regulators linking the suspension to the steering and brakes were later dropped from that connection;

- electronic control unit (ECU) with the ability to manually and automatically set the level of the body position.

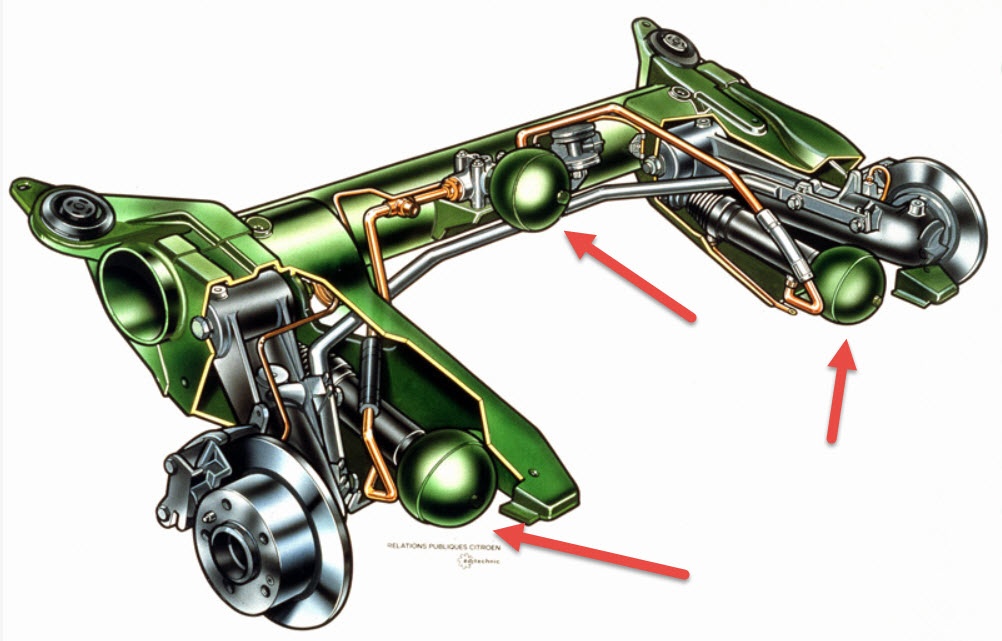

In addition to hydropneumatic elements, the suspension also included traditional units in the form of a guide vane, which form the overall structure of an independent suspension.

The principle of operation of the hydropneumatic suspension

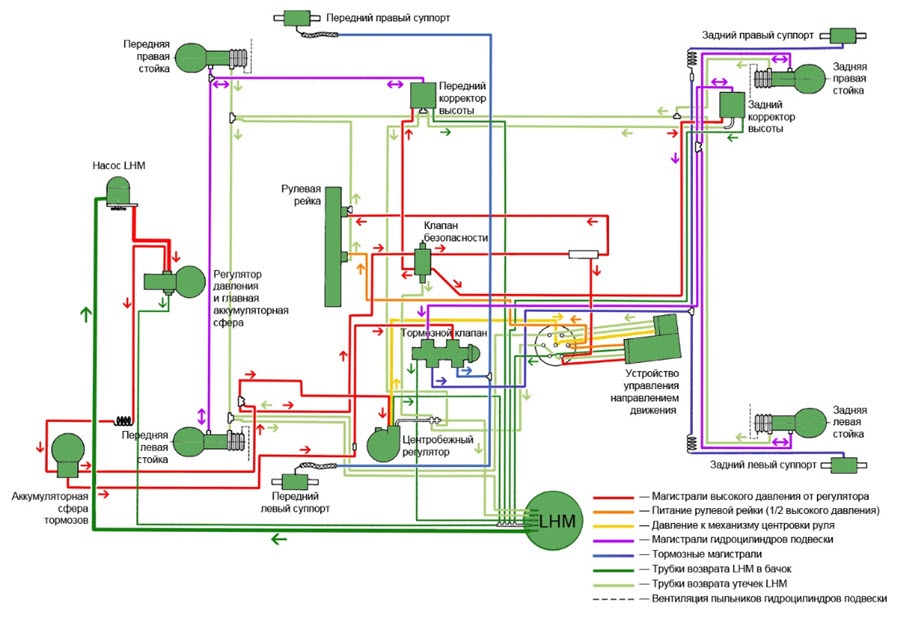

The suspension was based on a sphere containing nitrogen under high pressure, about 50-100 atmospheres, separated by a flexible and durable membrane from a purely hydraulic system, which first used green mineral oil of the LHM type, and starting from the third generation they began to use orange LDS synthetics.

