Clutch Audi 80 B3

Content

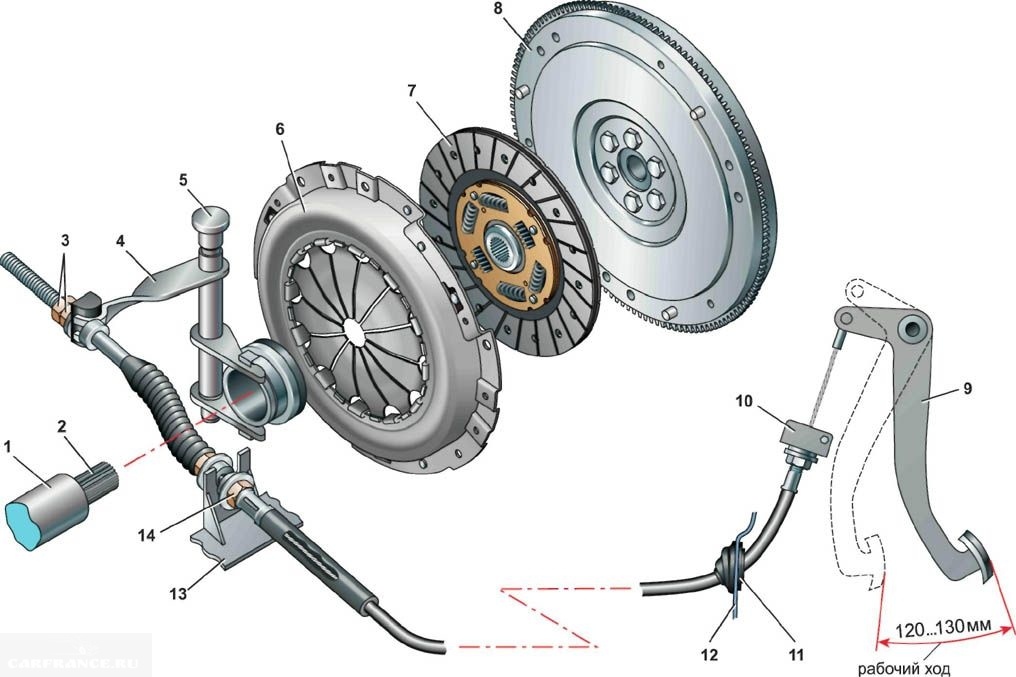

The clutch resource of the Audi-80 B3 is almost the same as that of any other car. A rare clutch passes a hundred thousand milestone. Sooner or later, a separating element from the structure. As a rule, the release bearing, the friction clutches of the driven disc, the spring diaphragm of the basket, and the elasticity are worn out. However, the price of replacing an Audi 80 clutch with any hundred will not cost less than $ 120-150, so it makes sense to change the assembly with your own hands.

Signs of wear, how to check the clutch Audi 80

The first signs of clutch wear or failure are difficulty shifting gears. This is due to the fact that the mechanism does not completely separate the crankshaft and the gearbox input shaft. The most likely sign is a characteristic smell from worn friction linings. If they are oily or badly worn, there is a problem in the assembly, the acceleration time of the car is greatly increased, the clutch can slip, and the upshift becomes a hell of a detection. Also noticeably noticeably small stroke of the pedal.

Worn driven discrete output to slipping of the clutch and burning of the friction linings When gear shifting is accompanied by jerks or bumps, this indicates problems in the system: wear of the friction linings of the driven disk, reduced elasticity of the diaphragm, wear of the release bearing. It happens that scuffs accumulate on the surface of the pressure plate or flywheel, which eventually reach the driven disk if measures are not taken in time. Well, we will accept.

Assembling a replacement tool

It’s not so easy to get to the clutch, if we decide that we need a replacement or repair as necessary, we will remove the gearbox. On all Audi "barrels", regardless of the installed engine, the gearbox is detected by a probable method, the difference is only in distinguishing nuances and the diameter of the flywheel. For work, we need a standard set of tools, with a drive key for bits and something: yes

- Podniker or spacious pit for at least two people.

- A set of keys and hexagons.

- Dodecahedron for 8.

- Hydraulic jack, it would be nice to be rolling.

- Penetrating aerosol WD-40 or equivalent.

Alone, removing the gearbox on the Audi 80 will not work. To the extent that the average level of physical development does not give guarantees, we ourselves are enough. In general, you need an assistant. Actually, it is needed only at the time of dismantling and installing the gearbox, since the unit is quite tight. It remains to buy the clutch on the Audi 80 assembly and get to work.

