CCGT repair on MAZ vehicles

Content

The CCGT unit on the MAZ is designed to reduce the force required to disengage the clutch. The machines have components of their own design, as well as imported Wabco products. For example, PGU Vabko 9700514370 (for MAZ 5516, 5336, 437041 (Zubrenok), 5551) or PGU Volchansky AZ 11.1602410-40 (suitable for MAZ-5440). The principle of operation of the devices is the same.

The device and the principle of operation

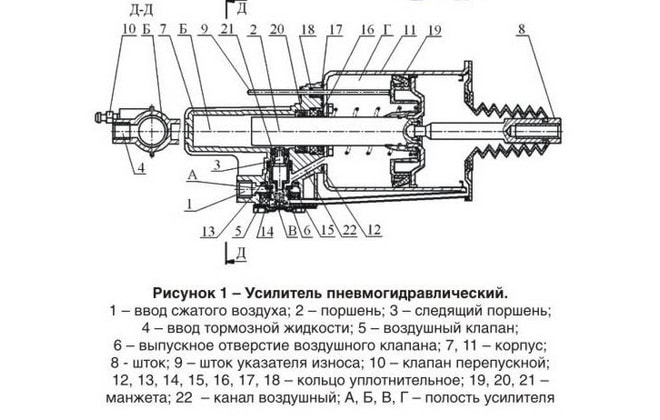

Pneumohydraulic amplifiers (PGU) are produced in various modifications, differing in the location of the lines and the design of the working bar and protective casing.

The CCGT device includes the following parts:

- a hydraulic cylinder mounted under the clutch pedal, together with a piston and a return spring;

- pneumatic part, including a piston, a rod and a return spring common to pneumatics and hydraulics;

- a control mechanism equipped with a diaphragm with an exhaust valve and a return spring;

- valve mechanism (inlet and outlet) with a common stem and an elastic element for returning parts to a neutral position;

- liner wear indicator rod.

To eliminate gaps in the design there are compression springs. There are no gaps in the connections with the clutch control fork, which allows you to control the degree of wear of the friction linings. As the thickness of the material decreases, the piston plunges deeper into the amplifier housing. The piston acts on a special indicator that informs the driver about the remaining clutch life. Replacement of the driven disc or pads is required when the probe length reaches 23 mm.

The clutch booster is equipped with a fitting for connecting to the regular pneumatic system of the truck. Normal operation of the unit is possible at a pressure in the air ducts of at least 8 kgf/cm². There are 4 holes for M8 bolts for attaching the CCGT to the truck frame.

How the device works:

- When you press the clutch pedal, the force is transferred to the piston of the hydraulic cylinder. In this case, the load is applied to the piston group of the pusher.

- The follower automatically starts to change the position of the piston in the pneumatic power unit. The piston acts on the control valve of the pusher, opening the air supply to the cavity of the pneumatic cylinder.

- Gas pressure applies force to the clutch control fork through a separate stem. The pushrod chain automatically adjusts pressure based on how hard your foot presses on the clutch pedal.

- When the pedal is released, fluid pressure is released and then the air supply valve closes. The piston of the pneumatic section returns to its original position.

Malfunctions

CCGT malfunctions on MAZ vehicles include:

- Jamming of the assembly due to swelling of the sealing sleeves.

- Delayed actuator response due to thick fluid or actuator pushrod piston sticking.

- Increased effort on the pedals. The cause of the malfunction may be the failure of the compressed air supply valve. With a strong swelling of the sealing elements, the pusher jams, which causes a decrease in the efficiency of the device.

- Clutch does not fully disengage. The defect occurs due to incorrect setting of the free play.

- Lowering of the liquid level in the tank due to cracks or hardening of the sealing sleeve.

Service

In order for the clutch system (single-disk or double-disk) of the MAZ truck to work properly, it is necessary to carry out maintenance not only of the main mechanism, but also of the auxiliary one - the pneumatic booster. Site maintenance includes:

- firstly, the CCGT should be inspected for external damage that could lead to fluid or air leakage;

- tighten all fixing screws;

- drain the condensate from the pneumatic booster;

- it is also necessary to adjust the free play of the pusher and the release bearing clutch;

- bleed the CCGT and add brake fluid to the system reservoir to the required level (do not mix fluids of different brands).

How to replace

The replacement of the CCGT MAZ provides for the installation of new hoses and lines. All nodes must have an internal diameter of at least 8 mm.

The replacement procedure consists of the following steps:

- Disconnect the lines from the previous assembly and unscrew the attachment points.

- Remove the assembly from the vehicle.

- Install the new unit in its original place, replace the damaged lines.

- Tighten the attachment points to the required torque. Worn out or rusty fittings are recommended to be replaced with new ones.

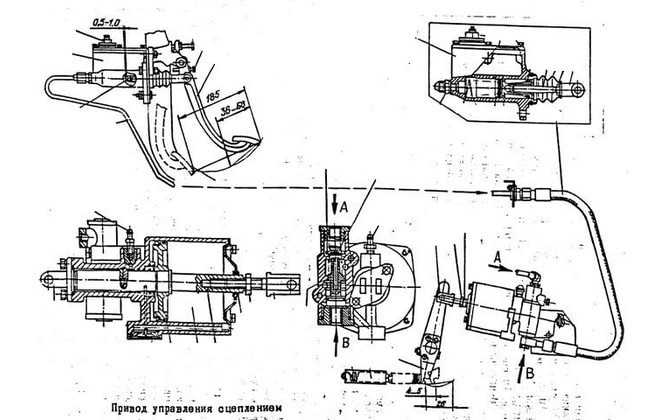

- After installing the CCGT, it is necessary to check the misalignment of the working rods, which should not exceed 3 mm.

