Features of operation and repair of the fuel pump VAZ 2107 injector

Content

The carburetor fuel supply system, proven by time and well known to domestic motorists, continues to be actively used in various models of the Volga Automobile Plant. At the same time, owners of VAZ 2107 cars, who have the opportunity to choose, increasingly prefer a more promising and reliable injection power system. One of the key components of such a system is an electric fuel pump.

Gasoline pump VAZ 2107 injector

The injection "seven" has a number of fundamental differences from the carburetor version of the car. This difference applies primarily to the fuel supply system. In the design of the VAZ 2107, the injector does not have a carburetor, and the gasoline pump pumps fuel directly to the nozzles: this resembles the supply system of diesel engines.

Purpose and device

An electric fuel pump, unlike a mechanical one, is responsible not only for delivering fuel from the tank to the combustion chamber, but also for creating high pressure in the fuel system. Fuel injection in injection systems is carried out using nozzles, and gasoline must be supplied to them under high pressure. Only an electric pump can cope with such a task, a mechanical one is not suitable here.

The fuel pump VAZ 2107 injector is quite simple and thanks to this it has a long service life. In fact, this is an electric motor with blades located on the front of the shaft, which pump gasoline into the system. The inlet pipe of the pump is equipped with a coarse fuel filter in the form of a mesh to trap large particles of dirt. The design of the electric pump is complemented by a fuel level sensor that transmits a signal to the instrument panel.

Operating principle

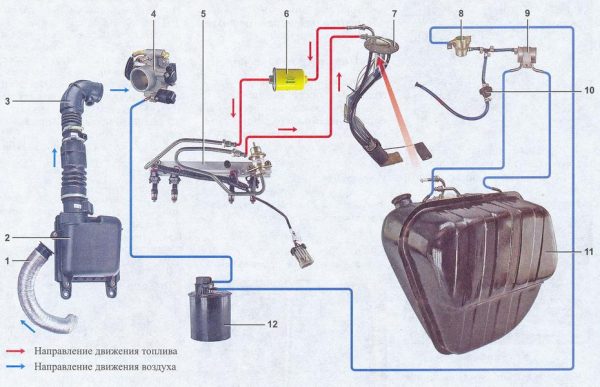

To better understand the principle of operation of a gasoline pump, you need to have an idea of \uXNUMXb\uXNUMXbthe injection system as a whole. Such a system consists of:

- Air intake.

- Air filter.

- Air sleeve.

- Throttle body.

- Ramps with four nozzles.

- Fuel filter.

- Gasoline pump.

- Gravity valve, thanks to which fuel does not spill out of an inverted car.

- The pressure regulator (bypass valve), which is responsible for maintaining the pressure in the system at the required level.

- Safety valve.

- fuel tank.

- Adsorber.

The fuel pump VAZ 2107 injector starts working after the driver turns the ignition key. At this moment, the pump motor is turned on, and the pressure in the system begins to rise. When the pressure in the fuel system reaches 2,8-3,2 bar (280-320 kPa), the engine starts. While the engine is running, the fuel pump pumps fuel into the system, and the pressure is kept at the required level. After the engine is turned off, the pressure drops within a few minutes.

Where is

The fuel pump of a VAZ 2107 car injector is located inside the fuel tank. If you open the boot lid, the tank with the pump can be seen on the right. The advantage of this arrangement is the simplification of the fuel system, the disadvantage is the difficult access to the gas pump.

Which fuel pump is better

If we compare the electric and mechanical fuel pump, it should be said that:

- the injection system itself is more reliable due to the fact that it does not have a carburetor that requires additional maintenance;

- an electric pump is preferable to a mechanical pump, because it:

- provides direct fuel supply to the injectors;

- can be located inside the fuel tank (i.e. saves engine compartment space);

- rarely fails due to the simplicity of the design.

