Repair of the steering gear VAZ 2106: device, malfunctions and their elimination

Content

The steering of the car must always be in good condition. The safety of driving a vehicle directly depends on its functioning. At the slightest manifestation of signs of malfunction, diagnostics are necessary, and then repair or replacement of the assembly, which can be done by hand.

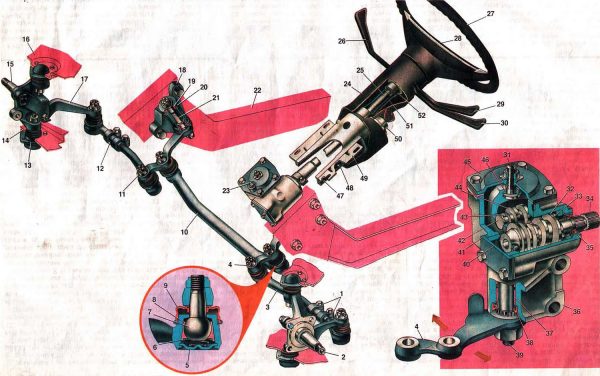

Steering gear VAZ 2106

The "six" uses a worm-type steering gear with a gear ratio of 16,4. It consists of the following nodes:

- steering wheel;

- steering shaft;

- worm-gear;

- steering rods.

One of the main nodes in the steering mechanism is the steering column.

One of the main nodes in the steering mechanism is the steering column.

Steering column VAZ 2106

The main purpose of the steering column is to transmit rotational movement from the steering wheel to the front wheels. Throughout the "classic" structurally identical nodes are used. The mechanism is attached to the left side member with three bolts. A bolt is located on the top cover, with the help of which the gap between the roller and the worm is adjusted. The need to set the gap arises when a large backlash appears in the mechanism. The gearbox and steering wheel are connected to each other through an intermediate shaft, which is mounted on splines that prevent it from turning.

Steering column device

In the crankcase of the steering mechanism, a worm shaft is installed on two bearings that do not have an inner race. Instead of the inner ring, special grooves are used on the ends of the worm. The required clearance in the bearings is set by means of gaskets, which are located under the bottom cover. The exit of the worm shaft from the housing is sealed with a cuff. On the side of the spline connection on the shaft there is a recess for the bolt connecting the gearbox shaft to the shaft from the steering wheel. A special roller is engaged with the worm, located on the axis and rotating with the help of a bearing. The bipod shaft at the outlet of the housing is also sealed with a cuff. A bipod is mounted on it in a certain position.

On the "Zhiguli" of the sixth model, the steering mechanism works in this order:

- The driver turns the steering wheel.

- The impact is transmitted through the shaft to the worm element, which reduces the number of revolutions.

- When the worm rotates, the double-ridged roller moves.

- A lever is installed on the bipod shaft, by means of which the steering rods are actuated.

- The steering trapezoid acts on the steering knuckles, which turn the front wheels in the right direction and at the required angle.

Steering column problems

The appearance of problems in the steering mechanism can be judged by the characteristic features:

- creak;

- backlash;

- grease leaks.

If any of the listed defects appear, repair should not be delayed.

Creaks in the column

The appearance of squeaks can be caused by the following reasons:

- excessive play in the wheel bearings. To fix the problem, it is necessary to adjust the clearance or replace the bearings;

- the tie rod pins are loose. The way out of the situation is to tighten the nuts;

- large play between the pendulum and bushings. The malfunction is eliminated by replacing the bushings;

- wear on the worm shaft bearings can manifest itself in the form of squeaks when the wheels are turned. To solve the problem, adjust the clearance in the bearings or replace them;

- loose fasteners of the swing arms. The way out of the situation is to tighten the nuts with the direct setting of the wheels.

Oil leak

Leakage of grease from the steering column on the "classic" is a fairly common phenomenon. This is due to the following:

- damage (wear) of the stuffing box on the shaft of the bipod or worm. The problem is solved by replacing the cuffs;

- loosening the bolts securing the crankcase cover. To eliminate the leak, the bolts are tightened diagonally, which ensures the tightness of the connection;

- damage to the seal under the crankcase cover. You will need to remove the cover and replace the gasket.

