Support bearing strut

Content

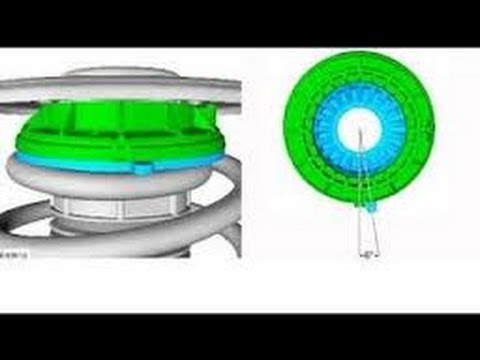

The support bearing of the front suspension strut of the car serves to provide a movable connection between the shock absorber and the car body. That is, it is located at the top of the strut, between the upper cup of the damping spring and the support.

Structurally, the assembly is a kind of rolling bearing. However, its feature is the large thickness of the outer ring. Cylindrical rollers serve as rolling elements in this case. They are located perpendicular to each other, and also separated from each other. This design of the device provides the ability to take loads from any side.

What is a support bearing for?

Support bearing operation

the basic task of a thrust bearing is allow the shock absorber to rotate freely in the support. Regardless of the type of support bearing design, it is always located just above the front spring, and the shock absorber rod passes through its central cavity. The shock absorber housing is attached to the car body exactly in the place where the thrust bearing is mounted. It provides a movable connection between the shock absorber and the car body.. Therefore, the bearing during operation experiences not only radial, but also axial loads.

Types of support bearings

Depending on the design, today there are several types of thrust bearings. Among them:

Varieties of thrust bearings

- With built-in outer or inner ring. It is mounted using the mounting holes on the housing, that is, it does not need to use clamping flanges.

- With detachable inner ring. The design implies that the outer ring is connected to the housing. usually, such a thrust bearing is used when the accuracy of rotation of the outer rings is important.

- With detachable outer ring. That is, the opposite of the previous one. In this case, the outer ring is separated and the inner ring is connected to the housing. This type of bearing is used when rotational accuracy of the inner ring is required.

- Single-separated. Here, the design involves splitting the outer ring at one point. This solution provides increased rigidity. This type of bearing is used in cases where it is necessary to ensure the rotation of the outer ring with sufficient accuracy.

Regardless of its design, dirt and sand still get inside along with moisture and are the main destructive factors along with strong shocks to the suspension.

Signs of a failed thrust bearing

Signs of bearing wear are two basic factors - the presence of a knock when turning the steering wheel in the area of \uXNUMXb\uXNUMXbthe front wheel arches (also felt on the steering wheel in some cases), as well as a deterioration in machine controllability. However, the knock from the racks may in some cases not be felt. It depends on their design.

Worn support bearing

For example, on a VAZ-2110 car, the inner race of the thrust bearing acts as a sleeve through which the shock absorber rod passes. When the bearing is sufficiently worn, its housing allows play, from which the shock absorber rod deviates from the axis. Because of this, there is a violation of the angles of collapse-convergence. Breakdowns can be detected by rocking the car. You will find detailed instructions on checking the support bearing in the supplementary material.

The main sign of a breakdown is the need to constantly steer when driving on a straight road. Due to the violation of the toe-in angle, the wear of the shock absorber support increases by approximately 15 ... 20%. the protectors on tires, connecting and steering rods, their tips also wear out additionally.

If the tasks of the bearing include only the rotation of the strut (that is, it does not interact with the shock absorber), then in this case there is no violation of the toe-in angles, since the shock absorber rod holds the bushing, which is pressed into the rubber damper of the structure (for example, on the “Lada Priora”, “Kalina”, Nissan X-Trail). However, this still affects the handling of the car, although to a lesser extent. Such a bearing will start knocking when it fails. Moreover, knocks will often be felt even on the steering wheel. In this case, it will not work to diagnose a bearing failure by simply swinging the car..

Problems of the work of the OP and their consequences

Support bearing operation

The suspension strut support bearing is subjected to severe use. Especially when driving on rough roads, cornering at high speed, non-compliance with the speed limit by the driver. The situation is aggravated by the fact that many bearings (but not all) are not designed to be protected from dust, moisture and dirt. Accordingly, over time, an abrasive mass is formed in them, which accelerates the wear of their mechanism. If the design of your bearings provides for the presence of protective caps, but they are not in place (they were lost), be sure to order new ones. this will prolong the life of the bearing. also don't forget to put grease in the bearing, we will talk about this further.

So, the main reasons for the failure of thrust bearings are the following reasons:

Scheme OP

- Natural wear of the part. As mentioned above, the replacement of thrust bearings must be carried out at least every 100 thousand kilometers of the car (usually more often, given the condition of domestic roads).

- Sharp driving style and non-compliance with the speed limit. In the event that the driver drives at high speed through pits or enters a turn, then the load on the entire suspension of the car, and the support bearing, in particular, increases significantly. And this leads to its excessive wear.

- Poor part quality. If you decide to save money and buy a low-quality fake, then there is a high probability that the bearing does not come out of the period indicated on its packaging.

- Vehicle operating conditions. Depending on the conditions the machine is designed for and how it is used, support bearing failure can occur much sooner than predicted by the manufacturer.

When performing repair work on the shock absorber, suspension strut and other related parts, we recommend that you put grease in the support bearing. This will increase its service life, as well as reduce the load on all the elements listed above.

