Timing belt for Santa Fe

Content

Hyundai Santa Fe has been in production since 2001. The car is presented in three generations, with diesel and gasoline engines of different sizes. The timing belt of the car is installed depending on the type of engine and partly depending on the year of manufacture of the car.

Timing Belt Santa Fe Diesel

For diesel cars Santa Fe of the first and second generation with a volume of 2,0 and 2,2 liters with D4EA, D4EB engines, the manufacturer installs a timing belt with article number 2431227000. The average price is 1800 rubles. Producer - KONTITECH. Direct analogue of the original - ST-1099. The price of the part is 1000 rubles. Also, along with the timing belt, the rollers change: bypass - 2481027000, average price - 1500 rubles, and tensioner - 2441027000, cost of the part - 3500 rubles.

The same timing belts are installed on Santa Fe Classic 2.0 and 2.2 diesel cars manufactured by the Russian TAGAZ plant.

Characteristics of the original timing belt 2431227000

| Wide | Number of teeth | Weight |

| 28mm | 123 | 180 grams |

The most famous analogues of the original timing belt on the Hyundai Santa Fe:

- 5579XS. Manufacturer: Doors. The average price is 1700 rubles A high-quality analogue, not inferior in quality to the original. This model is branded XS, which means a more reinforced construction;

- 123 EN28. Producer - DONGIL. Price - 700 rubles. The main advantage of this spare part model is its cost and acceptable quality.

Since 2010, diesel Santa Fe vehicles have been fitted with timing chains instead of belts. The reason for this is the installation of a D4HB diesel engine, with a chain drive. Factory part 243612F000. The average price is 2500 rubles.

Timing Belt Santa Fe 2.4

All 2,4-liter Santa Fe gasoline cars with G4JS-G and G4KE engines are factory equipped with a timing belt with article number 2431238220. The average price is 3400 rubles. This replacement model may also be sold under the old part number 2431238210. Supplied by Contitech. Manufacturer's analogue - CT1075. The average price is 1200 rubles. Together with the Santa Fe 2.4 gasoline timing belt, the following parts change:

- Tension roller - 2445038010. Price - 1500 rubles.

- Hydraulic tensioner - 2441038001. Price - 3000 rubles.

- Bypass roller - 2481038001. Price - 1000 rubles.

On Hyundai Santa Fe Classic 2.4 gasoline (engine modification G4JS-G), so the original timing belt 2431238220 is also suitable for it.

Features of the original timing belt 2431238220

| Wide | Number of teeth | Weight |

| 29mm | 175 | 250 grams |

The most famous analogues:

- 1987949623. Manufacturer - Bosch. The average price is 1100 rubles. This item has good customer reviews. Protect the declared resource with minimal wear;

- T-313. Producer - GATE. Price - 1400 rubles. He has only positive reviews. Also a big advantage of this model is that the percentage of fakes on the market is extremely small.