Symptoms of a malfunction of the gasoline pump

You can determine the malfunction of the fuel pump by the following signs:

- when starting a cold or warm engine, you have to turn it with a starter for a long time. This may be due to the fact that the required pressure has not been accumulated in the system for a long time;

- the car accelerates poorly, the engine is hard to gain momentum, the reaction to pressing the gas pedal is delayed, the car moves jerkily;

- a car with a full tank of gasoline starts, but then it can stall at any moment;

- there were extraneous sounds from the side of the fuel pump - hum, crackling or pops;

- gasoline consumption has sharply increased, etc.

Does not pump the gasoline pump

If, after turning the ignition key of the injector "seven", you did not hear the familiar sound of a fuel pump running, you need to check the electrical power circuit, as well as the mechanical part of this assembly.

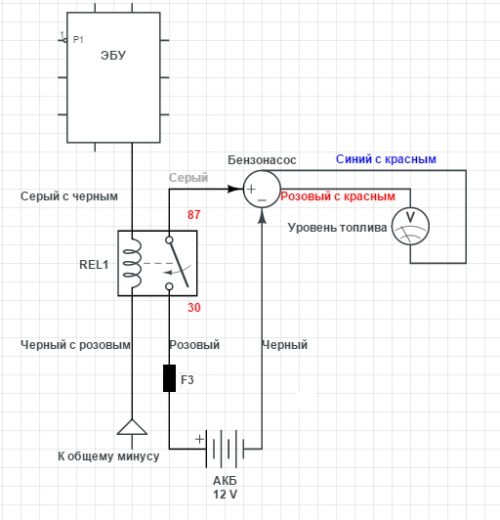

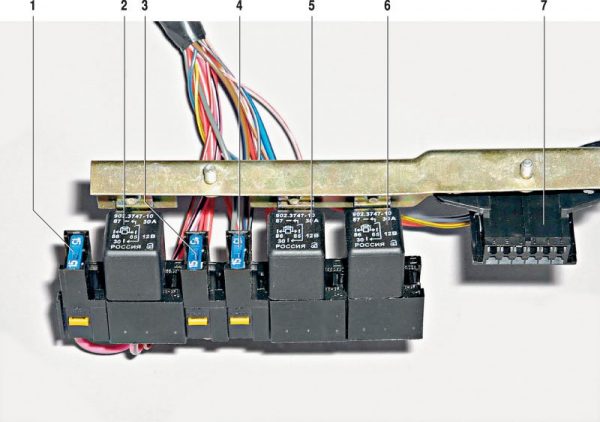

Relay and fuse check

Troubleshooting begins with the relay and fuse box located in the cabin under the glove box. To make it more convenient to work, the block must be removed from the niche by pulling it towards you. The fuel pump fuse is located in the middle of the block (indicated by the number 4 in the figure), the fuel pump relay is just to the right of the fuse (in the figure - 5).

From the wiring diagram it can be seen that the voltage to the fuel pump is supplied through a fuse and relay. Therefore, first of all, you need to check the integrity of the fuse: this can be done, for example, with a multimeter. If the fuse turned out to be blown, and after replacing it, the car worked normally, then you got the easiest emergency possible. If the fuse is intact, then further actions are as follows:

- We turn on the ignition and check for voltage on the pink wire that goes to terminal 30 of the relay. The test can be done with the same multimeter. If the device showed 12 V, proceed to the next step.

- We install a jumper between contacts 30 and 87 of the relay. If after that the fuel pump turned on, then most likely the cause of the malfunction was in the relay. To verify this, we check the voltage on the relay coil (see figure - REL1 coil contacts). If power comes to the coil, and the fuel pump does not turn on without a jumper, the relay must be changed.

If, after turning the ignition key, the fuel pump does not turn on, it is necessary to check the electrical power circuit of this unit

If, after turning the ignition key, the fuel pump does not turn on, it is necessary to check the electrical power circuit of this unit - If power does not come to the relay coil, you need to ring the black-gray wire that goes to the ECU (electronic control unit) and the black-pink wire that connects to the common minus. If there is no voltage on the first of them, the computer may be faulty, and in this case, most likely, one cannot do without service station specialists.

