Radiator and cooling system VAZ 2106: device, repair and replacement of antifreeze

Content

During the operation of an internal combustion engine, 50-60% of the released fuel energy is converted into heat. As a result, the metal parts of the motor are heated to a high temperature and expand in volume, which threatens to jam the rubbing elements. To ensure that the heating does not exceed the maximum allowable limit of 95-100 ° C, any car has a water cooling system. Its task is to remove excess heat from the power unit and transfer it to outside air through the main radiator.

The device and operation of the cooling circuit VAZ 2106

The main element of the cooling system - the water jacket - is part of the engine. Channels vertically penetrating the block and cylinder head have common walls with piston liners and combustion chambers. The non-freezing liquid circulating through the ducts - antifreeze - washes hot surfaces and takes away the lion's share of the heat generated.

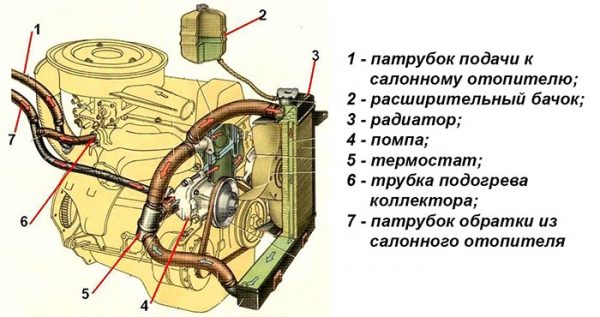

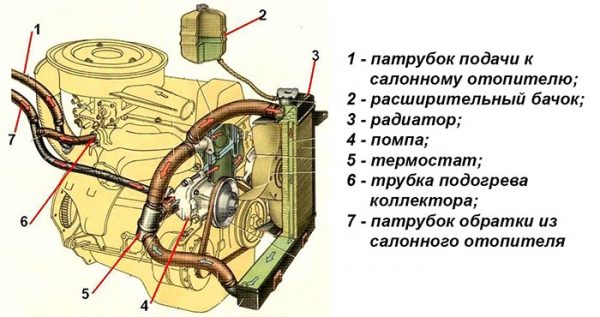

To transfer heat to the outside air and maintain a stable operating temperature of the engine, a number of parts and assemblies are involved in the cooling system of the "six":

- mechanical water pump - pump;

- 2 radiators - main and additional;

- thermostat;

- expansion tank;

- electric fan, triggered by a temperature sensor;

- connecting rubber hoses with reinforced walls.

Water cooling of the motor is one of the most conservative car systems. The device and principle of operation of the circuit is the same for all passenger cars, only modern models use electronics, high-performance pumps, and often 2 fans are installed instead of one.

The algorithm for the operation of the VAZ 2106 cooling circuit looks like this:

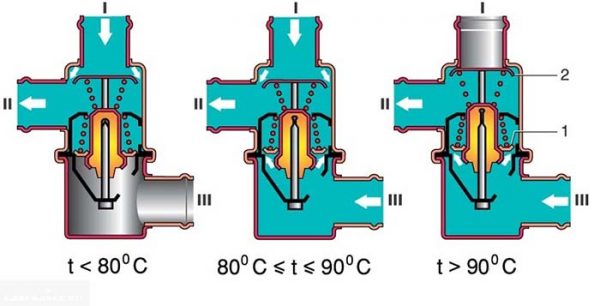

- After starting, the motor begins to warm up to an operating temperature of 90-95 degrees. The thermostat is in charge of limiting the heating - while the antifreeze is cold, this element closes the passage to the main radiator.

- The liquid pumped by the pump circulates in a small circle - from the cylinder head back to the block. If the cabin heater valve is open, the second flow of fluid passes through the small radiator of the stove, returns to the pump, and from there back to the cylinder block.

- When the antifreeze temperature reaches 80-83 °C, the thermoelement starts to open the damper. Hot liquid from the cylinder head enters the main heat exchanger through the upper hose, cools and moves to the thermostat through the lower pipe. The circulation takes place in a large circle.

The higher the temperature of the flowing liquid, the more the thermostat opens the passage to the main heat exchanger

The higher the temperature of the flowing liquid, the more the thermostat opens the passage to the main heat exchanger - At a temperature of 90 °C, the thermoelement damper is fully open. The antifreeze expanding in volume compresses the valve spring built into the radiator cap, pushes the lock washer and flows into the expansion tank through a separate tube.

