Guide to Hole Saw Teeth and TPI

Content

TPI | |

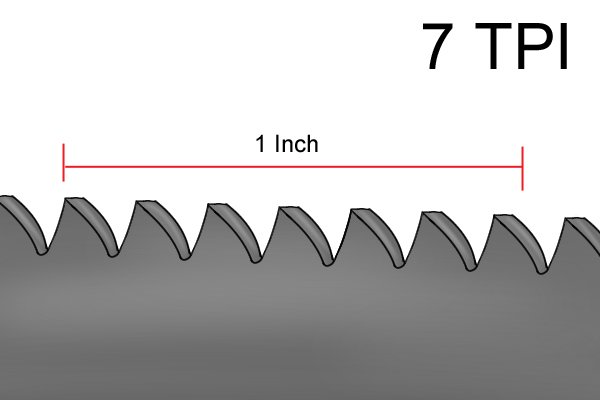

| TPI stands for "teeth per inch" and is a way to measure the frequency of teeth on a saw blade. Usually shortened to TPI, such as "a blade composed of 18TPI". | |

| How does TPI affect hole saw cutting?The TPI of a hole saw can affect: 1. How fast can it cut |

| 2. The quality of the finished cut, such as smooth or rough. |

| 3.Material which is best for cutting |

Cut speed and quality | |

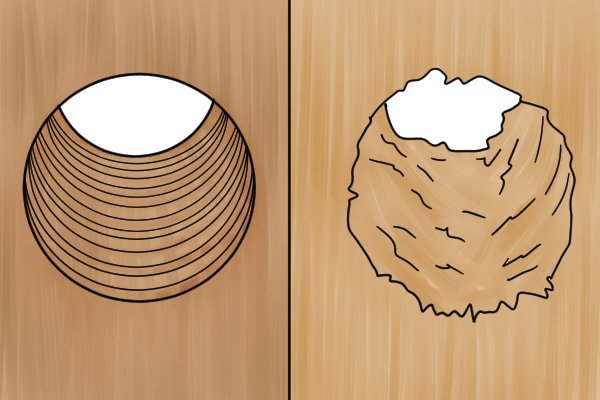

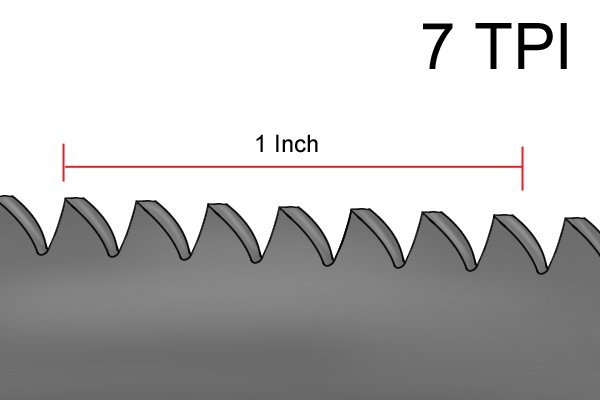

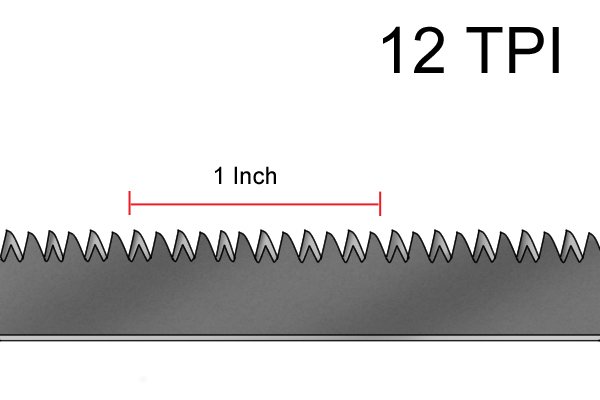

| The number of holesaw teeth per inch varies from type to type, but is typically between 3 and 14 TPI. |