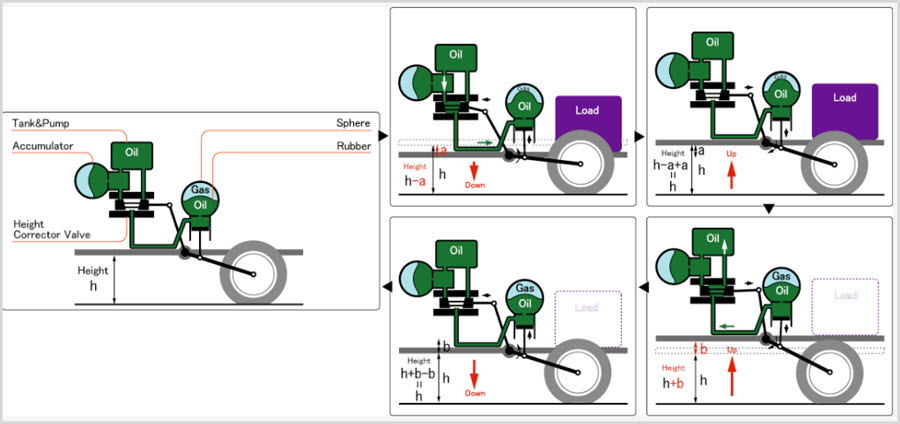

The spheres were of two types - working and accumulating. The working spheres were placed one at a time on each wheel, their membranes were connected from below to the rods of the suspension hydraulic cylinders, but not directly, but through a working fluid, the amount and pressure of which could change.

During operation, the force was transmitted through the liquid and the membrane, the gas was compressed, its pressure increased, thus it served as an elastic element.

The damping characteristics of the working racks from the cylinder and the sphere were ensured by the presence of petal valves and calibrated holes between them, preventing the free flow of liquid. Viscous friction converted the excess energy into heat, which dampened the resulting oscillations.

The rack acted as a hydraulic shock absorber, and very effective, since its liquid was under high pressure, did not boil or foam.

According to the same principle, then they began to make well-known gas shock absorbers for everyone, which allow them to experience heavy loads for a long time without boiling the oil and losing their properties.

Throttling of the overflow was multi-stage, depending on the nature of the obstacle, different valves were opened, the dynamic stiffness of the shock absorber changed, which ensured smooth running and energy consumption in all conditions.

To adapt the properties of the suspension, its stiffness could be changed by connecting additional spheres to a common line through separate valves. But the most spectacular was the appearance of a monitoring system for the level of the body and manual control of its height.

The car could be set in one of four height positions, two of which were operational, normal and with increased ground clearance, and two purely for convenience. In the upper position, it was possible to simulate lifting the car with a jack to change the wheel, and in the lower position, the car crouched to the ground to facilitate loading.

All this was controlled by a hydraulic pump, at the command of the ECU, increasing or decreasing the pressure in the system by pumping additional fluid. Shut-off valves could fix the result, after which the pump was turned off until the next need for it.

As the speed increased, the movement with a raised body became unsafe and uncomfortable, the car automatically reduced the clearance, bypassing part of the liquid through the return lines.

The same systems monitored the absence of rolls in corners, and also minimized the pecking of the body during braking and acceleration. It was enough just to redistribute the liquid in the lines between the wheels of one axle or between the axles.

Advantages and disadvantages

The use of gas as an elastic suspension element should theoretically be considered an ideal option.

It has no internal friction, it has minimal inertia and does not get tired, unlike the metal of springs and springs. But the theory cannot always be implemented with full efficiency. Hence the quite expected shortcomings that arose in parallel with the advantages of the new suspension.

