Car soundproofing

Content

When choosing a material, it is necessary to take into account its variety and the tasks performed. The maximum result can be achieved by combining several different directions.

- Noise absorbers.

The most popular type of insulation. They reduce the noise level of the road and vehicle elements. The material absorbs various sounds. Premium lining dampens up to 95% of ambient noise. Many motorists make the mistake of using it alone. Getting the maximum effect is possible only by combining several types of material. The basis can be structural products made of natural or synthetic fibers, gas-filled plastics. Silencers of the first type are used by the vehicle manufacturer. It is generally accepted that they have the highest efficiency, but due to moisture absorption they quickly become unusable. The plastic-based material does not have such problems.

- vibration dampers.

When moving, most parts of the body create vibrations and noise. The main task of the vibration damper is to dampen the vibration amplitude of mechanical units. Sound occurs in the elements as a result of impact on the surface and its subsequent transformation into vibrations. To pay for them, use a viscous material based on bitumen and mastic, covered with foil on top. The elastic part rubs against the sheet, and due to this, mechanical energy is converted into thermal energy. The adhesive base guarantees a secure fixation on the body. The main characteristic to pay attention to is the mechanical modulus of elasticity. In addition, the coefficient of mechanical losses is important. Its value affects the weight, dimensions and absorption efficiency.

- ripstop

A dense substance with a sticky composition underneath. With its help, close the minimum gaps at the joints of the air ducts. There are frequent cases of replacement with soft sound insulation and even ordinary foam rubber, window insulation, plasticine and other similar solutions. A high-quality anti-creak is durable, resistant to abrasion, tolerates the negative effects of the environment well and is comfortable to wear. This last quality is especially important, as it is used in hard-to-reach places.

- Liquid soundproofing.

It is mainly used in places where sheet metal cannot be used. As a rule, outside, this is due to the negative impact of the environment. There are two large groups of products: spray and oil. To apply the latter, a brush or spatula is used. This group is resistant to temperature fluctuations, strong chemical and physical influences.

What materials and tools are used for soundproofing

Depending on what parts we are going to insulate, we will need different materials:

- You can eliminate vibration from metal elements using mastic or bituminous vibration isolators. The viscous structure contributes to vibration damping. The thickness of such vibration isolation is 2-5 mm. These materials are used as a base layer for bonding metal parts of a machine.

- As the next (additional) layer, we glue heat and sound insulation. You should not ignore it, as it will help not only protect the car from noise, but also maintain a comfortable temperature and absorb excess moisture.

- We attach the Shumka self-adhesive polyethylene foam as the final layer. It is designed to absorb a significant amount of external noise.

- If you are concerned about creaking between interior elements, then we use anti-creaking materials. They are made in the form of thin strips, which can be easily "hammered" in hard-to-reach places.

One of the most common vibration isolators is Vibroplast Silver. The bitumen-mastic vibration damper is made in the form of a self-adhesive metallized material with a square mark of 5x5 cm, which makes it easy to cut the sheet into elements of the required size.

Vibration absorber Silver is flexible, elastic, anti-corrosion properties, sealing properties, resistance to moisture, ease of installation even on complex relief surfaces. The vibration damper is usually heated with a hair dryer before installation, but Silver does not need this. Material weight 3 kg/m2 with a thickness of 2 mm.

Vibroplast Gold has the same characteristics as Silver. However, its thickness of 2,3 mm provides better vibration isolation. The weight of the vibration damper is 4 kg/m2.

The BiMast Bomb vibration damper is a new generation multilayer material. The first layer is made of metal foil, then there is a layer based on bitumen, and then a layer based on rubber. Before installation, the vibration damper must be heated to 40-50 degrees. BiMast Bomb is considered one of the best vibration isolators. Sheet weight - 6 kg / m2, thickness - 4,2 mm. Elastic sheets are easily cut with a knife or scissors.

Heat-insulating self-adhesive "Barrier" is made on the basis of polyethylene foam. With it, they insulate the floor of the passenger compartment and the trunk of the car.

Adhesive soundproofing Splen 3004 has good thermal insulation and water repellency. Thanks to its flexibility, it is easy to mount on a surface with a complex relief. The acoustic absorber has a weight of 0,42 kg/m2 and a thickness of 4 mm. There is also 8mm Splen 3008 and 2mm Splen 3002.

