Where does carbon deposits come from in an engine?

Modern engines, especially gasoline engines, have an undesirable tendency to accumulate a large amount of carbon deposits - especially in the intake system. Consequently, after tens of thousands of kilometers, problems begin to arise. Are the engine manufacturers to blame or, as some mechanics say, the users? It turns out that the problem is exactly in the middle.

Engine buzz is especially common when it comes to modern direct injection turbocharged gasoline engines. The problem concerns both small units and larger ones. Weaker and stronger. It turns out that it is not the design itself that is to blame, but the opportunities that it gives.

Looking for low fuel consumption

If you break down fuel consumption into main factors and simplify the topic as much as possible, then from a technical point of view, two things affect them: engine size and speed. The higher both parameters, the higher the fuel consumption. There is no other way. Fuel consumption is, so to speak, the product of these factors. Therefore, there is sometimes a paradox that a larger car with a more powerful engine will burn less fuel on the highway than a smaller car with a smaller engine. Why? Because the former can run at a higher speed at a lower engine speed. So much lower that this coefficient contributes to a better combustion result than in the case of a small engine running at higher speeds. Pain relief:

- capacity 2 l, rotation speed 2500 rpm. – burning: 2 x 2500 = 5000

- capacity 3 l, rotation speed 1500 rpm. – burning: 3 x 1500 = 4500

Simple, right?

Turnover can be reduced in two ways - the gear ratio in the transmission and the corresponding engine setting. If the engine has high torque at low rpm, then a high gear ratio can be used because it will have the power to propel the vehicle. This is why 6-speed gearboxes only became so common after the introduction of turbocharging in petrol cars and, among other things, variable geometry compressors in diesel engines.

There is only one way to reduce engine powerif we want to get high torque at low revs, we use boost. In practice, we replace the container with forced compressed air, instead of naturally supplied with a similar portion (large engine).

The effect of a strong "bottom"

However, let's get to the point of this article. Well, the engineers, perfectly understanding the above, came to the conclusion that achieve low fuel consumption by improving torque values at the bottom of the revs and so prepare the engines that the maximum is reached even before exceeding 2000 rpm. This is what they have achieved in both diesel and gasoline engines. It also means that today - regardless of the type of fuel - most cars can be driven normally without exceeding 2500 rpm. and at the same time getting a satisfactory dynamics. They have such a strong “down”, that is, such a large torque at low revs, that sixth gear can be engaged already at 60-70 km / h, which was previously unthinkable.

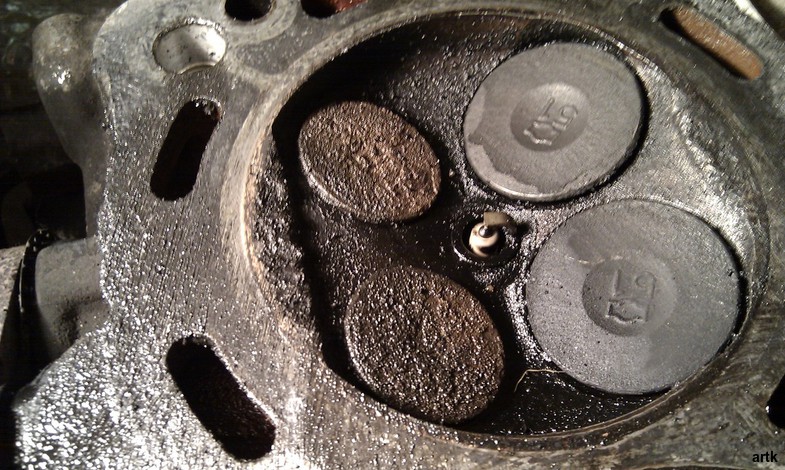

Many drivers shift according to this trend, so they shift gears earlier, clearly seeing the effect in front of the dispenser. Automatic transmissions are programmed to upshift as quickly as possible. Effect? Incorrect combustion of the mixture in the cylinder as a result of nipple combustion, low combustion temperature and as a result of direct injection, the valves are not washed with fuel and soot accumulates on them. Along with this, abnormal combustion progresses, since the air does not have a "clean" flow through the intake tract, combustion anomalies increase, which also leads to the accumulation of soot.

Other factors

Add to this ubiquitous use of cars and their availabilityso often, instead of walking 1-2 km on foot, by bike or by public transport, we get into the car. Engine overheats and stalls. Without the right temperature, carbon deposits must build up. Low speed and the lack of the desired temperature do not allow the engine to get rid of carbon deposits in a natural way. As a result, after 50 thousand km, sometimes up to 100 thousand km, the engine stops producing full power and has problems with smooth operation. The entire intake system must be cleaned, sometimes even with valves.

But that's not all. Inter-oil services with a long service life they are also responsible for the accumulation of carbon deposits. Oil ages, it does not flush the engine well, instead oil particles settle inside the engine. Maintenance every 25-30 thousand km is definitely too much for an engine with a compact design, the lubrication system of which can hold only 3-4 liters of oil. Often, old oil causes incorrect operation of the timing belt tensionerwhich can only run on engine oil. This leads to chain stretching and, as a result, to a partial shift in the gas distribution phases, and hence to improper combustion of the mixture. And we are coming to the starting point. This crazy wheel is hard to stop - these are the engines, and we use them. The payoff for this is soot.

In this way, Carbon deposits in the engine result from:

- “cold” mode - short distances, low speed

- direct fuel injection - no fuel flushing of intake valves

- improper combustion - high load at low speeds, fuel contamination of the valves, stretching of the timing chain

- too long oil change intervals - oil aging and dirt accumulation in the engine

- substandard fuel