- If there is no power at both coil terminals, check the main circuit and ECU fuses (F1 and F2) located to the left of the fuel pump fuse.

- After checking the relays and fuses, we find in the trunk the terminals of the fuel pump located in the tank, and check the integrity of the terminals - black and white. You can get to the second of them only by removing the fuel pump, and this is one of the inconveniences of servicing the injection power system.

- We make sure that the black ground wire is intact and securely fastened to the body with self-tapping screws. Ground attachment points can be seen at the bottom of the trunk.

If the fuel pump does not turn on, you need to look at the positive voltages not only on the relay, but also on the fuel pump plug. To do this, it is not necessary to turn the ignition on and off: just a jumper is placed on the fuel pump relay between pins 30 and 87, and the circuit to the fuel pump plug is viewed by the control. By the way, signaling devices, in the vast majority of cases, block the fuel pump circuit. It is in the gap of the positive (gray) wire that the contacts of the blocking relay are placed.

Checking the fuel pump motor

If everything is in order with the fuse, relay and wiring, and the fuel pump does not work or works intermittently, you need to check the pump motor. First of all, you should make sure that the terminals of the electric motor are not oxidized or clogged. After that, you need to connect the terminals of the multimeter or a regular 12 V light bulb to the terminals and turn on the ignition. If the light comes on or the multimeter shows the presence of voltage in the circuit, then there is a problem in the motor. A failed fuel pump motor is usually replaced with a new one.

Mechanical check

If the fuel pump receives a voltage of 12 V, the pump motor rotates properly, but the fuel is still supplied unevenly to the injectors and engine interruptions continue, you need to check the mechanical components of the assembly. First of all, you should measure the pressure in the rail. This is done as follows:

- Remove the fuel pump fuse and start the engine. We wait until the engine stalls after the remaining fuel in the system runs out.

- We attach the pressure gauge to the ramp. The connection point of the pressure gauge is usually closed with a plug, which must be removed. There is a special fitting under the plug, which must be unscrewed carefully, because there may be gasoline residues in the ramp.

- We securely fasten the pressure gauge hose to the ramp. The manometer itself is displayed through the edge of the hood on the windshield.

To measure the pressure in the rail, it is necessary to securely attach the pressure gauge hose to the fitting

To measure the pressure in the rail, it is necessary to securely attach the pressure gauge hose to the fitting - We return the fuel pump fuse to its place and start the engine. We fix the readings of the manometer. Normal pressure does not exceed 380 kPa.

- We accelerate the car to a speed of 50 km / h, the pressure should remain at the same level. If the pressure jumps, you need to look for this reason.

Low or intermittent pressure in the system may be due to excessive contamination of the fuel pump screen. For preventive purposes, this mesh, which plays the role of a coarse fuel filter, should be cleaned or changed every 70-100 thousand kilometers. To get to the grid, you will need to dismantle the fuel pump. The dismantling procedure will be discussed below.

Other causes of low system pressure include:

- failure of the regulator, as a result of which the pressure rises and falls uncontrollably;

- contamination of the fuel filter, which must be changed every 30-40 thousand kilometers;

- excessive wear of the injector valves. In this case, the engine "floods" with fuel.

Stops pumping hot

Owners of carburetor VAZ 2107 with mechanical gasoline pumps sometimes encounter the fact that the pump stops pumping hot. Most often, in this case, the car drives confidently along the highway, and in urban traffic jams it stalls for no apparent reason. Many drivers solve this problem by wetting the fuel pump with a damp cloth or pouring water over it. But in this way, only the consequence, and not the cause of the malfunction, is eliminated. The engine stalls due to air pockets in the power system when heated.