This sound insulator can be operated in the temperature range from minus 40 to plus 70 degrees. Splen in the form of an adhesive plaster is used at room temperature from plus 18 to plus 35 degrees. At temperatures below plus 10 degrees, its adhesive properties deteriorate.

The efficient Accent Premium muffler dampens engine noise in the cabin. It is also used to insulate the roof, doors, trunk. Reduces noise level by 80%.

The effective sound absorber Accent 10 has good heat-shielding characteristics. The bottom layer is adhesive, the middle layer is elastic polyurethane foam, the top layer is aluminum foil. Sound insulation indicators are limited to a temperature range from more than 40 to more than 100 degrees. Its weight is 0,5 kg/m2, thickness is 10 mm. Accent 10 eliminates up to 90% of noise.

Noise absorber and sealant Bitoplast 5 (anti-creak) is made on the basis of polyurethane foam. It has an adhesive layer protected by a non-stick gasket and a special impregnation. Differs in moisture resistance, long service life, fine heat-insulating qualities which remain at a temperature up to minus 50 degrees. In addition to sound absorption, Bitoplast 5 eliminates squeaks and rattles in the cabin. With a weight of 0,4 kg/m2, it has a thickness of 5 mm. Bitoplast 10 10 mm is also produced.

Sealing and decorative material Madeleine has a black fabric base and an adhesive layer protected by a non-stick gasket. Its thickness is 1-1,5 mm. It is used to eliminate gaps between the car body and decorative interior parts, gaps in the dashboard, air duct sealing.

All of the materials listed cost about 2500 rubles per set of sheets. But you can buy other similar materials.

From the tools we need to get:

- a building hair dryer to warm up the vibration isolator (you cannot use a household hair dryer instead, as it is ineffective);

- seam roller for winding sound insulation;

- scissors for metal or a clerical knife for cutting material;

- a set of tools for dismantling the inner lining;

- a set of wrenches or open-end wrenches;

- large ratchet with a rigid extension;

- heads on "14" and "17" or a powerful pneumatic wrench;

- 7 cm screwdriver or electric screwdriver to save time when disassembling and assembling fasteners;

- crosshead screwdriver;

- TORX screwdriver for unscrewing the screws on the doors;

- small ratchet;

- head on "10" with an extension cord;

- clip pullers;

- solvent (gasoline, anti-silicone, acetone or white spirit are suitable, you will degrease the surfaces before gluing the vibration isolator);

- microfiber for degreasing elements with a solvent. This step cannot be ignored, as the degreaser increases the adhesion between the metal surfaces and the adhesive layer of the vibration isolator.

All work is done with gloves.

General recommendations for working with materials

Vibration isolation is applied first. If this is a heat treatment, warm it up with a building hair dryer. When laying vibra, it is not enough just to apply it to the surface, it must be well rolled with a roller in all accessible places until the foil texture disappears. If the material is poorly pressed, over time it will begin to flake off. Please note that vibration will only have anti-corrosion properties if there are no bubbles under it, otherwise moisture will begin to accumulate in these places. Therefore, use a clerical knife, gently piercing them. At the joint, it is best to glue the vibration isolation end-to-end. Vibration need not be applied to all parts.

But it is better to apply soundproofing in as large pieces as possible, and in no case cut it into strips - this will reduce the soundproofing effect to almost zero. Also, individual small pieces will simply fall off over time. On a roll of Shumka, it is best to draw a kind of pattern, depending on the size of the surface on which you are going to stick it. After that, cut out the template and, slowly tearing off the protective film, start gluing the material in sequence. So step by step you can fix the sound insulation as evenly as possible. In this case, there should also be no bubbles, so go over the material well with a roller. If you still glue the soundproofing in pieces, make sure that each piece fits snugly against the next, leaving no gaps for noise.

When working with a sealant, there are no special subtleties, the main thing is to ensure that the material does not protrude at the ends of the parts.

Now consider where the heater is most often installed.

