BMW automatic transmission selector error

Content

- Automatic transmission malfunctions: signs, symptoms, causes, error codes

- BMW automatic transmission type

- What most often breaks down in an automatic transmission on a BMW

- Trouble-shooting

- Causes of BMW automatic transmission breakdowns

- Typical breakdowns

- BMW automatic transmission repair

- Error codes for automatic transmission malfunctions

- Automatic transmission repair cost

- Contract transmissions for BMW

Automatic transmission malfunctions: signs, symptoms, causes, error codes

The automatic transmission is subjected to significant loads during the operation of vehicles. This is the main cause of automatic transmission failures, which leads to various breakdowns and unpleasant surprises.

Modern cars are complemented by very reliable "automatic machines" designed for difficult conditions and operating modes. Such equipment significantly reduces the frequency and number of calls to repair shops. Thus, the latest automatic transmissions, with proper maintenance, timely execution and proper operation, can work out about one hundred and five hundred thousand kilometers. Only after such an impressive run will they need a major overhaul.

Automatic transmission diagnostics is a necessary event that must be carried out regularly in order to identify malfunctions in the mechanism and all kinds of symptoms of malfunctions. It begins with the elimination and decoding of automatic transmission fault codes, followed by troubleshooting with the help of a specialist.

BMW automatic transmission type

Large automakers do not produce anything themselves, since it is more profitable to order serial products from specialized companies. So, in terms of automatic transmission, BMW closely cooperates with the ZF concern, providing its cars with gearboxes.

The first digit in the name of the transmission indicates the number of gears. The last digit indicates the maximum torque for which the box is designed. The difference in modifications affects the cost of repairs. So, turnkey ZF6HP21 will be repaired for 78 rubles, and ZF000HP6 - for 26 rubles.

| BMW brand, body number | Years of issue | The model of car |

| BMW 1: | ||

| E81, E82, E88 | 2004 - 2007 years | ZF6HP19 |

| E87, F21 | 2007 - 2012 years | ZF6HP21 |

| F20, F21 | 2012 - 2015 years | ZF8HP45 |

| BMW 3: | ||

| E90, E91, E92, E93 | 2005 - 2012 years | ZF6HP19/21/26 |

| F30, F31, F34 | 2012 - 2015 years | ZF8HP45/70 |

| BMW 4 | ||

| F32 | 2013 - present | ZF8HP45 |

| BMW 5: | ||

| E60, E61 | 2003 - 2010 years | ZF6HP19/21/26/28 |

| F10, F11, F07 | 2009 - 2018 years | ZF8HP45/70 |

| BMW 6: | ||

| E63, E64 | 2003 - 2012 years | ZF6NR19/21/26/28 |

| F06, F12, F13 | 2011 - 2015 years | ZF8HP70 |

| BMW 7: | ||

| E38 | 1999 - 2002 years | ZF5HP24 |

| E65, E66 | 2002 - 2009 years | ZF6HP26 |

| F01, F02 | 2010 - 2015 years | ZF8HP70/90 |

| BMW X1: | ||

| E84 | 2006 - 2015 years | ZF6HP21, ZF8HP45 |

| BMW X3: | ||

| F25 | 2010 - 2015 years | ZF8HP45/70 |

| E83 | 2004 - 2011 years | ГМ5Л40Е, ЗФ6ХП21/26 |

| BMWH5: | ||

| F15 | 2010 - 2015 years | ZF8HP45/70 |

| E53 | 2000 - 2006 years | ГМ5Л40Э, ЗФ6ХП24/26 |

| E70 | 2006 - 2012 years | ZF6NR19/21/26/28 |

| BMW X6: | ||

| F16 | 2015 - present | ZF8HP45/70 |

| E71 | 2008 - 2015 years | ZF6HP21/28, ZF8HP45/70 |

| BMW Z4 Roadster: | ||

| E85, E86 | 2002 - 2015 years | ЗФ5ХП19, ЗФ6ХП19/21, ЗФ8ХП45 |

| E89 | 2009 - 2017 years | ZF6HP21, ZF8HP45 |

What most often breaks down in an automatic transmission on a BMW

The BMW automatic transmission is reliable, agile and economical. However, the complex design of the machine is not without drawbacks. A BMW transmission is being repaired with a faulty torque converter, a burnt clutch, or sticky solenoids.