Tight steering

There can be several reasons for the steering wheel to turn tight:

- incorrect alignment of the front wheels. To fix the problem, you will have to visit the service station and carry out adjustment work;

- deformation of any part in the steering. Tie rods are usually subjected to deformation, due to their low location and mechanical influences, for example, when hitting an obstacle. Twisted rods must be replaced;

- incorrect gap between the roller and the worm. The required clearance is set with a special bolt;

- strong tightening of the nut on the pendulum. The way out of the situation is to slightly loosen the fasteners.

Steering column repair

Repairing a gearbox, like any other assembly, involves preparing tools and following step-by-step instructions.

Dismantling

Of the tools you will need:

- head 17 and 30 mm;

- long and powerful collar;

- mount;

- a hammer;

- ratchet handle;

- regular open-end wrench 17.

To remove the steering gear, you will need a standard set of tools

To remove the steering gear, you will need a standard set of tools

The procedure for removing a node consists of the following steps:

- We turn out the bolt fixing the shaft and the steering column.

The steering column is connected to the intermediate shaft with a 17 mm bolt

The steering column is connected to the intermediate shaft with a 17 mm bolt - We unbend and remove the cotter pins, after which we unscrew the nuts that secure the tie rods to the bipod.

- We strike with a hammer on the bipod to extract the fingers of the rods.

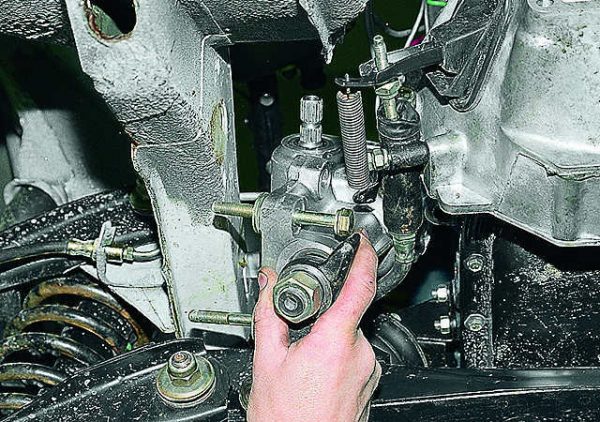

Having unscrewed the nuts, we disconnect the steering rods from the bipod of the steering gear

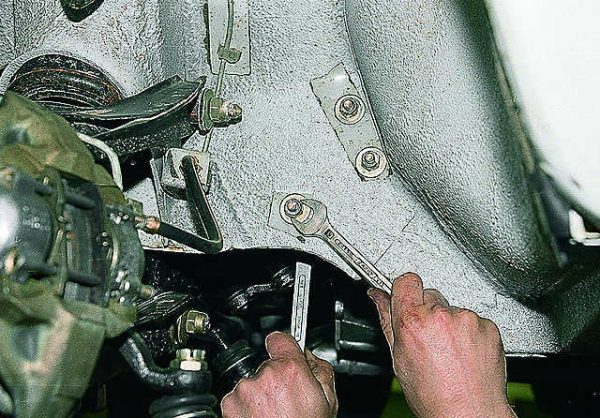

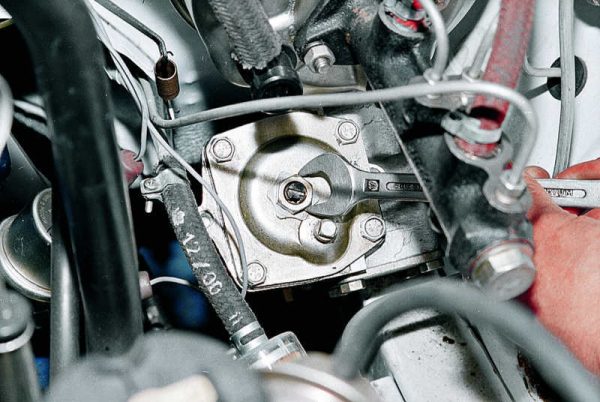

Having unscrewed the nuts, we disconnect the steering rods from the bipod of the steering gear - We unscrew the fasteners of the mechanism to the side member, having previously dismantled the left front wheel.