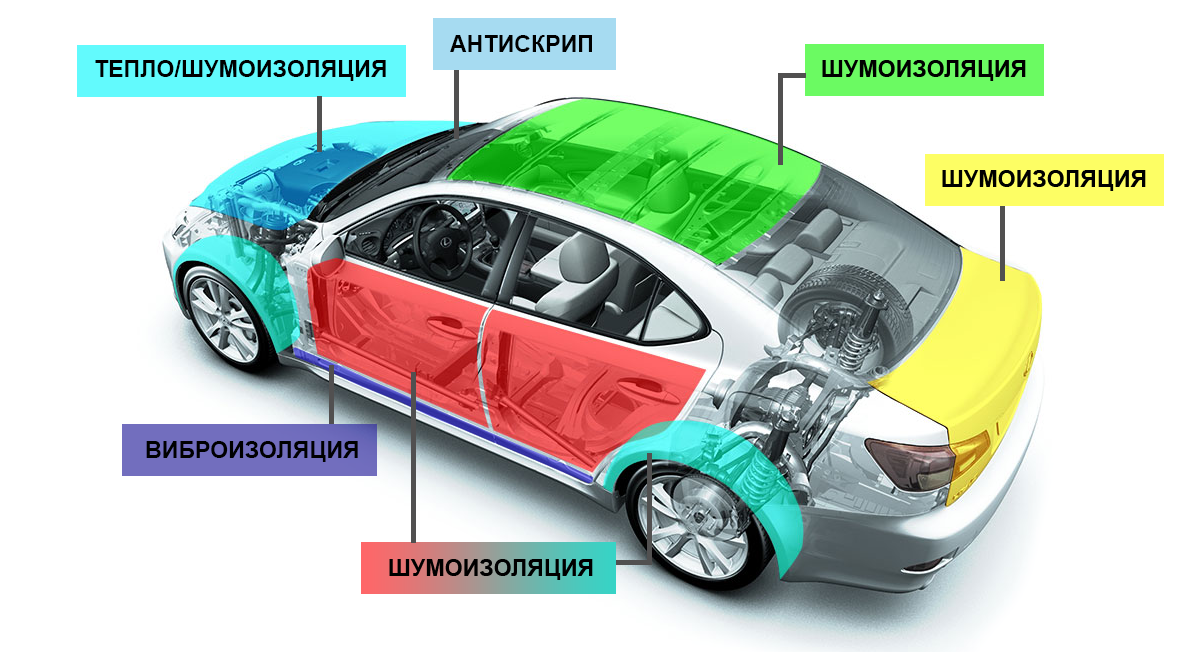

What needs to be silenced

In order for the soundproofing of the car to give the maximum result, it is necessary to drown out such parts of the car as:

- Doors. As a rule, door metal is very even, and the least attention is paid to door processing at the factory. Therefore, it is through the doors that external noise most often passes. Soundproofing the doors also offers some additional benefits in the form of a significant improvement in vehicle acoustics.

- Ceiling. Soundproofing the ceiling can eliminate the unpleasant hum coming from the ceiling when the car is moving at high speed. In addition, soundproofing the roof reduces the sound of raindrops in the car.

- Floor. A very serious source of all sorts of noise is the floor. That is why the soundproofing of the floor gives noticeable results, since during the trip the suspension makes noise and vibrates, the rumble comes from a bad road, etc.

- Arches. It is convenient to isolate these elements of the car, since the arches transmit rather strong vibrations to flat sections of the car.

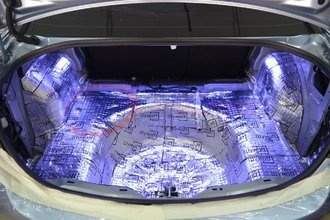

- Trunk. To avoid noise in the rear of the car, it is necessary to soundproof the trunk.