Choosing the best grip on the Audi 80

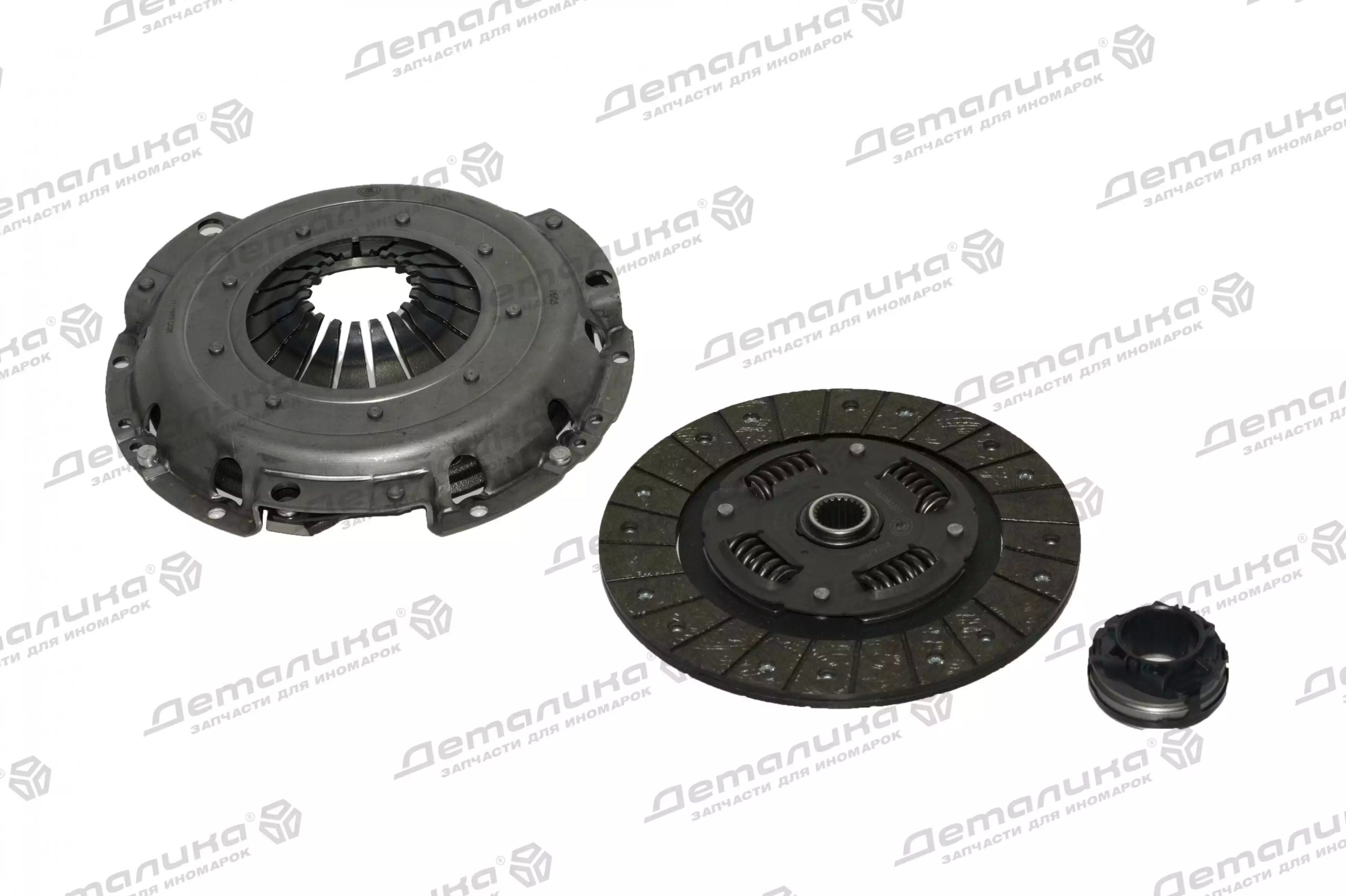

Experienced drivers and motorists who are well acquainted with vag cars choose not to choose a complete clutch kit, but randomly. For example, someone had a good experience using INA release bearings, someone prefers clutch discs from Luk, and who would prefer a Sachs clutch basket. If a set is found that matches the perspective of the driving style, the posupama set