Vibrations when turning on 1 (in 8 mortar) or 3 gears, buzzing, loss of power. The torque converter shows these symptoms if:

- the lock is not working properly. Early engagement of the lockout leads to rapid wear and oil contamination;

- a worn reactor freewheel slips, resulting in a loss of power transmitted from the BMW automatic transmission torque converter;

- a defect in the shaft seal through which pressure passes to activate and deactivate the lock;

- the input shaft seal is worn out;

- broken turbine blades or pump wheel. Rare but serious error. In this case, the BMW automatic transmission “steering wheel” is not repaired, but a new block is installed.

The loss of pressure in a BMW automatic transmission may be associated with savings on repairs. So, in boxes 6HP and 8HP, along with the oil, they change the filter built into a disposable tray with disposable aluminum bolts. Parts are expensive, but installing a fake sump and old bolts results in fluid leaks.

Shocks, kicks, bumps when shifting gears, slipping indicate wear on the clutches. Long-term slippage during compression of the discs causes abrasion of the friction layer and clogging of the fluid. In the most careless case, the offset may be completely absent and accompanied by the display of the "Check Engine" error.

Trouble-shooting

An automatic transmission is a complex unit that should be repaired by experienced professionals. But some problems that arise in the "machine" during the operation of the car, you can still solve it yourself. These decisions will be discussed below.

- The vehicle is moving when the lever is activated, or the signal on the vehicle's dashboard does not correctly reflect the actual position of the automatic transmission lever. The reason for this is a violation of the correct setting of the gearshift mechanism or damage to its structural elements. The problem can be solved by identifying and replacing failed components, followed by setting up equipment that meets the requirements of vehicle operating standards.

- The power unit of the car starts when the gear lever is moved to positions other than "N" and "P". Most likely, this state of affairs is due to malfunctions in the gear shift system, which were mentioned above. It is also possible that the starter switch built into the box is not working properly. Correcting the situation will make it possible to customize the work of the download activator.

- Gearbox oil leak. Causes: unauthorized loosening of fasteners that fix individual structural elements or breakage of o-rings for lubrication. In the first case, it is enough to tighten the bolts and nuts, and in the second case, replace the gaskets and seals with new and fresh analogues.

- Noise in the gearbox, spontaneous or difficult gear changes, as well as the refusal of the car to move regardless of the position of the lever indicate a lack of lubrication in the assembly. Measuring the lubricant level and adding it will help correct the situation.

- When it is not possible to downshift without depressing the accelerator pedal, this means that the setting is faulty or the throttle actuator components are broken. Here we need diagnostics, which will make it possible to determine the breakdown, with additional replacement of structural elements or making adjustments to the package.

Causes of BMW automatic transmission breakdowns

Premature failure of the BMW automatic transmission occurs due to improper operation and maintenance of the unit:

- Overheating above 130℃. The Sport Driving setting pushes the BMW automatic transmission to the limit. Due to the constant oil change, excess heat from the "donut" goes to the radiator. If the liquid is already old, and the radiator is clogged with aspen fluff or dirt, the case overheats, which brings the repair time closer. High temperatures quickly kill the torque converter, rubber seals, bushings, valve body spools and solenoids.

- Poor quality oil. Poor lubrication leads to the combustion of clutches, bearing and gear failure.

- Automatic transmission without heating. Preheaters heat the engine, but not the box. In frost, the viscosity of the liquid changes, the rubber and plastic parts of the machine become brittle. If you start work "cold", the pressure piston may burst, which will lead to clutch wear.

- Long slide in the mud. Excessive load on the machine leads to oil starvation of the planetary gear. If the engine is idling, the oil pump does not lubricate the entire gearbox. As a result, the transmission is repaired with a destroyed planetary gear.

