P0016 error of mismatch between the signals of the sensors KV and RV - cause and elimination

Content

Error p0016 signals to the driver that there is a discrepancy in the position of the shafts. Such a code pops up when the data from the crankshaft and camshaft sensors (DPKV and DPRV) do not match, that is, the angular position of the camshaft and crankshaft relative to each other has deviated from the norm.

Error code P0016: why does it appear?

Valve timing - the moments of opening and closing of the intake and exhaust valves, which are usually expressed in degrees of rotation of the crankshaft and are noted in relation to the initial or final moments of the corresponding strokes.

The shaft ratio is used by the control controller to determine whether the cylinders are ready before fuel injection from the corresponding injectors. Data from the camshaft sensor is also used by the ECM to determine gaps. And if the ECU does not receive such information, it generates a diagnostic code for a breakdown, and produces fuel using the variable-synchronous dual ignition method.

Such an error is mainly inherent in cars with a timing chain drive, but on cars with a timing belt, it can also sometimes pop up. At the same time, the behavior of the car may not change significantly; on some machines, if an error p 016 occurs, the car loses traction and the internal combustion engine is afraid. Moreover, such an error may appear in different operating modes (when warming up, at idle, under load), it all depends on the reasons for its occurrence.

Conditions for signaling a breakdown

The failure code is signaled when the DPRV control pulse cannot be determined at the required intervals on each of the 4 cylinders. At the same time, the control lamp on the instrument panel signaling a breakdown (“check”) starts to burn after 3 ignition cycles with failures, and goes out if such a breakdown is not detected during 4 consecutive cycles. Therefore, if there is a periodic ignition of the control indication, this may be due to unreliable contact, damaged insulation and / or broken wiring.

Causes of the error

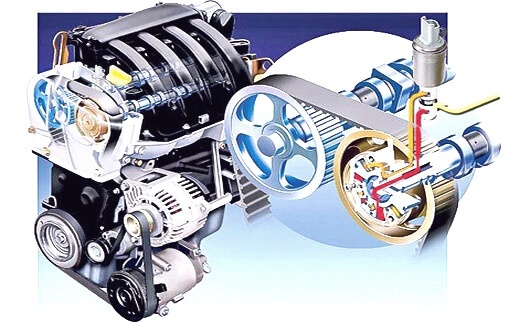

In this context, it should be remembered that the CKP (crankshaft position) crankshaft sensor is a kind of permanent magnet generator, also called variable resistance sensor. The magnetic field of this sensor is influenced by a relay wheel mounted on the motor shaft, which has 7 slots (or slots), 6 of which are equidistant from each other by 60 degrees, and the seventh has a distance of only 10 degrees. This sensor produces seven pulses per revolution of the crankshaft, the last of which, related to the 10-degree slot, is called a sync pulse. This pulse is used to synchronize the ignition sequence of the coil with the position of the crankshaft. The CKP sensor, in turn, is connected to the central engine sensor (PCM) via a signal circuit.

The camshaft position (CMP) sensor is activated by a sprocket inserted into the exhaust camshaft sprocket. This sensor generates 6 signal pulses with each revolution of the camshaft. The CMP and CKP signals are pulse-width coded, allowing the PCM to constantly monitor their relationship, which in turn allows the exact position of the camshaft actuator to be determined and its timing checked. The CMP sensor is then connected to the PCM via a 12 volt circuit.

In order to determine why error P0016 popped up, you need to rely on five basic reasons:

- Bad contact.

- Oil contamination or clogged oil passages.

- Sensors CKPS, CMPS (position sensors to / in r / in).

- OCV valve (oil control valve).

- CVVT (Variable Valve Timing Clutch).

VVT-i system

In 90% of cases, the shaft mismatch error appears when there are problems with the VVT-i system, namely:

- Clutch failure.

- Deterioration of the vvt-i control valve.

- Coking of oil channels.

- Clogged valve filter.

- Problems that have arisen with the timing drive, such as a stretched chain, a worn out tensioner and damper.

Elimination methods

Quite often, a short circuit, an open in the phase sensor circuit, or its failure (wear, coking, mechanical damage) can occur. In some cases, the problem of the relationship of the position of the shafts may occur due to a breakdown of the idle speed controller or the hall rotor.

In advanced cases, this procedure is not limited, since the stretched chain eats the gear teeth!

When car owners neglect the timely replacement of oil in the internal combustion engine, then, in addition to all other problems, it can also occur with the operation of the VVT clutch, due to the contamination of the oil channels of the geometry of the shaft control clutch, it contributes to incorrect operation, and as a result, a synchronization error pops up. And if there is a wear on the inner plate, then the CVVT clutch starts to wedge.

Steps to find the occurrence of the guilty part should begin with checking the wiring of the PKV and PRV sensors, and then sequentially, taking into account the above factors affecting the synchronization of the shafts.

If the error popped up after any preliminary procedures with the shafts, then the human factor usually plays a role here (something somewhere was set wrong, missed or not twisted).

Repair Tips

To properly diagnose a P0016 trouble code, a mechanic will usually do the following:

- Visual inspection of engine connections, wiring, OCV sensors, camshafts and crankshafts.

- Check engine oil for sufficient quantity, absence of impurities and correct viscosity.

- Turn the OCV on and off to check if the camshaft sensor is registering timing changes for the bank 1 camshaft.

- Perform manufacturer tests for code P0016 to find the cause of the code.

Some of the repairs that are most commonly performed to put an end to this DTC include the following:

- Reset trouble codes followed by a test drive.

- Replacing the camshaft sensor on bank 1.

- Repair wiring and connection to the OCV camshaft.

- Replacement of the distributed OCV.

- Replacing the timing chain.

Before any replacement or repair in any case, it is recommended to perform all of the above benchmark tests to prevent the code from reappearing even after replacing a component that works instead.

DTC P0016, although indicated by fairly general symptoms, should by no means be underestimated. While the vehicle may be roadworthy, prolonged use of the vehicle with this DTC can cause further engine damage, making the situation worse. It can also happen that problems occur in the tensioners, and in some cases it can also happen that the valves hitting the pistons can cause other damage.

Due to the complexity of diagnostic and repair operations, it is advisable to entrust the car to a good mechanic.

It is difficult to estimate the upcoming costs, since a lot depends on the results of the diagnostics carried out by the mechanic. Typically, the cost of replacing sensors in a workshop is around 200 euros.

Frequently Asked Questions (FAQ)

What does code P0016 mean?

DTC P0016 signals that the vehicle's system has registered a deviation in the timing of the vehicle's camshaft and crankshaft. The synchronization of these two components is used to regulate the injection and exhaust systems of the vehicle.

What causes the P0016 code?

The causes of DTC P0016 can be triggered in a variety of ways and could be related to the position sensors, the timing chain or belt, or other engine parts.

How to fix code P0016?

Using suitable equipment, check the condition of the wiring and the camshaft position sensor on bank 1.

Can code P0016 go away on its own?

Yes, this error code may disappear on its own.

Can I drive with code P0016?

While the vehicle may be roadworthy, prolonged use of the vehicle with this DTC can cause further engine damage, making the situation worse. It can also happen that problems occur in the tensioners, and in some cases it can also happen that the valves hitting the pistons can cause other damage.

How much does it cost to fix code P0016?

On average, the cost of replacing sensors in a workshop is about 200 euros, and replacing damaged wiring should not cost more than a few tens of euros.