Dismantling, troubleshooting and replacement of the camshaft on the VAZ 2106

Content

The operation of the gas distribution mechanism and, in general, the entire motor directly depends on the state of the camshaft. Even minor malfunctions of this part can lead to a decrease in engine power and thrust, and an increase in fuel consumption. To avoid these troubles, you need to be able to diagnose the problem in time and fix it in a timely manner.

Camshaft VAZ 2106

The camshaft is an integral part in the design of the gas distribution mechanism (timing) of any engine. It is made in the form of a cylinder, on which the necks and cams are located.

Description

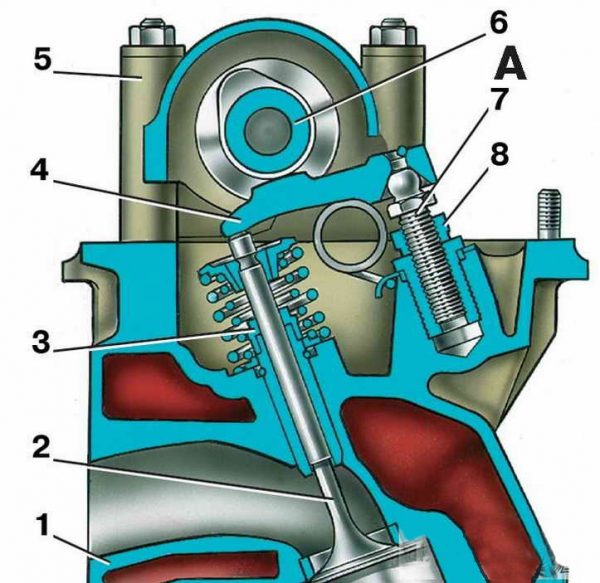

On the "Zhiguli" of the sixth model, the timing mechanism shaft is installed in the cylinder head (cylinder head) of the motor. This arrangement allows you to repair and change the part, as well as adjust valve clearances without any difficulties. Access to the shaft opens after removing the valve cover. The camshaft (RV) is assigned the role of controlling the opening and closing of valves in the engine cylinders - at the right time, it lets the fuel-air mixture into the cylinder and releases exhaust gases. A gear is installed on the camshaft, which is connected by means of a chain to the crankshaft star. This design ensures simultaneous rotation of both shafts.

Since gears of different sizes are installed on the crankshaft and camshaft, the rotation speed of the latter is halved. A complete work cycle in the power unit occurs in one revolution of the camshaft and two revolutions of the crankshaft. The valves in the cylinder head open in a certain order under the influence of the corresponding cams on the pushers, that is, when the camshaft rotates, the cam presses on the pusher and transfers force to the valve, which is preloaded by springs. In this case, the valve opens and lets in the fuel-air mixture or releases exhaust gases. As the cam turns further, the valve closes.

More about the design of the VAZ 2106 engine: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/ne-zavoditsya-vaz-2106.html

Parameters

The "six" camshaft has the following characteristics:

- phase width — 232˚;

- intake valve lift - 9,5 mm;

- intake valve lag - 40˚;

- exhaust valve advance - 42˚.

On the "Zhiguli" of the sixth model, the timing mechanism has eight valves, that is, two for each cylinder, the number of cams is equal to the number of valves.

Which camshaft is better to put

On the VAZ 2106, only one shaft of the gas distribution mechanism is suitable - from the Niva. The part is installed in order to increase the power and dynamic performance of the car. It is possible to achieve the desired results, albeit small ones, by increasing the width of the phases and the height of the intake valves. After installing the RV from the Niva, these parameters will have values of 283˚ and 10,7 mm. Thus, the intake valve will be open for a longer time and raised to a greater height relative to the seat, which will ensure that more fuel enters the cylinders.

When replacing a standard camshaft with a part from a VAZ 21213, the engine parameters will not change dramatically. You can install a "sports" shaft designed for tuning, but it is not cheap - 4-10 thousand rubles.

Table: the main parameters of the "sports" camshafts for the "classic"

| Name | Phase width, o | Valve lift, mm |

| "Estonian" | 256 | 10,5 |

| "Estonian +" | 289 | 11,2 |

| "Estonian-M" | 256 | 11,33 |

| Shrik-1 | 296 | 11,8 |

| Shrik-3 | 304 | 12,1 |

Signs of camshaft wear

The operation of the camshaft is associated with constant exposure to high loads, as a result of which the part gradually wears out and needs to be replaced. The need for repair arises when characteristic signs appear:

- knocking when the engine is running under load;

- decrease in power indicators.

