Car steering - how does it work? What are the most common faults?

Content

Steering is one of the most important components of the car - there is no need to convince of this. But it is also one of the most vulnerable components.

Steering is one of the most important components of the car - there is no need to convince of this. But it is also one of the most vulnerable components.

Pits in the road surface, unevenness, sudden changes in loads, changes in ambient temperature and, finally, humidity - all these are factors that negatively affect the steering system. The situation is aggravated by the fact that many drivers do not pay attention to the periodic inspection of the steering system.

Power steering system - hydraulic or electric

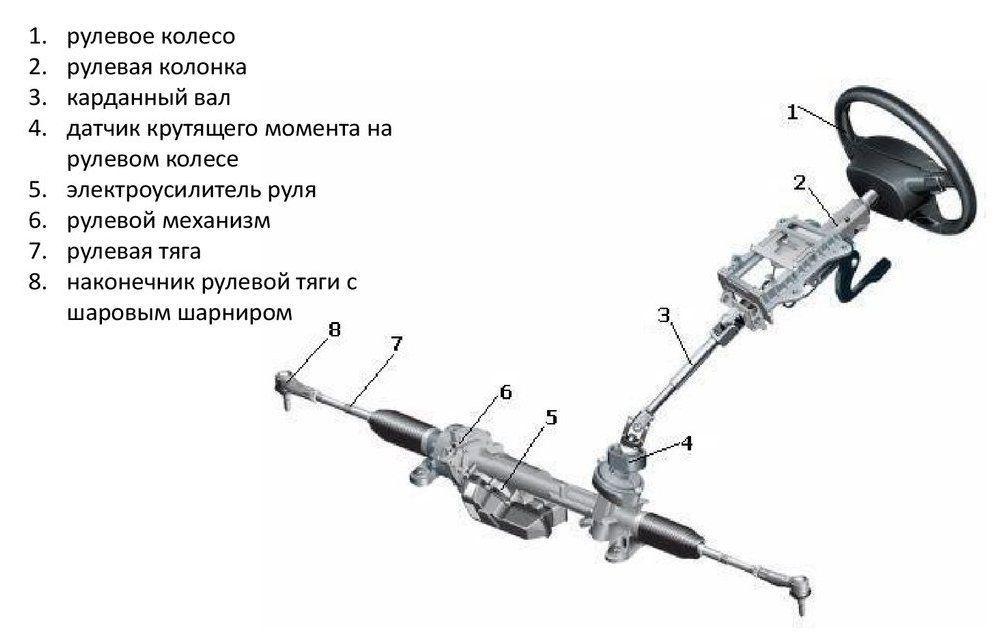

Without going into details of the steering system, it should be noted that the two most important parts are the steering column and the steering mechanism. The first element is a two-section shaft (in the event of an accident it breaks to protect the driver), descending from the steering wheel down, where the engine compartment is connected to the steering mechanism.

Currently, most car models use rack and pinion gears. They are located horizontally in relation to the steering column and are mainly used in front-wheel drive vehicles. Rear wheel drive vehicles use globoid, ball screw or worm gears (the latter usually found in higher end models).

The ends of the steering gear are connected to tie rods that change the position of the switches and therefore the wheels of the car.

Read also Installing a gas system in a car - what you need to remember to profit from HBO

The power steering system is used to reduce the amount of force the driver must use to turn the vehicle. Until recently, the standard was a pressurized hydraulic system in which the assisting force was generated by a pump (driven by an engine) that pumps a special fluid that fills the system.

Hydroelectric or all-electric steering systems are becoming more and more common. In the previous system, the power steering pump, which receives power from the engine, has been replaced with an electric pump, which is activated only when the wheels are turned.

In an all-electric system, pressure elements are replaced by electric actuators. Thus, the design of the system has been simplified (no pump, pressure pipes, liquid tank), reliability has been increased and its weight has been reduced, which, in turn, reduces fuel consumption. In addition, the use of electric drives, which are activated only when turning, helps to reduce fuel consumption. In the pressure system, the pump was running all the time.

Steering system malfunctions

– In the steering system, similar symptoms are accompanied by completely different causes. For example, a noticeable play in the steering wheel is usually caused, for example, by worn tie rod ends (or their incorrect mounting). But it could also be damage to the front wheel hub or air in the hydraulic power steering system, says Jacek Kowalski from the power steering repair service in Słupsk.

Air in the system also shows up jerky when cornering. However, jerks can also be the result of damage to the power steering pump or improper tension of the pump drive belt. The last two symptoms also lead to no help, but only when the system is already fully running.

See also Fuel additives - gasoline, diesel, liquefied gas. What can a motodoctor help you do?

Uneven steering when turning the steering wheel quickly means that the oil level in the system reservoir is too low, the pressure hoses are faulty, or the power steering pump is damaged. On the other hand, too slow return of the front wheels to the center position after a turn may be due to damage to the pump, wear on the ends of the steering rods or ball joints of the rocker arms, or incorrect centering of the rocker arms. wheel alignment adjustment. Steering wheel problems can also be caused by any of the above reasons.

- If you feel vibrations on the steering wheel in the parking lot and at low speed, then this is air in the power steering or the pump drive belt is incorrectly tensioned. It can also be assumed that the ball joint of the control lever or steering rods is damaged, says Jacek Kowalski.

When vibrations are felt while driving at both low and high speeds, they can be caused by damaged wheel bearings, unbalanced wheels, or even loose wheels. However, if the car pulls to the side or tires squeal when cornering, it is usually the result of improperly adjusted suspension geometry.

– After each repair of any element of the steering system, check the geometry of the wheels, emphasizes Kowalski.

Power steering for regeneration - how to save on gears

One of the elements most susceptible to failure is rack and pinion, i.e. steering gear with hydraulic booster. Unfortunately, it is also one of the most expensive elements of the steering system. An alternative to buying a new part is to rebuild a used steering gear. In Poland, there is no shortage of businesses providing such a service. They can also be found online when picking up and collecting a restored item.

Read also New compact car - comparison of the cost of buying and operating popular models

The price of this service depends on the size of the car. For example, in an Opel Corsa B we will restore the steering gear for about PLN 300. In Opel Vectra (A, B, C) the cost of restoration of the steering mechanism is approximately PLN 200 higher. In addition, you need to add about PLN 200-300 for the disassembly and assembly of this item.

Wojciech Frölichowski