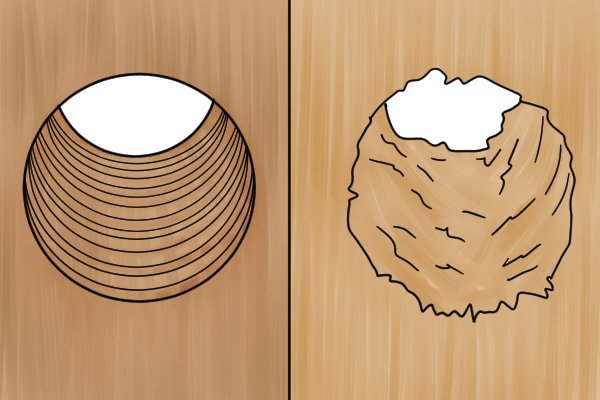

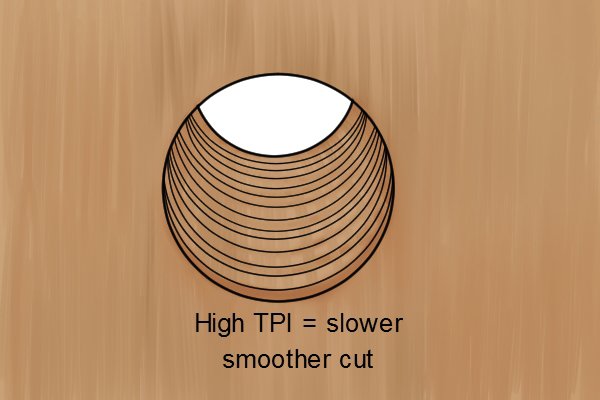

| As a general rule, the fewer teeth per inch a hole saw has, the faster it will cut through a workpiece. However, because the teeth are larger and rougher, they are more likely to tear through the fibers of the material you are cutting and end up with a rougher surface. This would be good for jobs where the accuracy of the hole is less important and where it won't be visible after completion. |

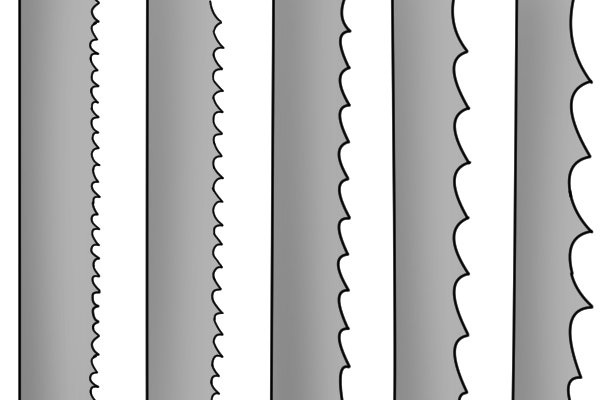

| The more teeth the saw has, the slower it will cut through the workpiece. However, because the teeth are smaller and thinner, they are less likely to tear through the fibers of the material and therefore the final cut will be smoother. A neater hole is needed for jobs where the hole will be visible and precision is required, such as making holes for a set of locks. |