Support bearing lubrication

At its core, a thrust bearing is a rolling bearing. In order to reduce the load on it during operation, as well as extend the service life, various lubricants are used. For lubrication of thrust bearings, their plastic types are most often used. Greases are designed to improve the performance of bearings. namely:

- increase bearing life and extend its service life;

- reduce the load on the suspension units (not only on the bearing, but also on other elements - steering, axle, steering and connecting rods, tips, and so on);

- increase the controllability of the car (do not let it decrease during operation).

Each type of lubricant has its own characteristics, advantages and disadvantages. Therefore, it is necessary to make a choice of one or another lubricant, taking into account the following reasons:

- specific loads that act on the support bearing (vehicle weight, its operating conditions);

- the probability of getting on / into the node of moisture;

- normal and maximum operating temperatures for which the bearing is designed;

- the material from which the mating working surfaces are made (metal-metal, metal-plastic, plastic-plastic, metal-rubber);

- the nature of the friction force.

In our country, popular lubricants for thrust bearings are the following:

- LITOL 24. This simple, proven and cheap grease is perfect for laying in a support bearing as one of the many types of bearings for which the mentioned grease is intended.

- Various lubricants for CV joints. You will find detailed information about popular brands, their advantages and disadvantages in the supplementary material.

- Lithium greases with the addition of molybdenum disulphide. There are many such compositions. One of the popular brands is Liqui Moly LM47. However, remember that these lubricants are afraid of moisture, so they can only be used in thrust bearings with protective caps.

- also, many drivers use one of Chevron's multipurpose greases: black Black Pearl Grease EP 2, and blue Delo Grease EP NLGI 2. Both greases are in 397 g tubes.

However, be that as it may, even with the use of lubrication, any bearing has its own limited resource. usually, the replacement of the thrust bearing is carried out along with the replacement of the shock absorber, if such a need arises.

Replacing the support bearing

OP replacement

With a complete or partial failure of the bearing, no one is engaged in its repair, because there is simply nothing to repair. However, you can get rid of the knock that so often worries car owners. namely, during operation, the damper rubber “sinks”, and a backlash is formed. As a result, there is a knock. You can consider how to get rid of this problem using the example of the VAZ 2110 in the following video.

The thrust bearing is installed on vehicles with a MacPherson strut front suspension. Accordingly, the process of replacing it is identical in most steps, with the exception of slight differences in the implementation of some components of individual car models. There are two methods of replacement - with the complete dismantling of the rack assembly or with partial removal of the top of the rack assembly. usually, they use the first option, which we will describe in more detail.

If the replacement of the OP is possible without dismantling the rack, then the work is carried out easily. You just need to remove the cup along with the old bearing and replace with a new one. When the design and location of the support bearing does not allow this, then you will need locksmith tools, as well as a jack, wrenches and spring ties to complete the work.

The algorithm for replacing the thrust bearing when removing the strut and disassembling the shock absorber is as follows:

- Loosen the support mounting nuts (usually there are three of them, located under the hood).

- Jack up the car on the side where the bearing is supposed to be changed, and remove the wheel.

- Unscrew the hub nut (usually it is pinned, so you need to use an impact tool).

- Loosen the bottom strut mount and loosen the bottom nut a little.

- Disconnect the brake caliper, then move it to the side, while disconnecting the brake hose is not necessary.

- Using a crowbar or pry bar, remove the lower rack mounts from the seat.

- Remove the strut assembly from the car body.

- Using the existing couplers, tighten the springs, after which you need to disassemble the suspension strut.

- After that, a direct procedure for replacing the bearing is carried out.

- The assembly of the system is carried out in the reverse order.

Replacement of OP without collapse on VAZ 2108-21099, 2113-2115.

OP replacement of VAZ 2110

Which support bearing to choose

Finally, a few words about which bearings are best to use. First of all, you need to understand that it all depends on the model of your car. Therefore, it is impossible to give unambiguous recommendations. Accordingly, you need to build on the information provided by the manufacturer of your car.

Popular bearing manufacturers:

- SM is a Chinese brand founded in 2005. Belongs to the middle price segment. In addition to bearings, other spare parts for various machines are also produced.

- Lemforder - a German company that is famous for its quality, produces almost the entire range of auto parts.

- SNR is a world-famous French company producing various bearings.

- SKF is the world's largest manufacturer of bearings for automobiles and other equipment.

- FAG is a company based in Germany. The products are distinguished by quality and reliability.

- NSK, NTN, Kowo - three similar manufacturers from Japan. Provide a wide variety and quality of manufactured bearings.

When choosing, you need to understand that it is not worth overpaying for an expensive part. Especially if you are the owner of a budget car. However, saving is also not worth it. It is best to make a choice of bearings from the middle price category. You can find reviews and recommendations on choosing an OP at the end of the article about checking thrust bearings, the link to which we gave above.

Hack and predictor Aviator

The thrust bearing is a small but important part of the suspension. Its failure can lead to unpleasant consequences in the form of a deterioration in the controllability of the car and an increase in the load on other, more expensive, components. Therefore, remember that it is easier and cheaper to replace this inexpensive part than to wait for the failure of more expensive car suspension components. Do not neglect this and carry out timely diagnostics and replacement of the OP.