To get rid of overheating of the fuel pump forever (or for a long time), you must:

- when replacing the pump, select the correct shims. If the gaskets are chosen correctly, the pusher in the “recessed” position protrudes from the edge of the heat-insulating spacer by 0,8–1,3 mm;

The shim must be chosen so thick that the plunger in the “recessed” position protrudes from the edge of the heat-insulating spacer by 0,8–1,3 mm

The shim must be chosen so thick that the plunger in the “recessed” position protrudes from the edge of the heat-insulating spacer by 0,8–1,3 mm - check the condition of the pusher cam and the rod itself. If these parts are worn or deformed, they must be replaced.

Fuel pump drive

The mechanical fuel pump VAZ 2107 is driven by a pusher and an eccentric. Among drivers, it is customary to call the pusher a rod, although the rod is another part of the fuel pump. The eccentric is located on the intermediate shaft, which is powered by a gas distribution mechanism.

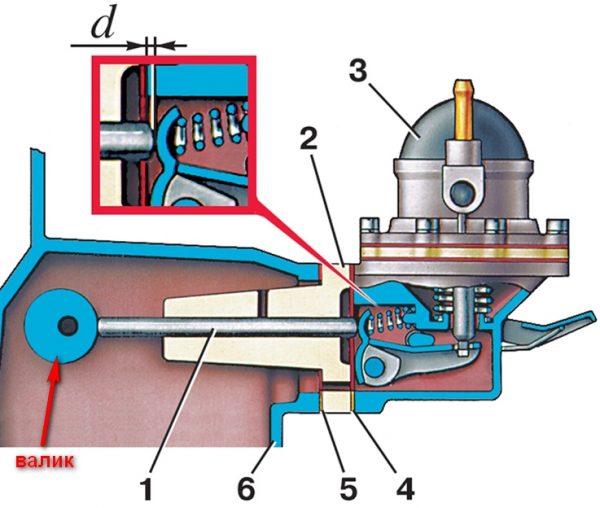

The fuel pump drive includes (see figure):

- 1 - pusher;

- 2 - heat-insulating spacer;

- 4 - adjusting gasket;

- 5 - sealing gasket;

- roller (cam).

Design and function

The operation of the drive of a mechanical fuel pump is not based on the fact that:

- the oil pump shaft is driven through the timing chain;

- the cam (or eccentric) begins to cyclically press on the pusher;

- the pusher transmits force to the lever and the fuel pump begins to pump fuel.

Drive faults

Malfunctions with the drive of a mechanical gasoline pump lead to interruptions in the operation of the fuel supply system. Drive failures are most often associated with deformation or excessive wear of the pushrod or cam.

Bending the fuel pump rod

The fuel pump pusher is often made of insufficiently strong metal. There are frequent cases when, after 2–3 thousand kilometers of run, such a pusher oppresses and flattens the constant impact of the cam. The length of the pusher should be 82,5 mm. If your fuel pump tappet is not this size and flattened on the cam side, it needs to be replaced.

Fuel pump repair

To dismantle the electric fuel pump, you will need:

- Phillips and flat screwdrivers;

- socket wrench for 7.

Removing the electric fuel pump

The dismantling of the electric fuel pump is carried out in the following sequence:

- The negative terminal of the battery is disconnected.

Disconnect the negative battery terminal before removing the fuel pump.

Disconnect the negative battery terminal before removing the fuel pump. - The pressure in the system is released. To do this, remove the cap on the ramp and press the fitting.

After that, you need to relieve the pressure in the rail

After that, you need to relieve the pressure in the rail - The block of wires and hoses of the pump tubes are disconnected. For the convenience of further work, the fuel tank is detached and set aside.

The electric fuel pump wiring harness must be disconnected and the tank taken aside

The electric fuel pump wiring harness must be disconnected and the tank taken aside - With a 7 key, 8 nuts securing the fuel pump to the tank are unscrewed (in the photo, the mounting cover is indicated by a red arrow).