There are a number of reasons why the RW fails:

- natural wear and tear;

- low-quality engine oil;

- low oil pressure in the lubrication system;

- insufficient oil level or so-called oil starvation;

- engine operation at high temperatures, which leads to a deterioration in the properties of the lubricant;

- mechanical damage (wear or chain breakage).

The main malfunctions that disrupt the performance of the camshaft are scuffing on the working surfaces (necks and cams) and the development of the limiter.

Knocking

It is rather problematic, but still possible, to identify by sounds coming from the engine compartment that the problem is related specifically to the camshaft. The sound of the RV resembles the dull blows of a hammer, which become more frequent with an increase in engine speed. However, the best way to diagnose the shaft is to dismantle it, disassemble and troubleshoot. During inspection, the shaft should not move in the housing relative to the axis, otherwise, when hitting the limiter, a dull sound will come out.

Video: causes of longitudinal play of the VAZ camshaft

Decrease in power

The drop in power on the classic Zhiguli is a phenomenon due to the wear of the camshaft and rockers. With proper operation of the engine (timely oil change, control of its level and pressure), the problem manifests itself only at high mileage of the car. When the cams are worn, the required phase width and valve lift at the inlet are no longer ensured.

Deformation

RV can be deformed with strong heat, which is caused by malfunctions in the cooling and lubrication systems. At first, the problem may manifest itself in the form of a knock. Therefore, if there is a suspicion of this breakdown, for example, the motor overheated, then it is recommended to perform shaft diagnostics in order to avoid more serious troubles with the engine timing.

Dismantling the camshaft VAZ 2106

To carry out repair work or replace the camshaft on the "six", you need to prepare the following tools:

- heads for 17 and 13 mm;

- ratchet handle;

- crank;

- extension;

- open-end or box wrench 13 mm.

We dismantle the node in the following sequence:

- Remove the valve cover from the cylinder head.

We unscrew the nuts securing the valve cover and remove it from the engine

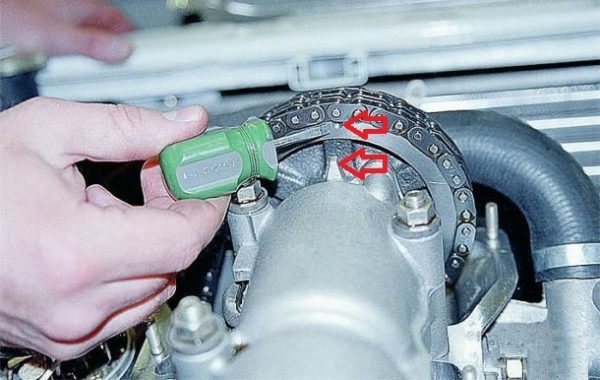

We unscrew the nuts securing the valve cover and remove it from the engine - We unscrew the cap nut of the chain tensioner and remove its stem with a screwdriver, then tighten the nut.

We loosen the chain tension by unscrewing the cap nut with a 13 mm wrench

We loosen the chain tension by unscrewing the cap nut with a 13 mm wrench - Unfold the lock washer.

The bolt holding the camshaft gear is fixed with a lock washer

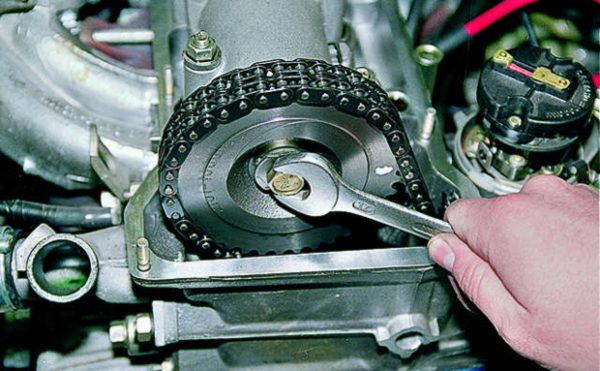

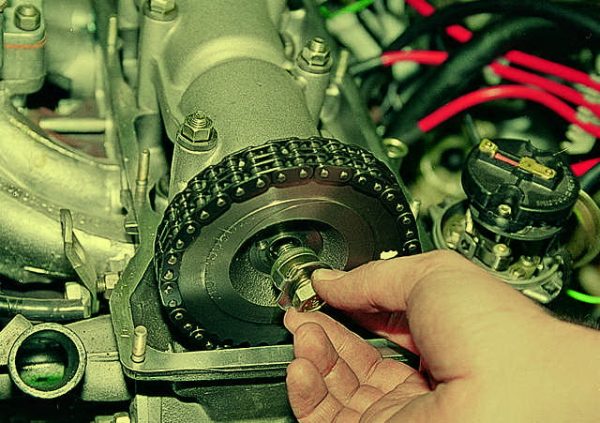

The bolt holding the camshaft gear is fixed with a lock washer - We unscrew the bolt holding the camshaft star with a 17 mm wrench. To prevent the shaft from turning, we put the car in gear, and we substitute an emphasis under the wheels.