Due to the maintainability of the BMW automatic transmission and the availability of spare parts, malfunctions can be treated. BMW and ZF repairmen approach the matter in a comprehensive manner, each time checking for weaknesses in the transmission that can cause problems on the road.

Typical breakdowns

Most of the malfunctions that occur during the operation of automatic transmissions are of a general nature and are grouped according to the principles that we will discuss in more detail below.

Backstage lever

The "automatic machines" of the previous generation, which were distinguished by a mechanical connection between the transmission and the selector, very often suffer from damage to the lever wings. Such a malfunction does not allow changing the transmission operating modes. Full restoration of the unit's performance occurs after the replacement of failed structural elements. A symptom of this problem is the difficult movement of the lever, which eventually stops completely “overlapping”. It is worth saying that some automatic transmissions do not need to be disassembled to repair such a malfunction, which significantly saves time on their elimination.

Oil

Oil leakage is a very common problem of "machines", which manifests itself in the form of greasy spots that appear under gaskets and seals. It is not difficult to detect an automatic transmission malfunction by such noticeable signs, but for this it is necessary to conduct a visual inspection of the unit with a lift. If you find the symptoms mentioned, you should contact the masters of a specialized service station, who solve such problems without difficulty and delay. The repair procedure consists in replacing the seals and restoring the amount of gear lubricant.

Control Unit (CU)

Failures in the operation of this node also happen quite regularly. They lead to the wrong choice of automatic transmission speed mode or to a complete blocking of the transmission. The problem can be solved by replacing failed control circuits and / or control unit modules.

Hydroblock (hereinafter GB)

Malfunctions of this unit are less common, but still happen from time to time, for example, an automatic transmission malfunction or a car “starts up” with unheated units. The symptomatology is very characteristic: shocks, shocks and vibrations of varying intensity. In modern cars, valve body malfunctions are detected by on-board automation, after which a warning is issued on the computer screen. Sometimes the car just won't run.

Hydrotransformer (also known as GT)

The failure of this node is another possible cause of automatic transmission malfunction. In this case, problems can only be solved by repair, which is usually cheaper than restoring an ECU or a valve body. You should contact a specialist if you notice a violation in the dynamics of the car, vibrations, squeaks and / or knocks. Also one of the symptoms is the presence of metal chips in the used gear lubricant.

BMW automatic transmission repair

BMW automatic transmission repair begins with diagnostics. This will help you quickly identify the problem. Save time and money on BMW automatic transmission repairs. The check includes an external examination, computer diagnostics, checking the level and quality of ATF, a test drive.

At the next stage, the master disassembles the box. Make a list of defects, according to which the cost of repairing a BMW automatic transmission is calculated. Defective parts are sent for repair or landfill. Consumables need to be changed. Then the master assembles the machine and checks the performance.

For overhauls of automatic transmissions, BMW orders ready-made OverolKit or MasterKit repair kits with clutch, bushings, spacer plate, rubber seals and oil seals. The remaining parts are purchased after the problem is solved.

Valve body repair

Starting with 6HP19, the valve body was combined with an electronic board in mechatronics, which led not only to an acceleration of signal transmission, but also to an excessive load on the hardware. To repair the valve body of a BMW car, you do not need to remove the body, just unscrew the pan.

When repairing the mechatronics of a BMW automatic transmission, consumables change: rubber bands, gaskets, hydraulic accumulators, solenoids and a separator plate. The separation plate is a thin sheet of metal with rubber tracks. Dirty oil "eats" the tracks, leading to leaks. The plate is selected according to the BMW box number.

Friction and metal dust clog the VFS solenoids. A malfunction of electromagnetic regulators is manifested in delays and errors in switching speeds. The ride comfort depends on this, as well as the condition of the clutches and hubs of the BMW automatic transmission.

When repairing the valve body of a BMW automatic transmission, the adapter in the solenoid wiring housing is changed. From the winter operation of the car without heating the oil, cracks appear in the adapter. Masters recommend changing the part, without waiting for wear, every 80 - 100 km.

