Self-diagnosis and troubleshooting of the driveline VAZ 2107

Content

The cardan shaft on cars of the VAZ family is a fairly reliable unit. However, it also needs periodic maintenance. All malfunctions of the cardan transmission should be eliminated as soon as possible. Otherwise, more serious and costly troubles may arise.

Purpose and arrangement of the cardan shaft VAZ 2107

The cardan shaft is a mechanism that connects the gearbox to the rear axle gearbox and is designed to transmit torque. This type of transmission is most widespread on cars with rear and all-wheel drive.

Cardan device

The cardan shaft VAZ 2107 consists of the following elements:

- one or more sections of thin-walled hollow pipe;

- slotted sliding connection;

- fork;

- crosspiece;

- outboard bearing;

- fastening elements;

- rear movable flange.

Cardan transmission can be single-shaft or two-shaft. The second option involves the use of an intermediate mechanism, to the back of which a shank with slots is attached on the outside, and a sliding sleeve is fixed on the front through a hinge. In single-shaft structures, there is no intermediate section.

The front part of the cardan is attached to the gearbox through a movable coupling on a spline connection. To do this, at the end of the shaft there is a hole with internal slots. The cardan device involves the longitudinal movement of these splines at the moment of rotation. The design also provides for an outboard bearing attached to the body with a bracket. It is an additional attachment point for the cardan and is designed to limit the amplitude of its movement.

A fork is located between the middle and front element of the cardan shaft. Together with the cross, it transmits torque when the cardan is bent. The rear part of the shaft is attached to the rear axle gearbox through a flange. The shank engages with the main gear flange by means of external splines.

Cardan is unified for all classic VAZ models.

More about the VAZ-2107 checkpoint: https://bumper.guru/klassicheskie-modeli-vaz/kpp/kpp-vaz-2107–5-stupka-ustroystvo.html

Cross device

The VAZ 2107 cross is designed to align the axes of the cardan and transfer the moment when its elements are bent. The hinge provides the connection of the forks attached to the ends of the mechanism. The main element of the cross are needle bearings, thanks to which the cardan can move. These bearings are inserted into the holes of the forks and are fixed with circlips. When the hinge wears, the cardan shaft begins to knock while driving. A worn cross is always replaced with a new one.

Types of cardan shafts

Cardan shafts are of the following types:

- with a constant velocity joint (CV joint);

- with a hinge of unequal angular velocities (classic design);

- with semi-cardan elastic hinges;

- with rigid semi-cardan joints.

The classic universal joint consists of a fork and a cross with needle bearings. Most of the rear-wheel drive vehicles are equipped with such shafts. Cardans with CV joints are usually installed on SUVs. This allows you to completely eliminate the vibration.

The resilient joint mechanism consists of a rubber sleeve capable of transmitting torque at angles not exceeding 8˚. Since the rubber is quite soft, the cardan provides a smooth start and prevents sudden loads. Such shafts do not require maintenance. The rigid semi-cardan joint has a complex design, which involves the transmission of torque due to gaps in the spline connection. Such shafts have a number of disadvantages associated with rapid wear and manufacturing complexity, and are not used in the automotive industry.

CV joint

The imperfection of the design of the classic cardan on the crosses is manifested in the fact that at large angles vibrations occur and torque is lost. The universal joint can deviate a maximum of 30-36˚. At such angles, the mechanism may jam or fail completely. These shortcomings are deprived of cardan shafts on CV joints, usually consisting of:

- balls;

- two rings (outer and inner) with grooves for balls;

- separator that limits the movement of the balls.

The maximum possible angle of inclination of the cardan of this design is 70˚, which is noticeably higher than that of the shaft on the crosses. There are other designs of CV joints.

Cardan mount VAZ 2107

Cardan VAZ 2107 is mounted in several places:

- the rear part is bolted to the flange of the rear axle gearbox;

- the front part is a movable spline connection with an elastic coupling;

- the middle part of the cardan is attached to the body through the cross member of the outboard bearing.

Learn more about rear axle repair: https://bumper.guru/klassicheskie-modeli-vaz/zadnij-most/reduktor-zadnego-mosta-vaz-2107.html

Cardan mounting bolts

To mount the cardan on the VAZ 2107, four bolts measuring M8x1.25x26 with a conical head are used. A self-locking nut with a nylon ring is screwed onto them. If the bolt turns when tightening or loosening, it is locked with a screwdriver.

