P029A Adjusting the fuel level of cylinder 1 at the maximum limit

Content

- P029A Adjusting the fuel level of cylinder 1 at the maximum limit

- OBD-II DTC Datasheet

- What does this mean?

- What is the severity of this DTC?

- What are some of the symptoms of the code?

- What are some of the common causes for the code?

- What are some steps to troubleshoot the P029A?

- Related DTC discussions

- Need more help with the P029A code?

P029A Adjusting the fuel level of cylinder 1 at the maximum limit

OBD-II DTC Datasheet

Adjusting the fuel level of cylinder 1 at the maximum limit

What does this mean?

This is a generic powertrain diagnostic trouble code (DTC) and is commonly applied to all gasoline OBD-II vehicles. This may include, but is not limited to, vehicles from Land Rover, Mazda, Jaguar, Ford, Mini, Nissan, GM, etc. Despite the general nature, the exact repair steps may vary depending on the year of manufacture, make, model and transmission configuration.

A stored code P029A means the powertrain control module (PCM) has detected an extremely lean mixture in a specific cylinder in the engine, in this case cylinder # 1.

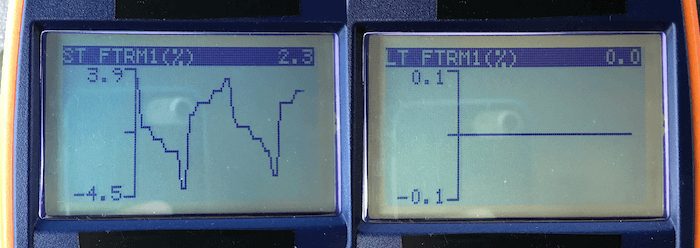

The PCM uses a fuel trim system to increase or decrease fuel delivery as needed. The oxygen sensor inputs provide the PCM with the data it needs to adjust the fuel trim. The PCM uses fuel injector pulse width modulation variations to change the air / fuel ratio.

The PCM continuously calculates short term fuel trim. It fluctuates quickly and is one of the key factors in calculating the long term fuel consumption correction. Each vehicle has minimum and maximum fuel trim percentages programmed into the PCM. The parameters for short term fuel trim are much broader than the parameter specifications for long term fuel trim.

Small deviations in fuel trim, usually measured in positive or negative percentages, are normal and will not store the P029A code. The maximum fuel trim settings (positive or negative) are typically in the twenty-five percent range. Once this maximum threshold is exceeded, this type of code will be saved.

When the engine is operating at optimum efficiency and there is no need to increase or decrease the amount of fuel supplied to each cylinder, the fuel consumption adjustment should reflect between zero and ten percent. When the PCM detects a lean exhaust condition, the fuel needs to be increased and the fuel consumption correction will reflect a positive percentage. If the exhaust is too rich, the engine needs less fuel and the fuel consumption adjustment should reflect a negative percentage.

See Also: Everything You Want To Know About Fuel Trims.

OBD-II vehicles will need to establish a pattern for a long term fuel trim strategy, which will require multiple ignition cycles.

Fuel Trim Graphs Shown by OBD-II:

What is the severity of this DTC?

The P029A code should be classified as serious because a lean fuel mixture can cause catastrophic engine damage.

What are some of the symptoms of the code?

Symptoms of a P029A trouble code may include:

- Reduced engine performance

- Delayed engine start

- Presence of stored lean exhaust codes

- Misfire codes can also be saved

What are some of the common causes for the code?

Reasons for this P029A fuel trim code may include:

- Defective / leaking fuel injector

- Bad fuel pump

- Leakage of vacuum in the engine (including failure of the EGR valve)

- Defective oxygen sensor

- Malfunction of the mass air flow (MAF) or manifold air pressure (MAP) sensor

What are some steps to troubleshoot the P029A?

If there are codes related to MAF or MAP, diagnose and repair them before trying to diagnose this P029A code.

