Design features, troubleshooting and replacement of the VAZ 2107 camshaft

Content

- Camshaft VAZ 2107

- Is it possible to increase the power of the VAZ 2107 engine by installing another camshaft

- Malfunctions of the camshaft VAZ 2107, their signs and causes

- Removing the camshaft VAZ 2107

- Troubleshooting the timing shaft VAZ 2107

- Installing a new camshaft

- Setting the ignition timing (valve timing) by marks

The efficiency of the entire automobile engine directly depends on the condition of the camshaft. Even the slightest malfunction of this gas distribution mechanism assembly affects the power and traction characteristics of the power unit, not to mention the increase in fuel consumption and related breakdowns. In this article we will talk about the purpose of the camshaft, the principle of its operation, the main malfunctions and how to eliminate them using the example of a VAZ 2107 car.

Camshaft VAZ 2107

The camshaft is the main element of the gas distribution mechanism of an automobile engine. This is an all-metal part, made in the form of a cylinder with bearing journals and cams placed on it.

Purpose

The timing shaft is used to control the processes of opening and closing valves in the combustion chambers of the engine. In other words, it synchronizes the working cycles of the power unit, in time letting the fuel-air mixture into the combustion chambers and releasing exhaust gases from them. The camshaft of the "sevens" is driven by the rotation of its star (gear), connected by a chain to the crankshaft gear.

Where is the

Depending on the design of the engine, the timing shaft may have a different location: upper and lower. At its lower location, it is installed directly in the cylinder block, and at the top - in the block head. At the "sevens" the camshaft is located at the top of the cylinder head. This arrangement, in the first place, makes it easily accessible for repair or replacement, as well as for adjusting valve clearances. In order to get to the timing shaft, it is enough to remove the valve cover.

Operating principle

As already mentioned, the camshaft is driven by the crankshaft gear. At the same time, the speed of its rotation, due to the different size of the drive gears, is reduced exactly by half. A full engine cycle takes place in two revolutions of the crankshaft, but the timing shaft makes only one revolution, during which it manages to let the fuel-air mixture into the cylinders in turn and release the exhaust gases.

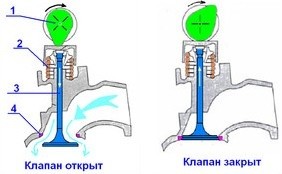

The opening (closing) of the corresponding valves is ensured by the action of the cams on the valve lifters. It looks like this. When the shaft rotates, the protruding side of the cam presses the pusher, which transfers force to the spring-loaded valve. The latter opens a window for the inlet of a combustible mixture (outlet of gases). When the cam turns further, the valve closes under the action of the spring.

Characteristics of the camshaft VAZ 2107

The operation of the timing shaft VAZ 2107 is determined by three main parameters:

- the width of the phases is 232о;

- intake valve lag - 40о;

- exhaust valve advance - 42о.

The number of cams on the camshaft corresponds to the number of intake and exhaust valves. The "seven" has eight of them - two for each of the four cylinders.

Learn more about timing: https://bumper.guru/klassicheskie-modeli-vaz/grm/grm-2107/metki-grm-vaz-2107-inzhektor.html

Is it possible to increase the power of the VAZ 2107 engine by installing another camshaft

Probably, every owner of the "seven" wants the engine of his car to work not only without interruption, but also with maximum efficiency. Therefore, some craftsmen are trying to tune power units in various ways. One of these methods is to install another, more "advanced" camshaft.

The essence of tuning

Theoretically, it is possible to increase the power indicators of the power unit by increasing the width of the phases and the lift height of the intake valve. The first indicator determines the period of time during which the intake valve will be open, and is expressed in the angle of rotation of the timing shaft. For the "seven" it is 232о. The height of the intake valve lift determines the area of the hole through which the fuel-air mixture will be supplied to the combustion chamber. For the VAZ 2107, it is 9,5 mm. Thus, again, in theory, with an increase in these indicators, we get a larger volume of combustible mixture in the cylinders, which can really positively affect the power of the power unit.

It is possible to increase the width of the phases and the height of the intake valve lift by changing the configuration of the corresponding cams of the timing shaft. Since such work cannot be done in a garage, it is better to use a finished part from another car for such tuning.

Camshaft from "Niva"

There is only one car, the camshaft from which is suitable for the "seven". This is VAZ 21213 Niva. Its timing shaft has a phase width of 283о, and the intake valve lift is 10,7 mm. Will the installation of such a part on the VAZ 2107 engine give something in reality? Practice shows that yes, a slight improvement in the operation of the power unit is noted. The increase in power is approximately 2 liters. with., but only at low speeds. Yes, the “seven” responds a little sharper to pressing the accelerator pedal at the start, but after gaining momentum, its power becomes the same.