8 nuts securing the non-pump to the tank must be unscrewed with a 7 wrench

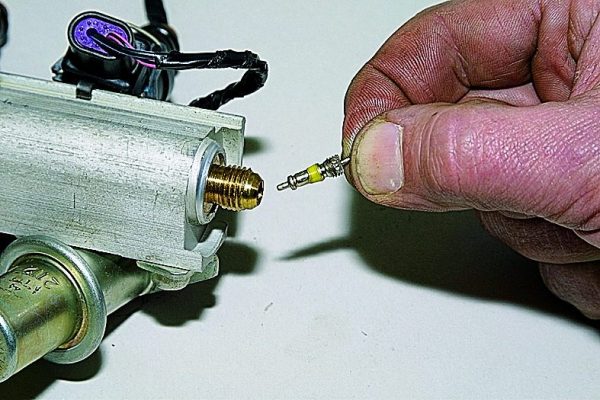

8 nuts securing the non-pump to the tank must be unscrewed with a 7 wrench - The electric fuel pump, together with the fuel level sensor, is carefully removed from the tank.

The electric fuel pump, together with the fuel level sensor, is carefully removed from the tank.

The electric fuel pump, together with the fuel level sensor, is carefully removed from the tank.

If you need to replace or wash the coarse filter, then you need to pry with a screwdriver and remove the old mesh. The new filter is installed with firm pressure.

The fuel pump is installed in reverse order.

Video: how to replace an electric fuel pump at a service station

Removing the mechanical fuel pump

To remove the mechanical fuel pump, it is necessary to prepare a Phillips screwdriver and a key for 13, after which:

- Loosen the inlet and outlet hose clamps and remove the hoses from the fittings.

- Unscrew the two fixing nuts of the pump with a 13 wrench.

Two fastening nuts of the fuel pump must be unscrewed with a key of 13

Two fastening nuts of the fuel pump must be unscrewed with a key of 13 - Remove the fuel pump from its seat.

After that, you need to assess the condition of the pusher and, if necessary, replace it.

Disassembly

To disassemble the mechanical fuel pump you will need:

- keys for 10 and 8;

- Phillips screwdriver.

To disassemble this type of fuel pump, you must:

- Loosen the top fixing screw.

Disassembly of the fuel pump begins with unscrewing the upper mounting bolt

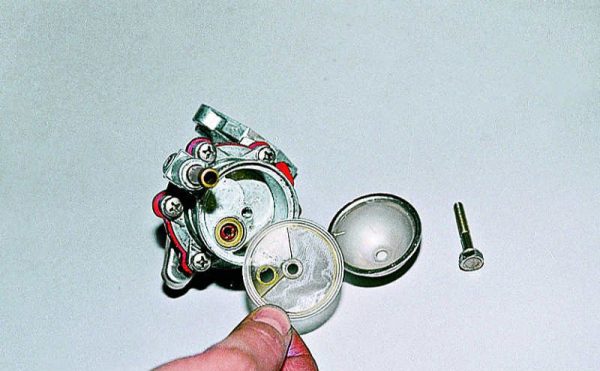

Disassembly of the fuel pump begins with unscrewing the upper mounting bolt - Remove the cover and remove the strainer.

Next, you need to remove the cover and remove the strainer

Next, you need to remove the cover and remove the strainer - Loosen the 6 screws around the perimeter.

After that, it is necessary to unscrew the 6 screws located around the perimeter

After that, it is necessary to unscrew the 6 screws located around the perimeter - Disconnect body parts.

- Rotate the diaphragm 90° and remove it from the body. Remove spring.