Repair of the valve body is rarely carried out with testing of the support, drilling holes. Expensive and difficult. The master cannot guarantee an excellent result and a solution to the problem. In this case, the mechatronic is replaced with a used one.

Torque converter repair

On powerful cars, the torque converter is a common reason for repairing BMW automatic transmissions. ZF installs SACHS and LVC torque converters in automatic transmissions. According to the maintenance regulations for BMW 6- and 8-speed automatic transmissions, the torque converter must be serviced after 250 km of run. With aggressive driving, the period is reduced to 000 km.

It is not possible to repair the torque converter of a BMW automatic transmission on your own. You need special equipment and experience with donuts. How the master works:

- Cutting a welded torque converter.

- Open the locking mechanism.

- Examines the internal condition, rejecting defective parts.

- Cleans the torque converter from dirt, dries and re-examines.

- Restore parts and assemble a "donut" with new consumables.

- Weld the body.

- Check the tightness of the torque converter in a special bath.

- Check the rhythm.

- Balance.

Repairing a donut on a BMW automatic transmission takes only 4 hours and is cheaper than buying a new one. But, if the assembly is beyond repair, consider replacing it. For the aftermarket, ZF offers commercially remanufactured Sachs torque converters for BMW 6HP automatic transmissions. The price of such a "reconstruction" will be high due to the use of original parts and complex work. If something does not suit you, choose a contract unit.

Repair of planetary gear

Repair of the planetary mechanism of a BMW automatic machine cannot be carried out without removing the box. But the knot breaks very rarely, as a rule, after 300 km of operation of the BMW automatic transmission:

- there is a knock, vibration, for example, if at least one bushing is worn out;

- howling or hum occurs when bearings and gears are worn;

- over time, axle play appears;

- large metal particles in the oil pan indicate "destruction" of the planetary gear.

Worn planetary gear parts damage the entire BMW automatic transmission. Oil seeps through damaged bushings and shafts, causing a lack of lubrication and clutch failure. Working at the limit destroys the mechanisms. The gear parts scatter around the box, the chips get into the mechatronics and clog the filter.

Repair of the planetary mechanism of the BMW automatic transmission consists in replacing bushings, burnt clutches, and destroyed gears.

Friction disc repair

No BMW automatic transmission repair is complete without inspection of the clutches. Teachers usually ask for a complete replacement kit. If the friction clutches burn out, the steel disks are also changed. The clutch packs in each BMW automatic transmission vary in number, thickness and clearance.

In the BMW 6HP automatic transmission, the “E” package is the weakest due to the minimum wear allowance. At 8 HP, backpack "C" burns first. Masters try to change all the clutches at once in order to delay the review.

Disc thickness 1,6 or 2,0 mm. The BMW automatic is selected by case number. Original consumables are manufactured by Borg Warner, but high-quality non-original ones can also be ordered.