Sports camshafts

In addition to the timing shaft from Niva, on the VAZ 2107 you can also install one of the shafts made specifically for "sports" tuning of power units. Such parts are produced by a number of domestic enterprises. Their cost ranges from 4000-10000 rubles. Consider the characteristics of such camshafts.

Table: main characteristics of "sports" timing shafts for VAZ 2101-2107

| Name | Phase width, 0 | Valve lift, mm |

| "Estonian" | 256 | 10,5 |

| "Estonian +" | 289 | 11,2 |

| "Estonian-M" | 256 | 11,33 |

| Shrik-1 | 296 | 11,8 |

| Shrik-3 | 304 | 12,1 |

Malfunctions of the camshaft VAZ 2107, their signs and causes

Given that the timing shaft is subject to constant dynamic and thermal loads, it cannot last forever. It is difficult even for a specialist to determine that this particular node has failed without detailed diagnostics and troubleshooting. There can be only two signs of its malfunction: a decrease in power and a soft knock, which manifests itself mainly under load.

The main malfunctions of the camshaft include:

- wear of the working bodies of the cams;

- wear of bearing journal surfaces;

- deformation of the whole part;

- shaft fracture.

More about timing chain repair: https://bumper.guru/klassicheskie-modeli-vaz/grm/grm-2107/kak-natyanut-tsep-na-vaz-2107.html

Wear of cams and necks

Wear is a natural occurrence in a constantly rotating part, but in some cases it can be excessive and premature. This leads to:

- insufficient oil pressure in the system, as a result of which lubrication does not enter the loaded areas or comes in a smaller amount;

- low-quality or non-compliant engine oil;

- marriage in the production of the shaft or its "bed".

In the event of wear on the cams, the engine power is noticeably reduced, since, being worn out, they cannot provide either the appropriate phase width or the required intake valve lift.

Deformation

The deformation of the camshaft appears as a result of severe overheating caused by malfunctions in the lubrication or cooling systems. At the initial stage, this malfunction may manifest itself in the form of a characteristic knock. If such a breakdown is suspected, further operation of the car is not recommended, as it can disable the entire gas distribution mechanism of the engine.

Fracture

A fracture of the camshaft may be the result of its deformation, as well as the uncoordinated work of the timing. In the event of this malfunction, the engine stops. In parallel with this problem, others arise: the destruction of the "bed" of the shaft, the distortion of valves, guides, damage to parts of the piston group.

Removing the camshaft VAZ 2107

To accurately determine the malfunction of the timing shaft, check its condition, repair and replace the part must be removed from the engine. This will require the following tools:

- socket wrench 10 mm;

- socket wrench 13 mm;

- open-end wrench 17 mm;

- torque wrench;

- passatizhi.

Dismantling procedure:

- We install the car on a level surface.

- Dismantle the air filter housing.

- Using pliers, disconnect the choke cable from the carburetor and the longitudinal thrust of the throttle actuator.

- Move the fuel line hose to the side.

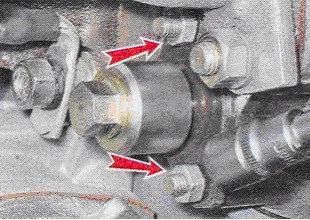

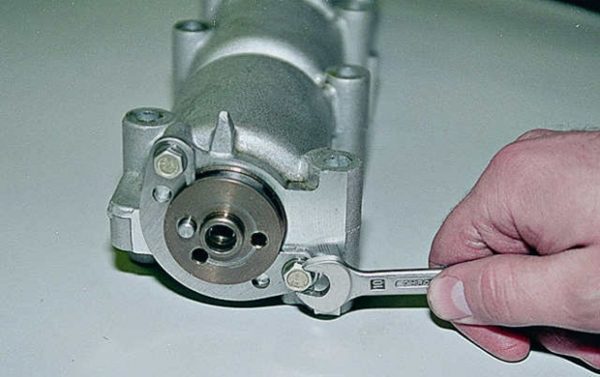

- Using a socket wrench or a 10 mm head with an extension, unscrew the two nuts securing the chain tensioner to the cylinder head and remove it.

The tensioner is attached with two nikes

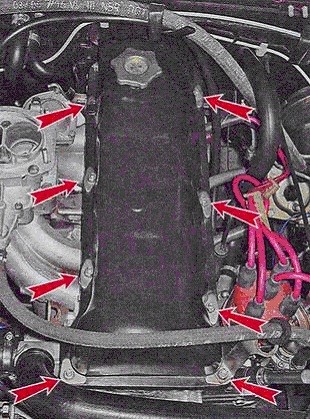

The tensioner is attached with two nikes - Using a 10 mm socket wrench, unscrew the eight nuts securing the cylinder head valve cover.

