We independently change the ball bearings on the VAZ 2106

Content

If there are problems with the wheels, the car will not go far. VAZ 2106 is no exception in this sense. The source of headache for the owners of the "sixes" has always been the ball bearings of the wheels, which have never been reliable. Taking into account the quality of domestic roads, the service life of these parts has never been long, and after a few years of intensive operation of the VAZ 2106, the driver had to replace the ball bearings. Can I change them myself? Of course. But this task requires preliminary preparation. Let's figure out how it's done.

The purpose of ball joints on the VAZ 2106

The ball joint is a conventional pivot joint that attaches the wheel hub to the suspension. The main function of the ball joint is as follows: a wheel with such a support must move freely in the horizontal plane, and not move in the vertical plane.

It should also be noted here that the hinges on the VAZ 2106 are used not only in the suspension. They can be found in steering rods, camber levers, and much more.

Ball joint device

At the dawn of the automotive industry, passenger car suspensions did not have any hinges. In their place were pivot joints, which were very heavy and required systematic lubrication. The main disadvantage of pivot joints was that they allowed the wheels to turn freely on only one axis, and this, in turn, drastically reduced handling. In the VAZ 2106 car, the engineers finally decided to abandon the pivot joints and used ball bearings.

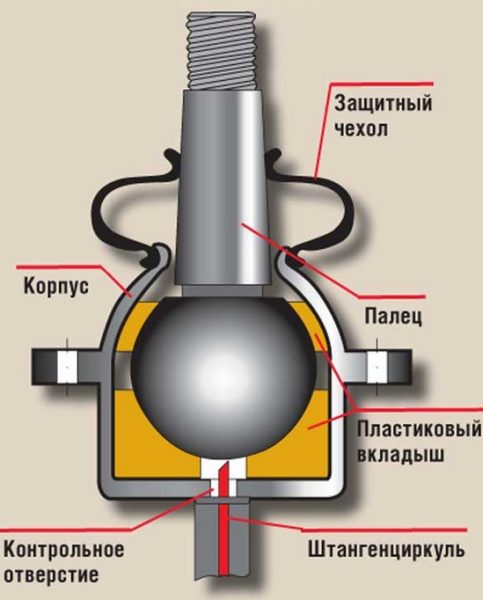

The device of the first supports was extremely simple: a pin with a ball was installed in a fixed body. A steel spring pressed on the finger, which was closed with a dust cap on top. Since when riding on the ball in the support there was a colossal shock load, it had to be periodically lubricated with a special syringe. In later VAZ 2106 models, ball bearings were no longer equipped with springs. The finger ball was located not in a metal base, but in a hemisphere made of wear-resistant plastic. In addition, non-separable ball bearings appeared, the entire repair of which was reduced to their replacement.

Causes and signs of ball joint breakage

Let's list the main reasons due to which the service life of ball joints is significantly reduced. Here they are:

- the strongest shock loads. This is the main cause of joint failure. And it is especially relevant if the driver constantly drives on dirt roads or on roads with dilapidated asphalt surfaces;

- lack of lubrication. If the driver does not carry out systematic maintenance of the ball joints and does not lubricate them, then the lubricant develops its resource and ceases to perform its functions. This usually happens within six months. After that, the destruction of the ball pin is only a matter of time;

- duster breakage. The purpose of this device is indicated by its name. When the boot fails, dirt begins to accumulate in the swivel joint. Over time, it begins to work as an abrasive material, which gradually damages the ball pin.

The anther on the support cracked, dirt got inside, which began to work as an abrasive

The anther on the support cracked, dirt got inside, which began to work as an abrasive

Now we list the main signs that unambiguously indicate a breakdown of the ball joint:

- the roar of the suspension. It can be heard especially clearly when the driver runs over a speed bump at a speed of 20-25 km / h. If the suspension rattles, it means that the grease has been completely squeezed out of the ball joint;

- when driving at high speed, one of the wheels begins to swing from side to side. This indicates that a large play has arisen in the ball joint. The situation is very dangerous, since the swinging wheel at any moment can turn almost perpendicular to the body of the machine. The car is then guaranteed to lose control, which can lead to a serious accident;

A broken ball joint can cause a serious accident.