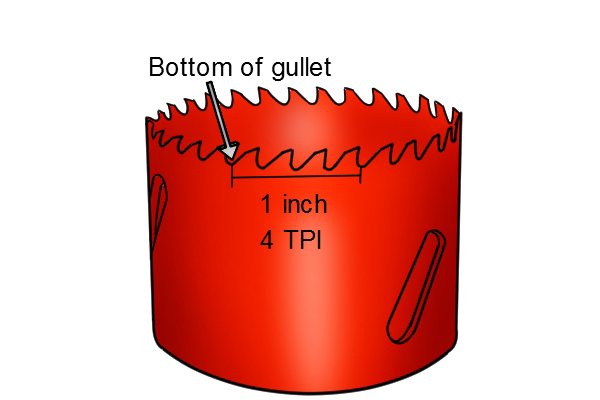

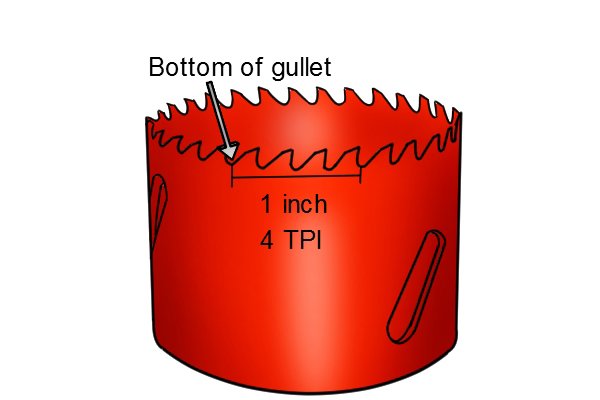

| Low TPI hole saws (1-4 teeth per inch)Low TPI saw blades tend to have larger teeth with deeper cavities between them. These saws cut quickly but are much more aggressive, leaving a rough surface on the workpiece. |

| Hole saws with medium TPI (5-9 teeth per inch)Saw blades with medium TPI tend to be a balance between fast, aggressive sawing and slow, smooth sawing. |

| High TPI Hole Saw Blades (10+ TPI)Saw blades with a high TPI value tend to have smaller teeth with smaller gaps between them. These saws will cut slowly but produce a much thinner and smoother cut. |

TPI measurement | |

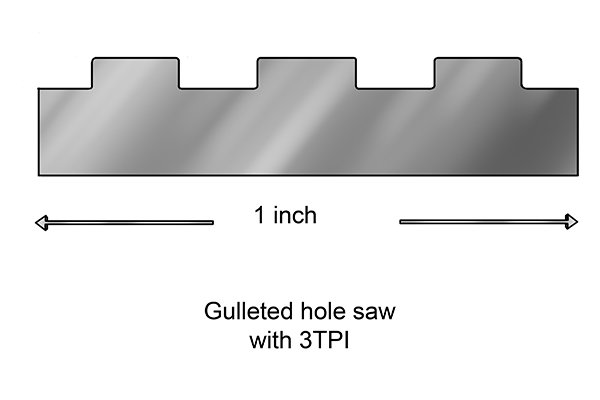

| To find the TPI of a saw blade, start measuring from the middle of the esophagus (usually its lowest point). No matter how many teeth per inch from this point, that's how many teeth per inch your hole saw has. |

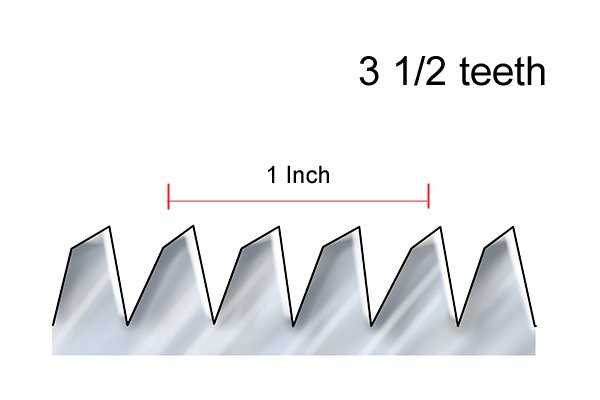

| It is worth noting here that not all circular saws have a round number of teeth per inch. Some hole saws may have 3 ½ steps per inch, for example. |