- If there is not enough liquid cooling and the temperature rise continues, the electric fan is activated by a sensor signal. The meter is mounted in the lower part of the heat exchanger, the impeller is installed directly behind the honeycombs.

While the thermostat damper is hermetically closed, only the upper part of the main radiator heats up, the bottom remains cold. When the thermoelement opens slightly and the antifreeze circulates in a large circle, the lower part also gets warmer. On this basis, it is easy to determine the performance of the thermostat.

Unlike more modern passenger cars, the expansion tank on the VAZ 2106 is a plastic container with a conventional air valve in the plug. The valve does not regulate the pressure in the system - this function is assigned to the top cover of the cooling radiator.

Characteristics of the main radiator

The purpose of the element is to cool the heated antifreeze, which drives the water pump through the system. For maximum airflow efficiency, the radiator is installed in the front of the body and is closed from mechanical damage by a decorative grille.

In recent years, the VAZ 2106 models were equipped with aluminum heat exchangers with side plastic tanks. Technical characteristics of the standard unit:

- catalog number of the radiator is 2106-1301012;

- honeycombs - 36 round aluminum tubes arranged horizontally in 2 rows;

- size - 660 x 470 x 140 mm, weight - 2,2 kg;

- number of fittings - 3 pcs., two large ones are connected to the cooling system, one small one - to the expansion tank;

- a drain plug is provided in the lower part of the left tank, a hole for the temperature sensor in the right one;

- The product comes with 2 rubber feet.

Cooling of antifreeze in the radiator occurs due to the flow through horizontal tubes and heat exchange with aluminum plates blown by air flow. The cover of the unit (not included with the purchase of spare parts) plays the role of a valve that passes excess coolant through the outlet pipe into the expansion tank.

Regular heat exchangers for the "six" are produced by the following companies:

- DAAZ - "Dimitrovgrad auto-aggregate plant";

- POINTS;

- Luzar;

- "Right".

DAAZ radiators are considered original, since it was these spare parts that were installed during the assembly of cars by the main manufacturer, AtoVAZ.

An alternative option is a brass heat exchanger with catalog number 2106-1301010, manufacturer - Orenburg Radiator. Cooling cells in this unit are located vertically, tanks - horizontally (top and bottom). The dimensions of the element are 510 x 390 x 100 mm, weight - 7,19 kg.

The VAZ 2106 radiator, made of copper, is considered more reliable and durable, but at a price it will cost twice as much. Similar spare parts were completed with all models of "Zhiguli" of early releases. The transition to aluminum is associated with a reduction in cost and lightening the car - a brass heat exchanger is three times heavier.

The design and mounting method of the main heat exchanger does not depend on the type of power supply system. In the carburetor and injection versions of the Six, the same cooling units are used.

In an artisanal way, you can install a unit from the tenth VAZ family or a large radiator from the Chevrolet Niva, equipped with two fans, on the "six". A serious reconstruction of the car will be required - you need to rearrange the hood opening hinges to another place, otherwise the unit will not fit on the front panel of the body.

How to repair the radiator "six"

During operation, the owner of a VAZ 2106 car may encounter such malfunctions of the main heat exchanger:

- the formation in the honeycombs of many small holes that allow antifreeze to pass through (the problem is characteristic of aluminum radiators with high mileage);

- leakage through the seal at the junction of the plastic tank with the housing mounting flange;

- cracks on the connecting fittings;

- mechanical damage to tubes and plates.

In most cases, it is possible to fix radiator malfunctions on your own. The exception is aluminum units with a mileage of over 200 thousand km, which have rotted in many places. If you find numerous leaks in the cells, it is better to replace the element with a new one.

The repair procedure is carried out in 3 stages:

- Dismantling the heat exchanger, assessing damage and choosing a sealing method.

- Elimination of leaks.

- Reassembly and filling of the system.

If a small leak is detected, try to fix the defect without removing the radiator from the machine. Buy a special sealant from an automotive store and add to the coolant, following the instructions on the package. Please note that chemistry does not always help to close holes or acts temporarily - after six months - a year antifreeze oozes again in the same place.

Dismantling and diagnostics of the element

To remove and identify all defects in the radiator, prepare a number of tools:

- a set of open-end wrenches 8–22 mm in size;

- a set of heads with a cardan and a collar;

- flat screwdriver;

- wide capacity for draining antifreeze and diagnostics of the heat exchanger;

- WD-40 lubricant in an aerosol can;

- protective fabric gloves.

