Suspension arm and its varieties

The transmission link between the vehicle body and the wheels is the suspension. It plays an important role in ensuring smooth movement on the road, good vehicle handling and sufficient comfort for the driver and passengers.

In each suspension, three groups of main structural components can be distinguished.

1. Elastic. They reduce the impact on the body of sharp blows while driving on a road with uneven surfaces. These elements include springs and springs.

2. Damping, or. They dampen vibrations and reduce the amplitude of swaying resulting from the use of elastic components.

3. Guides. These elements determine the possibilities and nature of the movement of the wheels relative to the road, the body and each other. These primarily include all kinds of levers, which we will discuss in more detail in this article.

The design of the lever for modern automotive suspensions can vary quite a lot depending on the specific engineering solution. In the simplest case, it is an elongated part with longitudinal stiffeners.

At one end there is a thickening with a seat into which a silent block is pressed. This end of the lever is attached to the body or frame. At the other end there may be a seat for mounting a ball joint. In some cases, it is secured to the lever using bolts and nuts. The rear multi-link suspension has an option with a silent block at both ends.

Previously, this suspension part was made exclusively from steel channels or square pipes. But recently, light alloys have been increasingly used. Although the strength of such a part is lower than that of steel, it is not subject to corrosion. In addition, light-alloy arms reduce the overall and, most importantly, unsprung weight of the vehicle. And this has a positive effect on the ride, handling and dynamics of the car. In addition, the reduction in unsprung weight contributes to lower fuel consumption.

The functional purpose of the levers may be different depending on where they are mounted.

According to their position, they can be upper or lower.

In addition, design differences have parts for the front and rear suspension.

There are also longitudinal and transverse levers. The first are located in the direction of the car, the second - across.

Previously, trailing arms were installed on the rear axle of some cars. Nowadays, trailing arms are mainly used in the rear multi-link suspension of front-wheel drive cars. There they help to hold the struts during acceleration or acceleration, preventing forces acting along the axis of movement of the machine. Currently, this type of suspension is the most common on the rear axle of passenger cars.

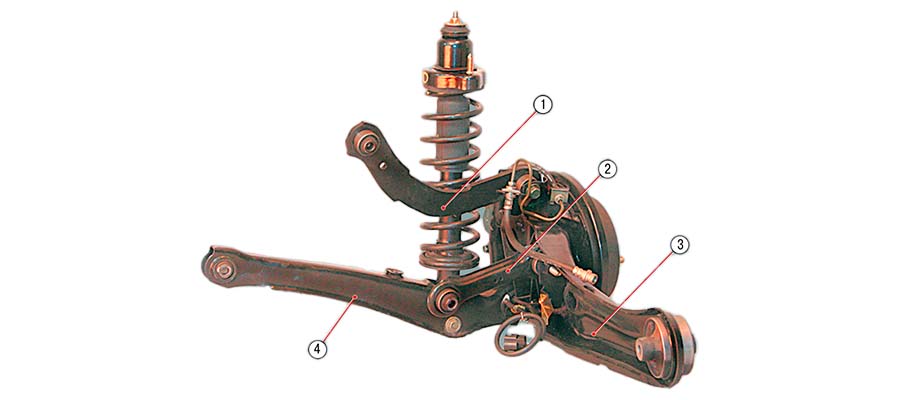

1 and 4 - upper and lower transverse lever;

2 - control lever;

3 - trailing arm

The levers can have a different number of attachment points and differ in shape. In addition to straight lines with two attachment points, a common variety is the part in the form of the letter H. In fact, these are two ordinary levers connected by a jumper.

But, perhaps, most often you can find triangular.

They have three attachment points. Often they have a crossbar, which is why they are also called A-shaped.

The triangular (A-shaped) arm in the front suspension is attached to the body or frame at two points, and at the third to the steering knuckle. In this design, it is held not only in the transverse direction in which the lever is installed, but also in the longitudinal direction. The simplicity and relative cheapness of this design have led to the widespread use of this design in many passenger cars as part of the MacPherson suspension.

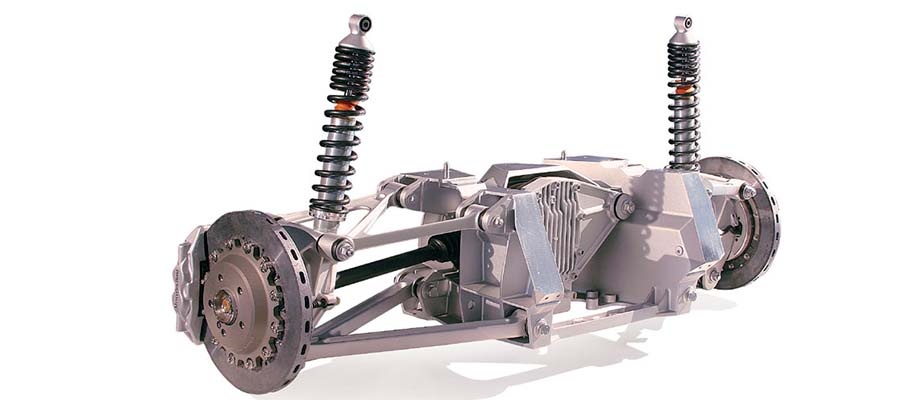

The independent double wishbone suspension provides better handling, cornering stability and overall increased comfort compared to MacPherson strut suspension. However, its development and configuration is much more complicated, and computer simulation is indispensable here. Consequently, this suspension option turns out to be much more expensive, and therefore you will not find it in budget car models. But the properties of this suspension are in high demand in sports and racing cars.

In this design, two levers are used, which are located one above the other. They can both be triangular, or one of them is triangular and the other simple. The bifurcated side has a connection with the body, and at the other end the lever is attached to the pivot pin with a hinge.

The top arm is usually shorter than the bottom arm. Such a device almost completely eliminates the change in camber due to roll during cornering, and thus increases the stability of the car.

The most complex and most expensive is the multi-link suspension. It can be seen as an evolution of the double wishbone suspension, in which each link is divided in two, and sometimes a fifth element is added. This option is installed only on executive class models. It provides excellent vehicle handling, maximum comfort and a high degree of sound insulation. However, bad roads are contraindicated for such a suspension, since pits and potholes can easily damage it, and repairs will be very expensive.

We have already written about. All tips regarding the preservation of the suspension resource in general, fully apply to the levers.

Their failure is possible mainly for two reasons - deformation or fracture, for example, due to falling into a pit or as a result of an accident, and also corrosion. Moreover, rust threatens only parts made of steel. If you take care of corrosion protection, steel elements can last quite a long time. But light-alloy parts are more vulnerable to mechanical stress, often they have to be changed simultaneously with spent silent blocks and ball bearings.

The following indirect signs may indicate damage to the levers:

- the car pulls to the side when driving in a straight line;

- wobbling left and right when driving at high speed;

- uneven or accelerated tire wear.

It should be borne in mind that there may be other reasons for this behavior of the car.

In the Chinese online store you can or others.