Pros:

- very decent ride, Citroen cars with hydropneumatic suspension have long been considered standards in this part;

- the possibility of prompt manual and automatic adjustment of the height of the suspension;

- adjustable stiffness, including for automatic adaptation;

- good compatibility with proven types of guide vane, MacPherson principle and multi-links were commonly used.

Cons:

- difficulties with practical implementation, fundamentally new materials and technologies were required;

- high price due to a large set of equipment;

- in practice, low durability, although it is fundamentally not limited;

- high cost of repair and maintenance;

- reliability problems.

After many years of production, the cons still outweighed. Faced with low competitiveness, Citroen stopped further use of hydropneumatics on budget cars.

This does not mean a complete abandonment of its use, expensive cars from other manufacturers continue to offer this type of comfortable adaptive suspension as options for a fee.

Repair Price

Many machines with hydropneumatic suspension continue to be used. But they are bought on the secondary market rather reluctantly. This is due to the high cost of maintaining such cars in good condition.

Spheres, pumps, high pressure lines, valves and regulators fail. The price of a sphere from a decent manufacturer starts from 8-10 thousand rubles, the original is about one and a half times higher. If the unit is still working, but has already lost pressure, then it can be refueled for about 1,5-2 thousand.

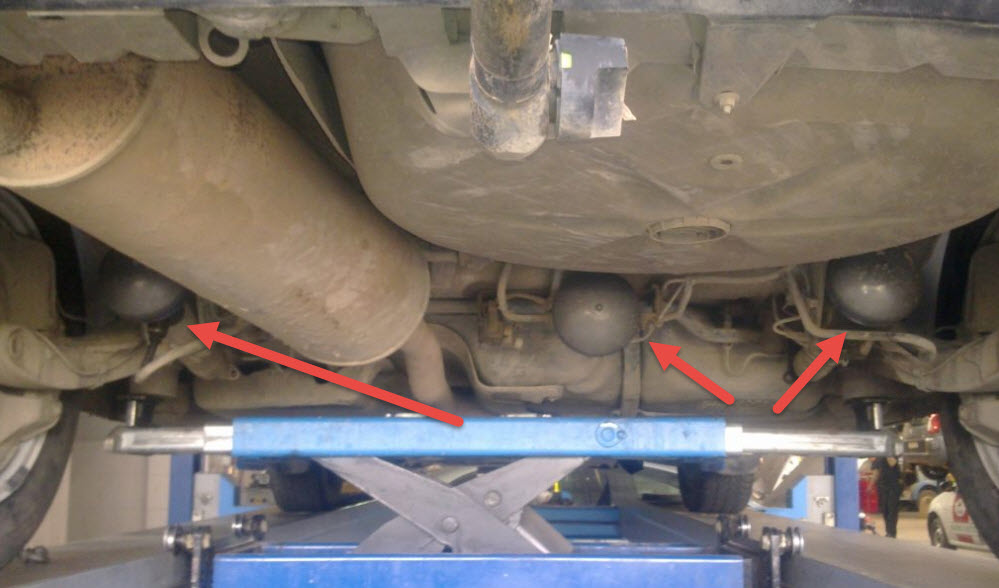

Most of the parts are located under the car body, so they suffer from corrosion. And if it is quite simple to replace the same sphere, then if its connection becomes thoroughly sour, then this turns into a big problem due to the inconvenience of applying significant effort. Therefore, the price of the service may approach the price of the part itself.

Moreover, many difficulties can arise when replacing pipelines leaking due to corrosion. For example, the tube from the pump goes through the entire machine, technological dismantling of many parts will be required.

The issue price can be up to 20 thousand rubles, and it is unpredictable due to corrosion of all other fasteners.

The working fluid for any repair and maintenance is required constantly and in significant quantities. The price is comparable to oils for automatic transmissions, about 500 rubles per liter for LHM and about 650 rubles for LDS synthetics.

Watch this video on YouTube

Replacing many parts, for example, those related to platforms, that is, adjusting the height of the body, with new ones is generally not economically feasible. Therefore, we have accumulated a lot of experience in the restoration and repair of parts.

Whether the comfort of fairly old cars is worth the constant care of the suspension - everyone decides for himself.