It is better to work on a viewing ditch, since you will have to remove the lower side protection (if any). Before disassembly, be sure to cool the motor, otherwise you will burn yourself with hot antifreeze. The radiator is removed like this:

- Put the car in the pit and dismantle the lower protective boot from the side of the radiator drain. The part is fastened with screws with a turnkey head of 8 mm.

The metal boot is screwed with self-tapping screws to the front beam and body parts

The metal boot is screwed with self-tapping screws to the front beam and body parts - Treat the connection points of the nozzles and fixing screws with WD-40 grease.

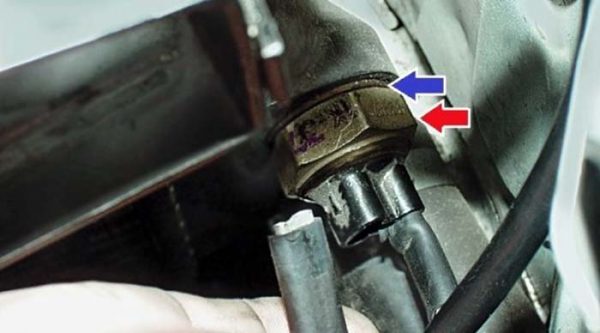

- Substitute the container and drain the antifreeze by unscrewing the bottom plug or sensor - fan thermal switch. The process of emptying the system is described in more detail below in the instructions for replacing the fluid.

Aluminum heat exchangers are equipped with a drain plug, in brass heat exchangers you have to unscrew the temperature sensor

Aluminum heat exchangers are equipped with a drain plug, in brass heat exchangers you have to unscrew the temperature sensor - Disconnect both battery terminals and remove the battery. Disconnect the power wires for the temperature sensor and the fan motor.

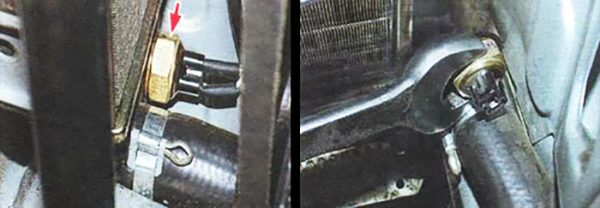

When disconnecting the sensor, it is not necessary to memorize the contacts - the terminals are put on in any order

When disconnecting the sensor, it is not necessary to memorize the contacts - the terminals are put on in any order - Loosen and unscrew the 3 screws securing the electric fan to the heat exchanger. Carefully remove the impeller together with the diffuser.

The impeller with diffuser is attached to the heat exchanger with three bolts

The impeller with diffuser is attached to the heat exchanger with three bolts - Using a flathead screwdriver, loosen the clamps and remove the hoses from the radiator fittings.

To remove the stuck hose, you need to loosen the clamp and pry it with a screwdriver

To remove the stuck hose, you need to loosen the clamp and pry it with a screwdriver - Unscrew the 2 M8 bolts for fastening the heat exchanger, on the right side it is better to use a union head and cardan. Pull out the unit and drain the remaining antifreeze from it.

The lower part of the VAZ 2106 heat exchanger is not screwed, but rests on 2 pillows

The lower part of the VAZ 2106 heat exchanger is not screwed, but rests on 2 pillows

The integrity of the radiator is checked by immersion in water and air injection with a hand pump. Large fittings must be plugged with homemade plugs, and air must be pumped through the small pipe of the expansion tank. Leaks will show themselves as air bubbles, clearly visible in the water.

In some cases, for example, after a stone strike or a small accident, it is not necessary to carry out diagnostics. Mechanical damage is easy to distinguish by crumpled plates and wet drips of antifreeze.

Depending on the type of defect, the method of repairing the unit is selected:

- Holes up to 3 mm in size found in brass honeycombs are sealed by soldering.

- Similar damage to aluminum tubes is repaired with a two-component adhesive or cold welding.

- Tank seal leaks are eliminated by fitting plastic parts to the sealant.

- Large holes and destroyed tubes cannot be restored - the cells will have to be drowned out.

If the number of small defects is too high, the radiator should be replaced. Repair will not work, rotten pipes will begin to leak in new places.