I would start my diagnosis with a general inspection of the engine intake manifold area. I would like to focus on vacuum leaks. At first I listened for the sound (hiss) of the vacuum leak. I would check all hoses and plastic lines for cracks or breakage. PCV lines are a common source of vacuum leaks. Also check the edges of the inlet for signs of damage to the gasket. Second, I would check the appropriate fuel injector (cylinder # 1) for fuel leaks. If the injector is wet with fuel, suspect that it has failed.

If there are no obvious mechanical problems in the engine compartment, several tools will be required to proceed with the diagnosis:

- Diagnostic Scanner

- Digital Volt / Ohmmeter (DVOM)

- Fuel pressure gauge with adapters

- Reliable source of vehicle information

Then I would connect the scanner to the car diagnostic port. I retrieved all the stored codes and freeze frame data and then wrote it all down for future reference. Now I would clear the codes and test drive the car to see if any are reset.

Access the scanner data stream and observe the operation of the oxygen sensor to see if there is indeed a lean exhaust mixture. I like to narrow the data stream to include only the relevant data. This provides faster data response times and more accurate readings.

If an actual lean exhaust mixture is present:

Step 1

Use a pressure gauge to check the fuel pressure and compare it with the manufacturer's data. If fuel pressure is within specification, go to step 2. If fuel pressure is below minimum specifications, use the DVOM to test the fuel pump relay and fuel pump voltage. If there is an acceptable voltage to the fuel pump (usually battery voltage), remove the fuel filter and see if it is clogged with debris. If the filter is clogged, it must be replaced. If the filter is not clogged, suspect a fuel pump malfunction.

Step 2

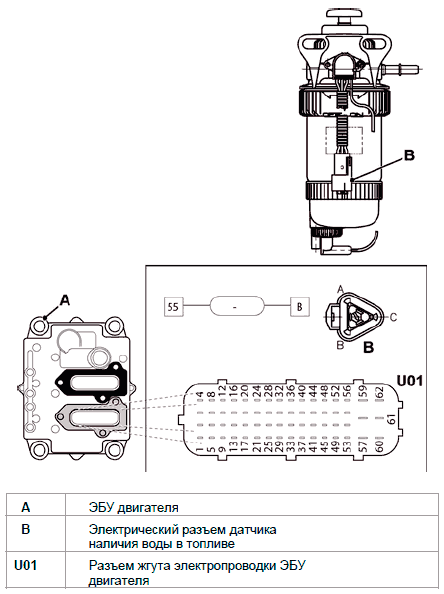

Access the injector connector (for the injector in question) and use the DVOM (or noid lamp if present) to check the injector voltage and ground pulse (the last of the PCM). If no voltage is detected at the injector connector, go to step 3. If voltage and ground impulse are present, reconnect the injector, use a stethoscope (or other listening device) and listen with the engine running. The audible clicking sound should be repeated at regular intervals. If there is no sound or it is intermittent, suspect that the injector of the corresponding cylinder is out of order or clogged. Any condition is likely to require an injector replacement.

Step 3

Most modern fuel injection systems provide a constant supply of battery voltage to each fuel injector, with the PCM delivering a ground pulse at the appropriate time to close the circuit and cause fuel to spray into the cylinder. Use the DVOM to test system fuses and relays for battery voltage. Replace fuses and / or relays if necessary. On-load fuse test system.

I was fooled by a faulty fuse that appeared to be OK when the chain was not loaded (key on / engine off) and then failed when the circuit was loaded (key on / engine running). If all fuses and relays in the system are OK and no voltage is present, use your vehicle information source to trace the circuit. Most likely, it will lead you to the ignition or fuel injection module (if any). Repair the chain if necessary.

Note. Use caution when checking / replacing high pressure fuel system components.

Related DTC discussions

- There are currently no related topics in our forums. Post a new topic on the forum now.

Need more help with the P029A code?

If you still need help regarding DTC P029A, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.