Repair of power accumulators of KamAZ vehicles

Content

The KamAZ vehicle has a dual-circuit pneumatic brake system that ensures the safety of the vehicle in all driving modes. When braking (when you press the brake pedal), compressed air is immediately supplied to the brakes of all wheels. The parking brake blocks only the wheels on the central and rear axles. The main element of operation of the specified brake is the energy accumulator. There are 4 such devices on KamAZ: 1 for each wheel of the rear bogie.

Устройство

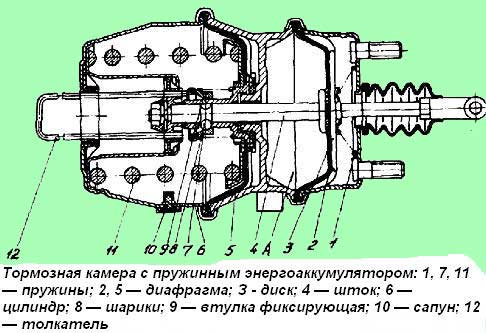

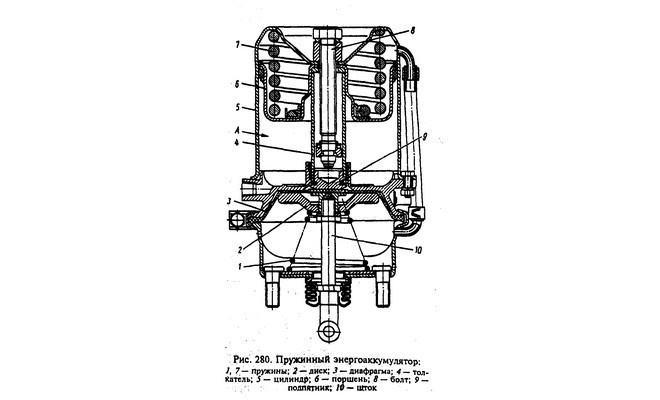

The spring accumulator is installed on the cover of the brake chamber and serves to store the energy of the compressed spring.

The main parts of the device are:

- cylinder;

- piston;

- power spring;

- upstart;

- thrust bearing;

- release screw with roller bearing;

- bypass tube;

- seals.

The battery is attached to the camera with bolts, which ensures a secure connection and eliminates play during operation. Tightness between the cylinder and the brake chamber is ensured by the installation of a sealing rubber ring. A nut for the unlocking screw is welded to the top of the housing. At the bottom of the cylinder there is a threaded fitting through which the pneumatic line is connected.

The tubular pusher is welded to a metal piston with a rubber sealing ring. The steel power spring is located in the piston groove and rests against the top of the cylinder. The pusher has a thrust bearing that transmits force to the brake chamber rod through the membrane.

The screw is used for manual reset when there is a lack of compressed air in the system due to a compressor failure or a faulty receiver. A roller bearing and 2 thrust rings are installed at the bottom of the auger.

The cavity located above the piston communicates with the atmosphere through a bypass tube through the brake chamber. Air is supplied to the chamber under the piston from the parking brake control valve. All energy accumulators simultaneously participate in the air analysis.

Various models of KamAZ power accumulators

KamAZ produces energy accumulators and brake chambers according to the classification of the ratio of the membrane area and the area of the energy accumulator piston:

- 20/20

- 20/24

- 24/20

- 30/30

KAMAZ 65115 is equipped with a model 6520 power accumulator with a reinforced spring of class 30/24.

Type 5320 20/20 is also common.

Such energy accumulators provide safety, as they are responsible for the emergency and parking brake system, which works with the engine turned off and without a constant supply of compressed air.

Principle of operation

In the parking lot, the car is held by the brake system of the rear wheels of the trolley, which is driven by spring accumulators. The crane with the parking brake control handle is located to the right of the driver's seat. The principle of operation of the energy accumulator is simple and is based on the effect of the energy released by the power springs on the driving elements of the brake system.

When the parking brake is applied, compressed air in the lower cavity of the hydraulic accumulator cylinder is released into the atmosphere. The spring, straightening, moves the piston down. Together with it, the pusher moves, which transfers force to the diaphragm and the rod of the brake chamber. The latter rotates the axle through a lever, the opening fists of which press the brake pads against the drum, thereby blocking the wheels of the rear bogie of the truck.

If the air brake reservoir or circuit is damaged, the air in the line escapes to the atmosphere. The released spring activates the parking brake and blocks the wheels. After releasing (unlocking) the wheels, you can continue driving the truck.

How to release

To release the parking brake, the control handle must be released from the latch and moved to the lowest position. The control compressed air through the pneumatic line through the open valve enters the throttle valve, which starts the flow of the working fluid from the receiver through the bypass valve into the lower cavity of the energy accumulator. The piston moves up and compresses the spring. Brake rods return to their original position and release the pads. The truck is ready to move.