Video: how to remove the VAZ 2106 radiator yourself

Repair by soldering

To solder a fistula or crack in a brass radiator, you will need the following tools and materials:

- soldering iron with extended tip, minimum power - 350 W;

- sandpaper, metal brush;

- pliers, nippers;

- degreaser - white spirit, nefras, gasoline "galosh";

- soldering acid, small brush;

- flux, solder.

Before starting work, the unit should be washed and dried. Then carefully remove part of the heat exchange plates in order to reach the damaged tube with a soldering iron tip. Soldering is done in this order:

- Clean the place of the defect with a brush and sandpaper to a characteristic shine.

Near the crack, it is important to peel off all the paint to the metal

Near the crack, it is important to peel off all the paint to the metal - Degrease the area around the damage and apply soldering acid with a brush.

Orthophosphoric acid is applied after degreasing the surface

Orthophosphoric acid is applied after degreasing the surface - Heat up the soldering iron and apply a layer of flux.

- Capturing solder with a sting, try to tighten the fistula. Repeat the application of flux and solder several times as needed.

Solder is applied with a well-heated soldering iron in several layers.

Solder is applied with a well-heated soldering iron in several layers.

When the tin is completely dry, re-immerse the heat exchanger in water and pump air over the honeycomb to check the tightness of the solder. If the damage cannot be repaired, try the second method described below.

Video: how to solder a radiator in a garage

Watch this video on YouTube

The use of chemical compounds

Fistulas in aluminum tubes cannot be soldered without argon welding. In such cases, embedding with a two-component composition or a mixture called "cold welding" is practiced. The work algorithm partially repeats soldering with solder:

- Thoroughly clean the section of the tube near the hole using sandpaper.

- Degrease the surface.

- Based on the instructions on the package, prepare the adhesive composition.

- Without touching the degreased area with your hands, apply glue and hold for the specified time.

Cold welding does not always adhere well to aluminum surfaces. The patch partially lags behind the vibration and thermal expansion of the metal, as a result, the liquid oozes out of the radiator again. Therefore, this method is best considered as temporary - until the purchase of a new heat exchanger.

Sealing tanks and large holes

Violation of the tightness of the sealing gaskets between the plastic tanks and the aluminum case of the heat exchanger is eliminated in the following way:

- The radiator tank is attached to the body with metal brackets. Bend each of them with pliers and remove the plastic container.

To separate the tank, you will have to bend a lot of metal brackets

To separate the tank, you will have to bend a lot of metal brackets - Remove the gasket, wash and dry all parts.

- Degrease the surfaces to be joined.

- Place the gasket on the high temperature silicone sealant.

The tank gasket is seated on the body flange and lubricated with sealant

The tank gasket is seated on the body flange and lubricated with sealant - Apply sealant silicone to the tank flange and attach it back with staples.

After assembly, the edge of the tank must be pressed again with curved teeth

After assembly, the edge of the tank must be pressed again with curved teeth

Gaskets for the VAZ 2106 aluminum radiator are not always commercially available, so the old seal must be removed very carefully.

Broken and torn heat exchanger tubes cannot be soldered. In such situations, jamming of damaged cells is practiced with cutting out some of the jammed plates. The destroyed sections of the tubes are removed with wire cutters, then the honeycombs are jammed by repeated bending with pliers.

The performance of the unit is restored, but the cooling efficiency is deteriorating. The more tubes you had to plug, the smaller the heat exchange surface and the temperature drop of the antifreeze during the ride. If the damage area is too large, it is pointless to make repairs - the unit should be changed.

Assembly instructions

Installation of a new or repaired radiator is carried out in the reverse order, taking into account the recommendations:

- Check the condition of the rubber pads on which the unit rests. It is better to replace a cracked and “hardened” rubber product.

- Lubricate the fixing bolts with used oil or nigrol before screwing in.

- If the ends of the rubber hoses are cracked, try cutting the pipes or installing new ones.

- The small pipe coming from the expansion tank is usually made of cheap hard plastic. To make it easier to pull on the radiator fitting, lower the end of the tube into hot water - the material will soften and easily fit over the nozzle.

The tube from the expansion tank is made of hard plastic and is heavily pulled onto the fitting without heating.

The tube from the expansion tank is made of hard plastic and is heavily pulled onto the fitting without heating.

After assembly, fill the system with antifreeze, start the engine and warm up to a temperature of 90 ° C. During heating, observe the heat exchanger and piping connections to ensure that the system is completely sealed.