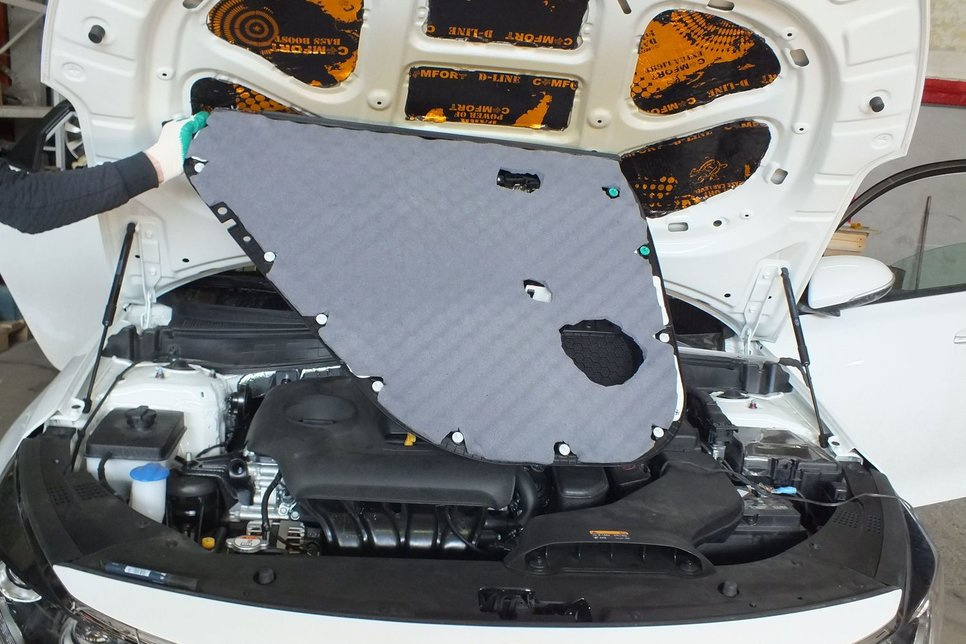

- Hood. The area of the hood of any car is large enough that the vibrations coming from the engine are easily transferred to the aircraft, causing unpleasant noise and noise.

If you are going to soundproof your car, do not forget to take care of eliminating the squeaks that the decorative interior elements emit. Perhaps, earlier, when the car was not silent, it was possible not to notice any extraneous sounds in the cabin. But after the soundproofing work is completed, the noise level in the cabin is significantly reduced, so you may notice problems that did not bother you before. These problems can be solved by gluing the joints with special anti-vibration or suture materials.

Hood work

Hood soundproofing is not designed to completely eliminate engine noise, it's just not realistic. You can just reduce it a little and at the same time insulate the motor during operation in winter. For these purposes, best suited - Accent and "Silver". When working with the hood, special attention should be paid to the weight of the materials. Do not get carried away, otherwise you will soon have to change the shock absorbers. It is important to consider the presence of a factory "skimmer". In the event that it is not there, we will need an "Accent" 15 mm thick, if there is factory thermal insulation, then it does not need to be removed and a thinner "Accent" is needed.

Door work

The doors have a fairly large area, and the main noise comes from them. Particular attention is paid to soundproofing, if the speakers are built in - the sound of music after work will be much better. For simple processing, a vibroplast type material will suffice. It is glued inside the door, trying to cover as much surface as possible. Next, you need to glue all possible places so that they do not creak. For these purposes, "bitoplast" is excellent and the thicker it is, the better for us.

Roof work

Such work is aimed at getting rid of the drums on the roof during rain. Here it is important to take into account the severity of the material so that the center of gravity does not shift, which is highly undesirable. It is also important to keep in mind that it is also necessary to install the ceiling sheathing in its original place.

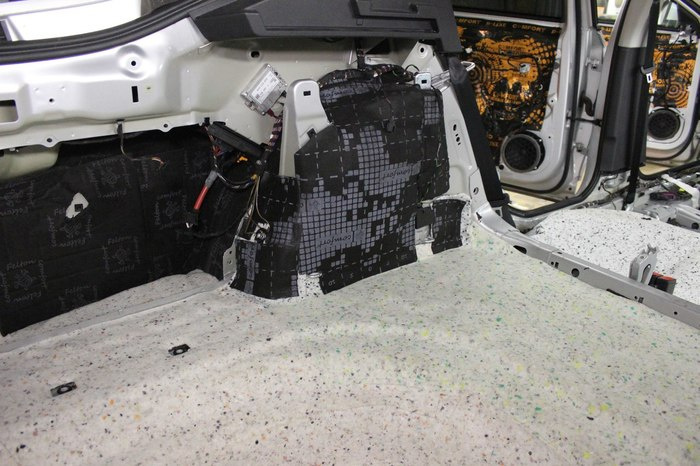

Floor work

By covering the floor, you can reduce the noise from small reeds hitting the bottom of cars. For these purposes, BiMast pumps are usually used, and on top it is covered, for example, with "Splenom" in two layers. It is better to take a thinner option - this will improve coverage. Particular attention during these works will require the insulation of wheel arches. This will require at least two layers of BiMast pumps.