Elastic coupling

The elastic coupling is an intermediate element for connecting the cardan cross and the output shaft of the box. It is made of high strength rubber to reduce vibration. The clutch is removed in case of mechanical damage for replacement or when repairing the gearbox. When installing an old coupling, you will need a clamp of the appropriate size to tighten it. New flexible couplings are usually sold with a clamp, which is removed after installation.

Cardan malfunctions

The VAZ 2107 cardan shaft wears out during operation under the influence of constant loads. The crosspiece is subjected to the most wear. As a result, the cardan loses its original characteristics, vibration, knocks, etc. appear.

Vibration

Sometimes while driving on the VAZ 2107, the body begins to vibrate. The reason for this usually lies in the driveline. This may be the installation of a shaft of initially poor quality or improper assembly of the assembly. Vibration can also appear during mechanical impacts on the cardan when hitting obstacles or in an accident. Such a problem can also be due to improper hardening of the metal.

There are many reasons leading to an imbalance in the driveline. Vibration may appear under heavy loads. In addition, the VAZ 2107 cardan can be deformed even with infrequent use of the car. This will also cause vibration. In such situations, balancing or replacement of the node is required, and the problem should be fixed immediately. Otherwise, the vibration of the cardan can lead to the destruction of the crosses and the rear axle gearbox, and the cost of repairs will increase many times over.

In addition, vibration may occur due to the rubber element of the outboard bearing. Rubber becomes less elastic over time, and the balance can be disturbed. The development of the bearing can also lead to vibration of the body when starting off. This, in turn, can cause premature failure of the crosses. When buying a new outboard bearing, special attention should be paid to the elasticity of the rubber suspension and the ease of rotation of the bearing itself. There should not be any jamming and backlash.

Read about hub bearing malfunctions: https://bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/zamena-stupichnogo-podshipnika-vaz-2107.html

Knocking

Malfunctions and wear of individual elements of the propeller shaft VAZ 2107 as a result of friction leads to the formation of backlash in the mechanism and, as a result, to the appearance of knocks. The most common causes of knocking are:

- Wrong cross. Knock appears as a result of wear and destruction of bearings. The part should be replaced.

- Loosening of the cardan mounting bolts. The problem is solved by inspecting and tightening loose connections.

- Severe wear of the spline connection. In this case, change the splines of the driveline.

- Outboard bearing play. The bearing is replaced with a new one.

To increase the service life of the driveline elements, their periodic maintenance is necessary, which involves lubrication with a special syringe. If the crosses are maintenance-free, they are simply replaced when play appears. The outboard bearing and crosses are lubricated with Litol-24 every 60 thousand km. run, and the slotted part - "Fiol-1" every 30 thousand km.

Clicking when touching

Often, when starting off classic VAZ models, you can hear clicks. They have a characteristic metallic sound, are the result of play in any element of the cardan and can be caused by the following reasons:

- the crosspiece is out of order;

- a slotted connection has been developed;

- loosened cardan mounting bolts.

In the first case, the cross is replaced with a new one. When developing a spline connection, it will be necessary to replace the front flange of the universal joint. If this does not help, you will have to change the cardan shaft completely. When loosening the mounting bolts, they simply need to be tightened securely.

Repair cardan VAZ 2107

It is possible to dismantle the VAZ 2107 cardan for repair or replacement without a flyover or a lift. This will require:

- open-end and socket wrenches for 13;

- flat screwdriver;

- head 13 with a knob or ratchet;

- a hammer;

- passatizhi.

Dismantling

To repair or replace the flexible coupling, the cardan will need to be removed from the vehicle. Its dismantling is carried out in the following order:

- The parking brake locks the rear wheels.

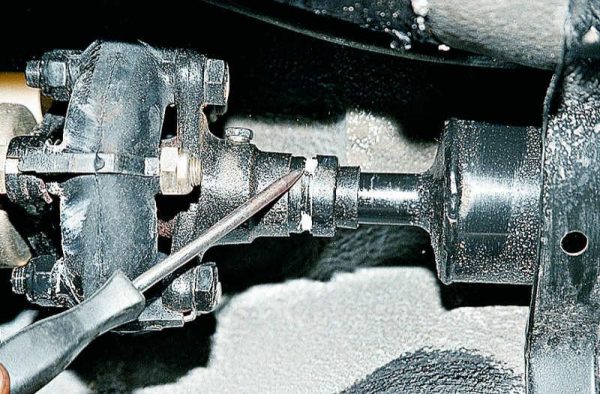

- Four bolts securing the cardan to the rear gearbox are unscrewed.

