Nissan Qashqai Silent Blocks

Content

During the operation of the car, its structural parts and components are subjected to vibration loads. Over time, mechanical vibrations of varying degrees of intensity lead to the destruction of parts of the functional units of the car.

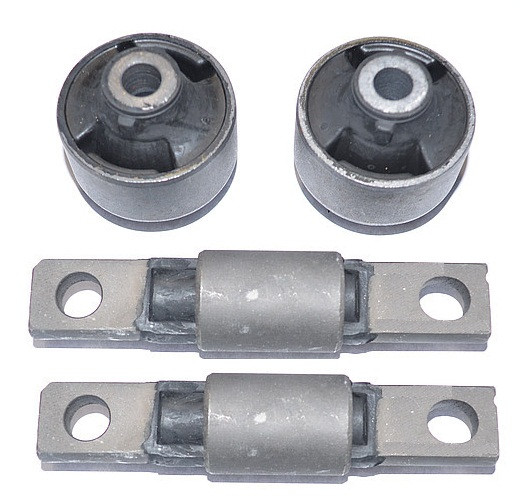

To level vibrations and vibrations in the car design, special elements are used - silent blocks (non-separable rubber and metal hinges). According to many car owners, silent blocks on Nissan Qashqai cars are quite a weak spot.

General information

The silent block is a non-separable anti-vibration element consisting of two metal bushings (internal and external). Between themselves, the bushings are connected by a vulcanized layer of elastomer (rubber or polyurethane). The main task of the elastic insert is to absorb and dissipate perceived vibrations.

Vibration isolators are used in the front and rear suspension arms. They are attached to the levers, shock absorbers, engine, gearbox, jet propulsion.

As the car is used, the elastic insert between the bushings of silent blocks gradually begins to crack and collapse. As wear increases, the elastomer absorbs less and less vibrations, which immediately affects the behavior of the machine.

Nominal and real life of vibration isolators

The nominal resource of silent blocks is designed for 100 thousand kilometers. However, under the conditions of domestic roads, the recommended replacement interval for these elements is every 50 thousand kilometers.

Practical observations also indicate a lower resource of individual groups of vibration isolators installed on Nissan Qashqai cars. So, the service life of the silent blocks of the front levers varies by only 30 thousand kilometers, and the rear silent blocks of the front subframe - by 40 thousand kilometers.

Signs of wear or failure of silent blocks

The fact that the bushings of the Nissan Qashqai subframe or their other components require careful diagnosis with possible subsequent replacement is evidenced by the following signs:

- reduced vehicle maneuverability;

- deterioration in manageability;

- uneven braking;

- increase the speed of the reaction of transport to the steering wheel;

- pull the car to the side when driving at high speed;

- jerks and vibrations of the body while driving;

- uneven tire wear.

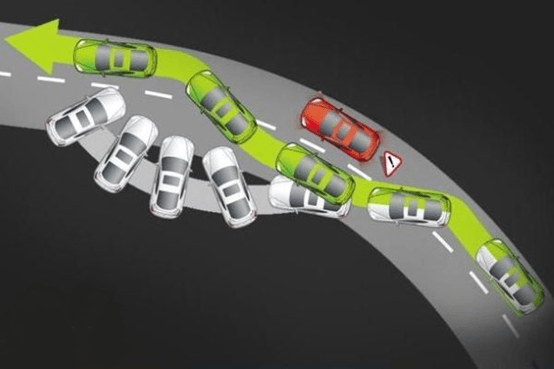

Ignoring such signs is quite dangerous. The deterioration of the operational properties of silent blocks leads not only to premature wear of the structural parts and mechanisms of the car, but also to a decrease in its controllability. Together, these changes can cause an emergency.

In addition to a safety hazard for the driver, worn bushings can cause destruction of other parts and mechanisms. This threatens with costly repairs, up to the complete replacement of functional units.

Diagnostics

You can independently assess the condition of the vibration isolators by performing a visual inspection of the chassis. To do this, the car is installed in the elevator or on top of the gazebo. Remove ball joints if necessary.

Next, the condition of parts functionally related to silent blocks is assessed:

- swing the suspension arms - serviceable arms do not sink, but, having jumped, return to their original position;

- inspect the sleeve: it should not rotate relative to the protrusions;

- inspect the vibration isolating element itself for cracks and deformations;

- check if there is any play in the silent blocks - the larger it is, the sooner it will need to be replaced.

Which is better: polyurethane or rubber products?

Depending on the elastomer used between the bushings, a distinction is made between polyurethane and rubber bushings.

Polyurethane products are more expensive, but have such advantages as:

- high degree of strength;

- longer service life (about 5 times;

- resistance to low temperatures.

Such products are often used for racing cars. They are optimal in severe operating conditions, where suspension stiffness and precise vehicle control are important.

Rubber vibration isolators are less durable, but more affordable. Rubber, unlike polyurethane, is subject to rapid abrasion and wear. However, at the same time, rubber products provide the car with a smoother ride and smoother handling.

Therefore, when choosing suitable Nissan Qashqai silent blocks, it is advisable to focus on the operating conditions of the car. If they require maximum strength from the machine, then the rational solution would be to purchase polyurethane products. If the crossover is operated in a smooth mode, rubber vibration isolators are optimal.

Replacing the silent blocks of the stretcher

On Nissan Qashqai cars, there are 4 anti-vibration elements on the subframe. To increase the total resource, it is desirable to replace all elements at once.

Recommended catalog numbers of spare parts: 54466-JD000 - front; 54467-BR00A - rear.

Replacement is done as follows:

- the car is fixed on a lift or on a viewer;

- put the steering wheel in the "straight" position;

- remove the intermediate shaft;

- unscrew the bolt securing the connection of the steering mechanism and the hinge;

- remove the rubber pad from the bracket;

- remove the pivot pin;

- disassemble the supports and the ball;

- the subframe is disassembled;

- use a drift or hammer to remove the worn bushing.

Then install a new replacement part and assemble the assembly in reverse order.

Replacing the silent blocks of the front suspension arm

To replace the vibration isolators of the front arms, it is necessary to install the machine on a lift or on a TV viewer. Remove the wheel from the side being repaired.

Farther:

- unscrew the ball nut;

- release the ball;

- unscrew the bolts of the vibration isolator (first the front, then the rear);

- remove the lever;

- press the old vibration isolator into the press or hit it with a mallet;

- a new vibration isolator is pressed in and the assembly is assembled.