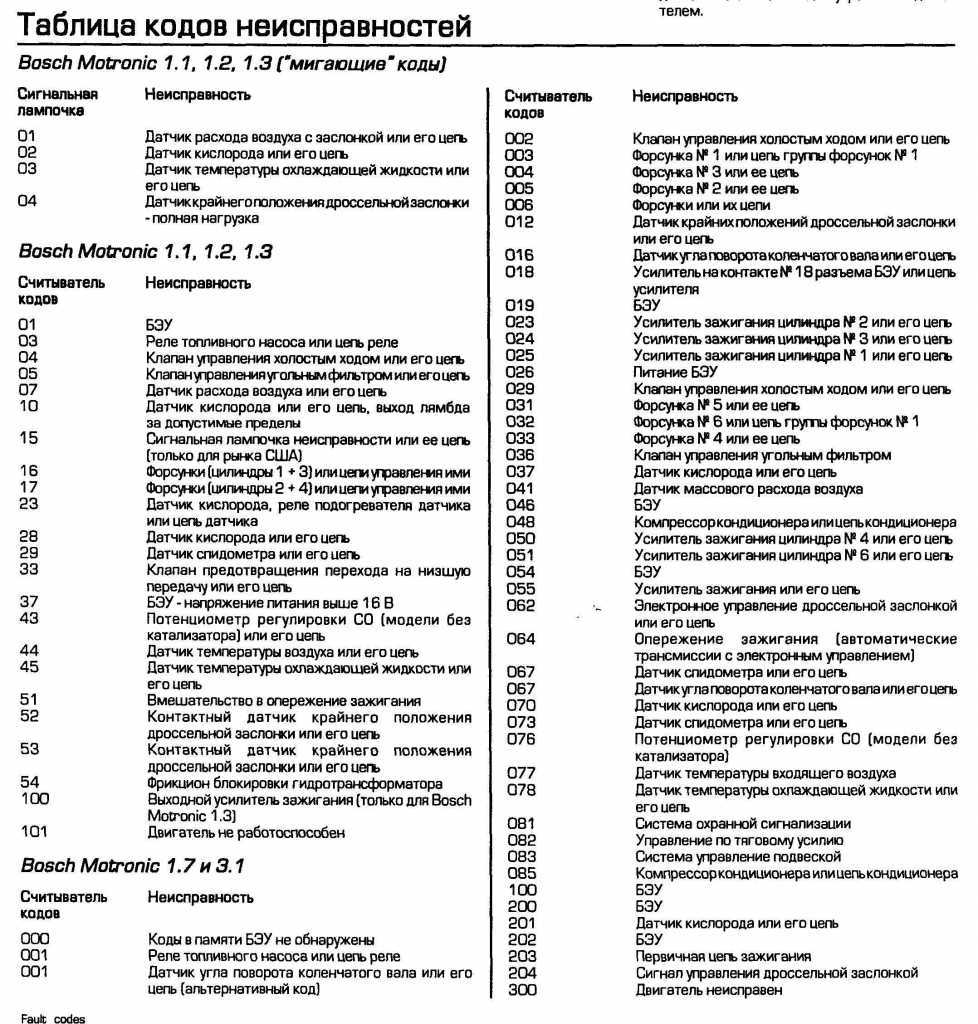

Error codes for automatic transmission malfunctions

Consider the most popular automatic transmission errors that occur on the dashboard of a car. For your convenience, the information is presented in the form of a table.

| wrong number | Meaning in English | Meaning in Russian |

| P0700 | TRANSMISSION CONTROL SYSTEM FAILURE | Transmission control system malfunction |

| P0701 | RANGE/PERFORMANCE OF TRANS CONTROL SYSTEM | Transmission control system is not working properly |

| P0703 | FAULT TORQ CONV/BRK SW B CKT | Faulty driveshaft/brake switch |

| P0704 | CLUTCH SWITCH INPUT CIRCUIT FAILURE | Faulty Clutch Engagement Sensor Circuit |

| P0705 | GEAR RANGE SENSOR (PRNDL) FAILURE | Faulty transmission range sensor |

| P0706 | SENSOR RANGE TRANS RANGE/SPECIFICATIONS | Sensor signal out of range |

| P0707 | TRANS RANGE SENSOR CIRCUIT LOW INPUT | Sensor signal low |

| P0708 | TRANS RANGE SENSOR CIRCUIT HIGH INPUT | Sensor signal high |

| P0709 | TRAVELING TRANSMISSION RANGE SENSOR | Intermittent sensor signal |

| P0710 | LIQUID TEMPERATURE SENSOR FAILURE | Defective transmission fluid temperature sensor |

| P0711 | TEMPERATURE RANGE / TRANSFORMER FLUID CHARACTERISTICS | Sensor signal out of range |

| P0712 | TRANSFORMER FLUID TEMPERATURE SENSOR, LOW INPUT | Sensor signal low |

| P0713 | TRANSFORMER FLUID TEMPERATURE SENSOR, HIGH INPUT | Sensor signal high |