The rear part of the cardan is attached to the rear axle gearbox with four bolts.

The rear part of the cardan is attached to the rear axle gearbox with four bolts. - Unscrew the two nuts securing the outboard bearing to the body.

To dismantle the outboard bearing bracket, unscrew the two nuts

To dismantle the outboard bearing bracket, unscrew the two nuts - With a slight blow of the hammer, the shaft is knocked out of the splines. If the clutch is working, it does not need to be removed.

To remove the cardan from the splines, you need to lightly hit the shaft with a hammer

To remove the cardan from the splines, you need to lightly hit the shaft with a hammer - Marks are applied to the universal joint and flange of the rear axle (notches with a hammer, screwdriver or chisel) so that their position does not change during subsequent assembly. Otherwise, noise and vibration may occur.

When dismantling, marks are applied to the cardan and flange to facilitate subsequent assembly.

When dismantling, marks are applied to the cardan and flange to facilitate subsequent assembly.

Replacing the universal joint cross

If play appears in the hinges, the cross is usually changed to a new one. The fact is that worn needle bearings cannot be repaired. The dismantling of the cross after removing the cardan is carried out as follows:

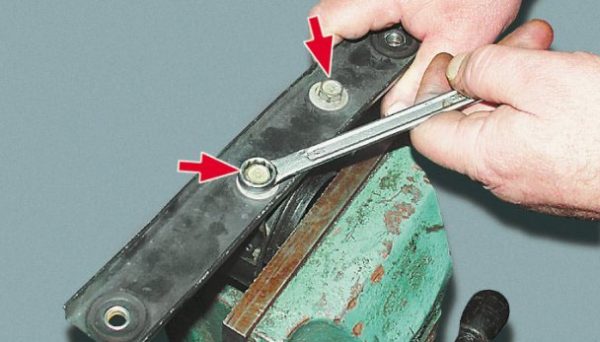

- With a special puller or improvised tools, they take out the retaining rings that hold the hinge cups in the grooves.

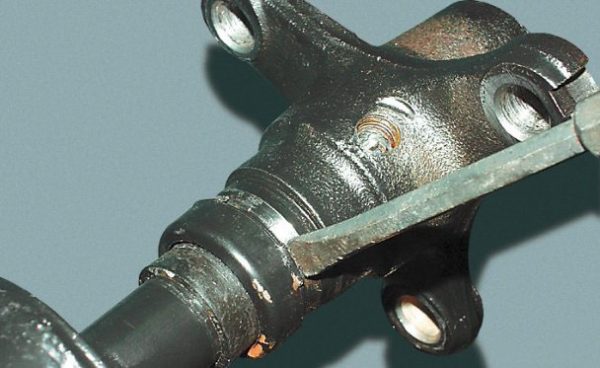

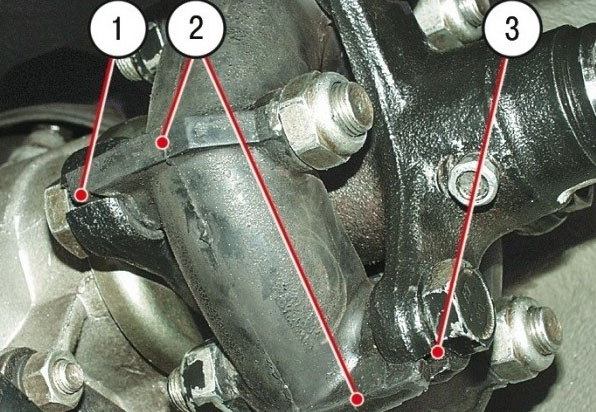

The hinge cups are held in the grooves by retaining rings, which must be removed when dismantling the cross.

The hinge cups are held in the grooves by retaining rings, which must be removed when dismantling the cross. - By striking sharp blows on the cross with a hammer, the glasses are removed. The glasses that came out as a result of blows from their seats are removed with pliers.

As a result of hitting the cross with a hammer, the glasses come out of their seats

As a result of hitting the cross with a hammer, the glasses come out of their seats - Seats for the hinge are cleaned of dirt and rust with fine sandpaper.

- The new cross is installed in the reverse order.

The installation of a new cross is carried out in the reverse order.

The installation of a new cross is carried out in the reverse order.

Video: replacing the VAZ 2107 cross

Replacing the outboard bearing

If the bearing or rubber suspension has exhausted its resource, the replacement is carried out in the following order:

- The cardan is removed from the car and the plugs in its central part are disconnected.