Soundproofing wheel arches outside

Doors are the most frequently insulated body element. Why? Firstly, they have an impressive area relative to the entire body, secondly, they often have hollow insides, and thirdly, they are conveniently located. But thermal insulation doors have their own nuances. Even at the stage of separating the door trim from the metal, one should not forget about fragile clips and wiring - a careless movement, and you can be left without power windows and other electrics. Often a small piece of vibration isolation is already glued to the inside of the door at the factory. If it fits snugly against the metal, a new layer is applied on top, but if bubbles are visible and the foil barely holds, it is removed.

Water Resistance

It is important to understand that due to temperature changes, moisture appears on the inside of the doors. With rain, more water forms on the doors. When soundproofing, it is necessary to take into account the presence of moisture and try to minimize this indicator. It is necessary to use moisture-resistant insulating materials, and to maintain the warming effect in winter, they are also frost-resistant. Particular attention is paid to embossed surfaces, such as door reinforcements. It is recommended to leave such elements without insulation, as well as drainage holes, as well as surfaces covered with factory anticorrosive. Also, when applying insulation from the upper edge of the door, it is better to step back a few centimeters so that the material does not come off the sliding glass.

Isolating doors have the effect of reducing external noise from the road, and also significantly improve the sound of even an average audio system. Particular attention is paid to the ringing and rattling details of the locks and power window mechanisms: they are treated with anti-creak gasket materials.

Tools

Soundproofing work begins with the analysis of the cabin. To do this, use special clips and plastic spatulas. Sometimes they are replaced by screwdrivers. Scissors or a clerical knife are used to cut the material. After application, the material is “smoothed” with a special iron roller.

Experts recommend processing doors in four layers. The first is the use of a vibration isolator (2 mm thick). In order for the vibration isolation sheet to work more efficiently, it must be rolled with a metal roller. For the second layer, a sound absorber (10 mm) with a moisture-resistant sealant is used. The third layer closes the holes in the door body. For this, a vibration isolator (2 mm) is used and it is also wound. The role of this layer is moisture insulation, but it is optional. Layer number four (or the third, if you do not include an additional layer of vibration isolator in the “cake”) is noise insulation, which is a foamy substance that is applied to the inside of the plastic door lining, so that if repair is needed, it is not necessary to tear it off from the third layer. If the door is prepared for car audio, more rigid materials can be used.

Cabin floor and trunk. Remove interior elements, upholstery, floors. The inside is vacuumed to remove accumulated dust and sand. The bare metal is rubbed, degreased and dried. As with soundproof doors, a vibration isolator is used as the first layer. But here it is a bit thicker (3mm). Depending on the type of material, heating may be required, but there are materials on the market that can be used without it if the work is carried out at room temperature (16 degrees and above). The second layer is gas-filled polyethylene that does not absorb moisture (4 mm). You can use thicker mats, but then there is a risk of complicating the assembly of the interior and the appearance of waves on the floor due to its high level.

Soundproofing a ceiling is usually not a priority area. It is no coincidence that often in the car from the conveyor there is no roof insulation at all. What else is good "Shumka" for this subject? Firstly, it eliminates the sound of falling drops and, of course, hides the sound of the road, especially at high speeds when the roof starts to vibrate. The first layer is a vibration isolator (spiral), the second layer (15 mm) is a relief ceiling damper designed to capture sound waves. As with doors, it is not recommended to cover the fittings (carbide strips) with insulating materials to maintain ventilation.