| P0714 | TRANS FLUID TEMP CKT BREAK | Intermittent sensor signal |

| P0715 | INPUT/TURBINE SPEED SENSOR FAILURE | Faulty turbine speed sensor |

| P0716 | INPUT / TURBINE SPEED RANGE / OUTPUT | Sensor signal out of range |

| P0717 | INPUT/TURBINE SPEED SENSOR NO SIGNAL | No sensor signal |

| P0718 | PERIODIC SPEED INLET / TURBINE | Intermittent sensor signal |

| P0719 | TORQ CONV/BRK SW B CRCCUIT LOW | Drive shaft/brake switch shorted to ground |

| P0720 | OUTPUT SPEED SENSOR CIRCUIT FAILURE | Malfunction of a chain of the gauge "external speed |

| P0721 | OUTPUT SPEED SENSOR RANGE/SPECIFICATIONS | Sensor signal "External speed" is out of range of complement |

| P0722 | SPEED SENSOR OUTPUT CIRCUIT NO SIGNAL | There is no sensor signal "External speed |

| P0723 | RECTANGULAR OUTPUT SPEED SENSOR | Intermittent sensor signal "External speed |

| P0724 | TORQ CONV/BRK SW B CRCCUIT HIGH | Drive Shaft/Brake Switch Shorted to Power |

| P0725 | ENGINE SPEED SENSOR CIRCUIT FAILURE | Engine Speed Sensor Circuit Malfunction |

| P0726 | ENGINE RPM SENSOR RANGE/SPECIFICATIONS | Sensor signal out of range |

| P0727 | ENGINE SPEED SENSOR CIRCUIT NO SIGNAL | No sensor signal |

| P0728 | ENGINE RPM SENSOR intermittent CKT | Intermittent sensor signal |

| P0730 | INCORRECT TRANSMISSION | Incorrect transmission ratio |

| P0731 | TRANSMISSION 1 INCORRECT TRANSMITTER | Incorrect transmission ratio in 1st gear |

| P0732 | TRANSMISSION 2 INCORRECT TRANSMITTER | Incorrect transmission ratio in 2st gear |

| P0733 | INCORRECT TRANSMISSION 3 | Transmission ratio in 3rd gear incorrect |

| P0734 | TRANSMISSION 4 INCORRECT TRANSMITTER | Gear ratio in 4th gear wrong |

| P0735 | TRANSMISSION 5 INCORRECT TRANSMITTER | Gear ratio in 5th gear wrong |

| P0736 | CHANGE WRONG RELATIONSHIPS | The gear ratio of the transmission when moving the reverse gear is incorrect |

| P0740 | FAULT TCC CIRCUIT | Differential Lock Control Circuit Malfunction |

| P0741 | TCC PERFORMANCE OR CLEANING | Differential is always off (unlocked) |

| P0742 | STOP TCC CIRCUIT | Differential always active (locked) |

| P0744 | BREAK TCC CIRCUIT | Unstable differential state |

| P0745 | SOLAR PULSE CONTROL FAILURE | Compression Solenoid Control Malfunction |

| P0746 | PRESS PERF SOLENOID CONT OR STACK OFF | Solenoid is always off |

| P0747 | PRESSURE SOLENOID LOCK | Solenoid always on |

| P0749 | SUN PRESSURE CONTROL FLASHING | Solenoid status unstable |

| P0750 | SWITCH SOLENOID FAILURE | Faulty Shift Solenoid "A" |

| P0751 | SWITCHING THE ELECTROMAGNETIC SOLENOID TO OPERATION OR STORAGE OFF | Solenoid "A" is always off |

| P0752 | Shift Solenoid A Stuck | Solenoid "A" always on |

| P0754 | SOLENOID SOLENOID VALVE | Solenoid "A" status unstable |

| P0755 | SWITCH SOLENOID B FAULT | Faulty shift solenoid "B |

| P0756 | SWITCH SOLENOID OPERATION ON OR OFF | Solenoid "B" is always off |

| P0757 | SWITCH SOLENOID B Stuck | Solenoid "B" is always on |

| P0759 | ELECTROMAGNETIC SOLENOID SWITCH B INTERMITTENT | Solenoid "B" status unstable |