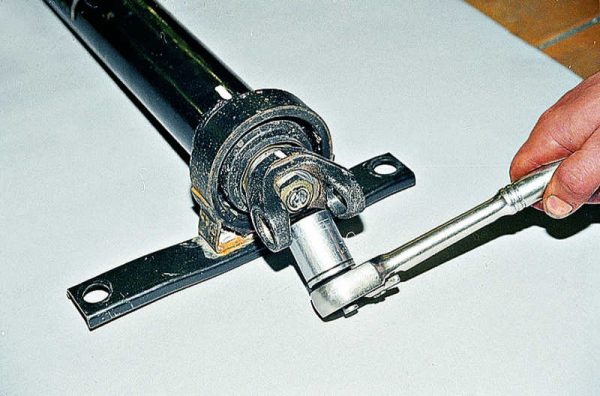

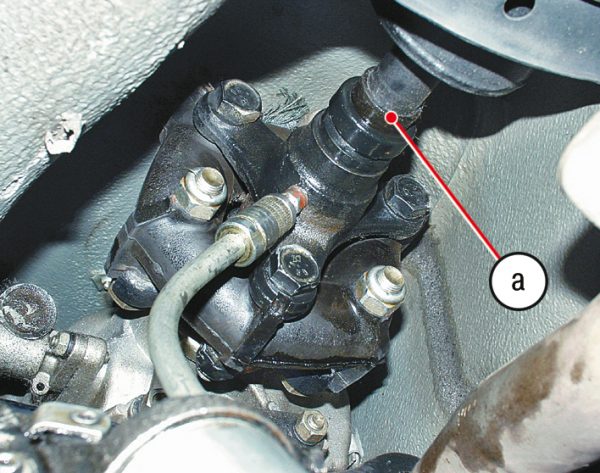

To get access to the bearing mounting nut, you will need to disconnect the cardan forks

To get access to the bearing mounting nut, you will need to disconnect the cardan forks - With a key of 27, loosen the central nut of the bearing on the shaft.

The bearing fastening nut on the shaft is loosened with a key of 27

The bearing fastening nut on the shaft is loosened with a key of 27 - The fork is pressed out with a puller, the nut is unscrewed and the fork itself is removed.

To dismantle the cardan fork, use a special puller

To dismantle the cardan fork, use a special puller - Unscrew the two bolts securing the bearing to the cross member. The crossbar is removed.

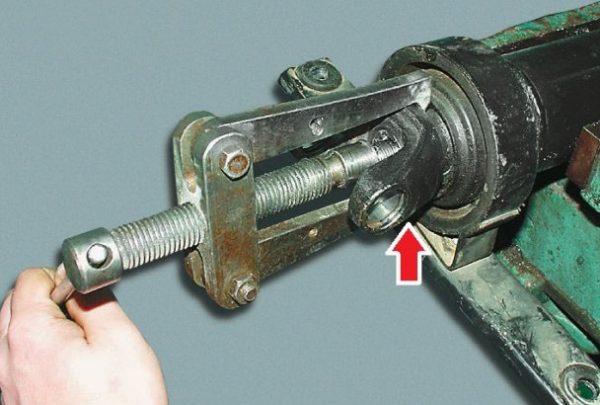

To remove the outboard bearing from the cross member, you need to unscrew the two bolts

To remove the outboard bearing from the cross member, you need to unscrew the two bolts - An intermediate support with an outboard bearing is installed on spacers (for example, on a corner). The bearing is knocked down with a head.

Having installed the bearing on the metal corners, the cardan shaft is knocked out with a hammer

Having installed the bearing on the metal corners, the cardan shaft is knocked out with a hammer - When replacing a bearing without a rubber part, remove the retaining ring with a suitable tool and, setting a suitable head, knock out the bearing itself.

When replacing a bearing without a rubber part, remove the retaining ring and knock out the bearing itself

When replacing a bearing without a rubber part, remove the retaining ring and knock out the bearing itself - Assembly is carried out in the reverse order, after lubricating the bearing.

Video: replacing the outboard bearing VAZ 2107

Watch this video on YouTube

Cardan assembly

The assembly and installation of the cardan shaft on the VAZ 2107 is carried out in the reverse order. In doing so, you should pay attention to the following important points:

- When repairing an outboard bearing, before installing the fork, the spline connection and the fork itself must be lubricated. Litol is best suited for this.

- The fork fastening nut should be tightened with a torque wrench with a torque of 79,4–98 Nm. After that, the nut must be fixed with a metal adapter.