We remove the left front wheel and unscrew the nuts securing the gearbox to the side member

We remove the left front wheel and unscrew the nuts securing the gearbox to the side member - To keep the bolts from turning from the inside, set the wrench.

To hold the bolts on the opposite side, we instruct the open-end wrench

To hold the bolts on the opposite side, we instruct the open-end wrench - We take the column to the side and take it out from under the hood.

After unscrewing the fasteners, we remove the steering column from under the hood

After unscrewing the fasteners, we remove the steering column from under the hood

How to disassemble

The disassembly of the mechanism is carried out in order to troubleshoot parts and subsequent repairs. From the tools you will need:

- large socket head 30 mm;

- key or head 14 mm;

- puller for gear bipod;

- flat screwdriver;

- a hammer;

- vise.

The procedure consists of the following steps:

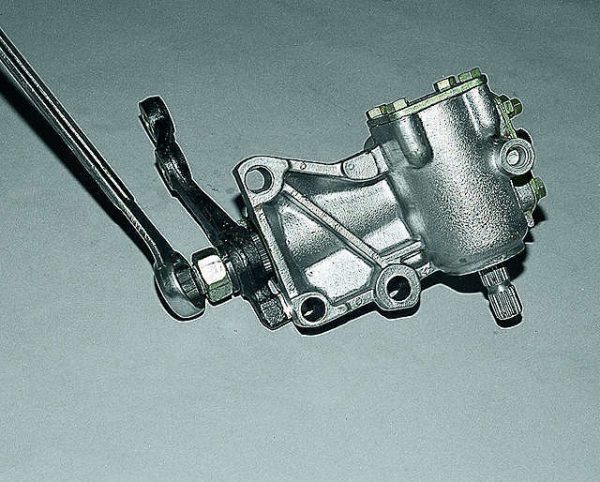

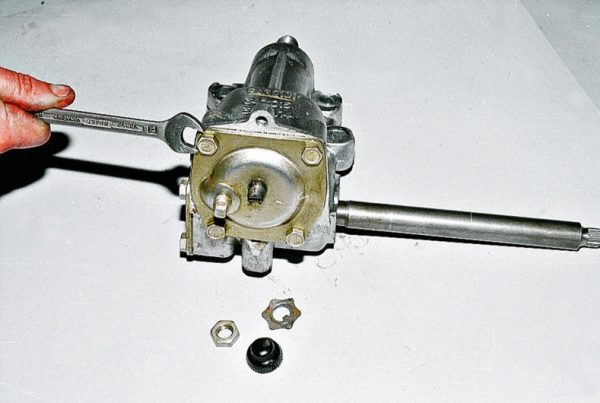

- We unscrew the nut that secures the bipod to the shaft with a wrench, after which we clamp the gearbox in a vice.

Using a 30 mm wrench, unscrew the bipod mounting nut

Using a 30 mm wrench, unscrew the bipod mounting nut - With the help of a puller, we move the bipod from the shaft.

We install the puller and use it to pull the bipod from the shaft

We install the puller and use it to pull the bipod from the shaft - We unscrew the plug for filling the oil and drain the lubricant into a suitable container.

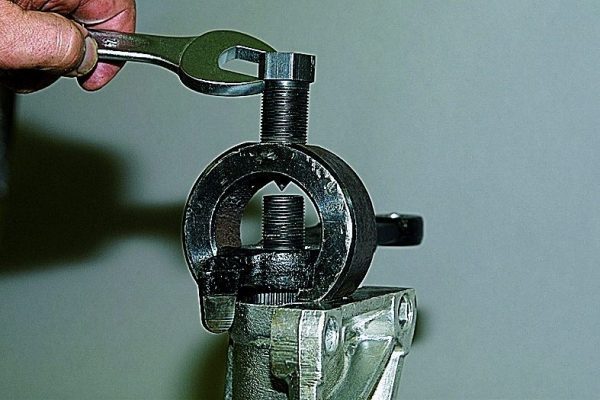

- Unscrew the nut holding the adjustment rod and remove the washer.

