We independently install the turbine on the VAZ 2106

Content

Any car enthusiast wants the engine of his car to be as powerful as possible. The owners of the VAZ 2106 are no exception in this sense. There are many different ways to increase engine power and make the car go faster. But in this case, let's try to deal with only one method, which is called a turbine.

Purpose of the turbine

The technical characteristics of the VAZ 2106 engine cannot be called outstanding. For this reason, many motorists begin to refine the engines of their "sixes" on their own. Installing a turbine on a VAZ 2106 engine is the most radical, but also the most effective way to increase engine performance.

By installing a turbine, the driver receives several advantages at once:

- the acceleration time of the car from standstill to 100 km / h is almost halved;

- engine power and efficiency increase;

- fuel consumption remains virtually unchanged.

How does a car turbine work?

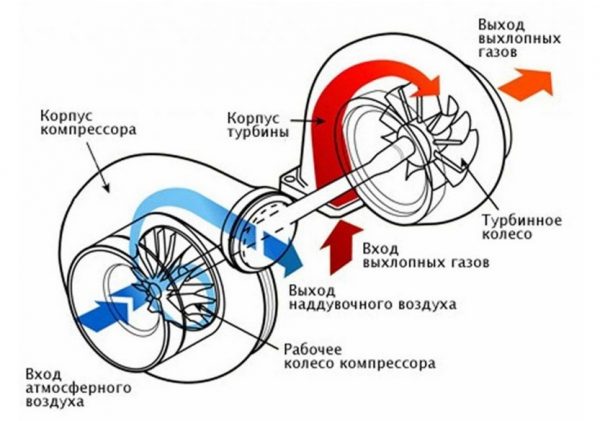

In short, the meaning of the operation of any turbocharging system is to increase the rate of supply of the fuel mixture to the combustion chambers of the engine. The turbine is connected to the exhaust system of the "six". A powerful stream of exhaust gas enters the impeller in the turbine. The impeller blades rotate and create excess pressure, which is forced into the fuel supply system.

As a result, the speed of the fuel mixture increases, and this mixture begins to burn much more intensively. The standard engine of the "six" fuel combustion coefficient is 26-28%. After installing a turbocharging system, this coefficient can increase up to 40%, which increases the initial efficiency of the engine by almost a third.

About the choice of turbocharging systems

Nowadays, there is no need for car enthusiasts to design turbines themselves, since a wide range of ready-made systems are available on the aftermarket. But with such an abundance, the question will inevitably arise: which system to choose? To answer this question, the driver must decide how much he is going to remake the engine, that is, how deep the modernization will be. Having decided on the degree of intervention in the engine, you can move on to turbines, which are of two types:

- low power turbines. These devices rarely produce pressures above 0.6 bar. Most often it varies from 0.3 to 0.5 bar. Installing a reduced power turbine does not imply serious intervention in the design of the motor. But they also give an insignificant increase in productivity - 15-18%.

- powerful turbocharging systems. Such a system is capable of creating a pressure of 1.2 bar or more. To install it in the engine, the driver will have to seriously upgrade the engine. In this case, the parameters of the motor may change, and not the fact that for the better (this is especially true for the CO indicator in the exhaust gas). However, engine power can increase by a third.

What is meant by modernization

Before it comes to installing the turbine, the driver will have to carry out a number of preparatory procedures:

- cooler installation. This is an air cooling device. Since the turbocharging system runs on hot exhaust gas, it gradually heats up itself. Its temperature can reach 800°C. If the turbine is not cooled in a timely manner, it will simply burn out. In addition, the engine can also be damaged. So you can't do without an additional cooling system;

- the carburetor "six" will have to be converted into an injection one. The old carburetor "sixes" intake manifolds have never been durable. After installing the turbine, the pressure in such a collector increases by about five times, after which it breaks.

All of the above points indicate that putting a turbine on an old carburetor six is a dubious decision, to put it mildly. It will be much more expedient for the owner of such a car to put a turbocharger on it.

This solution has several advantages:

- the driver will no longer worry about the problem of high pressure in the intake manifold;

- there is no need to install additional cooling systems;

- it will not be necessary to redo the fuel supply system;

- installing a compressor is half the price of installing a full-fledged turbine;

- motor power will increase by 30%.

Installation of a turbocharging system

There are two methods for installing turbines on the "six":

- connection to the collector;

- connection to the carburetor;

The vast majority of drivers are inclined towards the second option, since there is less trouble with it. In addition, the fuel mixture in the case of a carburetor connection is formed directly, bypassing the manifold. To establish this connection, you will need the following things:

- spanner wrenches included;

- flat screwdriver;

- two empty containers for draining antifreeze and grease.

