Synchronizing carburetor

When the carburettors are out of sync, the idle is noisy, the throttle is insufficient, and the engine is not delivering full power. It's time to properly adjust the carburetors.

What you need to know about carburetor timing

Erratic idling, poor throttle response, and more than normal vibration in a multi-cylinder engine are often signs that carburetors are out of sync. To compare this phenomenon with a team of horses, imagine that one horse thinks only about starting to gallop, while the other prefers to move quietly at a trot, and the last two at a walk. The first pulls the cart in vain, the last two stumble, the trotter no longer knows what to do and check, nothing goes.

Mandatory conditions

Before considering timing carburetors, you need to make sure everything else works. It is necessary to correctly adjust the ignition and valves, as well as the play in the throttle cables. The air filter, intake pipes and spark plugs must be in good condition.

What does synchronization consist of?

When it reaches its proper operating speed, the engine draws the gas / air mixture from the carburetors. And whoever speaks aspiration also speaks of depression. The combustion chambers are energized at the same rate only if this vacuum is the same in all the intake manifolds of the cylinders. This is one of the conditions necessary for the smooth operation of the engine. The feed rate is regulated by a larger or smaller opening of the hatch; in our case, this is the position of the throttle or valve of various carburetors.

How do I make the setting?

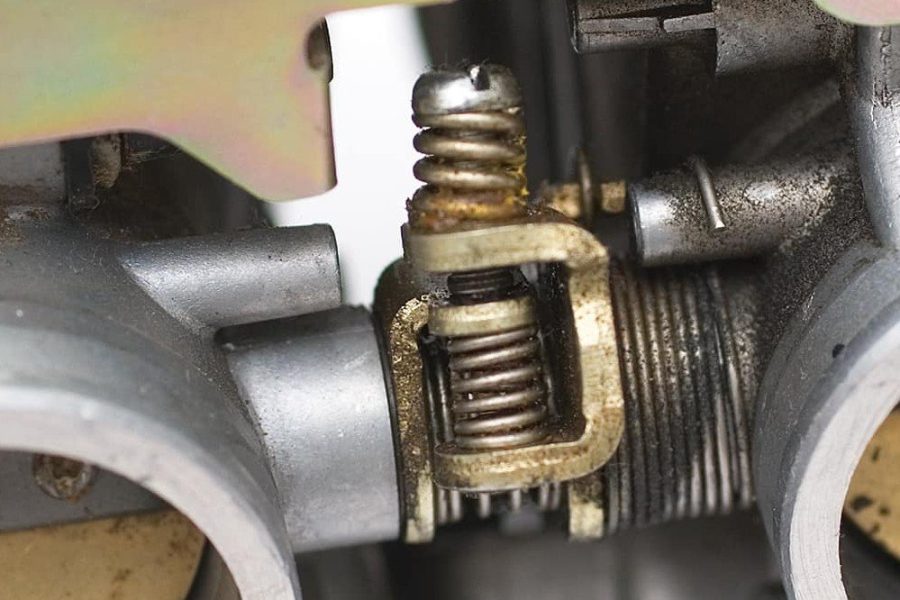

Often, you will need a very long screwdriver to gain access to the adjusting screws. Most often, the throttle valves of vacuum carburetors are interconnected by a spring clutch equipped with an adjusting screw. In the case of four-cylinder engines, synchronize by turning the screws as follows: first calibrate the two right-hand carburettors relative to each other, then do the same with the two left-hand ones. Then adjust the two pairs of carburettors in the middle until all four carburettors have the same vacuum.

In other cases (eg plug-type carburettors), the series of carburetors has a carburetor that serves as a fixed reference value to synchronize other carburettors. In most cases, the adjusting screw is located under the top cover.

Depressiometer: an indispensable tool

In order to be able to regulate the same gas / air mixture delivery rate to all intake manifolds, you need vacuum gauges, hence the opposite of the gauges used to check the tire pressure. Unlike tires, you need to measure all cylinders at the same time, so you need one gauge per cylinder. These gauges are available in sets of 2 and 4, called vacuum gauges, and also contain the required hoses and adapters. In most cases, when making adjustments, it is necessary to disassemble the tank, but start the engine. Therefore, we recommend buying a small bottle of gasoline for your carburetors. You can fix this for example. to the rearview mirror.