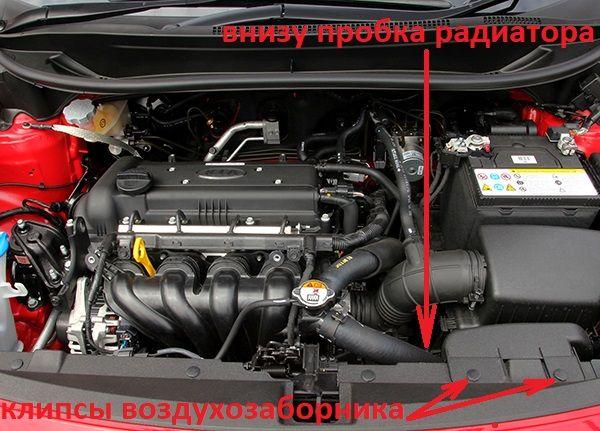

Space under the hood. Due to the small thickness of the metal of the hood and the relatively thin windshield, resonance during engine operation (especially at high speeds) is often transferred to the cabin. For gluing, the regular edge of the hood is removed, under which relief depressions, the so-called windows, are hidden. The approach is the same. First, the surface is prepared: it is washed, degreased, dried, after which two layers of insulating materials are applied: vibration isolation and sound absorber (10 mm).

How to soundproof your car step by step

Before you start soundproofing work, you need to decide what task you set for yourself: improve acoustic sound, eliminate squeaks inside the cabin, add comfort. Depending on the purpose, it is necessary to choose the material.

If the budget is limited and the work has to be done independently, then it is better to do it in stages, gradually improving. First, the doors are soundproofed, then the floor, car trunk, etc.

1. List of required tools.

For work you will need:

- building hair dryer (homemade is not good);

- seam roller for rolling stock - will bring tangible benefits (it is inexpensive, no more than 300 rubles);

- scissors for cutting;

- solvent for degreasing surfaces (white turpentine is suitable).

2. List of used materials.

Most often for soundproofing are used:

- Silver vibroplast. It is a self-adhesive composition of flexible plastic with aluminum foil. The material is marked in the form of squares (5x5 cm). This helps to cut the sheet into parts of the required parameters. Vibroplast Silver has water-repellent characteristics and does not decompose under the influence of the environment. In addition, the material has anti-corrosion properties and sealing qualities. This vibroplast is easily mounted even on difficult terrain, plus it does not need to be heated. The value of the coefficient of mechanical losses is from 0,25 to 0,35 conventional units. Weight 3 kg per m2, thickness 2 mm. Installation is carried out on the floor of the cabin, doors, roof, side parts of the body, hood, trunk, front panel of the car.

- Vibroplast Gold is a material similar to the previous one, but slightly thicker (2,3 mm).

Therefore, its vibration isolation performance is better. Mechanical losses are 0,33 units. Vibroplast Gold weighs 4 kg per m2.

Therefore, its vibration isolation performance is better. Mechanical losses are 0,33 units. Vibroplast Gold weighs 4 kg per m2. - "Bimast pump". This type of vibration damping material is a multilayer structure, including a face layer (made of aluminum foil), 2 sheets with a composition of bitumen and rubber. Before installation, it is necessary to warm up to about 50 degrees. "Bimast Bomb" has water-repellent properties. This is the best vibration material, characterized by the highest efficiency value. Ideal for preparing audio speakers. The value of mechanical losses is not less than 0,50 conventional units. The weight of the material is approximately 6 kg per m², the thickness is 4,2 mm. Mounted on the bulkhead, tunnel, wheel arches, area above the muffler and cardan shaft.

- Bazo 3004. This brand of material refers to soundproof. It has an adhesive layer and is endowed with high thermal insulation characteristics. "Splen" is easily mounted on the surface (vertical and curvilinear). In addition, the material is resistant to moisture and is not subject to decomposition processes under the influence of the environment. Thickness - 4 mm and weight - 0,42 kg per 1 m³. Use is possible at temperatures from -40 to +70°C. The front panels are glued from inside the car, wheel arches, doors, tunnel ... There are two more varieties: Splen 3008 8 mm thick and Splen 3002 2 mm thick. Stick "Splen" on the vibration-absorbing layer. They process doors, rear and front arches, as well as side sections. In order for the connection to be strong, all surfaces are pre-cleaned and dried. For degreasing, white spirit or acetone is used. In order for the adhesive to retain its adhesive properties, it is necessary to observe the temperature regime (ideally from 18 to 35 ° C). At temperatures below +10 ͦС, Splen is not recommended. The tape must be glued, trying not to stretch. The protective layer is removed only before starting work.

