P068A ECM/PCM power relay operation de-energized - too early

Content

Trouble code P068A is defined as ECM/PCM power relay de-energized too early. This code is a generic fault code, meaning it applies to all vehicles equipped with an OBD-II system, especially vehicles manufactured from 1996 to present. Some of the more common brands that have this code include Audi, Cadillac, Chevrolet, Dodge, Ford, Jeep, Volkswagen, etc. Specifications for identifying, troubleshooting, and repairing, of course, vary from one make and model to another. .

OBD-II DTC Datasheet

ECM/PCM power relay de-energized - too early

What does this mean?

This is a generic Diagnostic Trouble Code (DTC) applicable to many OBD-II vehicles (1996 and newer). It can occur in vehicles from Audi, Chrysler, Dodge, Jeep, Ram, Volkswagen, etc., among others. Although common, the exact repair steps may vary depending on year, make, model, and transmission configuration.

If a P068A code is stored, the engine / powertrain control module (ECM / PCM) has detected a malfunction in the procedure for disconnecting power to the relay that energizes it. In this case, the relay was de-energized too early.

The PCM power relay is used to safely supply battery voltage to the appropriate PCM circuits. This is a contact type relay that is activated by a signal wire from the ignition switch. This relay must be de-energized gradually to avoid power surges and possible damage to the controller. This type of relay usually has a five-wire circuit. One wire is supplied with constant battery voltage; land on the other. The third circuit supplies the signal from the ignition switch, and the fourth circuit supplies voltage to the PCM. The fifth wire is the power relay sensor circuit. It is used by the PCM to monitor the supply relay voltage.

If the PCM detects a malfunction when the ECM / PCM relay is powered off, a P068A code will be stored and a malfunction indicator lamp (MIL) may illuminate.

Typical PCM Powertrain Control Module disclosed:

What is the severity of this DTC?

The P068A code must be classified as serious and dealt with accordingly. This can lead to inability to start and / or to various problems with the vehicle's handling.

What are some of the symptoms of the code?

Symptoms of a P068A trouble code may include:

- Delayed start or car won't start

- Engine control problems

Common symptoms may include one or more of the following, but note that the severity of one or more of the symptoms listed here may vary:

- A fault code is stored and an illuminated warning light may or may not flash

- In some cases, there may be several additional codes along with P068A, depending on whether the incorrect power-down procedure has damaged circuits and / or components in one or more control modules.

- Difficult starting or no starting is common, although this can sometimes be resolved by replacing the relay and reprogramming the PCM.

- The vehicle may exhibit a wide range of handling problems including, but not limited to, rough idle, misfiring, lack of power, increased fuel consumption, unpredictable shift patterns, and frequent engine shutdowns.

What are some of the common causes for the code?

Reasons for this code may include:

- Automatic transmission control module.

- Car battery. Damaged car batteries can cause a lot of problems.

- Automatic transmission shift solenoid - is the engine control module OK, but is the OBD code P068A still flashing? Then there is definitely some kind of malfunction in the automatic transmission shift solenoid. Check it and replace if necessary.

- Electronic control unit - The electronic control unit is an important part of the car that should never be neglected. It is possible that there is some kind of malfunction in it, due to which the P068A code may start flashing.

- Engine control module — OBD code P068A may appear due to a faulty engine control module.

- Module power unit control is the powertrain control module OK, but is code P068A still set? You should check the powertrain control module.

- Battery cable replacement terminal — code P068A may be displayed due to some problems in the battery cable replacement terminal. Therefore, it is very important to replace the battery cable replacement terminal

- Faulty, faulty ignition switch.

- Faulty or defective PCM power relay

Diagnosing Causes of Error Code P068A

As with many codes, a good starting point for diagnosing this code is to check with the TSB (Technical Service Bulletins) for the specific vehicle. The issue may be a known issue with a known solution provided by the manufacturer.

Retrieve all stored codes and freeze frame data by connecting the scanner to the vehicle's diagnostic port. Pay attention to this information in case the problem appears to be intermittent.

