Engineer's straight edge maintenance and care

Content

How to check if a ruler is straight | |

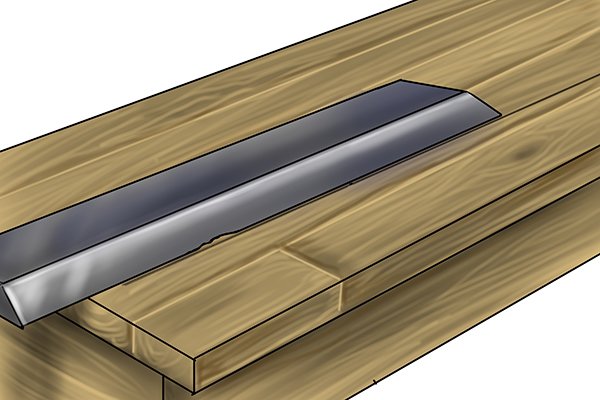

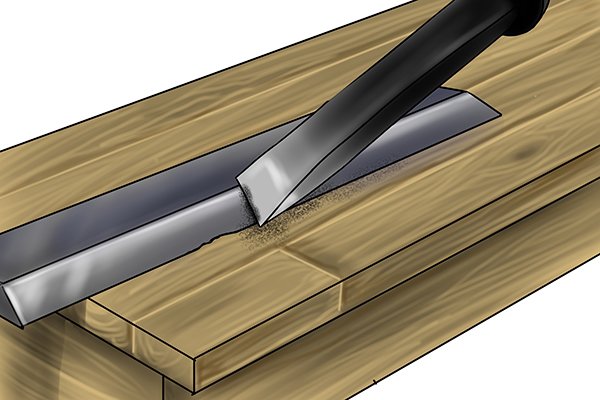

| Without the aid of another ruler or flat plate, the best way to check if a ruler is straight is to place it on a wooden board. | |

| With the working side of the ruler at an angle of 90 degree to the surface of the wooden board, run a marking knife along the length of the straight edge. Then rotate the ruler 180 degrees and place it opposite the line you just marked. |

| If there are gaps between the line and the ruler, then the ruler is not straight. Note: This method is only suitable for rough checking the accuracy of workshop straight edges. In order to accurately check if a ruler is straight, it must be tested with precision instruments, and this is best done by an accredited laboratory. |

Engineer's ruler calibration | |

| Engineering rulers must be calibrated at a UKAS (United Kingdom Accreditation Service) accredited calibration laboratory in the UK or an appropriate regional body in other parts of the world. The calibration laboratory must also comply with ISO/IEC 17025. |

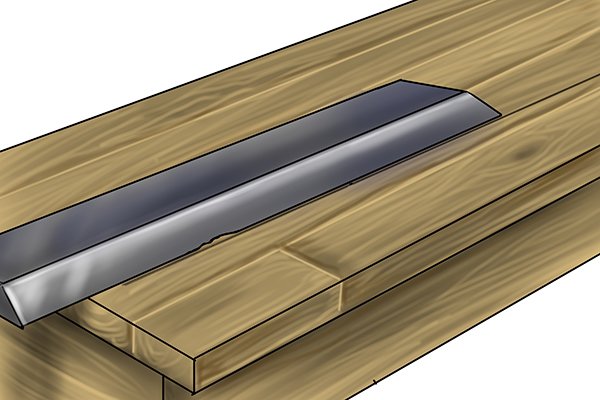

| UKAS publication ref:Lab 21 states that engineering rulers should be calibrated at least once a year by competent personnel in the facility using appropriate calibrated equipment in accordance with a documented procedure. This is in addition to a minimum five year calibration in a UKAS accredited laboratory for which a UKAS calibration certificate is issued. A list of UKAS accredited laboratories can be found on the UKAS website. |

Engineer's ruler cleaning | |

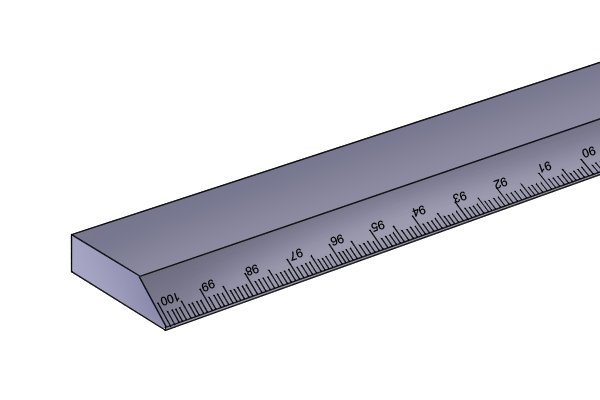

| How you clean an engineer's ruler depends a lot on the material it's made of. |

| If the ruler has marking ink or any other liquid on it, the first thing to do is wipe it off with a soft cloth. |

| Steel and cast iron straight edges should then be sprayed with water repellent oil or grease and the excess wiped off with a rag. This helps prevent moisture from entering the ruler and minimizes the risk of corrosion over time. |