How to adjust

Adjustment means changing the free play of the release clutch. The gap is checked by moving the fork lever away from the spherical surface of the booster pusher nut. The operation is performed manually, to reduce the effort, it is necessary to disassemble the lever spring. Normal travel is 5 to 6 mm (measured over a 90 mm radius). If the measured value is within 3 mm, it must be corrected by turning the ball nut.

After adjustment, it is required to check the full stroke of the pusher, which must be at least 25 mm. The test is performed by fully depressing the clutch pedal.

At lower values, the booster does not fully disengage the clutch discs.

Additionally, the free play of the pedal is adjusted, corresponding to the beginning of the operation of the master cylinder. The value depends on the gap between the piston and the pusher. A travel of 6-12mm measured at the middle of the pedal is considered normal. The clearance between the piston and the pusher is adjusted by turning the eccentric pin. Adjustment is made with the clutch pedal fully released (until it comes into contact with the rubber stop). The pin rotates until the desired free play is reached. The adjusting nut is then tightened and the shear pin installed.

How to pump

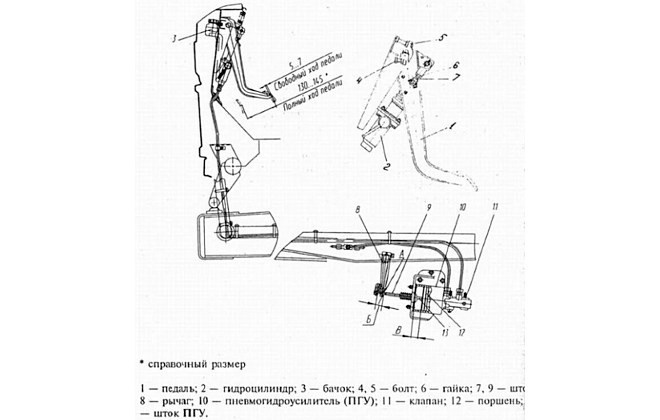

There are two ways to properly pump the CCGT. The first is with a homemade supercharger. CCGT pumping at MAZ is carried out as follows:

- Make a homemade pressure device from a plastic bottle with a capacity of 0,5-1,0 liters. Holes are drilled in the lid and bottom, into which nipples for tubeless tires are then installed.

- From the part installed on the bottom of the tank, it is required to remove the spool valve.

- Fill the bottle with new brake fluid to 60-70%. Close the valve opening when filling.

- Connect the container with a hose to the fitting installed on the amplifier. A spoolless valve is used for connection. Before installing the line, it is required to remove the protective element and loosen the fitting by turning it 1-2 turns.

- Supply compressed air to the cylinder through the valve mounted on the cap. The gas source can be a compressor with a tire inflation gun. The pressure gauge installed in the unit allows you to control the pressure in the tank, which should be within 3-4 kgf / cm².

- Under the action of air pressure, the liquid enters the cavity of the amplifier and displaces the air inside.

- The procedure continues until the disappearance of air bubbles in the expansion tank.

- After filling the lines, it is necessary to tighten the fitting and bring the liquid level in the tank to the required value. A level located 10-15 mm below the edge of the filler neck is considered normal.

A reverse pumping method is allowed, when liquid under pressure is supplied to the tank. Filling continues until no more gas bubbles come out of the fitting (previously unscrewed by 1-2 turns). After refueling, the valve is tightened and closed from above with a rubber protective element.

You can familiarize yourself with the second method in detail by watching the video below, and the pumping instructions are quite simple:

- Loosen the stem and fill the tank with working fluid.

- Unscrew the outlet valve and wait 10-15 minutes for the fluid to drain off by gravity. Substitute a bucket or basin under the jet.

- Remove the lever rod and press it hard until it stops. Fluid will actively flow out of the hole.

- Without releasing the stem, tighten the fitting.

- Release the accessory to return it to its original position.

- Fill the tank with brake fluid.

After bleeding the CCGT coupling, it is recommended to check the condition of the connecting rods, which should not be deformed. In addition, the position of the brake pad wear sensor is checked, the rod of which should not protrude from the pneumatic cylinder body by more than 23 mm.

After that, you need to check the operation of the amplifier on a truck with a running engine. If there is pressure in the pneumatic system of the car, it is necessary to depress the pedal to the stop and check the ease of gear shifting. Gears should shift easily and without extraneous noise. When installing a box with a divider, it is required to check the operation of the assembly unit. In the event of a malfunction, the position of the control arm must be adjusted.

What hydraulic clutch bleeding method do you use? Poll functionality is limited because JavaScript is disabled in your browser.

- one of those described in the article 60%, 3 votes 3 votes 60% 3 votes - 60% of all votes

- own, unique 40%, 2 votes 2 votes 40% 2 votes - 40% of all votes