Then clear the codes and then test drive the vehicle (if possible) until the code clears or the PCM enters ready mode. If the PCM does the latter, then the problem is intermittent, meaning you need to wait until it gets worse before you can run a full diagnosis. On the other hand, if the code CANNOT be reset and there is no drivability, continue to operate the vehicle as normal.

Contact TSB for stored code, vehicle (make, year, model and engine) and symptoms. This may help you in making a diagnosis.

If the code CLEARS immediately, proceed with a thorough inspection of the wiring and connector system. Broken harnesses must be repaired if not replaced.

If the wiring and connectors look good and function, use the vehicle information to obtain a wiring diagram, connector pinouts, connector views, and diagnostic flowcharts. With this information, verify that the PCM power relay is receiving battery voltage by checking all fuses and relays.

If DC (or switched) voltage is not present at the power relay connector, trace the right circuit to the fuse or relay it is coming from. Repair or replace defective fuses or fuse links as necessary.

If the power relay input supply voltage and ground are present (on all right terminals), use a DVOM (digital volt/ohmmeter) to check the relay output characteristics on the right connector pins. If the voltage of the output circuit of the power relay is not enough, then a faulty relay can be suspected.

If the PCM power supply relay output voltage is within specifications (at all terminals), test the appropriate relay output circuits at the PCM.

If a relay output voltage signal is detected at the PCM connector, you may suspect a malfunction or programming error in the PCM.

If there is no relay output voltage signal at the PCM connector, the problem is most likely caused by an open circuit.

To avoid misdiagnosis, fuses and fuse links must be checked with the circuit loaded.

Fuses and fuse links should be tested with the circuit loaded to avoid misdiagnosis.

What are the troubleshooting steps for P068A?

A diagnostic scanner and a digital volt / ohmmeter (DVOM) are required to diagnose the P068A code.

You will also need a source of reliable information about the vehicles. It provides diagnostic block diagrams, wiring diagrams, connector faces, connector pinouts, and component locations. You will also find procedures and specifications for testing components and circuits. All of this information will be needed to successfully diagnose the P068A code.

Connect the scanner to the vehicle diagnostic port and get all stored codes and freeze frame data. Make a note of this information as it may be helpful if the code turns out to be intermittent.

After recording all relevant information, clear the codes and test drive the vehicle (if possible) until the code is cleared or the PCM enters ready mode.

If the PCM goes into ready mode, the code will be intermittent and even more difficult to diagnose. The condition that led to the persistence of P068A may need to worsen before an accurate diagnosis can be made. On the other hand, if the code cannot be cleared and the symptoms of handling do not appear, the vehicle can be driven normally.

Consult your vehicle information source for technical service bulletins (TSBs) that reproduce the stored code, vehicle (year, make, model and engine) and symptoms detected. If you find an appropriate TSB, it can provide useful diagnostic information.

If the P068A code resets immediately, visually inspect the wiring and connectors associated with the system. Belts that have been broken or unplugged should be repaired or replaced as needed.

If the wiring and connectors are OK, use your vehicle information source to obtain related wiring diagrams, connector face views, connector pinout diagrams, and diagnostic block diagrams.

Once you have the information you need, check all fuses and relays in the system to ensure that battery voltage is being supplied to the PCM power supply relay.

Obtain the PCM relay power off parameters and apply them to the next diagnostic steps.

If there is no DC (or switched) voltage at the power relay connector, trace the appropriate circuit to the fuse or relay from which it comes. Repair or replace defective fuses or fuses as necessary.

If the relay power supply input voltage and ground are present (at all appropriate terminals), use the DVOM to test the performance of the relay output at the appropriate connector pins. If the voltage of the output circuit of the power supply relay does not meet the requirements, suspect that the relay is faulty.

If the PCM power supply relay output voltage is within specification (at all terminals), check the appropriate relay output circuits on the PCM.