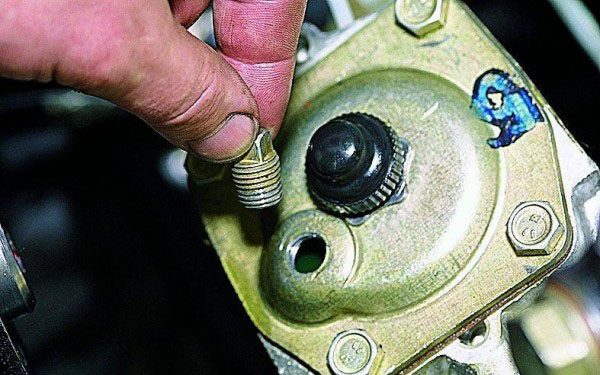

The adjusting screw is held by a nut, unscrew it

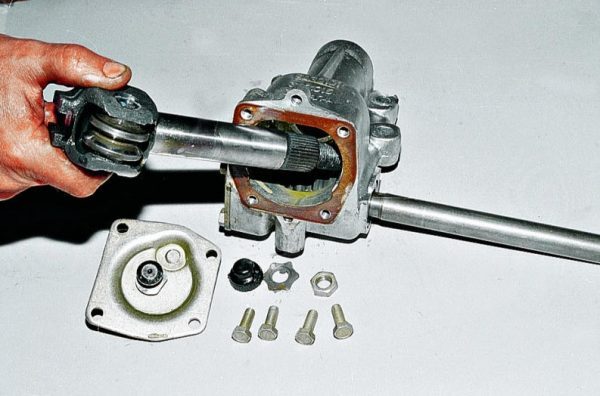

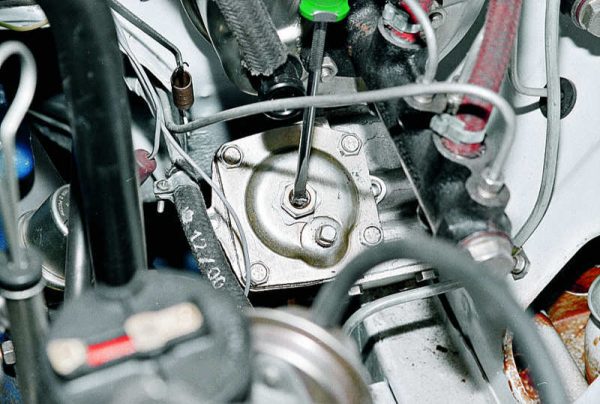

The adjusting screw is held by a nut, unscrew it - With a 14 mm wrench, unscrew the fasteners of the top cover and remove it.

To remove the top cover, unscrew 4 bolts

To remove the top cover, unscrew 4 bolts - We remove the roller and the axis of the bipod from the body.

From the gearbox housing we remove the bipod shaft with a roller

From the gearbox housing we remove the bipod shaft with a roller - Having unscrewed the fasteners, we dismantle the worm cover.

To remove the worm shaft cover, unscrew the corresponding fasteners and remove the part along with the gaskets

To remove the worm shaft cover, unscrew the corresponding fasteners and remove the part along with the gaskets - We knock out the worm shaft and take it out together with the bearings.

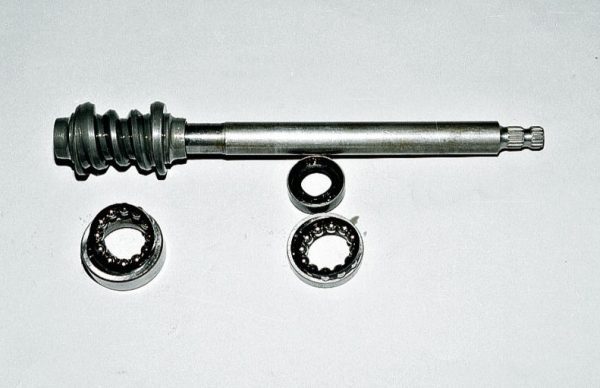

We knock out the worm shaft with a hammer, after which we remove it from the housing along with the bearings

We knock out the worm shaft with a hammer, after which we remove it from the housing along with the bearings - We take out the cuff from the shaft hole by hooking it with a flat screwdriver.

