Parking brake and its drive cable. Purpose and device

The parking brake, also known as a hand brake, is an important part of the vehicle's braking system, which many underestimate, and some even almost completely ignore. The handbrake allows you to block the wheels while parking, which is especially important if the parking place has even an imperceptible slope. Its use helps to start on a hill without rolling back. In addition, it can serve as a backup braking system when the main one fails for any reason.

With the exception of the electromechanical drive, which is found on relatively expensive car models, and the very rarely used hydraulics, in most cases the parking brake is actuated by mechanics. The key element of the mechanical drive is the cable.

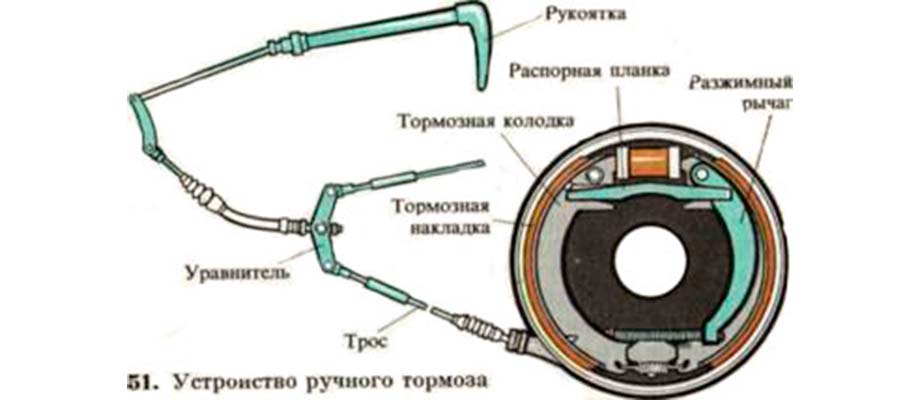

Handbrake mechanisms, as a rule, are placed on the rear wheels. On many old cars, as well as budget models produced in our time, they are installed on the rear axle. In mechanisms of this type, the implementation of the parking brake is quite simple. To block the wheels while stationary, the same brake pads are used as for normal braking of a moving vehicle. Only in this case, instead of hydraulics, a special lever placed inside the drum is used, which is connected to the handbrake drive. When the driver pulls the handbrake handle, and with it the cable, this lever turns and pushes the pads apart, pressing them against the working surface of the drum. Thus, the wheels are blocked.

A ratchet mechanism built into the handle keeps the cable taut and prevents the parking brake from disengaging spontaneously. When the hand brake is released, the return spring allows the system to return to its original state.

It should be noted that there are many cars in which the parking brake is activated not by the handle, but by the foot pedal. The term "handbrake" in this case is not entirely appropriate.

If disc brakes are installed on the rear axle, the situation is different. In this case, it is possible to organize the parking brake in several ways. This can be a separate drum-type mechanism with its own pads or the so-called transmission parking brake, which is often used on trucks, where it is usually placed on the gearbox and slows down the transmission parts (cardan shaft).

In other cases, the main one is supplemented with elements that allow it to be activated not only using hydraulics, but also mechanically. For example, the piston acting on the brake pads may have a rod that is connected to the handbrake cable directly or through a cam transmission mechanism.

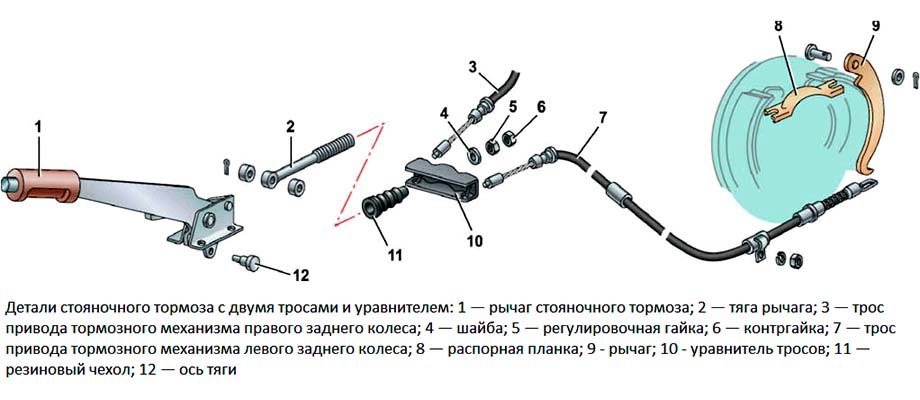

The parking brake uses a twisted steel cable. Its diameter is usually about 2-3 mm. Thanks to its flexibility, it can easily bypass various body and suspension protrusions. This greatly simplifies the design of the drive as a whole, eliminating the need for rigid links, swivel joints and numerous fasteners.