If a relay output voltage signal is detected at the PCM connector, suspect a faulty PCM or a PCM programming error.

If no matching PCM power relay voltage output signal is found on the PCM connector, suspect an open or short circuit between the PCM power relay and the PCM.

- Fuses and fuses should be checked with a loaded circuit to avoid misdiagnosis.

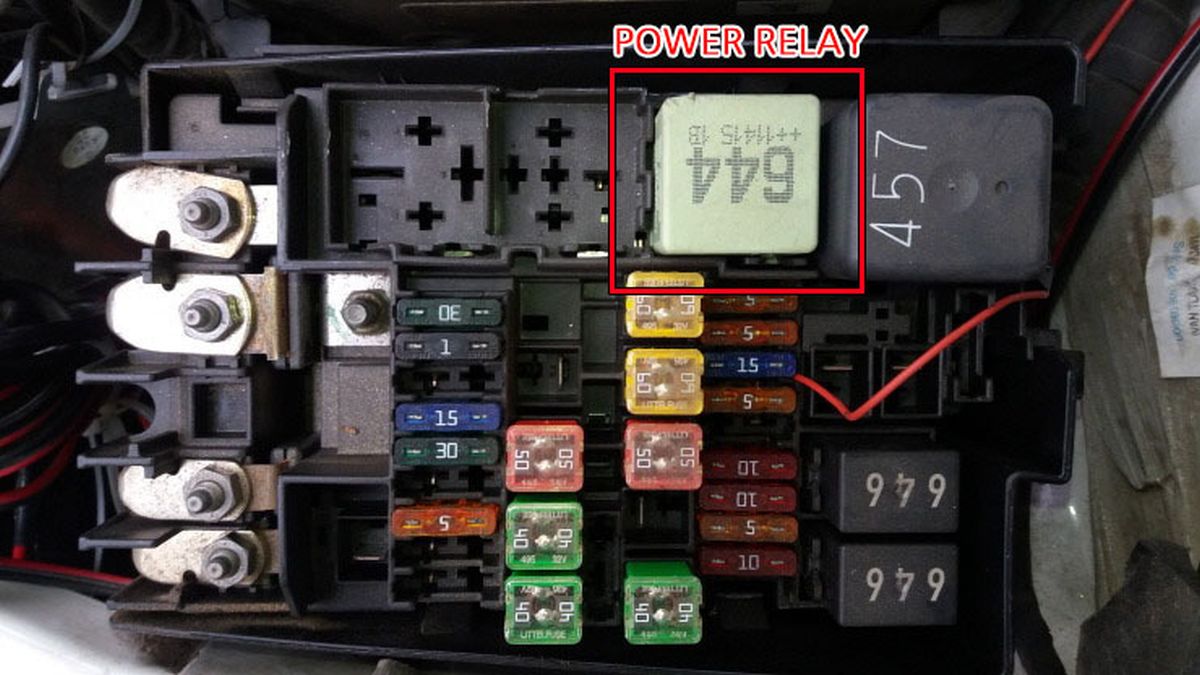

Where is the P068A sensor located?

This image shows a typical example of a PCM power relay. Note, however, that while this relay is usually found in the main fuse box, its actual location in the fuse boxes varies by make and even model of vehicle. Also note that in many cases this relay is superficially identical to other, unrelated relays, so be sure to check with reliable service information for the affected vehicle to correctly locate and identify the PCM power relay.

Please also note that industry standards and best practices require this relay to be replaced with an OEM part. While a high quality replacement part will likely perform satisfactorily in the short term, the demands placed on this particular relay are such that only an OEM replacement part will provide reliable and predictable performance in the long term.

.

3 comment

July

Excellent explanation and dedication to those of us who are rejecting private vehicles. Greetings

junioracessorios

I have a 2018 year ducato. With this failure, I have already tested the module power supply and the injector nozzles but it does not work at all.

Slyder1985

My Ford Transit 3.2 Tdci died while driving and hasn't started since. Would be grateful for any tip. attila.helyes@gmail.com