The cover is mounted on 8 studs and fixed with nuts

The cover is mounted on 8 studs and fixed with nuts - Carefully remove the cover, and after it the rubber gasket.

A seal is installed under the lid

A seal is installed under the lid - Using a slotted screwdriver, straighten the lock washer under the camshaft star mounting bolt.

The star is fixed with a bolt, which is fixed from turning with a folding washer

The star is fixed with a bolt, which is fixed from turning with a folding washer - We switch the gearbox to the position corresponding to the first speed, and using a 17 mm wrench, unscrew the bolt securing the camshaft star.

The bolt is unscrewed with a key of 17

The bolt is unscrewed with a key of 17 - We remove the star along with the bolt, washers and chain.

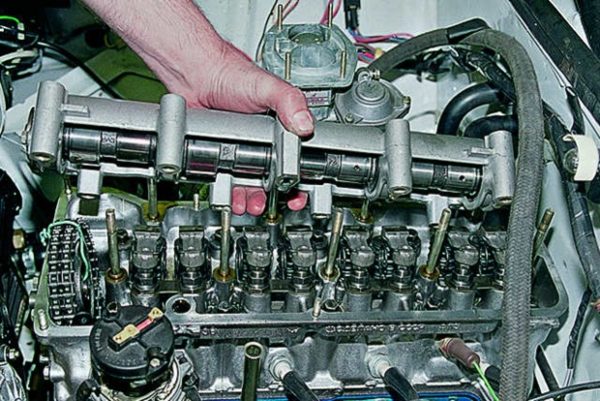

- Using a 13 mm wrench, unscrew all nine nuts on the camshaft bed mounting studs.

To remove the "bed" you need to unscrew 9 nuts

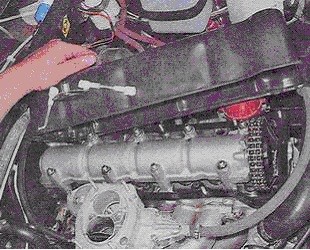

To remove the "bed" you need to unscrew 9 nuts - We dismantle the camshaft assembly with the "bed".

The camshaft is removed assembled with the "bed"

The camshaft is removed assembled with the "bed" - Using a 10 mm wrench, unscrew the two bolts of the fixing flange.

To disconnect the flange, you need to unscrew 2 bolts

To disconnect the flange, you need to unscrew 2 bolts - Disconnect the flange.

- We take out the camshaft from the "bed".

After removing the flange, the camshaft is easily removed from the "bed"

After removing the flange, the camshaft is easily removed from the "bed"

Learn how to unscrew a bolt with worn edges: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/kak-otkrutit-bolt-s-sorvannymi-granyami.html

Troubleshooting the timing shaft VAZ 2107

When the camshaft is taken out of the "bed", it is necessary to assess its condition. This is done visually first. The camshaft must be replaced if its working surfaces (cams and bearing journals) have:

- scratches;

- bullies;

- cut wear (for cams);

- enveloping a layer of aluminum from the "bed" (for support necks).

In addition, the camshaft must be replaced if even the slightest trace of deformation is found.

The degree of wear of the bearing necks and the bearings themselves is determined using a micrometer and a caliper. The table below shows the permissible diameters of the necks and working surfaces of the supports.

Table: permissible diameters of the camshaft bearing journals and supports of its “bed” for VZ 2107

| The serial number of the neck (support), starting from the front | Permissible dimensions, mm | |

| Minimum | Maximum | |

| Support necks | ||

| 1 | 45,91 | 45,93 |

| 2 | 45,61 | 45,63 |

| 3 | 45,31 | 45,33 |

| 4 | 45,01 | 45,03 |

| 5 | 43,41 | 43,43 |

| Supports | ||

| 1 | 46,00 | 46,02 |

| 2 | 45,70 | 45,72 |

| 3 | 45,40 | 45,42 |

| 4 | 45,10 | 45,12 |

| 5 | 43,50 | 43,52 |

If during the inspection it is found that the dimensions of the working surfaces of the parts do not correspond to those given, the camshaft or “bed” must be replaced.

Installing a new camshaft

In order to install a new timing shaft, you will need the same tools as for dismantling it. The order of installation work is as follows:

- Without fail, we lubricate the surfaces of the cams, bearing journals and supports with engine oil.

- We install the camshaft in the "bed".