Remove the gearbox seal by prying with a screwdriver

Remove the gearbox seal by prying with a screwdriver - We dismantle the worm bearing and knock out its outer race using a suitable adapter.

To remove the outer race of the bearing, you will need a suitable tool

To remove the outer race of the bearing, you will need a suitable tool

Unit repair

To troubleshoot parts, they are washed in diesel fuel or kerosene. After that, they check the condition of the worm shaft and roller. They must not have any damage. The rotation of the ball bearings of the assembly must be free and without jamming. Structural elements of bearings must be in good condition, i.e., be free from wear, dents and other flaws. The presence of cracks in the gearbox housing is unacceptable. When parts with wear are identified, they are replaced with serviceable elements. Cuffs are changed during any repair work with the column.

Assembly

Transmission oil is applied to the internal elements before assembly, and the process itself consists of the following actions:

- Lightly hit with a hammer on the adapter for pressing the ring of the inner ball bearing into the mechanism housing.

To press the inner bearing race, use a piece of pipe of a suitable diameter

To press the inner bearing race, use a piece of pipe of a suitable diameter - We mount the separator together with the balls in the bearing cage and put the worm in place.

- We put the separator of the outer ball bearing on the shaft and install the outer race.

After installing the worm shaft and the outer bearing, we press the outer race

After installing the worm shaft and the outer bearing, we press the outer race - Install seal and cover.

- We press in new oil seals, after which we lubricate their working surfaces with Litol-24 grease.

- We put the worm shaft in place.

- Using gaskets for adjustment, we select a torque of 2–5 kgf * cm.

- We mount the bipod shaft.

- Install the gearbox in reverse order.

Video: disassembly and assembly of the VAZ steering gear

Oil in the steering column

To reduce friction between the parts inside the assembly, grease is poured into the crankcase. In Zhiguli, for the product in question, oil of class GL5 or GL4 is used with a viscosity class of SAE80-W90. However, some car owners use TAD-17 instead of modern lubricants. The steering column is filled with oil in a volume of 0,2 liters.

Change of oil

On the VAZ 2106, as well as on the other "classic", it is recommended to change the lubricant in the steering mechanism every 20-40 thousand km. More frequent replacement is just a waste of time and money. If it was noticed that the oil had become very dark, and the steering wheel became heavier when cornering, then the lubricant must be replaced as soon as possible. From the tools for work you will need:

- open-end wrench 8 mm;

- 2 medical syringes of large volume;

- tube or hose of small diameter;

- suitable container for draining used oil.

The work is reduced to the following steps:

- We unscrew the plug on the gearbox.

- We put a tube on the syringe and use it to suck out the old grease, pouring it into a container.

Old grease is removed from the steering column with a syringe

Old grease is removed from the steering column with a syringe - Using a new syringe, we collect new oil and pour it into the gearbox.

A new lubricant is drawn into the syringe, after which it is poured into the gearbox

A new lubricant is drawn into the syringe, after which it is poured into the gearbox - We put the plug in place and remove smudges.

When filling oil, it is recommended to shake the steering wheel to release air from the crankcase.

Video: changing the lubricant in the steering column "Lada"

Watch this video on YouTube

Level check

Experienced “classic” car owners claim that oil leaks from the gearbox even when a new mechanism is installed, so periodic checking of the level will be quite useful. To determine the level of lubrication, you will need to perform the following steps:

- We wipe the surface of the node with a rag.

- Unscrew the filler plug.

The filler plug is unscrewed with an 8 mm wrench

The filler plug is unscrewed with an 8 mm wrench - We lower a clean screwdriver or other suitable tool into the hole and check the lubricant level. A level just below the edge of the filler hole is considered normal.