- A Sachs clutch assembly with part number 3000181001 will cost about $160. This is a suitable kit that can last at least 80-100 thousand depending on the style. New Sachs clutch kit

- The Dutch company Quinton Hazell Produces very good kits with catalog number qkt1055AF, the clutch price is about $180. Quinton Hazell Clutch Kits

- The German LuK kit with article 623080600 will cost about the same amount. Not a bad choice. Their driven discs are characterized by increased wear resistance. Clutch LuK with article number 623080600

- You can often find on sale an expensive and high-quality Valeo kit with Article 801462. You will be asked to pay at least $410 for the kit. Expensive, but we love our car, don't we?

In addition to the clutch, most likely, you will have to replace the release fork, crankshaft oil seal, exhaust manifold gasket, and mounting bolts:

- release fork VAG 012141719E - $ 20;

- crankshaft oil seal Reinz 812370840 - 7;

- BOSAL Proclamation 256-901 - $3.

Interest on the topic: Rear wheel bearing Renault Duster: how to choose and change the Crankshaft oil seal, which is also desirable to replace

We change the clutch. Work algorithm

Audi clutch design "barrels"

In order to change the clutch, we put the car on a lift or on a viewing hole. Next, we raise the front axle (if we are in a pit) and be sure to fix it on the racks, and also removed

It is advisable to install the car on a lift and jack up the rear of the engine so as not to tear the pillows

After the car has been prepared for work, we remove the external CV joints. Unscrewing the bolts of the clamping fastening of the support pin, to remove it from the hub, it is not necessary to unscrew the bolts fixing the ball joint to the lever in case the wheel alignment is disturbed.

We remove the CV joints external ...

The kitchen CV joints are dismantled with a dodecahedron and, after removal, they are set aside. Now you can unscrew the bolt of the clutch slave cylinder, as well as remove the reverse gear and speedometer connectors.

... and intrusion too

For future work, it is likely to dismantle part of the exhaust system. The exhaust "pants" are disconnected from the manifold (fixed with nuts). It is necessary to loosen the connection of the catalyst and the resonator and move visibility to the side.

You can unscrew the checkpoint

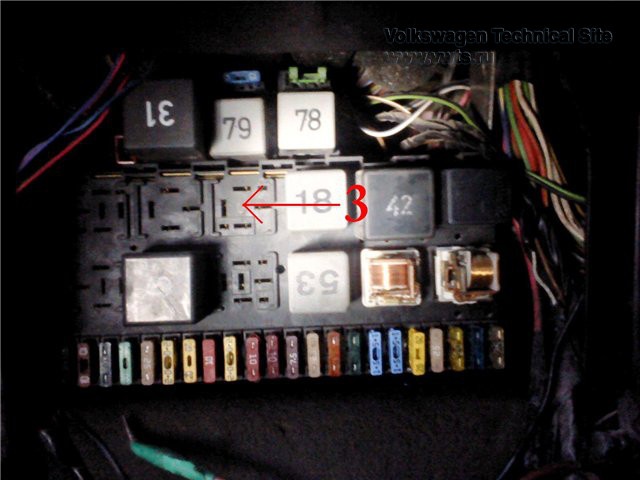

Now access to the removal of the checkpoint is open. We remove the clutch slave cylinder and carefully hang it on. All mounting bolts are unscrewed, two pillow mounts and the box is removed. Of course, we remember that the unit is quite heavy and help is inevitable here. At this event, you can immediately replace the release bearing Audi 80.

Change the fork and release bearing

Audi clutch basket It is mounted on eight bolts for a hexagon by 6. It is desirable to unscrew it crosswise to prevent the Diaphragm from being skewed. After removal, it is necessary to carry out an internal inspection, and replace worn parts. Leave some items that can be excluded. Since we are already here, we change the crankshaft oil seal.

Now you can start assembling. In general, everything turned out in the reverse order, but you need to center the clutch disc.

At first, the structure is not tightly tightened, it is fixed with such an effort that the fire can be displaced. You can find the center using the old gearbox drive shaft, but if it is not there, you can center the adapter that is likely in diameter. We stretch all the bolts of the basket to the end with a force of 2,5 N • m and install the gearbox. We put a new basket with the help of a guide spacer

When installing boxes, there should not be any complex sets. After installation, we will once again check the performance of the clutch, after which you can hang the exhaust. Good luck to everyone and good roads!