A broken ball joint can cause a serious accident. - a grinding sound is heard when turning the steering wheel. The reason is the same: there is no lubricant in the ball joints;

- uneven wear on the front and rear tires. This is another sign that something is wrong with the ball joints. It should be noted here that the wheels can wear unevenly not only due to the breakdown of the ball joints, but also for many other reasons (for example, the car may not have the wheel alignment adjusted).

Checking the health of the ball joint

If the owner of the VAZ 2106 suspects a malfunction of the ball joint, but does not know how to check it, we will list several simple diagnostic methods. Here they are:

- hearing test. This is perhaps the easiest way to diagnose. All it takes is a partner to help rock the car with the engine off up and down. When rocking, listen for the sounds that the suspension makes. If a knock or creak is clearly heard from behind the wheel, it's time to change the ball joint;

- check for backlash. Here, too, you can not do without a partner. One of the wheels of the car is lifted with a jack. The partner sits in the cab and depresses the brake pedal all the way. The car owner at this moment swings the wheel first in a vertical and then in a horizontal plane. When the brakes are pressed, play is felt immediately. And if it is, the support needs to be replaced;

The wheel should be jacked up and rocked up and down

The wheel should be jacked up and rocked up and down - check for finger wear. In the latest models of the VAZ 2106, ball bearings were installed with special diagnostic holes, looking into which you can determine how worn out the ball pin is. If the pin wear is 7 mm or more, the support should be replaced.

About the choice of ball joints

As mentioned above, the ball pin is the most important part of the support. The reliability of the suspension as a whole depends on its durability. Therefore, the requirements for high-quality fingers are very serious:

- a good ball pin should be made of high alloy steel;

- the surface of the finger (but not the ball) must be hardened without fail;

- the pin and the rest of the support parts must be made using the cold heading method and only then subjected to heat treatment.

The nuances of the technological process listed above are very costly, therefore they are used only by large manufacturers of ball joints, of which there are not so many on the domestic market. Let's list them:

- "Belmag";

Ball bearings "Belmag" have the most affordable cost

Ball bearings "Belmag" have the most affordable cost - "Track";

A feature of these supports are transparent anthers, which is very convenient for inspection.

A feature of these supports are transparent anthers, which is very convenient for inspection. - "Cedar";

Supports "Cedar" were once very popular. It is not so easy to find them on the market now.

Supports "Cedar" were once very popular. It is not so easy to find them on the market now. - «Lemforder».

The products of the French company Lemforder have always been famous for their excellent quality and high price.

The products of the French company Lemforder have always been famous for their excellent quality and high price.

The products of these four companies are in consistently high demand among the owners of the VAZ 2106. It should also be noted here that at present the market is literally littered with fake ball joints for the VAZ classics. Fortunately, it is quite easy to recognize a fake: it costs half the price of the same Trek or Cedar. But it is categorically not recommended to save on such an important detail.

Replacing the upper and lower ball joints on the VAZ 2106

Ball joints, due to their design, cannot be repaired. Because it is impossible to restore the surface of a worn ball pin in a garage. So the only way to repair this part is to replace it. But before starting work, we will select the necessary tools. Here it is:

- jack;

- open-end wrenches, set;

- a hammer;

- new ball joints, set;

- flat screwdriver;

- tool for extrusion of ball joints;

- socket wrenches, set.