| P0760 | SWITCH SOLENOID FAULT C | Faulty Shift Solenoid "C" |

| P0761 | SWITCH SOLENOID C OPERATING OR FLOODING | Solenoid "C" is always off |

| P0762 | ELECTROMAGNETIC SOLENOID WITH POWER SWITCHING | Solenoid "C" always on |

| P0764 | ELECTROMAGNETIC SOLENOID C INTERRUPTED SWITCHING | Solenoid "C" status unstable |

| P0765 | SWITCH SOLENOID D FAULT | Faulty gear shift solenoid "D" |

| P0766 | ELECTROMAGNETIC SOLENOID D PERF OR STIC OFF | Solenoid "D" is always off |

| P0767 | SWITCH SOLENOID D LOCKED | Solenoid "D" always on |

| P0769 | INTERMITTENT TRANSMISSION SOLENOID D | Solenoid "D" status unstable |

| P0770 | SWITCH SOLENOID E FAULT | Faulty Shift Solenoid "E" |

| P0771 | ELECTROMAGNETIC SOLENOID E PERF OR STICK OFF | Solenoid "E" is always off |

| P0772 | ELECTROMAGNETIC SOLENOID SWITCH E FLOOD | Solenoid "E" always on |

| P0774 | SWITCHING AND INTERRUPTED SOLENOID | The state of the solenoid "E" is unstable |

| P0780 | TRANSMISSION FAILURE | Gear shift not working |

| P0781 | GEARBOX FAILURE 1-2 | Switching from 1 to 2 does not work |

| P0782 | 2-3 TRANSMISSION FAILURE | Gear shifting from 2 to 3 does not work |

| P0783 | TRANSMISSION FAILURE 3-4 | Gear shifting from 3 to 4 does not work |

| P0784 | GEARBOX FAILURE 4-5 | Gear shifting from 4 to 5 does not work |

| P0785 | SHIFT/TIMING SOL TROUBLE | Faulty synchronizer control solenoid |

| P0787 | CHANGE/LOW WEATHER SUN | Synchronizer control solenoid is always off |

| P0788 | CHANGE/HIGH WEATHER SUN | Synchronizer control solenoid is always on |

| P0789 | SHIFT/TIME FLASHING SUN | Synchronizer control solenoid unstable |

| P0790 | NORM/PERFORM SWITCH CIRCUIT FAILURE | Faulty drive mode switch circuit |

In conclusion, we note that every motorist must check the condition of all vehicle components and periodically check the condition of the lubricant and clean the oil filters. But if you still suspect a malfunction in the automatic transmission of your car, feel free to fill out the form below, and our specialists will help you find out the causes of the malfunction and carry out the necessary repairs.

Automatic transmission repair cost

BMW automatic transmission repairs are expensive. The cost depends on the degree of wear of the box, the price of spare parts and labor. The older the automatic transmission, the more problems it accumulates. The master can determine the exact cost only after troubleshooting, but, having extensive experience, it will not be difficult to navigate the price range for such cases.

Offer of specialized repair services for automatic transmissions BMW at a fixed price, which depends on the model of transmission. The price includes disassembly / installation of the machine, oil change, repair of mechatronics, torque converter, adaptation and start-up.

| box model | Cost, r |

| 5 HP | 45 - 60 000 |

| 6 HP | 70 - 80 000 |

| 8HP | 80 - 98 000 |

Contract transmissions for BMW

BMW contract gearboxes are the best solution for replacing a faulty transmission:

- price 3 - 500 rubles;

- residual life of the machine from 100 km;

- the box comes from Europe or the USA, where the operating conditions are almost ideal.

And yet, before agreeing to the "agreement", make sure that it is not profitable to repair the original box. You must understand that the contract machine may have defects because it has been in operation.

We deliver automatic boxes free of charge throughout the Russian Federation and CIS countries. You will have 90 days to verify its fix. For prices and delivery times, leave a request on the website or by phone. Let's find a car for your BMW.