To remove the camshaft star, unscrew the bolt with a 17 mm wrench

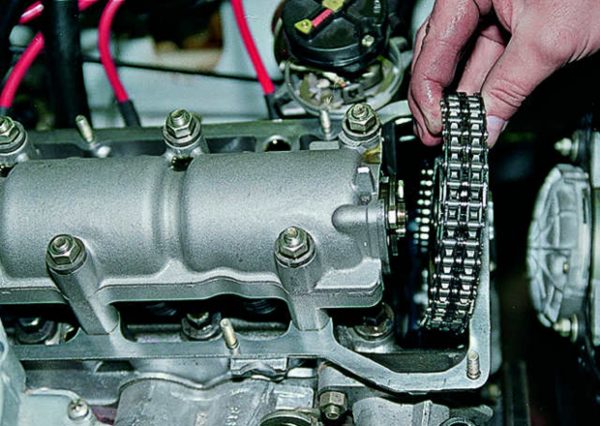

To remove the camshaft star, unscrew the bolt with a 17 mm wrench - Set the star aside.

Having unscrewed the mount, we take the gear along with the chain to the side

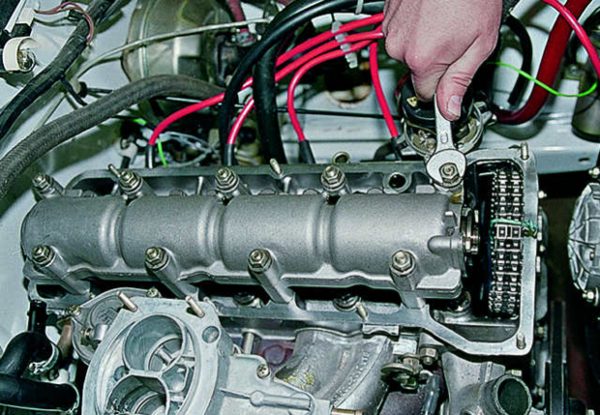

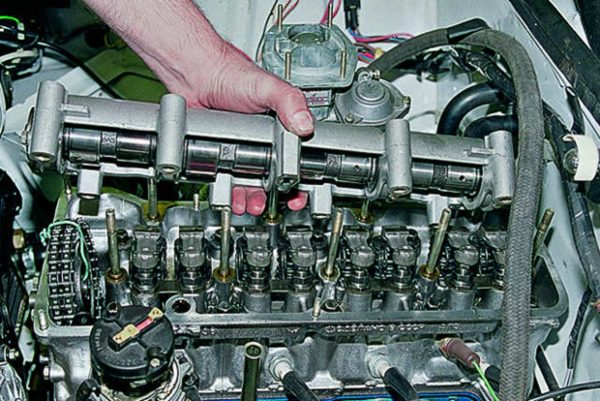

Having unscrewed the mount, we take the gear along with the chain to the side - We unscrew the nuts securing the mechanism housing with a key or a 13 mm head.

The camshaft housing is attached to the cylinder head with nuts, unscrew them

The camshaft housing is attached to the cylinder head with nuts, unscrew them - If you plan to completely disassemble the RV, you must unscrew two more nuts with a 10 mm wrench.

If the camshaft is removed from the housing, unscrew the two nuts by 10 mm

If the camshaft is removed from the housing, unscrew the two nuts by 10 mm - When all the fastening elements are unscrewed, we take the cover of the product and with some effort we pull it up through the studs, slightly swinging it from side to side.

When the camshaft is freed from the fasteners, we pull it up from the studs

When the camshaft is freed from the fasteners, we pull it up from the studs - From the back of the camshaft, lightly tap with a hammer through a wooden tip.

