Jerky brakes

There are a number of reasons why, when braking, the car slows down jerkily. Among them are the use of new, also not lapped, brake pads, air ingress into the braking system fluid, curvature of the brake discs, partial failure of silent blocks and / or steering tips, problems with the pendulum bushings. In isolated cases, a situation is possible when the car not only slows down in jerks, but also hits the steering wheel.

It should be said right away that the listed breakdowns are very dangerous and can lead not only to the failure of the critical components of the car, but also to the creation of an emergency on the roads! Accordingly, when a situation arises when the car slows down jerkily, it is necessary to take emergency measures to identify the breakdown and eliminate it.

Causes of jerking when braking

To begin with, we list the most common reasons that the car slows down jerkily. Yes, they include:

- Airing the hydraulic brake system. This phenomenon occurs due to the depressurization of the corresponding system on hoses, cylinders or in its other components. Air in the brake system reduces the efficiency of its work, including sometimes a situation when the car brakes jerkily when braking. Often, before the appearance of jerks, there is a general decrease in the effectiveness of the braking system. Therefore, jerks are already the final signal that the system needs to be pumped and brake fluid added to it.

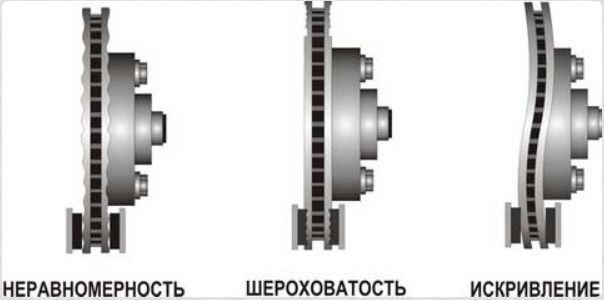

- Curvature of brake/brake discs. Such a situation may arise, for example, due to their sudden cooling. namely, after sudden braking, when the disc is very hot, the car drives into a puddle of cold water, as a result of which there is a sharp temperature drop in the material from which the brake disc is made. If it (the material) is of insufficient quality, then there is a possibility that the product can change its geometric shape (it can be tritely “led”). This situation is especially relevant for non-original or simply cheap low-quality discs.

Types of deformation of brake discs

remember, that the thickness of the brake discs must be greater than 20 mm! If this is not the case, both disks need to be replaced.

- Rust on disc. A very exotic option, relevant, namely, for used cars from Japan. So, when the car is parked for a long time without movement, a rust coating forms between the brake pad and the disc, which is subsequently perceived as impacts during braking. The phenomenon is especially active when the disks rotate synchronously. For reference: in the coastal conditions of Japan or Vladivostok (fogs, high humidity), discs can rust in just a couple of months, provided that the car is standing on the street without movement.

- Incorrect disk installation. When replacing this node / nodes by inexperienced craftsmen, sometimes there are situations when the disc is installed crookedly, which causes its friction on the block. This is even if the disc is new and even.

- Curvature of drums. Similar to the previous points. Changes in the geometry of the drums can be caused by wear or due to sudden changes in their operating temperature.

- Worn brake pads. Some car owners note a situation when, with very worn brake pads, the car starts to slow down jerkily. A whistle when braking can also serve as confirmation of wear. It can be caused both by a critical level of pad wear and by the work of the so-called "squeakers" - special metal antennae that rub against the discs, causing a squeak and thereby signaling the car owner to replace the brake pads. Sometimes vibration is possible when even new pads are working, more often provided that they are of very poor quality.

- Sticking rear pads. This is a fairly rare situation, which sometimes occurs in the case of prolonged braking and poor-quality pads. But in this case, the vibration will be not only when braking, but also in the process of driving.

- Loose front calipers. More precisely, we are talking about the fact that their fingers simply wore off during operation. This situation appears infrequently and only on machines with very high mileage.

- disc and pad softness discrepancy. This situation implies that "soft" discs (drums) and "hard" pads have been installed. As a result, the pads bite into the discs (drums), thereby damaging them.

Worn brake disc

- Large wheel bearing play. In this case, when braking, the wheels will vibrate, and this will automatically cause the entire car to vibrate. This is especially true for the front wheels, as they are more loaded during braking.

- Damaged silent blocks. We are talking about the silent blocks of the rear of the suspension. With their significant wear, some car owners note a situation where the car starts to twitch when braking.

According to statistics, about 90% of cases when vibration appears during movement is associated with curvature of the brake discs. Accordingly, the check should begin with these nodes.

Troubleshooting methods

Now let's move on to the description of the repair work, with which you can fix the problem when the car brakes jerkily at low and / or high speed. We list the methods in the same order as the causes. So:

- Airing the system. In this case, it needs to be pumped, air expelled and the right amount of new brake fluid added. You will find the relevant information in the material, which tells about how to properly bleed the brake system of a car.

- Warped brake disc. Two options are possible here. The first is that if the thickness of the disk is large enough, then you can try to grind it on a special machine. To do this, seek help from a service station or car service. However, not all services perform such work. You can contact a familiar turner. The second option is more rational and safer. It consists in the complete replacement of the disk in case its deformation is significant, and/or the disk is already worn out and thin enough. In this case, it is better not to take risks and make an appropriate replacement. And you need to change discs (drums) in pairs (simultaneously left and right). Self-checking the disk is only worthwhile if the disk is severely damaged. Therefore, it is better to carry out an inspection, and even more so a repair, at a specialized service station.

- Incorrect disk installation. To correct the situation, you need to remove and install the disk / disks exactly in accordance with the instructions.

- Curvature of drums. There are two exits here. The first is to give it to a turner for boring. The second is their replacement. Depends on the degree of wear and the curved geometry of the drums. But it is better to install new nodes.

- Worn out pads. In this case, everything is very simple - you need to replace them with new ones. The main thing is to choose them correctly. And the replacement procedure can be done independently (if you have experience and understanding of such work) or in a car service.

- Sticking pads. It is necessary to carry out repair work on the lift to restore the health of the pads and calipers. It is best to replace used pads with new ones of good quality in order to prevent such situations from occurring in the future.

- Loose calipers. Repair in this case is not possible. it is necessary to replace the calipers, fingers, and, if necessary, the pads. When reassembling all components, do not forget to lubricate everything thoroughly with caliper and guide grease.

- disc and pad softness discrepancy. When choosing those and other nodes, you need to pay attention to the corresponding stiffness value. If necessary, replace one or more parts.

- Large wheel bearing play. Here it is necessary, most likely, to replace the corresponding nodes. You can try to repair them, however, as practice shows, such an undertaking is ineffective.

- Rust on the brake disc. If the rust coating is small, then you can do nothing, but operate the car for 500 ... 1000 kilometers, until the rust is removed naturally, under the influence of brake pads. Another option is to grind discs. In fact, the second option is preferable, but more expensive.

- Damaged silent blocks. it is necessary to revise the mentioned nodes, and if necessary, replace them.

It is noteworthy that in most cases, the identification of the cause should be carried out not in a garage, but at a service station using the appropriate equipment. After all, “by eye” it is impossible to feel the slightest deviations from the norm, which, in fact, at high speed can be sources of vibrations and other unpleasant phenomena that can not only cause discomfort for the driver and passengers, but also cause an emergency on the roads.

If you have come across the reasons for the situation when the car brakes jerkily, which were not listed, we will be glad to hear your thoughts and experience on this matter in the comments under this material.