To check the oil level in the gearbox, a screwdriver or other handy tool is suitable

To check the oil level in the gearbox, a screwdriver or other handy tool is suitable - If the level turned out to be less than necessary, bring it to normal and screw in the cork.

Steering column backlash adjustment

The need for adjustment arises after the repair of the assembly or when a large play appears when the steering wheel is turned. If there is a lot of free play in the mechanism, the wheels are somewhat late behind the movement of the steering wheel. To carry out the adjustment you will need:

- flat screwdriver;

- key 19 mm.

We set the steering wheel in the center, after which we perform the following actions:

- Using a 19 mm wrench, unscrew the nut located on top of the steering gear.

The adjustment rod is fixed with a nut, unscrew it

The adjustment rod is fixed with a nut, unscrew it - Remove the lock washer.

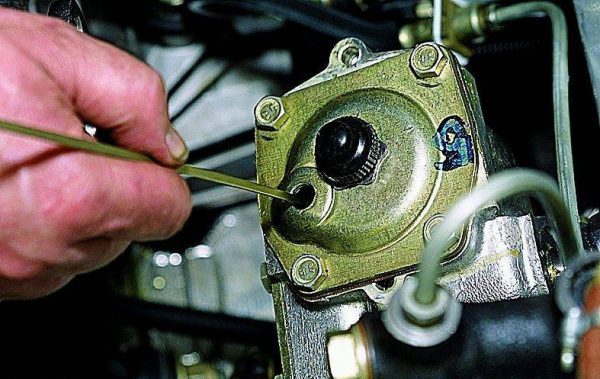

- Turn the stem of the mechanism clockwise by 180˚ with a flat screwdriver.

Using a flat screwdriver, turn the gearbox stem clockwise by 180˚

Using a flat screwdriver, turn the gearbox stem clockwise by 180˚ - Turn the front wheels left and right. The procedure can be considered complete if there is no backlash. Otherwise, we rotate the stem until the free play is minimal, and the steering wheel rotates without much effort and jamming.

- After adjustment, put the washer in place and tighten the nut.

Video: adjusting the backlash of the steering column on the "classic"

Watch this video on YouTube

Pendulum VAZ 2106

A pendulum arm or simply a pendulum is a part that connects the steering rods and the steering gear. The product is located under the hood symmetrically to the steering gear and is mounted on the right side member.

Pendulum replacement

Like other parts of a car, the swingarm is subject to wear and sometimes needs to be repaired or replaced. The following are some of the signs that he has problems:

- when driving on rough roads, knocks are heard;

- large steering wheel play.

When the pendulum breaks, sometimes you have to make a lot of effort to rotate the steering wheel.

It should be taken into account that the listed symptoms can manifest themselves not only with malfunctions of the pendulum lever, but also with a weak tightening of the assembly fastening or an overtightened adjusting nut.

How to remove

For dismantling you will need:

- a set of open-end or spanner wrenches;

- ball pin puller.

The procedure is performed in the following sequence:

- Dismantle the right front wheel.

- We unscrew the fastening of the fingers of the rods to the pendulum lever.

We unscrew the nuts securing the tie rod pins to the pendulum arm

We unscrew the nuts securing the tie rod pins to the pendulum arm - With a puller we pull the fingers off the lever.

- We unscrew the fastening of the pendulum to the side member.

The pendulum is attached to the spar with two bolts.

The pendulum is attached to the spar with two bolts. - We take out the lower bolt immediately, and the upper one - together with the mechanism.

First we take out the lower bolt, and then the upper one together with the pendulum

First we take out the lower bolt, and then the upper one together with the pendulum - Installation after repair or replacement of the pendulum is carried out in the reverse order.

Pendulum repair

Assembly repair is reduced to the replacement of bushings or bearings (depending on the design).

Replacing bushings

Repair is carried out with the following tools:

- key 19 mm;

- vice;

- new bushings;

- Litol-24 grease.

