Types, device and purpose of the flywheel engine

Content

Externally, the engine flywheel is an ordinary device - a simple heavy disk. However, at the same time, it performs an important function in the operation of the engine and the entire machine. In this article we will consider its main purpose, types of flywheels, as well as their device.

Purpose and functions

A simple flywheel is a precisely balanced solid cast iron disk on which metal teeth are pressed to engage with the motor starter, the so-called ring gear. The flywheel transmits torque from the engine to the gearbox, so it sits between the engine and transmission. When using a manual transmission, a clutch basket is attached to the flywheel, and in an automatic transmission, a torque converter.

The flywheel is a fairly heavy element. Its weight depends on the engine power and the number of cylinders. This is explained by the fact that the main purpose of the flywheel is to accumulate kinetic energy from the crankshaft, as well as to form the required inertia. The fact is that in an internal combustion engine of 4 cycles, only 1 does the necessary work - the working stroke. The other 3 cycles of the crankshaft and the piston group must be carried out by inertia. Directly for this, a flywheel is needed, fixed at the end of the crankshaft.

From all that has been said before, it follows that the purpose of the flywheel and its main functions are as follows:

- ensuring smooth operation of the motor;

- transmission of torque from the motor to the gearbox, as well as ensuring the operation of the clutch;

- transmission of torque from the starter to the flywheel ring to start the engine.

Types of flywheels

Today, there are 3 types of flywheels:

- Solid. More popular and conventional design. This is a dense metal disk, the device of which was described earlier. The flywheel for an automatic transmission is much lighter than a simple one, as it is designed for use together with a torque converter.

- Lightweight. During tuning of the car, transmission, as well as the motor, a lightweight flywheel is often installed. Its small mass reduces inertia and increases motor efficiency by 4-5%. Auto reacts faster to the gas pedal, becomes the most active. But it is necessary to install a lightweight flywheel only in conjunction with other work to improve the performance of the motor, as well as the transmission. The use of lightweight flywheels without refining the piston, as well as the crankshaft, can lead to unstable operation of the engine at idle.

- Dual mass. A two-mass or damper flywheel is considered the most complex in design and is installed on modern car brands. It can be used on cars with manual and automatic transmission without a torque converter. In the case of a manual transmission, a clutch disc without a torsional vibration damper is used.

Dual mass flywheels have become very common due to improved vibration dampening, hum, transmission protection, and synchronizers. Directly this variety should be considered in more detail.

The design and properties of a dual-mass flywheel

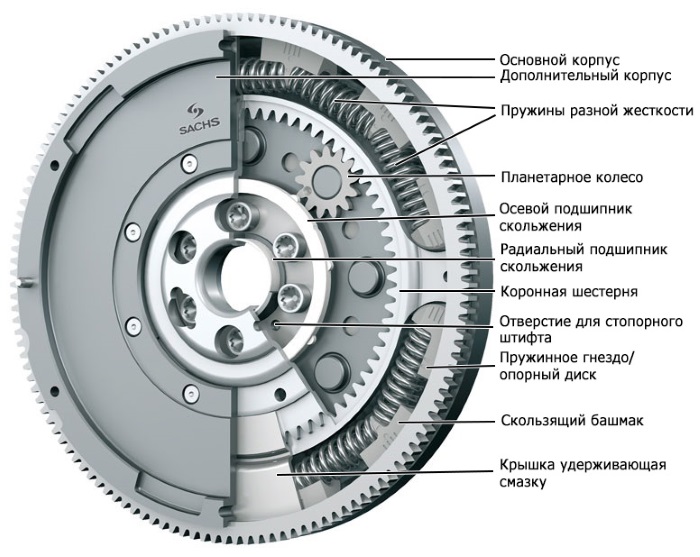

The design of the two-mass type contains not 1, but 2 disks. One disc is connected to the motor, and the second disc is connected to the gearbox. Both can function independently of each other. In addition, the first disc has a flywheel crown with teeth to engage with the starter. Both bearings (axial and radial) ensure the union of 2 housings.

Inside the discs is an improved spring-damper design, which consists of soft as well as hard springs. Soft springs provide softness at low speeds during starting and stopping the motor. Stiffer springs also dampen vibrations at high speeds. Inside is a specialized lubricant.

Principle of operation

For the first time, dual-mass flywheels were received by cars with automatic transmission. A robotic gearbox is characterized by a fast, as well as a fairly frequent gear change. With this "two-mass" copes perfectly. Then, because of these advantages, they began to be installed on cars with a manual transmission.

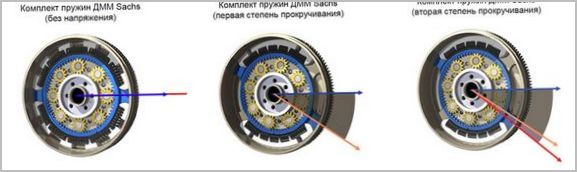

The principle of operation is simple. The torque from the crankshaft goes to the first disk, which deflects the spring system from the inside. Having reached a certain level of compression, the torque goes to the 2nd disc. This design eliminates large vibrations from the motor, allowing you to greatly reduce the load on the transmission.

Pros and cons of a dual mass flywheel

The advantages of such a design are obvious:

- soft and uniform operation of the motor and gearbox;

- low vibration and hum.

However, there are also disadvantages. The average life of a dual-mass flywheel is approximately 3 years. The system is regularly subjected to high loads. In addition, internal lubrication is produced. The replacement cost is quite high. And this is its main disadvantage.

Major faults

The flywheel is subject to powerful loads, so sooner or later it stops working. A sign of its malfunction may be a creak, extraneous noise during the start and stop of the engine.

Feeling a strong vibration can also mean a flywheel malfunction. Many believe that this is due to the "triple" of the motor. If you shift to a higher gear, then the vibrations usually disappear. Clicks during start and acceleration can also indicate malfunctions. However, you do not need to immediately rush to replace the flywheel, as these signs may indicate other problems. For example, with engine mounts, gearbox, attachments, exhaust system and more.

The most accurate way to determine the cause of the breakdown is to directly inspect the part. However, to get to it, it will be necessary to disassemble the checkpoint, and this requires special skills and devices.

Recovery of the dual-mass flywheel

Due to the high price of the "original", almost all drivers are thinking about the possibility of restoring the flywheel. It should be noted right away that the manufacturers do not imply the restoration of this element. It is considered non-separable, so it is better to install a new one.

However, there are still specialists who can get to work. It all depends on the extent of the problem. If the springs fail, they can be replaced in the service. They are the first to wear out. However, if the housing or one bearing has collapsed, then the right decision would be to buy a new one. In each case, few people will be able to guarantee the long-term operation of the motor, as well as the transmission after repair work.

Replacement for single-mass

Purely theoretically, this can be done. A qualified service technician can do this easily. However, does it make sense to do so? No one will be able to predict how long the gearbox and engine will last after that, therefore, for our part, we do not advise doing this!

If you have a powerful engine, as well as a manual transmission, then significant vibrations and shaking cannot be avoided during starting and stopping. You can ride, but with significant discomfort. The robotic box will not be able to withstand a tandem with a cast flywheel, so it will stop working pretty quickly. At the same time, together with the box, restoration will cost much more.