Oil filter device

each internal combustion engine includes many metal components that constantly and very actively interact with each other. Everyone is well aware that an unlubricated mechanism will not function effectively and will not last long. Friction parts wear out, resulting in small chips that clog the gaps between the parts and make the work of mechanics even more difficult. All this is accompanied by the release of a large amount of heat, which can lead to overheating of the internal combustion engine and ultimately disable it.

Lubrication helps to minimize the negative effects of friction. The oil circulating in the lubrication system removes metal particles formed due to friction, as well as small debris from the internal combustion engine. In addition, the circulation of lubricant helps the cooling system to cope with the heating of the internal combustion engine, partially removing heat from it. It is worth remembering also that the oil film on the metal protects it from corrosion.

The only problem is that metal shavings and other mechanical impurities do not disappear from the closed system and can return to the internal combustion engine again. To prevent this from happening, a special cleaning filter is included in the circulation circuit. There is a set of varieties of oil filters, but devices with a mechanical filtering method are most often used.

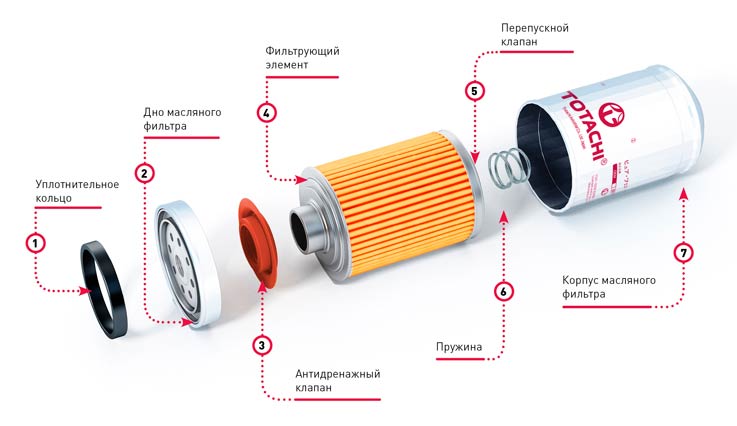

The design of the filter can be non-separable or collapsible. At the same time, the internal structure does not have significant differences.

The non-separable disposable element is simply replaced when fresh oil is poured into the lubrication system.

The collapsible design allows you to replace only one filter element.

In most cases, the oil filter is full-flow, that is, the entire volume of lubricant pumped by the pump passes through it.

In the old days, part-flow filters were widely used, through which a part of the lubricant passed - usually about 10%. Such a device could be the only one in the system, or it could function in parallel with the coarse filter. Now they are rare, detergent and dispersant additives in most modern grades of ICE oil make it possible to get by with just one full-flow option.

The degree of oil purification is characterized by such a parameter as the fineness of filtration. In practice, they usually mean the nominal filtration fineness, that is, the size of the particles that the filter filters out by 95%. Absolute filtration fineness implies 100% retention of particles of a certain size. Most modern oil filters have a nominal filtration fineness of 25…35 microns. This, as a rule, is quite enough, since smaller particles do not have a serious negative effect on the internal combustion engine.

The filter housing is a cylindrical metal cup with a bottom cover, which is welded or rolled in a non-separable design. A set of inlets are placed along the radius in the cover, and an outlet with a mounting thread is located in the center. Rubber o-ring prevents grease leakage.

Since during operation the pressure can often reach more than 10 atmospheres, serious requirements are imposed on the strength of the case; it is usually made of steel.

Inside the housing there is a filter element made of porous material, which can be paper or cardboard of special grades with special impregnation, felt and various synthetics. The corrugated filter element has a dense packing and is placed around a perforated protective sleeve. This design allows you to create a large filtration area in a small volume of the glass. And the metal protective clip gives additional strength and does not allow the filter to collapse under pressure drops.

An important component of the filter is a bypass (overflow) valve with a spring. When the pressure exceeds a certain threshold, the bypass valve opens to let crude oil into the system. This situation can occur when the filter is heavily contaminated or the viscosity of the lubricant is high, for example, when starting an internal combustion engine in frosty weather. An unrefined lubricant for internal combustion engines is a much lesser evil than even a short-term oil starvation.

The anti-drain (check) valve prevents oil from flowing out of the filter after the engine stops. Thus, lubricant is constantly left in the system, which is almost immediately supplied to the internal combustion engine when it is restarted. The check valve is actually a rubber ring that tightly closes the inlets when not in use and opens under pressure when the oil pump starts.

The design also includes an anti-drain valve that prevents oil from spilling out of the filter housing during filter changes.

There are other types of this device that differ in the way the cleaning is carried out.

Magnetic filter - usually mounted in the oil pan and collects steel chips using a permanent magnet or electromagnet. Periodically, you need to unscrew the magnetic plug and clean it.

Filter-sump - here the dirt simply settles to the bottom of the sump under the influence of gravity, so this filter is also called gravity. Here, maintenance is reduced to unscrewing the plug and draining some of the contaminated oil. In cars, such filters are practically no longer used, since almost no sediment forms in modern types of ICE oil.

Centrifugal cleaner (centrifuge) - such a device is often used in ICEs of trucks and automotive units, although occasionally it can also be found in cars. In it, heavy particles of impurities under the action of centrifugal force that occurs during the rotation of the rotor fly off to the walls of the centrifuge and remain on them in the form of a resinous precipitate. Oil is fed into the rotor through a channel in its axis under pressure and exits at high speed through nozzles, entering the oil sump. Jets of lubricant have a repulsive effect on the rotor, due to which it rotates.

The recommended interval for changing the oil filter may differ depending on the model of the car, but, as a rule, it is 10 ... 20 thousand kilometers for gasoline ICEs, for diesel engines - 1,5 ... 2 times more often. It is more convenient and practical to do this simultaneously with a planned replacement.

If the vehicle is operated in difficult conditions - heat, dust, mountainous terrain, frequent traffic jams - then the interval for changing the lubricant and oil filter should be shorter.

may differ in volume (capacity), degree of purification (filter fineness), opening pressure of the bypass valve, as well as the dimensions of the body and internal thread. These parameters are related to the pressure in the lubrication system, type, power and various design features of the internal combustion engine. There are also filters without a bypass valve, they are used in cases where such a valve is present in the engine itself.

All this should be taken into account when choosing a shift instead of a spent element. The use of an inappropriate filter can lead to serious consequences for the internal combustion engine. It is most reasonable to install those filters that the automaker recommends.

Replacing the oil filter, as a rule, is not difficult - it is simply screwed onto a threaded fitting, which must be cleaned before installation. But to create sufficient force, a special key is required.

If an air lock has formed in the lubrication system, the pressure in it will be insufficient, so the air must be disposed of. It’s easy to do this - after giving the filter a little, turn the crankshaft with the starter until oil begins to seep, then tighten the filter again.