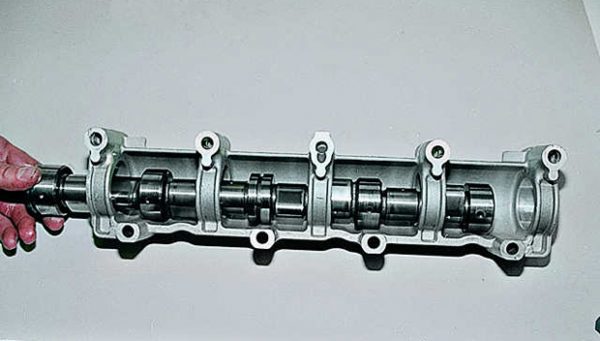

- We push the shaft forward and remove it from the housing.

To remove the shaft from the housing, it is enough to lightly knock through the wooden extension on the back side, and then push it out.

To remove the shaft from the housing, it is enough to lightly knock through the wooden extension on the back side, and then push it out.

Learn more about cylinder head problems: https://bumper.guru/klassicheskie-modeli-vaz/grm/poryadok-zatyazhki-golovki-bloka-cilindrov-vaz-2106.html

Camshaft Troubleshooting

After the RV is removed from the engine, all its components are washed in gasoline, cleaned of contaminants. Troubleshooting involves a visual inspection of the shaft for damage: cracks, scuffs, shells. If they are found, the shaft must be replaced. Otherwise, the main parameters characterizing the degree of its wear are checked, for which a micrometer is used.

Table: the main dimensions of the VAZ 2106 camshaft and its beds in the bearing housing

| Number of the neck (bed) starting from the gear | Size mm | |

| Nominal | Maximum allowable | |

| Support necks | ||

| 1 | 45,91 | 45,93 |

| 2 | 45,61 | 45,63 |

| 3 | 45,31 | 45,33 |

| 4 | 45,01 | 45,03 |

| 5 | 43,41 | 43,43 |

| Supports | ||

| 1 | 46,00 | 46,02 |

| 2 | 45,70 | 45,72 |

| 3 | 45,40 | 45,42 |

| 4 | 45,10 | 45,12 |

| 5 | 43,50 | 43,52 |

The condition of the RV can also be assessed by other parameters, for example, beating, but special tools are needed to remove them.

If, according to the results of troubleshooting, it was revealed that the timing shaft needs to be replaced due to heavy wear, then the rockers should also be replaced with it.

Installing the camshaft

The process of mounting the shaft takes place in the reverse order using the same tools as for its removal. Additionally, you will need a torque wrench with which you can control the tightening torque. The work is carried out as follows:

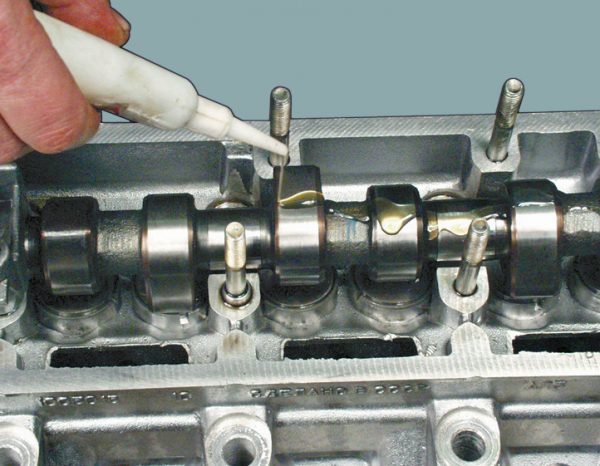

- Before mounting the part in the body, lubricate the bearing journals, bearings and cams with clean engine oil.

The necks and camshaft cams are lubricated with clean engine oil before installation in the housing.

The necks and camshaft cams are lubricated with clean engine oil before installation in the housing. - We mount the product in the housing and tighten the fastening of the thrust plate.

After installing the shaft in the housing, we fix it with a thrust plate

After installing the shaft in the housing, we fix it with a thrust plate - Check shaft rotation. It should easily scroll around its axis.

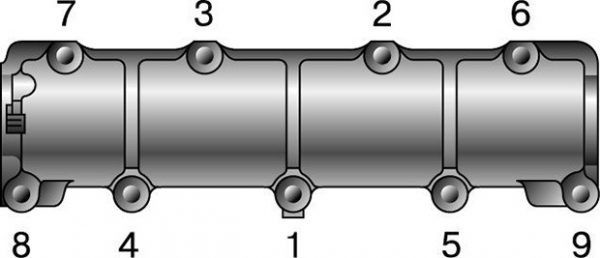

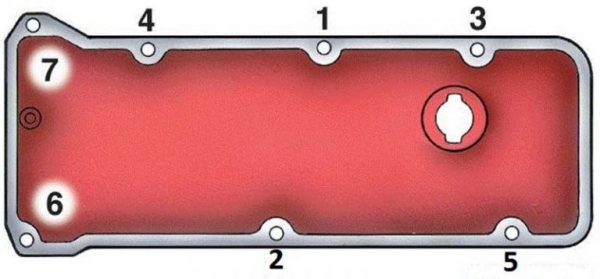

- We mount the housing together with the shaft on the studs in the cylinder head and tighten in a certain sequence with a force of 18,3–22,6 Nm.

