Head planning - what is engine head regeneration? What is head polishing for? Is it necessary to replace seals?

Content

What is head planning?

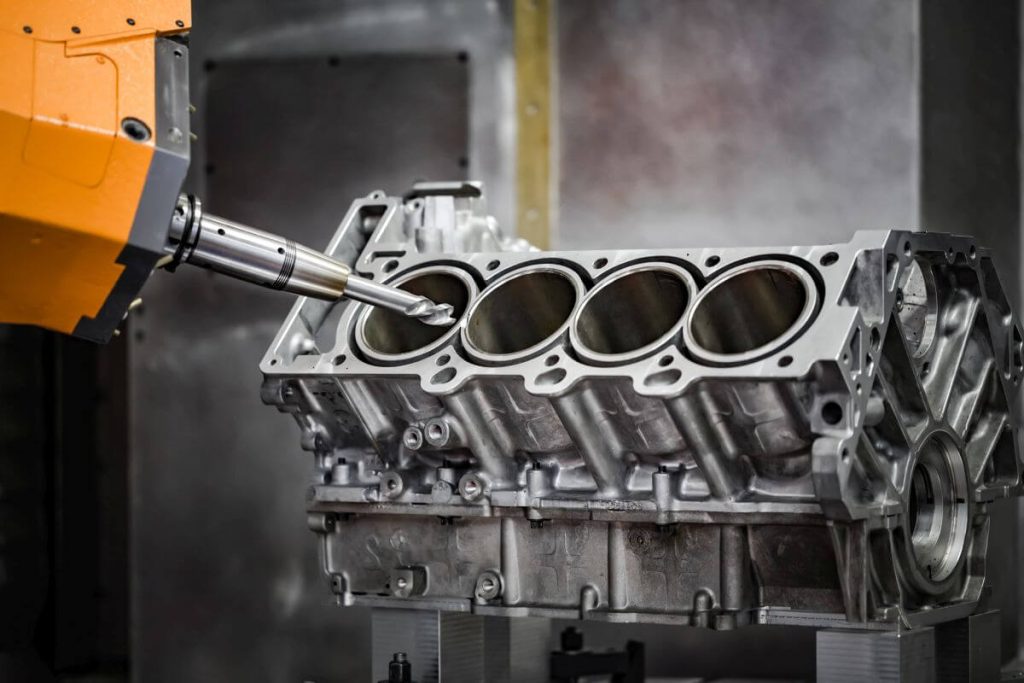

Simply put, Head planning is the alignment of the contact surface between the engine head and its block. Usually, milling machines or magnetic grinders are used for this. The choice of device depends on the drive and the material used for production. The planning of the engine head is an extremely precise operation and must be carried out with sufficient accuracy so that the combustion chamber is sealed and no coolant enters the lubricating medium.

Why do you need to plan your head? Is head polishing necessary?

After removing the head and removing the gasket, you will certainly notice defects in the contact surface. The disassembly of this part is associated with the formation of deformations that must be leveled. It is true that the material between the cylinder block and the cylinder head additionally ensures the tightness of the connection, but for the perfect operation of the engine, additional grinding of the cylinder head is necessary. Otherwise, the coolant circulating in the engine channels could get into the oil.

When is head planning done? Check if gasket needs to be replaced

It is important to note that polishing of the head surface is usually planned during the overhaul of the unit. Most often, the motivation for dismantling the head is replacement gasket between block and head. The need to change this element arises when you notice a significant loss of coolant. This indicates a leak. Some drivers choose to replace the gasket and plan the head when they make major modifications to the powertrain to increase its power.

Removing more material from the head increases the compressed air pressure. This makes it possible to increase engine power. It is important to make other necessary modifications to this procedure. By itself, splicing can only cause knocking.

What is engine head planning?

If the mechanic who performs the service for you does not have the necessary tools, he gives the head to a specialized machining shop. Your head is then cleaned and polished with a special metal surface finishing machine. It is mounted on the desktop and after applying the appropriate parameters, the corresponding layer of material is removed. The use of automatic devices ensures proper planning of the motor head. The processes of planning and regeneration of the cylinder head after the failure of the timing usually take 1-2 days, in some cases it can be extended up to 3-4 days.

Homemade head layout

Should I do this process myself? In the vast majority of cases, the answer is no. If you don't have the right sanding equipment, don't do it. This must be done with great precision. Seals and valves must also be removed during the inspection. Do you only have sandpaper? Don't count at all.

The cost of such processing at a processing plant usually starts from 10 euros, and you can be sure that it is done correctly. However, the price may increase depending on the type of component and the number of parts that need to be sanded. For larger heads, or scheduling two that come from a V-twin engine, the cost will certainly be a bit higher.

However, whether you're paying €100 or €15 for head planning, it's worth taking it to a professional. Failure to do this job properly will result in the head being raised again and the head gasket replaced at the next scheduling.