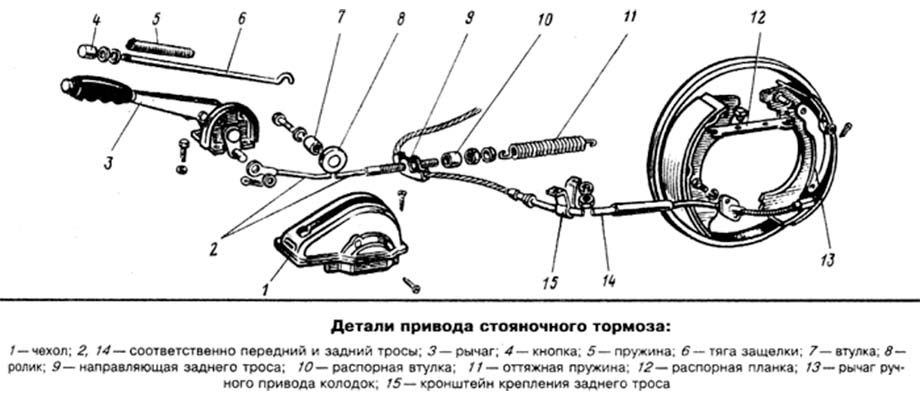

For articulation with other elements of the drive, the cable has tips that are fixed at its ends. They can be made in the form of cylinders, balls, forks, loops.

Inside the protective polymer shell, which is often made reinforced, grease is stuffed. Thanks to the lubrication, the cable does not rust or jam during use. There are rubber boots to protect against dirt and grease leakage.

At the ends of the shell, metal bushings of various types and purposes are fixed. A bracket or stop plate at one end allows the cable to be fixed to the brake support plate. The bushing with an external thread is intended for fastening to the equalizer. Other bushing options are also possible, depending on the specific drive design.

Brackets or clamps can also be placed on the shell for fastening to the frame or body.

In the simplest case, the drive includes a single cable and a rigid rod placed between the manual drive handle, which is located in the cabin, and a metal guide. A cable is connected to this guide, which is further divided into two outlets - to the right and left wheels.

In this embodiment, a single cable failure will completely disable the parking brake. Therefore, such a system is almost never used, despite the simplicity of design and configuration.

The variant with two cables is much more widespread. Rigid traction is also used here, an equalizer (compensator) is fixed on it, and two separate cables are already connected to it. Thus, in the event of failure of one of the cables, it will remain possible to block the other wheel.

There is also a third version of the drive, in which another cable is installed between the handbrake handle and the equalizer instead of a rigid rod. Such a construction gives more opportunities for tuning, and some misalignment of the components of the system has almost no effect on its operation. This design is also actively used by automakers.

In addition, there is another type of drive, where a long cable directly controls the pads of one of the wheels. At a certain distance from the lever, a second, shorter cable is connected to this cable, going to the second wheel.

Routine work must necessarily include checking the operation of the parking brake and the condition of its drive cable. Over time, it can stretch, wear out, and corrode. If the adjustment fails to compensate for the stretching of the cable or it is badly worn, then it will have to be replaced.

It is best to choose a new one for replacement based on the corresponding catalog number or based on the model and date of manufacture of the car. As a last resort, look for a suitable analogue taking into account the drive design, cable length and type of tips.

If there are two rear cables in the handbrake drive, it is strongly recommended to change both at the same time. Even if only one of them is faulty, the second, most likely, is also close to exhausting its resource.

Depending on the specific drive device, the replacement may have its own nuances and should be carried out on the basis of a repair manual for this car model. Before carrying out work, make sure that the machine is stable and immobilize it.

In the general case, the equalizer is first attached to the rod, which makes it possible to loosen the cable tension. then the nuts are unscrewed and the tips are removed from both sides.

Assembly is done in reverse order, after which you need to adjust the tension of the cable and make sure that the brake pads securely block the wheels.

Irregular use of the manual drive does not benefit him and does not save his resource at all. On the contrary, ignoring the handbrake can lead to corrosion and souring of its components, especially the cable, which can jam and eventually break.

Owners of cars with an automatic transmission are also mistaken, considering that in the “Parking” switch position, you can do without a handbrake even on a slope. The fact is that in such a situation, the automatic transmission actually performs the role of a handbrake, and at the same time it is under serious stress.

And let us remind you once again - in winter, in frost, the handbrake should not be used, since the pads can freeze to the surface of the disc or drum. And when the car is left on the parking brake for more than one or two weeks, they may stick due to corrosion. In both cases, the result may be the repair of the brake mechanism.