The bearing nut is tightened with a torque wrench.

The bearing nut is tightened with a torque wrench. - After installing the gland cage and the gland itself, as well as the flange on the spline connection, the cage should be fixed by bending the antennae with a screwdriver.

To fix the cage on the shaft, you need to bend the antennae with a suitable screwdriver

To fix the cage on the shaft, you need to bend the antennae with a suitable screwdriver - The spline connection of the front shaft must be lubricated with a special syringe. For this, it is recommended to use "Fiol-1" and "Shrus-4". The crosses themselves are lubricated with the same syringe.

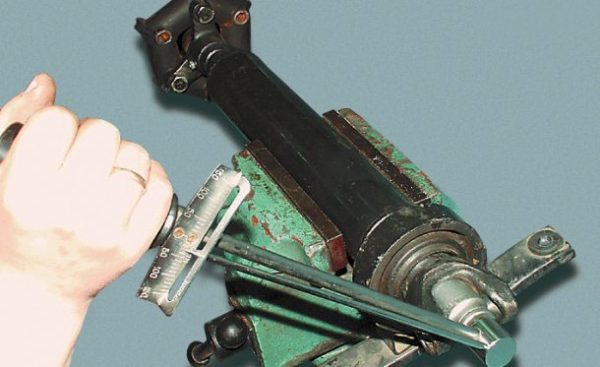

Using a syringe, the splined joint is lubricated

Using a syringe, the splined joint is lubricated - After installing the hinges with a flat feeler gauge, it is necessary to check the gap between the cup of each of the bearings and the groove for the snap ring. The gap should be between 1,51 and 1,66 mm.

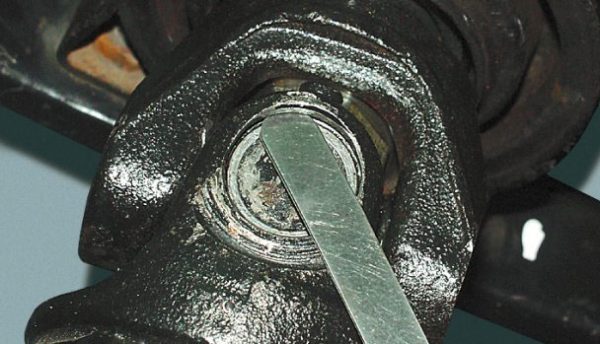

Between each bearing cup and the groove for the retaining ring, check the gap, the value of which should be 1,51–1,66 mm

Between each bearing cup and the groove for the retaining ring, check the gap, the value of which should be 1,51–1,66 mm - After installing the retaining rings, hit the forks of the crosses with a hammer several times from different sides.

- The front flange and the back of the gimbal must be attached to the flexible coupling and the rear gearbox, respectively.

The front part of the cardan is attached to the elastic coupling with three bolts.

The front part of the cardan is attached to the elastic coupling with three bolts.

When assembling, it is recommended to lubricate all bolted connections. This will make repairs much easier in the future.

Balancing cardan VAZ 2107

If vibration occurs due to imbalance of the cardan shaft, it will need to be balanced. It is problematic to do this on your own, so they usually turn to a car service. Balance the cardan as follows.

- The cardan shaft is installed on a special machine, on which a number of parameters are measured.

- A weight is attached to one side of the gimbal and tested again.

- The parameters of the cardan are measured with a weight attached to the opposite side.

- Shaft turn the shaft 180˚ and repeat the measurements.

The results obtained make it possible to balance the cardan by welding weights into the places determined by the results of measurements. After that, the balance is checked again.

Video: cardan balancing

Watch this video on YouTube

Craftsmen figured out how to balance the cardan VAZ 2107 with their own hands. The procedure is as follows:

- The cardan shaft is conditionally divided into four equal parts, after driving the car into a pit or overpass.

- A weight of about 30 g is attached to the first part of the cardan and tested.

- They drive out onto the road with a smooth surface and check whether the vibration has decreased or increased.

- The actions are repeated with a weight attached to another part of the gimbal.

- After determining the problematic part of the cardan, the weight of the weight is selected. To do this, the car is tested on the go with weights of different weights. When the vibration disappears, the weight is welded to the cardan.

Obviously, it will not be possible to achieve high balancing accuracy in a folk way.

Repair of a VAZ 2107 driveline is not particularly difficult even for inexperienced car owners. All you need is desire, free time, a minimum set of locksmith tools and careful adherence to the instructions of specialists.