The sequence of connecting a full-fledged turbine

First of all, it should be said that the turbine is a rather large device. Therefore, in the engine compartment, it will require space. Since there is not enough space, many owners of "sixes" put the turbines where the battery is installed. The battery itself is removed from under the hood and installed in the trunk. It should also be noted here that the sequence of connecting the turbocharging system depends on what type of engine is installed on the "six". If the car owner has the earliest version of the "six", then a new intake manifold will have to be installed on it, since the standard one will not be able to work with the turbine. Only after these preparatory operations can proceed directly to the installation of the turbocharging system.

- First, an additional intake duct is installed.

- The exhaust manifold is removed. A small piece of air pipe is installed in its place.

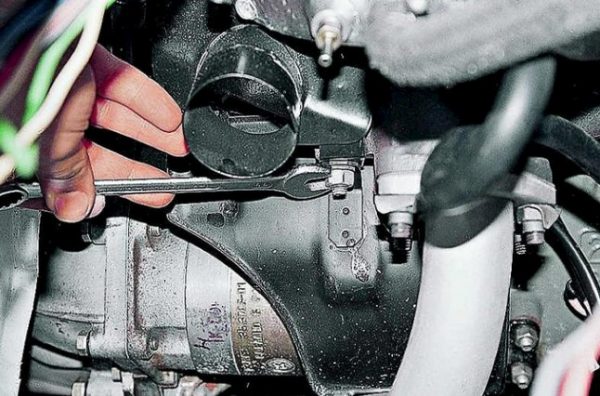

The manifold is removed, a short air tube is installed in its place

The manifold is removed, a short air tube is installed in its place - Now the air filter is removed along with the generator.

- Antifreeze is drained from the main radiator (an empty container should be placed under the radiator before draining).

- The hose that connects the engine to the cooling system is disconnected.

- The lubricant is drained into a previously prepared container.

- A hole is drilled on the engine cover using an electric drill. A thread is cut in it with the help of a tap, after which a cross-shaped adapter is installed in this hole.

A cross-shaped adapter is required to organize the supply of oil to the turbine

A cross-shaped adapter is required to organize the supply of oil to the turbine - The oil sensor is unscrewed.

- The turbine is connected to a previously installed air pipe.

Video: we connect the turbine to the "classic"

Compressor connection sequence

It was mentioned above that connecting a full-fledged turbocharging system to an old “six” may not always be justified, and that installing a conventional compressor may be a more acceptable option for many drivers. So it makes sense to disassemble the installation sequence of this device.

- The old air filter is removed from the inlet air pipe. A new one is put in its place, the resistance of this filter should be zero.

- Now a piece of special wire is taken (it usually comes with the compressor). One end of this wire is screwed to the fitting on the carburetor, the other end is attached to the air outlet pipe on the compressor. Steel clamps from the kit are usually used as fasteners.

The compressor comes with fittings that should be connected before installing the compressor.

The compressor comes with fittings that should be connected before installing the compressor. - The turbocharger itself is installed next to the distributor (there is enough space there, so a medium-sized compressor can be installed without problems).

- Almost all modern compressors come with mounting brackets. With these brackets, the compressor is attached to the cylinder block.

- After installing the compressor, it is not possible to install a regular air filter. Therefore, instead of filters in standard cases, drivers put special boxes made of plastic. Such a box serves as a kind of adapter for air injection. Moreover, the tighter the box, the more efficient the compressor will work.

The box works as an adapter when pressurizing

The box works as an adapter when pressurizing - Now a new filter is installed on the suction tube, the resistance of which tends to zero.

This sequence is the simplest and at the same time the most effective when installing a turbocharger on the entire VAZ "classic". Being engaged in the installation of this system, the driver himself can look for new ways to increase the tightness of the box and pipe connections. Many people use regular high temperature sealant for this, which can be found at any auto parts store.

How oil is supplied to the turbine

A complete turbocharging system cannot function without oil. So the driver who decides to install a turbine will have to solve this problem as well. When the turbine is installed, a special adapter is screwed to it (such adapters usually come with turbines). Then a heat dissipating screen is installed on the intake manifold. Oil is supplied to the turbine through an adapter, on which a silicone tube is first put on. In addition, the turbine must be equipped with a cooler and an air tube through which air will flow into the manifold. Only in this way can an acceptable temperature of the oil supplied to the turbine be achieved. It should also be said here that sets of tubes and clamps for supplying oil to turbocharging systems can be found in parts stores.

Such a set costs from 1200 rubles. Despite the obviously inflated price, such a purchase will save the car owner a lot of time, since you do not have to fiddle with cutting and fitting silicone tubes.