The next step is to remove the diaphragm and spring

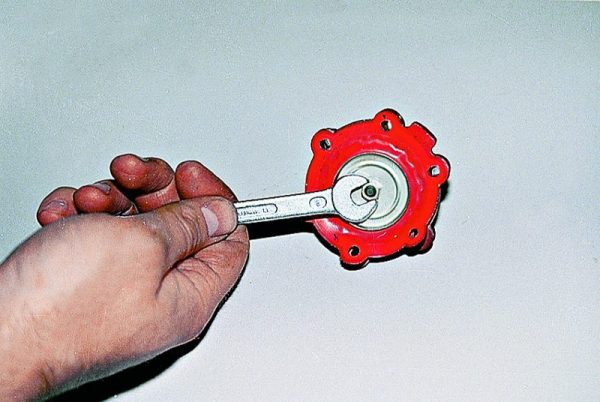

The next step is to remove the diaphragm and spring - Disassemble the diaphragm assembly using an 8 wrench.

The diaphragm assembly is disassembled with a key of 8

The diaphragm assembly is disassembled with a key of 8 - Remove all diaphragm components one by one.

After complete disassembly, it is necessary to assess the condition of the parts of the diaphragm and, if necessary, replace them.

After complete disassembly, it is necessary to assess the condition of the parts of the diaphragm and, if necessary, replace them.

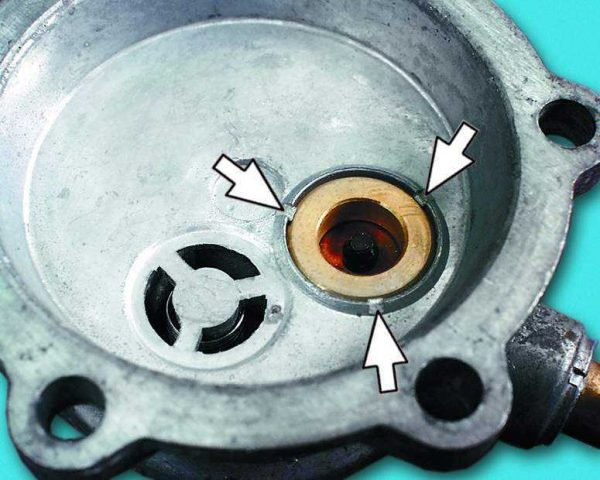

After that, you need to evaluate the condition of the parts of the diaphragm and the mesh filter. If necessary, replace worn, deformed or damaged components.

Valve replacement

New valves are available in the fuel pump repair kit. To replace the valves, you need a needle file and tips for pressing out the old valves. Replacement is performed as follows:

- The needle file grinds the cores.

To replace the valves, it is necessary to grind off the punches with a needle file

To replace the valves, it is necessary to grind off the punches with a needle file - With the help of tips, old valves are removed.

- New valves are mounted and the seat is punched at three points.

New valves can be taken from the VAZ 2107 fuel pump repair kit

New valves can be taken from the VAZ 2107 fuel pump repair kit

Installing a fuel pump

Installing the mechanical fuel pump in place is carried out in the reverse order of removal. The most important point during installation is the correct choice of gaskets. There will be two such pads:

- adjusting thickness 0,75 mm or 1,25 mm;

- sealing - 0,3 mm.

Between them is a heat-insulating spacer. When installing a fuel pump, you must:

- Place the seal.

- Insert pusher.

- Slide a heat-insulating spacer onto the studs.

- Install the adjusting shim.

The adjusting gasket is installed after the heat-insulating element

The adjusting gasket is installed after the heat-insulating element

Press all installed gaskets firmly. Turn the crankshaft with a wrench by the pulley so that the tappet protrudes from the edge of the gasket as little as possible. The protrusion of the pusher in this case should not exceed 0,8–1,3 mm. If the minimum protrusion of the pusher differs from this value, a shim of a different thickness must be selected.

The electric fuel pump of the injector "seven" is responsible for providing the engine with fuel and maintaining the pressure in the power supply system at the required level. An electric fuel pump generally does not overheat, so it is more reliable to operate than a mechanical fuel pump. Proper operation and timely maintenance of the fuel pump can ensure its long trouble-free operation.