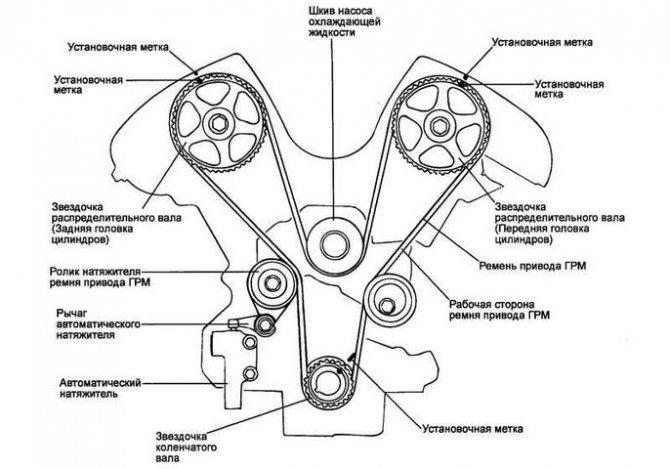

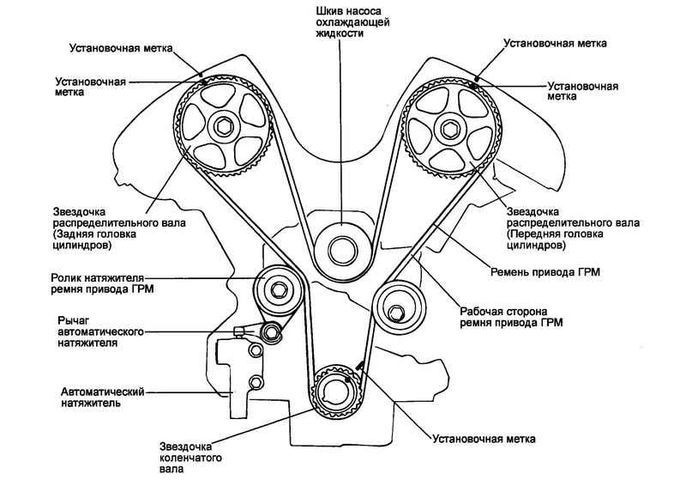

Timing Belt Santa Fe 2.7

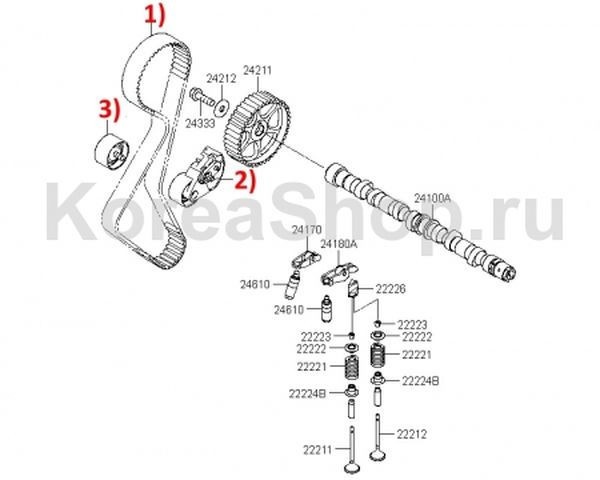

For all generations of 2,7-liter gasoline Santa Fe with G6EA and G6BA-G engines, a timing belt with article number 2431237500 is installed. The average price of one piece is 4200 rubles. The manufacturer is the same as in all the others: Contitech. Direct analogue - part CT1085. The cost is 1300 rubles. Together with the timing belt, we change:

- tension roller - 2481037120. Price - 1000 rubles.

- bypass roller - 2445037120. Price - 1200 rubles.

- hydraulic tensioner - 2441037100. Price - 2800 rubles.

The same engines are installed on the gasoline Hyundai Santa Fe Classic with a volume of 2,7 liters. Therefore, the original timing belt 2431237500 is also suitable for the Classic.

Features of the original timing belt 2431237500

| Wide | Number of teeth | Weight |

| 32mm | 207 | 290 grams |

The most famous analogues of the original timing belt on Santa Fe 2.7:

- 5555XS. Producer - GATE. The cost of the part is 1700 rubles. Like all parts of this manufacturer, this model is of good quality. It is more popular with buyers than the original. The design of this belt is also reinforced, as the XS marking is present in the name;

- 94838. Manufacturer - DAYCO. The price of the part is 1100 rubles. An excellent option in the price / quality category. Judging by customer reviews, this part copes well with its service life.

When to change

According to Hyundai Santa Fe service standards, both in gasoline and diesel engines, the manufacturer recommends changing the timing belt every 60 thousand kilometers. In fact, original timing belts usually have a longer life span. Many Santa Fe car owners change it after 70-90 thousand kilometers. In this case, after the planned run, it is necessary to constantly monitor the timing belt, since its breakage threatens with bent valves, and in some cases a broken cylinder head.

Why eats timing belt

In total, there are seven main reasons why the timing belt eats up. To begin with, we will simply list and describe them, and in the next section we will talk about how each problem can be solved.

- Incorrect belt tension. In particular, if the belt is too tight, then it is possible that wear occurs at one of its edges, since a significant friction force is formed there.

- Poor quality belt. Sometimes a situation arises when domestic manufacturers produce low-quality belts that are made from material that does not meet standards or in violation of production technologies. Especially if this belt is cheap and of some unknown brand (just a fake). Its cross-sectional surface may not be uniform, but may have the shape of a cone or oval.

- Bomb disposal. In particular, we are talking about the wear of the bearings of the water pump. This can cause the timing belt to slip to one side.

- The pump is installed crooked. However, this is a rather exceptional case, the probability of which is extremely small, because if it is crooked even by a few millimeters (due to the remnants of the old gasket or just dirt), then a coolant leak will appear.

- Roller issues. Like a belt, it can be plain poor quality. Currently, rollers are often made on the basis of single-row bearings, which are resource-intensive and can play. It is also possible that the surface of the bead is not smooth, but rather conical or oval. Naturally, the belt on such a surface will “walk” in one direction or the other.