About spigots

Pipes are necessary not only for supplying oil. Exhaust gases from the turbine must also be removed. To remove excess gas not used by the turbine, a massive silicone pipe on steel clamps is used. In some cases, a whole system of silicone pipes is used to remove the exhaust (their number is determined by the design of the turbine). Usually there are two, in some cases four. Pipes before installation are carefully inspected for internal contamination. Any, even the smallest speck that has fallen into the turbine, can cause a breakdown. It is for this reason that each pipe is carefully wiped from the inside with a napkin soaked in kerosene.

When choosing clamps for pipes, you should remember: silicone is not a very durable material. And if, when installing the pipe, tighten the steel clamp too much, then it can simply cut the pipe. For this reason, experienced motorists recommend not using steel clamps at all, but using clamps made of special high-temperature plastic instead. It provides reliable fastening and at the same time does not cut silicone.

How is the turbine connected to the carburetor?

If the driver decides to connect the turbo system directly through the carburetor, then he must be prepared for a number of problems that will have to be addressed. Firstly, with this connection method, the air consumption will increase significantly. Secondly, the turbine will have to be placed near the carburetor, and there is very little space there. That is why the driver should think twice before applying such a technical solution. On the other hand, if the turbine can still be placed next to the carburetor, it will work very efficiently, since it does not have to spend energy on supplying air flow through a long duct system.

Fuel consumption in old carburetors on the "sixes" is regulated by three jets. In addition, there are several fuel channels. When the carburetor is operating normally, the pressure in these channels does not rise above 1.8 bar, so these channels perform their functions perfectly. But after installing the turbine, the situation changes. There are two ways to connect the turbocharging system.

- Installation behind the carburetor. When the turbine is placed like this, the fuel mixture has to pass through the entire system.

- Installation in front of the carburetor. In this case, the turbine will force air in the opposite direction, and the fuel mixture will not go through the turbine.

Each method has both advantages and disadvantages:

- the first way is much easier. Yes, the air pressure in the system will not be too high. But at the same time, the carburetor will not have to be seriously upgraded, put in it an additional valve for the compressor and additional coolers;

- the second way is much more difficult. The total pressure in the system will be much higher. At the same time, the CO content in the car's exhaust will be lower, and in addition, it will be easier to start a cold engine. But to implement such a connection is more difficult, since it will be necessary to upgrade the carburetor, as mentioned above.

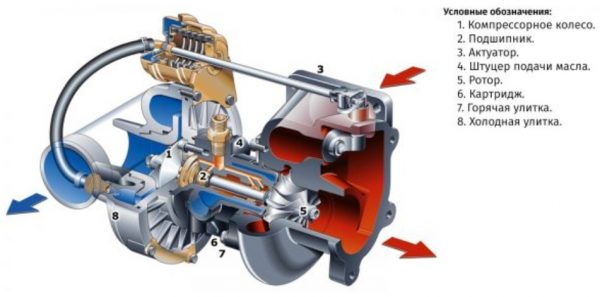

About connecting turbines to the injector

Putting a turbocharging system on an injection engine is much more expedient than on a carburetor. Fuel consumption becomes lower, engine performance improves. This primarily applies to environmental parameters. They are improving, as about a quarter of the exhaust is not emitted into the environment. In addition, the vibration of the motor will decrease. The sequence of connecting the turbine to injection engines has already been detailed above, so there is no point in repeating it. But something still needs to be added. Some owners of injection machines are trying to further increase the boost of the turbine. To achieve this, they disassemble the turbine, find the so-called actuator in it and put a reinforced spring under it instead of the standard one. Several tubes are connected to the solenoids in the turbine. These tubes are silenced, while the solenoid remains connected to its connector. All these measures lead to an increase in the pressure generated by the turbine by 15–20%.

How is a turbine checked?

Before installing the turbine, it is strongly recommended to change the oil. In addition, it is imperative to replace the oil filter and air filter. The sequence for checking the turbocharging system is as follows:

- the turbine should be inspected for oil leaks (this applies to both the part through which oil is supplied and the part through which it drains from the turbine);

- all air ducts are also carefully inspected. None of them should contain dirt and foreign objects;

- if the machine is equipped with a catalyst, then it should also be checked for wear (excessive exhaust from a worn out catalyst can significantly impair the operation of the turbine, it simply cannot cope with a large volume of incoming gas);

Knowing the device of the turbine, it is easier to check its performance

Knowing the device of the turbine, it is easier to check its performance - Finally, you should check whether the turbine rotor rotates normally. The buzz generated by the rotor must be uniform. It should not contain any extraneous sounds: creaking, whistling, etc.

So, installing a turbine on a VAZ 2106 is a long and painstaking process. In some situations, instead of a full-fledged turbine, you can think about installing a turbocharger. This is the least expensive and easiest option. Well, if the car owner has firmly decided to put a turbine on his “six”, then he should prepare for a serious engine upgrade and serious financial expenses.