The camshaft should be tightened with a force of 18,3–22,6 Nm in a certain sequence

The camshaft should be tightened with a force of 18,3–22,6 Nm in a certain sequence - We make the final assembly after marking.

To ensure that the camshaft is evenly pressed against the cylinder head, the tightening should be carried out in several stages.

Video: installing a camshaft on a classic Zhiguli

Watch this video on YouTube

Installation by labels

At the end of the replacement, it is necessary to set the camshaft and crankshaft according to the marks. Only after such a procedure will the ignition timing be correct, and engine operation stable. Of the tools, you will additionally need a key to rotate the crankshaft, and the work itself consists of the following steps:

- We put the asterisk RV in place and tighten it, but not completely.

- We pull the chain. To do this, unscrew the tensioner nut, turn the crankshaft a little, and then tighten the nut back.

- We turn the crankshaft with a key until the risk on the pulley is set opposite the length of the mark on the cover of the timing mechanism.

We turn the crankshaft until the risk on the pulley is set opposite the long mark on the timing cover

We turn the crankshaft until the risk on the pulley is set opposite the long mark on the timing cover - The mark on the PB star must match the ebb on the hull. If this does not happen, unscrew the bolt, remove the gear and shift the chain by one tooth in the required direction.

To install the camshaft according to the marks, the notch on the gear must coincide with the ebb on the bearing housing

To install the camshaft according to the marks, the notch on the gear must coincide with the ebb on the bearing housing - We install and clamp the gear with a bolt, check the coincidence of the marks of both shafts. We fix the bolt with a special washer.

After marking the camshaft gear, we clamp it with a bolt

After marking the camshaft gear, we clamp it with a bolt - We adjust the thermal clearance of the valves.

- We mount the valve cover, tightening it in a certain order.

The valve cover must be tightened in a certain order, without applying much force.

The valve cover must be tightened in a certain order, without applying much force. - We install the remaining elements in their places.

Adjustment of valves

Valves on the "classic" are recommended to be adjusted every 30 thousand km. mileage or after engine repair. From the tools you need to prepare:

- open-end wrench for 13 and 17;

- probe 0,15 mm.

Work is carried out on a cooled engine after removing the valve cover and tensioning the chain:

- We combine the marks of the crankshaft and camshaft with the risks, which corresponds to the top dead center of the fourth cylinder.

- We check the clearance of valves 6 and 8. To do this, insert the probe between the PB cam and the rocker. If it comes in without effort, the gap needs to be made smaller. If it is tight, then more.

To check the gap between the rocker and the PB cam, insert a feeler gauge

To check the gap between the rocker and the PB cam, insert a feeler gauge - To adjust, we loosen the lock nut with a 17 mm wrench, and set the desired gap with a 13 mm wrench, after which we tighten the lock nut.

To loosen the adjusting screw, unscrew the lock nut with a 17 mm key, and then adjust the gap with a 13 mm key

To loosen the adjusting screw, unscrew the lock nut with a 17 mm key, and then adjust the gap with a 13 mm key - The remaining valves are regulated in the same way, but in a certain order, for which we turn the crankshaft.

Table: cylinder head valve adjustment procedure on the "classic"

| Angle of rotation crankshaft, o | Angle of rotation distributed, o | Cylinder numbers | Adjustable Valve Numbers |

| 0 | 0 | 4 and 3 | 8 and 6 |

| 180 | 90 | 2 and 4 | 4 and 7 |

| 360 | 180 | 1 and 2 | 1 and 3 |

| 540 | 270 | 3 and 1 | 5 and 2 |

Video: valve adjustment on the VAZ 2101-07

Watch this video on YouTube

Replacing a camshaft with a VAZ 2106 does not require high qualifications and special tools from the owner. Repairs can be carried out in a garage with an ordinary car set of keys and screwdrivers. When following the step-by-step instructions, the procedure will take about 2-3 hours, after which the gas distribution mechanism of your car will work clearly and smoothly.