- "Bitoplast 5" (anti-creak). This is a type of material that absorbs and seals noise and is designed to eliminate squeaks and rattles inside the cabin. The base is polyurethane foam with an adhesive layer, which is protected by a non-stick gasket impregnated with a special compound.

The material has high moisture resistance, durability, excellent thermal insulation characteristics. In addition, Bitoplast 5 is odorless, does not decompose, does not lose its properties at very low temperatures (up to minus 50 o). Thickness can be from 5 to 10 mm, and weight: 0,4 kg per m².

The material has high moisture resistance, durability, excellent thermal insulation characteristics. In addition, Bitoplast 5 is odorless, does not decompose, does not lose its properties at very low temperatures (up to minus 50 o). Thickness can be from 5 to 10 mm, and weight: 0,4 kg per m². - "Accent 10". Refers to materials that absorb sound. Composition metallized film, flexible polyurethane foam, adhesive mounting layer. It has good thermal protection characteristics and an extended operating frequency range. With a thickness of 10 mm and a weight of 0,5 kg per m², it is able to absorb up to 90% of extraneous sounds. Application temperature from -40 to +100 ͦС. Mounted on the hood, trunk, partition in the engine compartment.

- Madeleine. This material on a black fabric base is not only a sealant, but also decorative. It has an adhesive layer protected by a non-stick pad. Thickness from 1 to 1,5 mm.

Exploitation

The purpose of using vibration isolating materials is achieved if it is possible to reduce vibrations emanating from the engine compartment, wheel arches and transmission. Up to 50% of the body surface is covered with plates, which is not critical for the total mass of the car.

The procedure for mounting a vibration isolator is carried out in several stages:

- Clean body surfaces from dirt, rust and dust, degrease.

- First, remove the protective layer of the anti-vibration sheet and place it on the surface to be treated.

- Heat the foil with a building hair dryer from the side of the adhesive layer evenly, without boiling.

- Glue the sheet to the surface and run a mounting roller over it.

The installation method, when heating occurs inside the machine after gluing one end of the sheet, is not recommended. This threatens to damage parts of the car interior and melt the paint.

Rating of the best materials for soundproofing for 2020

STP Vibroplast

It replaces one of the most popular materials with which you can protect the body and interior of the car from vibrations. The line includes four samples: Vibroplast M1, Vibroplast M2, Vibroplast Silver, Vibroplast Gold. Each sample has individual characteristics.

Vibroplast M1 turned out to be the cheapest, the performance of its work is noticeable only when interacting with thin metal. Domestic cars are only included in the range of their work, and the owners of modern foreign cars made of thicker layers of metal will not achieve the desired result. The product is accompanied by an instruction indicating the elements of the car on which the specified material can be applied.

Vibroplast M2 is essentially an improved version of M1. Its layer is slightly thicker, but the product is also a budget product, despite the higher price than its predecessor.

The next two options presented in the line belong to the premium class. Vibroplast Silver is a modified analogue of Vibroplast M2. The latest model with the pronounced name "Gold" is an almost perfect material. Even the most complex shapes can be laid without much effort. Hence the conclusion that the installation of such a product can be done without the help of specialists. The only drawback is the high cost.

Advantages of STP Vibroplast:

- A wide range of linear noise isolators;

- Easy installation of Vibroplast Gold.

Defects:

- Vibroplast M1 is not effective for foreign cars;

- Vibroplast Gold has a high cost.

STP Bimast

The materials in this series are multi-layered. Suitable for use on thicker metal coatings, therefore also suitable for foreign cars. The line includes 4 representatives:

- STP Bimast Standard is considered the most cost-effective solution. The level of efficiency of its work is average, which allows it to be used in relation to any passenger car. However, it has one significant drawback: during installation, it crumbles into lumps. Some consumers note that sometimes the product does not differ in durability and does not adhere well to the protective layer, and after a while it may even come off completely.

- STP Bimast Super is a more perfect product than the previous one. An increase in thickness and mass is observed, which allows it to be used in cases where the metal is wider. However, a large mass sometimes acts as a significant obstacle when mounting in hard-to-reach places, which sometimes leads to delamination of the foil layer. For this reason, the procedure must be performed with great care or entrusted to professionals.