Air cooling fan operation

If, due to heat or other reasons, the main radiator cannot cope with cooling and the temperature of the liquid continues to rise, an electric fan mounted on the rear surface of the heat exchanger is switched on. It forces a large volume of air through the plates, increasing the cooling efficiency of the antifreeze.

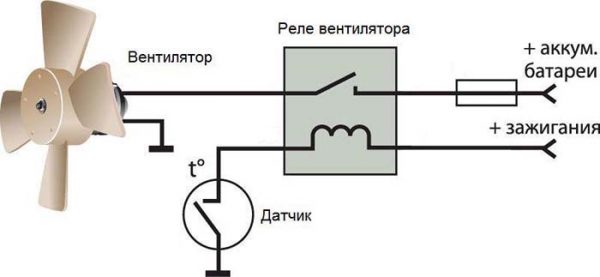

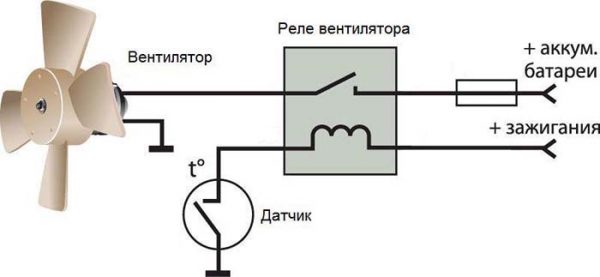

How does the electric fan start:

- When the antifreeze warms up to 92 ± 2 ° C, a temperature sensor is activated - a thermistor installed in the lower zone of the radiator.

- The sensor closes the electrical circuit of the relay that controls the fan on. The electric motor starts, forced airflow of the heat exchanger begins.

- The thermistor opens the circuit after the liquid temperature drops to 87-89 degrees, the impeller stops.

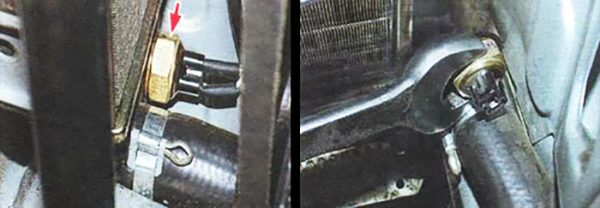

The location of the sensor depends on the design of the radiator. In units made of aluminum, the thermal switch is located at the bottom of the right plastic tank. In a brass heat exchanger, the sensor is located on the left side of the lower horizontal tank.

The thermistor of the VAZ 2106 fan often fails, shorting the circuit or not responding to an increase in temperature. In the first case, the fan spins continuously, in the second case it never turns on. To check the device, it is enough to disconnect the contacts from the sensor, turn on the ignition and close the terminals manually. If the fan starts, the thermistor must be replaced.

Replacing the temperature sensor VAZ 2106 is carried out without emptying the system. It is necessary to prepare a new element, unscrew the old device with a 30 mm key and quickly swap them. In the most unfortunate scenario, you will lose no more than 0,5 liters of antifreeze.

When buying a new sensor, pay attention to 2 points: the response temperature and the presence of an o-ring. The fact is that the thermal switches of VAZ 2109-2115 cars look like a part from the "six", including the thread. The difference is the switch-on temperature, which is higher for front-wheel drive models.