The repair sequence is as follows:

- Clamp the pendulum in a vise. We take out the cotter pin and unscrew the fasteners.

To unscrew the adjusting nut, clamp the pendulum in a vice

To unscrew the adjusting nut, clamp the pendulum in a vice - We take the puck.

Under the nut is a small washer, remove it

Under the nut is a small washer, remove it - We dismantle the large washer by prying it with a screwdriver.

To remove a large washer, you need to pry it with a screwdriver.

To remove a large washer, you need to pry it with a screwdriver. - Remove the bushing and sealing element.

Remove the bushing and o-ring from the axle.

Remove the bushing and o-ring from the axle. - We remove the bracket and remove the second seal.

We remove the bracket and remove the second sealing ring

We remove the bracket and remove the second sealing ring - We hook it with a screwdriver and remove the second sleeve.

Prying with a flat screwdriver, remove the second sleeve

Prying with a flat screwdriver, remove the second sleeve

Troubleshooting and assembly

After disassembling the pendulum, we check the condition of all parts. There must be no defects on the axle and lever (traces of wear, deformation). Bushings with a high mileage of the car are subject to development. Therefore, they have to be replaced with new ones. There should be no cracks or other damage on the bracket. The pendulum is assembled in the reverse order, while Litol-24 is applied to the axis of the pendulum and the hole under it. The adjusting nut must be tightened so that the bipod rotates when a force of 1–2 kg is applied to its end. A dynamometer is used to determine the force.

Video: replacing pendulum arm bushings on the "classic"

Watch this video on YouTube

Bearing replacement

With high vehicle mileage, the bearings in the pendulum begin to bite, wedge, which requires their replacement. Of the tools, you will need the same list as in the previous case, only bearings are needed instead of bushings. Repair consists of the following steps:

- We clamp the part in a vise and unscrew the adjusting nut, but not completely.

Clamping the pendulum in a vice, unscrew the nut, but not completely

Clamping the pendulum in a vice, unscrew the nut, but not completely - We install the pendulum in a vice so that the axis is free, after which we strike the loosened nut with a hammer.

- We completely unscrew the nut and take out the axle with the bipod and the lower bearing.

Having unscrewed the nut, we take out the axle together with the bipod and the lower bearing

Having unscrewed the nut, we take out the axle together with the bipod and the lower bearing - We unscrew the nut holding the bipod, holding the axis in a vice.

To unscrew the nut holding the bipod, clamp the axle in a vice

To unscrew the nut holding the bipod, clamp the axle in a vice - We remove the bearing.

Remove the old bearing from the axle

Remove the old bearing from the axle - We knock out the upper bearing with a suitable tip.

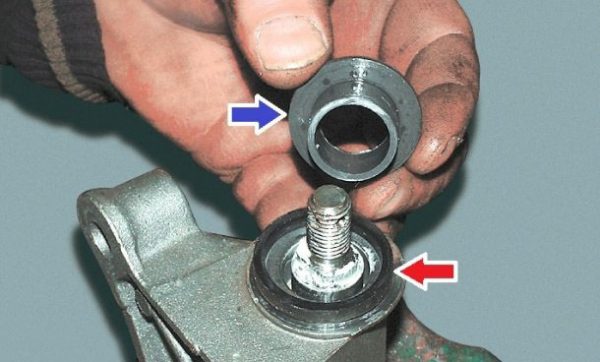

To remove the upper bearing, you will need a suitable tool

To remove the upper bearing, you will need a suitable tool - We clean the pendulum body from dirt and old grease and press the bearings in reverse order through a wooden adapter.

- Tighten the nuts on the axle.

When assembling the pendulum, the bearings are pressed in such a way that the rotation is free, but without play.

Video: repair of a pendulum on VAZ 2101–07 bearings

Watch this video on YouTube

You can repair the steering gear on the VAZ "six" with a garage tool kit consisting of a hammer, keys and screwdrivers. The work does not require special knowledge and skills. After reading the step-by-step instructions, repairs can be performed even by a motorist without experience. The main thing is to be careful when inspecting parts and assembling the mechanism.