- With a 10 mm wrench, we tighten the bolts of the thrust flange.

- We check how the shaft rotates. It should easily rotate around its axis.

- We set the position of the shaft in which its pin would coincide with the hole on the fixing flange.

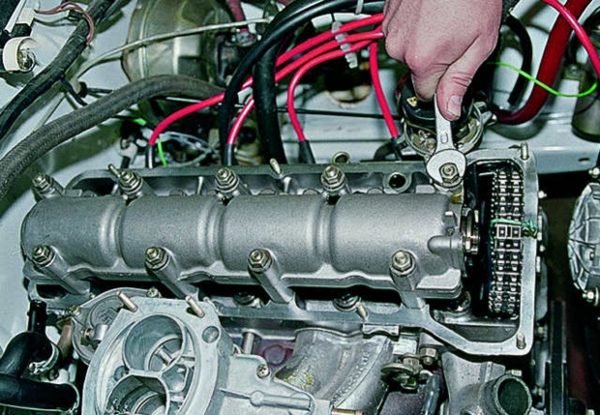

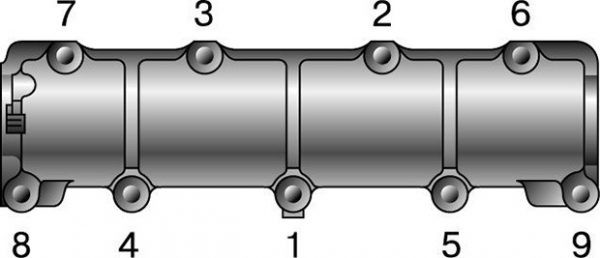

- We install the bed on the studs, wind the nuts, tighten them. It is important to follow the established order. The tightening torque is in the range of 18,3–22,6 Nm.

The nuts are tightened with a torque wrench to a torque of 18,3–22,6 Nm

The nuts are tightened with a torque wrench to a torque of 18,3–22,6 Nm - We do not install the valve cover and the camshaft star in place, since it will still be necessary to set the valve timing.

Setting the ignition timing (valve timing) by marks

After the repair work has been carried out, it is imperative to set the correct ignition timing. To do this, you must perform the following work:

- Install the camshaft sprocket with the chain, fix it with a bolt, do not tighten it.

- Install the chain tensioner.

- Put the chain on the gears of the crankshaft, accessory shaft and camshaft.

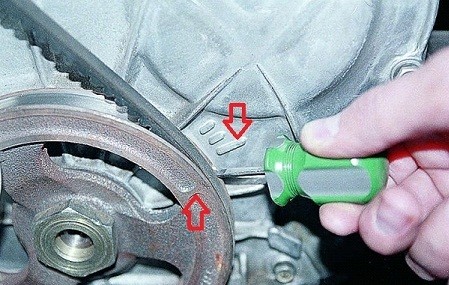

- Using a 36 wrench, put on the crankshaft pulley nut, turn the crankshaft until the mark on the pulley matches the mark on the engine cover.

Labels must match

Labels must match - Determine the position of the camshaft star in relation to the "bed". The mark on the star must also line up with the ledge.

If the marks do not match, you need to move the star relative to the chain

If the marks do not match, you need to move the star relative to the chain - If the marks do not match, unscrew the camshaft star bolt, remove it together with the chain.

- Remove the chain and rotate the star left or right (depending on where the mark is shifted) by one tooth. Put the chain on the star and install it on the camshaft, fixing it with a bolt.

- Check the position of the marks.

- If necessary, repeat the displacement of the star by one tooth, until the marks match.

- Upon completion of work, fix the star with a bolt, and the bolt with a washer.

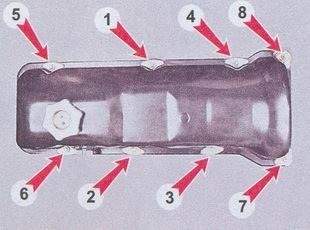

- Install valve cover. Fix it with nuts. Tighten the nuts in the order shown in the photo. Tightening torque - 5,1–8,2 Nm.

Nuts must be tightened with a torque wrench to a torque of 5,1–8,2 Nm

Nuts must be tightened with a torque wrench to a torque of 5,1–8,2 Nm - Perform further assembly of the engine.

Video installation of the camshaft VAZ 2107

After checking the operation of the engine, it is recommended to adjust the valves in two stages: the first immediately, the second - after 2-3 thousand kilometers.

As you can see, there is nothing particularly difficult in diagnosing and replacing the VAZ 2107 camshaft. The main thing is to find the right tool and allocate two to three hours of free time for engine repair.