Sequence of work

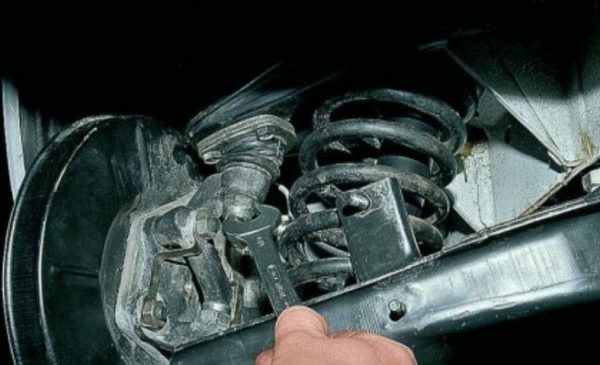

Before starting work, the wheel on which it is planned to replace the ball joint should be raised with a jack, and then removed using a socket wrench. This preparatory procedure will have to be carried out when replacing both the upper and lower supports.

- After removing the wheel, access to the suspension of the car opens. There is a fixing nut on the top ball pin. It is unscrewed with a wrench.

To unscrew the upper mounting nut on the support, a 22 wrench is suitable

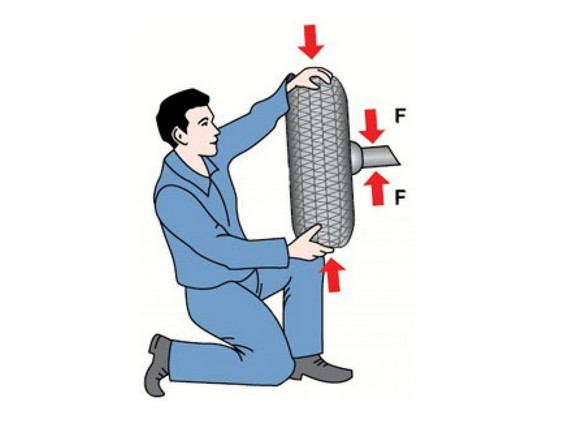

To unscrew the upper mounting nut on the support, a 22 wrench is suitable - With a special tool, the finger is squeezed out of the fist on the suspension.

Significant force is required to use a special pressing tool

Significant force is required to use a special pressing tool - If there was no suitable tool at hand, then you can remove the finger by hitting the suspension eyelet hard with a hammer. In this case, the upper part of the ball joint must be pry off with a mount and squeezed upwards.

Impacts are applied to the eye, and the finger must be pulled up with a mount

Impacts are applied to the eye, and the finger must be pulled up with a mount - The upper ball joint is attached to the suspension with three 13 nuts, which are unscrewed with an open-end wrench.

The ball joint rests on three nuts at 13

The ball joint rests on three nuts at 13 - The upper ball joint can now be removed and disassembled. The plastic boot is removed from the support manually.

The boot from the worn support is removed manually

The boot from the worn support is removed manually - There is also a fastening nut on the pin of the lower ball joint. However, unscrewing it immediately and completely will not work, because after a few revolutions it will rest against the suspension. Therefore, to begin with, this nut must be unscrewed by 5-6 turns.

- After that, with a special tool, the lower support is pressed out of the eye in the suspension.

Before pressing out, the support must be loosened by unscrewing the fixing nut by 5 turns.

Before pressing out, the support must be loosened by unscrewing the fixing nut by 5 turns. - The above-mentioned fastening nut must then be completely unscrewed.

- With a 13 open-end wrench, the fixing nuts holding the ball joint in the eye are unscrewed, after which the lower support is removed.

It is more convenient to remove fasteners from the lower support with a socket wrench for 13

It is more convenient to remove fasteners from the lower support with a socket wrench for 13 - Worn ball joints are replaced with new ones, after which the VAZ 2106 suspension is reassembled.

Video: changing ball joints on a classic

As you can see, replacing ball bearings with a VAZ 2106 is a very time-consuming task. In addition, considerable physical strength is required to press out the old supports. If a novice motorist has all this, he may well refrain from visiting a service center. Well, if a person still has doubts about his abilities, then it would be wiser to entrust this work to a qualified auto mechanic.