Warning: Due to the running engine, perform timing outdoors or under an open canopy, never indoors (even partially). In unfavorable winds, you run the risk of carbon monoxide (exhaust) poisoning, even in an open garage.

Carburetor Timing - Let's Go

01 - Important: start by reducing the air passage

Start by spinning the motorcycle, then place it on the center stand and stop the engine. Then remove the tank and any covers and fairings that might get in the way. In any case, the gas tank should be located above the carburetors. Now it's the turn for the depressionometer. In most cases, for packaging reasons, the gauge is shipped unassembled. However, assembling it is very easy, you just need to follow the instructions in the manual. Be sure to hand tighten the thumbscrew (to regulate air flow) before use without damaging the hose.

Indeed, due to the fact that the indentations are very low, the pressure gauge needles are all the more sensitive. If you connect a pressure gauge with too little damping and then start the engine, the needle will move from one extreme position to the other with each engine cycle and the pressure gauge may fail.

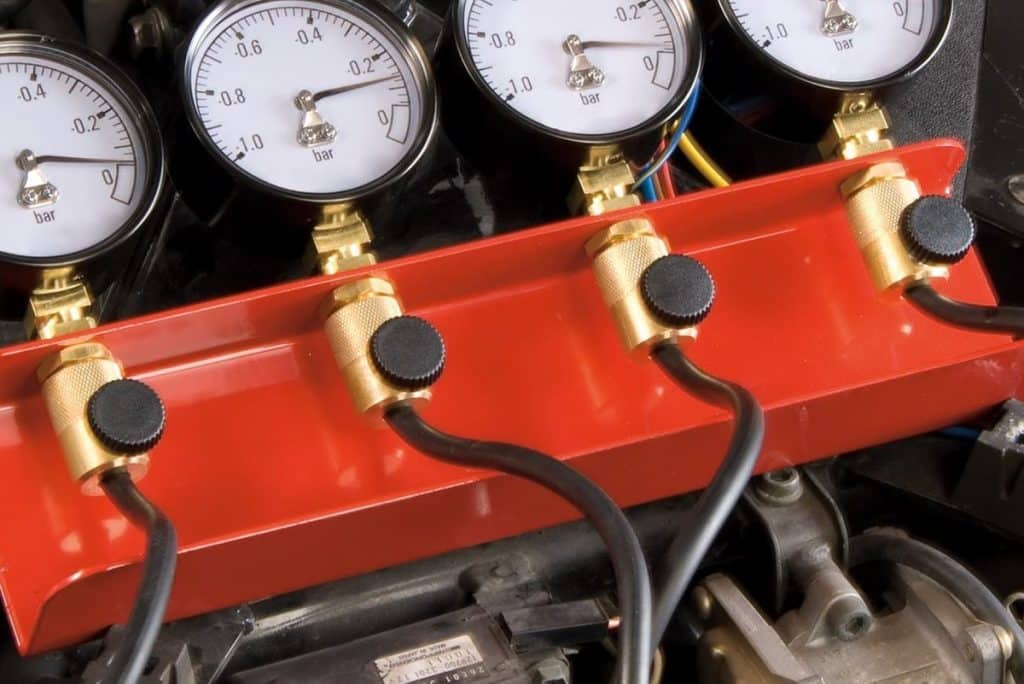

02 - Assembly and connection of depression meters

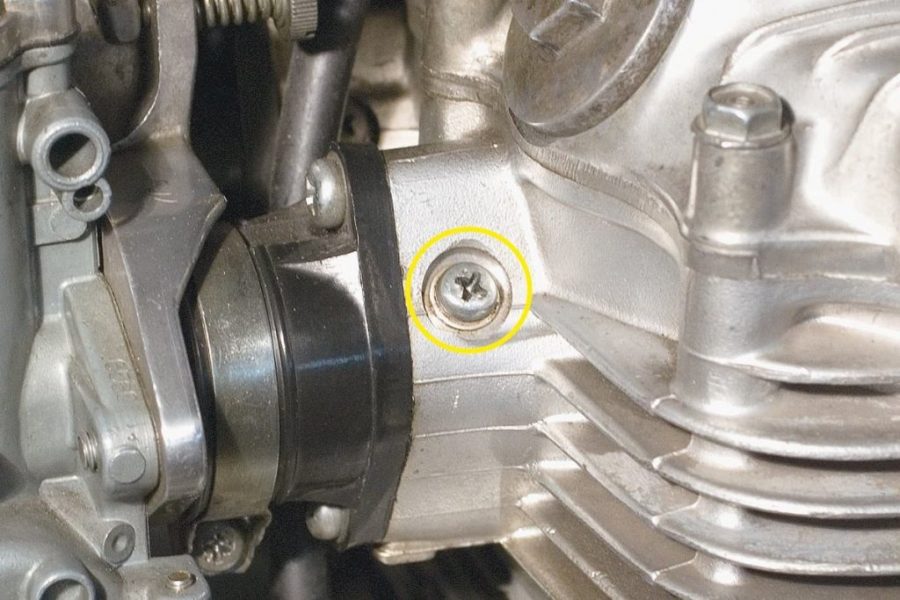

The vacuum gauge tubes are now motorcycle-mounted; Depending on the car, they are installed either on the cylinder head (see photo 1), or on the carburetors (most often at the top, facing the intake pipe), or on the intake pipe (see photo 2).

There are usually small connecting tubes closed with a rubber stopper. The small cover screws of the carburetor or cylinder head should be loosened and replaced with small screw-in tube adapters (the most common are often supplied with vacuum gauges).

03 - Synchronization of all pressure gauges

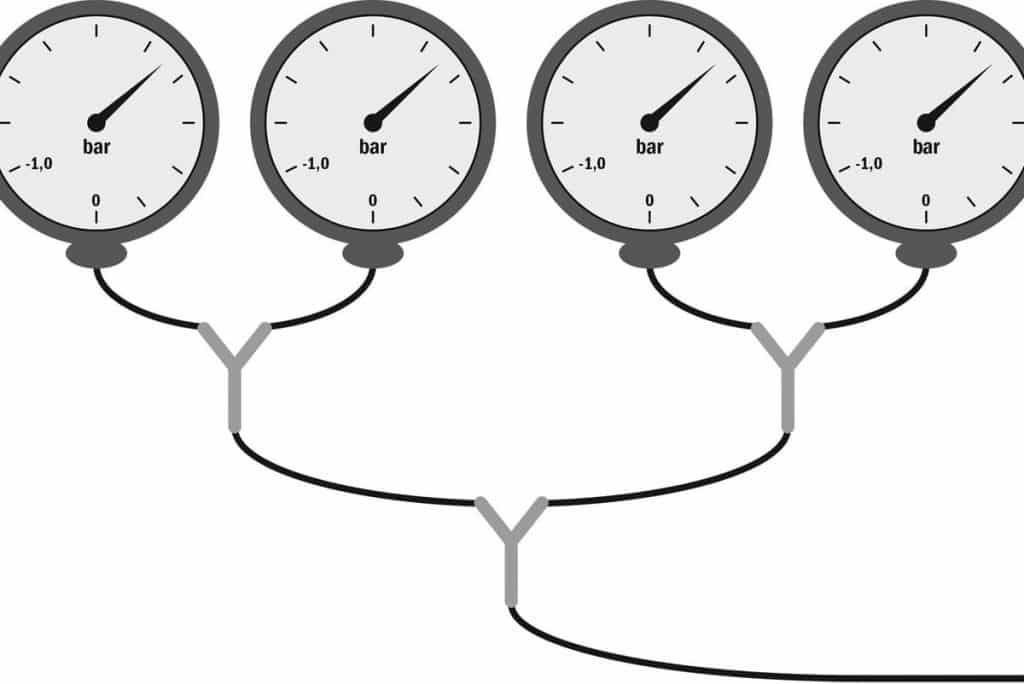

Calibrate the gauges together before connecting them. In any case, this allows the identification of gauges showing faulty readings or a leaking hose connection. To do this, first connect all gauges together using T-piece or Y-piece adapters (also often supplied with vacuum gauges) so that they all come out on one end of the pipe. Connect the latter to the carburetor or intake pipe. The rest of the connections must remain closed.