- Stud thread damage. If the stud nut is overtightened, the threads on the stud itself or the threads inside the aluminum block may become damaged or damaged. Due to this, the stud is not installed strictly perpendicular to the plane, but at a slight angle.

- Roller pin curve. This is the tensioner pulley. A fairly common cause caused by the unprofessional installation of a new tensioner. In this case, a situation often arises when the tightening torque of the eccentric nut is chosen not according to the technical documentation, but “from the heart”, that is, with a margin. This, in turn, leads to the fact that even the slightest displacement (up to 0,1 mm) will lead to the timing belt slipping towards the engine or displacement in the opposite direction.

- The stud may bend if twisted with a torque greater than 4,2 kgf m. The data is relevant for all front-wheel drive vehicles, where this problem is more common.

As practice shows, the last described reason is most common. And motorists have come up with a universal method with which you can correct the situation.

Breakdown elimination methods

Now we list the methods for eliminating these causes. We go in the same order.

Belt tension. First you need to check the tension level and compare it with the recommended car manufacturer (usually indicated in the technical documentation for the car, it can also be found on the Internet). If this value is higher than recommended, then the tension should be loosened. This is done with a torque wrench. If you do not have it, it is best to contact a car service. In extreme cases, you can perform this procedure "by eye", but at the first opportunity, use the indicated devices. You can also use a regular dynamometer and a regular wrench for this.

Poor quality belt. If the stiffness at the two ends of the belt is different, then a situation arises where the distributing roller swallows the belt from the softer side. You can check this by replacing its right and left sides. If after replacement the second side does not wear out, then the fault lies with the belt. There is only one way out - to buy and install a new, better part.

Pump bearing wear. To diagnose this problem, you need to remove the belt and check the backlash of the toothed pulley. If there is play, then the part must be replaced. Bearings cannot be repaired.

The pump is installed crooked. This situation is possible if during the previous replacement the adjacent surface was poorly cleaned and small particles of the old gasket and / or pieces of dirt remained, but if this happened, then you will most likely understand this by a leak that appeared after filling the antifreeze and start the engine. When installing a new pump (or even an old one if it is in good condition), be sure to thoroughly clean both surfaces (including bolt locations) on both the pump and the motor housing, and install a new gasket. In some cases, instead of a gasket, a sealant is placed under the pump.

Roller issues. The video needs to be reviewed. You should have minimal play and a level work surface. To check, you can use a ruler or other similar object of the required width. It also makes sense to check the presence of grease in the bearing. If it's small, add it. If the roller is of poor quality, then it should be replaced. It is almost impossible to repair the bearing, and even more so the surface of the roller.

Stud thread damage. There are two options to remedy this situation. The easiest way is to use an appropriately sized rod to turn the internal thread and/or a die to turn a similar thread on the stud. Another option is more laborious and involves the complete dismantling of the block to restore the specified thread. This method is used if for some reason it is not possible to use a sword.

Roller pin curve. It is almost impossible to fix the pin mechanically. Sometimes (but not in all cases, and this depends on the degree of curvature of the stud and the place of its curvature), you can try to unscrew the stud and screw it back, but from the other side. If the curvature is small, this solution may be successful. However, in most cases, shims are used. We will consider this item separately, since most motorists consider this method a real panacea if the timing belt eats from the engine side or from the opposite side.

Using shims when the belt slips

Sinks can be made independently, for example, from the body of aluminum cans for beer, coffee, or you can use ready-made factory ones. The main thing is that the washers are the same size as the spacer ring that is installed between the block and the gear eccentric. There are two options. The first uses factory washers. Thickness and quantity are selected empirically. The use of this method is ambiguous as the washers are flat and therefore the contact plane of the roller will remain parallel to it. However, this method helped some motorists.

Another way is to make crescent washers yourself. The number and width of washers are also selected empirically. The use of such washers is more convenient, since they can be used to change the angle of inclination of the stud and roller so that it forms a normal relative to the plane of the cylinder block housing.

The installation of the washing machine must be carried out according to the diagram shown in the figure. In particular, if the timing belt is slipping towards the engine, the washer(s) should be installed closer to the center of the block. If the belt moves away from the engine, then vice versa - closer to the edge of the block. When mounting the washers, it is recommended to use a heat-resistant sealant that will prevent them from sliding to one side with or without load.