If there is no air in the system or the engine (compressor) fails and the vehicle needs to be towed, the energy accumulator must be released manually. To do this, use a socket wrench to unscrew the bolts on the cylinders of all batteries. Due to the presence of a thrust bearing, the force will be transmitted to the piston, which, moving, will compress the power spring. After removing the load, the return spring will move the diaphragm and the rod with the support disk to the upper position. The brake pad actuators will reset and unlock the wheels.

Often on flights there are situations when it is necessary to repair the KamAZ power accumulator with your own hands in the field. The design of the device allows you to do this. However, it will be much easier to replace a faulty power accumulator with a repairable one and repair it in the garage.

How to remove and disassemble

To repair a defective battery, it must be removed from its original location. To do this, remove the air hoses and unscrew the 2 nuts that secure the device to the base. Disassembly is carried out using a "balloon" key. To remove the brake chamber rod assembly and the shoe drive, it is necessary to unscrew and remove the conical gasket from the seat.

Before repairing the device, it is necessary to remove the bypass pipe between the cylinder and the brake chamber. Disassembly begins by removing the bottom of the camera. It is attached to the upper body with a clamp. For safe operation, the energy accumulator is installed with the cylinder down and fixed in a vice. After disassembling the clamp, by lightly tapping on the camera body, it is released from its seat.

When performing these works, care must be taken, since under the action of the return spring the cap can “shoot out”.

The weak point of the brake chamber is the membrane. The defective element must be replaced.

Due to the low corrosion resistance of the cylinder body material, cavities and pittings form on the inner surface. This is facilitated by the ingress of moisture and dirt on the glass in the upper part of the energy storage. All this leads to a violation of the tightness of the cavities and, as a result, to the failure of the entire device. To eliminate the defect, it is necessary to replace the glass of the cylinder or try to polish the inner surface. And this leads to a complete disassembly of the cylinder.

To detach the upper part of the battery from the camera cover, it is necessary to unscrew the M8 screws located along the perimeter of the case. The remaining 2 bolts will not allow the cover to "turn off" the spring. Use a clamp or press to compress the spring and loosen the rest of the fasteners. Masters involved in such repairs professionally prefer a lathe.

The barrel is attached to the cartridge and the spring is compressed by the head. After unscrewing the remaining bolts with the stem fully depressed, they begin to slowly retract. All sealing elements were replaced with new ones from the repair kit. The assembly of the cylinder is carried out in the reverse order. The repaired device is checked on the stand by compressed air supply. Installation of the power accumulator in a regular place is carried out after receiving positive test results.

How to disassemble the KamAZ power accumulator without a stand

The most convenient way to disassemble the KamAZ spring energy accumulator is to use a special bracket. It is usually used at service stations and repair shops, but what if the breakdown occurred far from them? You can do it without support.

First you need to remove the air hoses and disconnect the energy accumulator from the pneumatic chamber. In addition, the entire process must be carried out in strict sequence. Find videos and photos showing in detail how to disassemble can be freely available on the Internet.

It is necessary to unscrew the pusher, remove the sealing ring, and then, slightly loosening the cylinder screw, disconnect the flange. Install the cylinder in place, remove the retaining ring. Fully relax the spring, releasing the piston, remove it and the spring-cylinder. Remove the piston guide ring, unscrew the cylinder screw, remove the sealing washer.

Assembly is carried out in the reverse order, the parts on which friction is exerted must be lubricated.

Faults and repair of the energy accumulator

Energy storage plays an important role in pneumatic brake application. The most common malfunction is system depressurization. Air hoses should be checked for air leakage. The most likely place for such a breakdown is the connections of pipes and hoses, which should be paid more attention to when diagnosing. If a problem occurs at the junction, then it is eliminated by pinching the hose; if the hose passes air, then it must be replaced.

A common cause of poor brake performance is damage to the energy storage housing: it may have a dent or corrosion, as the metal of the housing is not resistant to wear. The cylinders begin to let air through, which leads to depressurization of the entire system. In this case, the cylinder glass must be replaced.

On the Internet, you can easily find videos that show step by step the process of disassembling and disassembling the energy accumulator, as well as solving some problems.

How much does it cost?

The price of the goods depends on the modification, manufacturer and region of purchase. A restored power device at an enterprise for KamAZ type 20/20 in the central regions of Russia can be purchased for 1500-1800 rubles. A similar new model costs from 4 to 6 thousand rubles. The price of more powerful devices, such as 30/30, ranges from 10 to 13,5 thousand rubles. Given that the cost of a repair kit is about 300 rubles, it makes sense to restore faulty devices.