Video: diagnostics and replacement of the six thermal switch

Watch this video on YouTube

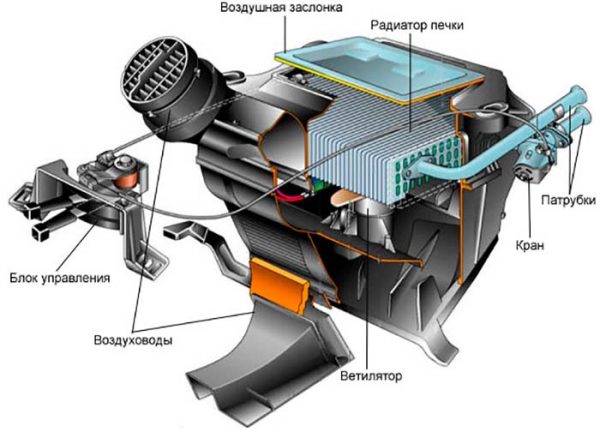

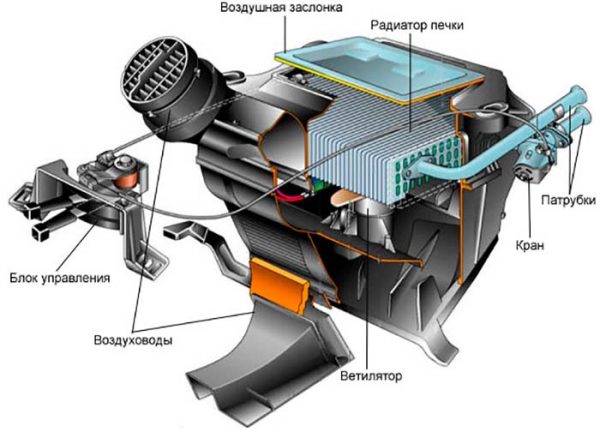

How does the interior heater work?

To heat the driver and passengers, the VAZ 2106 has a small radiator installed inside the main air duct under the front panel of the car. The hot coolant comes from the engine through two hoses connected to the small circulation of the cooling system. How interior heating works:

- Liquid is supplied to the radiator through a special valve, opened by a cable drive from a lever on the central panel.

- In summer mode, the valve is closed, the outside air passing through the heat exchanger is not heated.

- When cold weather sets in, the driver shifts the valve control lever, the cable turns the valve stem and hot antifreeze enters the radiator. The air flow is warming up.

As with the main radiator, cabin heaters are available in brass and aluminum. The latter serve less and fail more often, sometimes the tubes rot within 5 years.

The regular stove faucet is considered a reliable device, but often fails due to cable drive malfunctions. The latter jumps off or wears out and the valve has to be adjusted manually. To get to the regulator and put the cable in place, you need to disassemble the central panel.

Video: tips for installing a stove faucet on the "classic"

Watch this video on YouTube

Replacing the coolant

The antifreeze circulating through the VAZ 2106 cooling circuit gradually loses its anti-corrosion properties, becomes contaminated and forms scale. Therefore, periodic fluid replacement is needed at intervals of 2-3 years, depending on the intensity of operation. Which coolant is better to choose:

- initially, the manufacturer recommended pouring antifreeze class G11, painted in blue or green (this also includes the antifreeze invented in the USSR);

- it is allowed to fill in liquids of classes G12 and G12 +, made on the basis of ethylene glycol, color - mainly yellow and orange;

- the best and most modern option is G13 antifreeze based on propylene glycol, the color is pink or purple.

G13 class fluid is significantly more expensive than ethylene glycol antifreeze, but more durable. The minimum service life is 4 years.

To replace antifreeze in the VAZ 2106 cooling circuit, you need to purchase 10 liters of new fluid and follow the instructions:

- While the engine is cooling, remove the dust protection located under the radiator drain plug. It is fastened with 4 8 mm wrench screws.

- Open the stove tap, place a container under the drain neck of the body exchanger and unscrew the plug. A small amount of liquid drains.

Immediately after unscrewing the plug, no more than a liter of liquid will flow out of the unit

Immediately after unscrewing the plug, no more than a liter of liquid will flow out of the unit - Remove the expansion tank cap and slowly unscrew the top radiator cap. Antifreeze will run out of the hole again.

The bulk of the antifreeze will merge after opening the top cover of the heat exchanger

The bulk of the antifreeze will merge after opening the top cover of the heat exchanger - Unscrew the cap completely and wait for the system to empty. Screw the plug into the drain hole.

Brass radiators may not have a drain port. Then it is necessary to unscrew the temperature sensor or remove the large lower hose and drain the antifreeze through the pipe.

To avoid air pockets when filling the circuit with new fluid, you need to remove the hose at the highest point of the system. On carburetor versions, this is a manifold heating tube, in injector versions, it is a throttle valve.

Perform filling through the upper neck of the radiator, observing the removed pipe. As soon as antifreeze flows from the hose, immediately put it on the fitting. Then install the heat exchanger plug and add fluid to the expansion tank. Start the engine, warm up to a temperature of 90 ° C and make sure that the radiator housing warms up from top to bottom.

Video: how to change the coolant on the VAZ 2106

The cooling system of the VAZ 2106 does not require much attention from the owner of the car. The driver will be informed about the emerging problems associated with overheating of the motor, the fluid temperature gauge on the instrument panel. During operation, it is important to monitor the level of antifreeze in the expansion tank and the appearance of wet spots under the car, indicating leaks.