- STP Bimast Bomb rightfully received the title of one of the best materials in the line, where price and quality are optimally correlated. Excellent characteristics allow you to install the product on both cheap cars and expensive cars. However, cases of defective products have become more frequent, which significantly undermined the credibility of the model.

- STP Bimast Bomb Premium Product with the highest level of performance. You can install it on almost all elements of the car. However, high-quality material is covered with a large mass, which causes significant difficulties when working in hard-to-reach places. Although the quality is at a high level, the cost is also not inferior, which makes the product not available to all consumers.

Advantages of STP Bimast:

- A wide range of noise isolators designed for different cars and different prices.

Defects:

- Complaints about wear resistance and short service life of STP Bimast Standard;

- Claims for defective products.

STP Vizomat

This line has not lost its popularity for many years. They received a separate distribution among motorists when it comes to thick metal.

Advantages of STP Vizomat:

- A wide range of noise isolators, differing in cost and effectiveness in relation to different vehicles.

Defects:

- Some types of screeds require heating during installation.

IZOTON LM 15

This noise-absorbing material consists of a sound-transparent PVC face film. Thickness from ten to twenty millimeters. There is also a sticky layer, which is protected by a non-stick pad. The coating on the front side is resistant to oils and gasoline. This material also has heat-shielding characteristics. The manufacturer claims that sound absorption is in the frequency range from 600 to 4000 Hertz.

Advantages

- Easy to install.

- Quality fixation.

defects

- Lost.

Comfort Ultra Soft 5

The material has improved adhesive characteristics.

This sound absorber is made of high density polyurethane foam impregnated with special polymers using a special technology. Thickness five millimeters.

This solution is one of the best noise absorbers for cars and, at the same time, a sealing material. This solution has special acoustic properties, it is ideally suited for suppressing external and internal noise in the car. Used when processing the second layer.

The manufacturer claims that this material uses glue, which is specially made by well-known brands using special technologies. The glue is adapted for use in difficult conditions, which is relevant for Russian conditions.

The material tolerates sudden changes in temperature, as well as an increased level of humidity. It is used for finishing doors, arches, roofs, trunk, shield of the power unit. This solution is convenient for installation on both simple and complex surfaces.

Efficiency is maintained both in winter and in summer. This material is applied as a second layer over vibration absorbing coatings. Before gluing, it is worth deciding on the dimensions and characteristics. For maximum efficiency, it is recommended to glue this material end-to-end.

Advantages

- Easy to install.

- Quality fixation.

- Versatility.

- Efficiency in different temperature conditions.

- Moisture resistant.

- Excellent non-stick performance.

defects

- Lost.

NOISE BLOCK 3

High-quality two-layer sound-absorbing material based on putty. This material has excellent sound insulation performance. The manufacturer claims that in this solution it was possible to achieve the maximum coefficient of isolation from external noise.

This solution is a sheet material consisting of a non-woven fabric and a polymer-based adhesive layer. There are protective functions presented in the form of separating paper.

This material is used as a heat-insulating layer on the floor, in the trunk, arches, partitions of the power unit compartment. This solution cannot be installed directly on the car body, so it is mounted on heat-insulating and absorbent materials.

This material is offered to customers in various thickness variations: two and three millimeters. Operating temperature range from -50 to +100 degrees Celsius. This material is plastic, it is easy to mount it on a surface with a complex relief. Convenient to use.

Advantages

- Easy to install.

- Efficiency in different temperature conditions.

- Moisture resistant.

- Excellent non-stick performance.

defects

- Lost.

Therefore, its vibration isolation performance is better. Mechanical losses are 0,33 units. Vibroplast Gold weighs 4 kg per m2.

Therefore, its vibration isolation performance is better. Mechanical losses are 0,33 units. Vibroplast Gold weighs 4 kg per m2. The material has high moisture resistance, durability, excellent thermal insulation characteristics. In addition, Bitoplast 5 is odorless, does not decompose, does not lose its properties at very low temperatures (up to minus 50 o). Thickness can be from 5 to 10 mm, and weight: 0,4 kg per m².

The material has high moisture resistance, durability, excellent thermal insulation characteristics. In addition, Bitoplast 5 is odorless, does not decompose, does not lose its properties at very low temperatures (up to minus 50 o). Thickness can be from 5 to 10 mm, and weight: 0,4 kg per m².