Then start the engine and adjust the gauges with the knurled nuts so that the needles hardly move, making sure that the needle damping is sufficient. If the needles are completely stationary, the gauge is blocked; Then loosen the knurled nuts slightly. All gauges should now show the same reading. Stop the engine again. If the gauges are fully functional, connect one to each cylinder, then place them in a suitable place on the motorcycle, securing them to prevent them from falling (gauges move easily due to engine vibration).

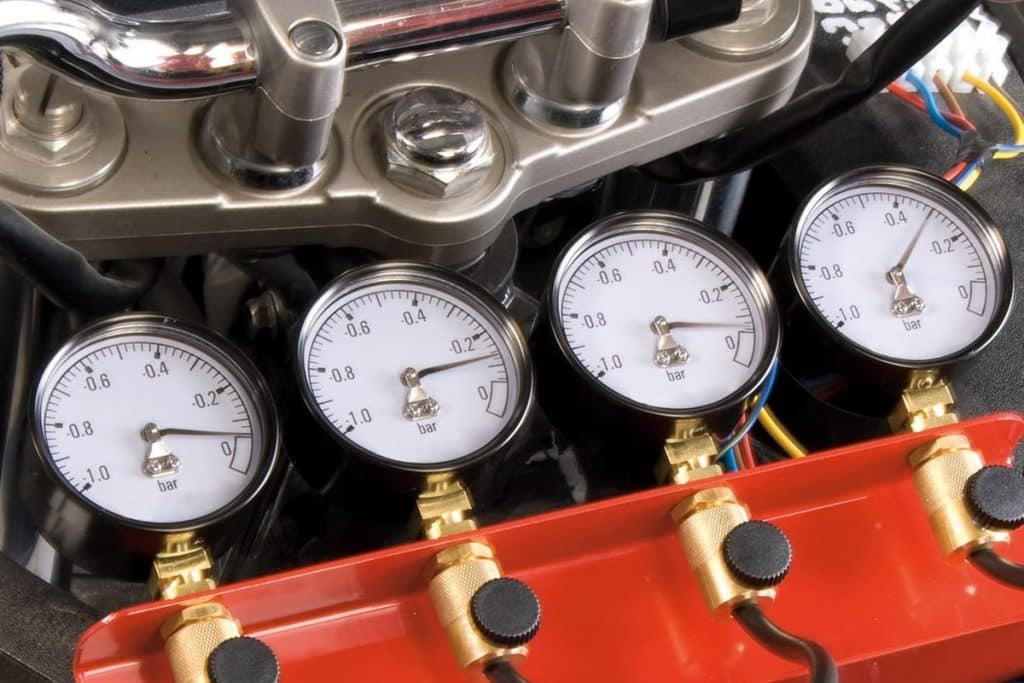

Start the engine, give the throttle a few light strokes until it reaches about 3 rpm, then allow it to stabilize at idle speed. Check scale indicators and adjust with knurled nuts until readable enough. Most manufacturers allow a deviation of approximately 000 bar or less.

04 - Adjust the carburetor to the same measured values

Depending on the model, find the “reference carburetor” of the carburetor battery, then calibrate all other carburettors, one by one, to the maximum precision to the reference value using the adjusting screw. Or proceed as described earlier: first calibrate the two right carburetors, then the two left ones, then set the two pairs in the middle. In the meantime, check if the idle speed is still stabilized at the correct engine speed by lightly moving the accelerator pedal; adjust if necessary with the idle speed adjusting screw. If you are unable to synchronize, it is possible that the cylinders are sucking in extra air, either because the intake pipes are porous, or because they are not tight at carburetor or cylinder head transitions, or because the base setting is the carburetor was completely broken. Less commonly, a heavily clogged carburetor may be the cause. In any case, you must find and eliminate these possible malfunctions; otherwise, no further synchronization attempt is required. More information on cleaning carburetors can be found in the Carburetor Mechanics Council.

We assume you have a positive outcome, and congratulations: Your motorcycle will now run more regularly and accelerate more spontaneously ... for even more fun than ever before. You can now remove the gauge and relieve pressure in the hoses by slightly loosening the knurled nuts. Screw in the pins (take the opportunity to make sure they are not porous) or the cover screws without force (flexible material!). Finally, collect the tank, caps / fairings, then, if necessary, pour the rest of the gas tank directly into the tank, done!