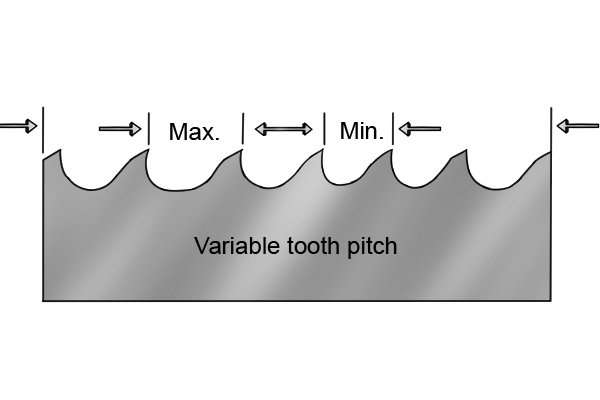

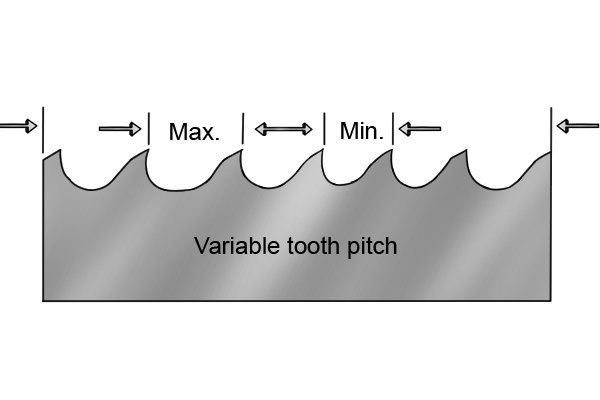

| It's also worth noting that some variable pitch hole saws oscillate and will have a different number of teeth per inch compared to the next inch along the saw blade. For example, this can be expressed as 4/6 TPI. This means it has 4 to 6 teeth per inch. |

Materials | |

| It is difficult to say with any certainty that a particular TPI is suitable for cutting a certain material, since other important factors must be taken into account, such as the material from which the teeth of the hole saw are made. For more information on which hole saws are best for cutting certain materials, see the page titled: What are the types of hole saws? |

Hole saw teeth | |

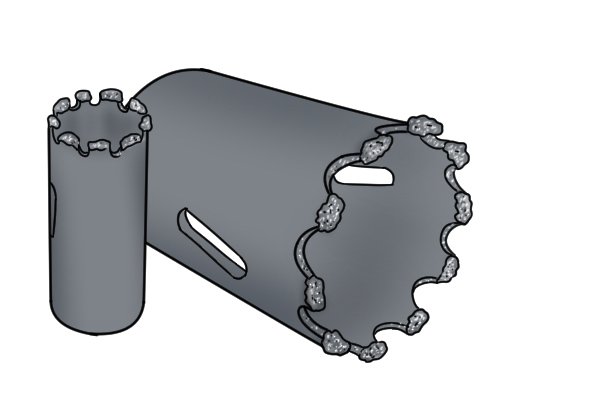

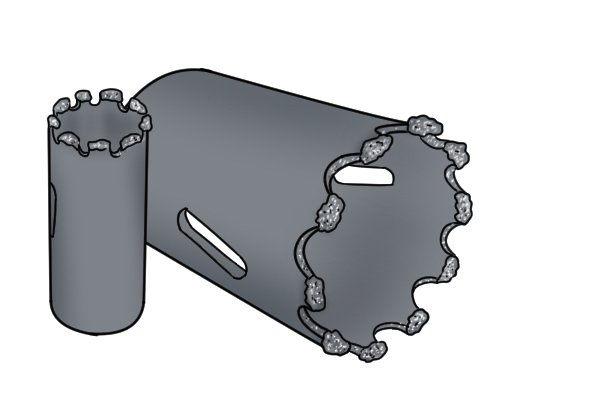

| The teeth of some hole saws are often made from or coated with the material to improve their working properties. Usually to improve hardness, wear resistance and cutting ability. For more information see the page titled: Which material should I choose? |

| Serrated/square teethSponge or square teeth are slightly different from standard saw teeth, but you can still determine their TPI (teeth per inch) by measuring an inch from the middle of its trough (usually the lowest point) and counting how many teeth fall into that inch. . This particular image shows a square toothed hole saw with 3TPI. Serrated or square tooth core saws and core drills are designed for cutting hard abrasive materials such as concrete, masonry, ceramic tile, glass and stone. |