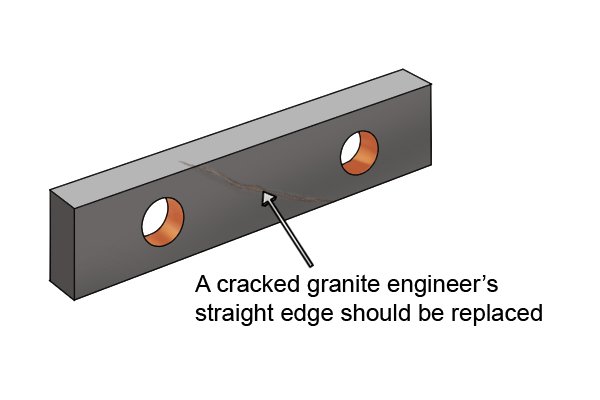

| The straight edges of a granite engineer should be sprayed with a special granite cleaner and wiped off the excess. This not only cleans the granite but also helps to seal any pores in the granite structure, preventing moisture from entering which can cause the granite to crack. |

| Because aluminum rulers do not rust, they only need to be brushed and wiped clean of any debris or liquid before storage. |

Storage of the engineer's ruler | |

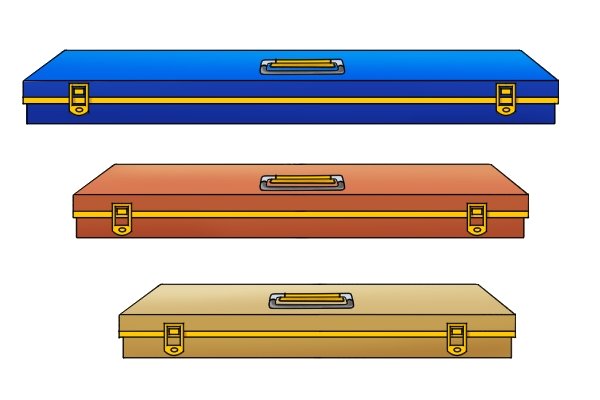

| Engineering rulers should be stored separately from other tools so as not to damage their work surface. |

| You should be aware that steel and cast iron rulers can rust if left in a damp atmosphere, so it's especially important to store them in a dry place. |

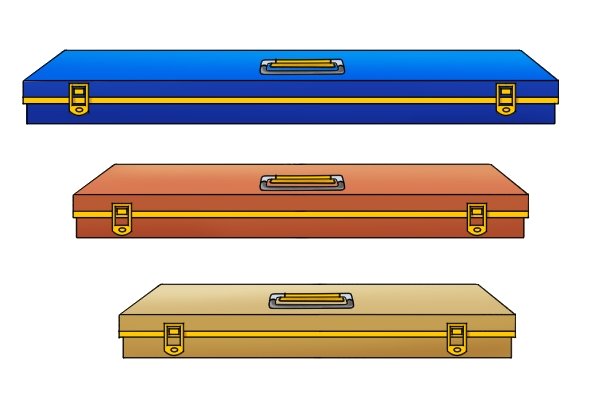

| Some engineer lines come with their own storage boxes to prevent damage to the work surface. If you don't have them, you can buy them separately or make your own. Many of them feature a form-fitting foam rubber interior that provides superior insulation against any bumps and bumps that could damage your engineer's ruler or affect its accuracy. |

| If you are not using a storage case, engineering rulers should be stored either with anchor points/feet or with a work surface resting on an equally flat surface such as a base plate. This will minimize any deviation that may be caused by the working surface of the straight edge. |

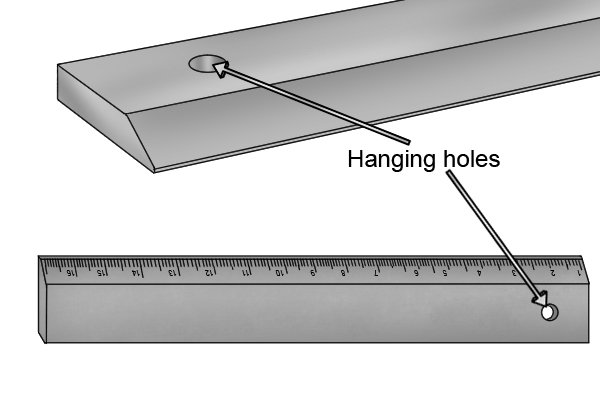

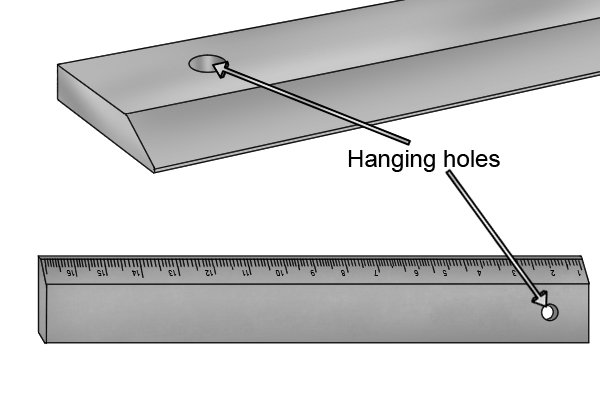

| Some smaller and thinner rectangular and sharp engineering rulers have a hanging hole at one end. This allows the straight edge to be suspended when not in use and minimizes the forces on the work surface, thereby reducing any possible deformation of the work surface. |

Can a damaged engineering ruler be repaired? | |

| If the engineer's ruler is damaged, it can be repaired, depending on the nature of the damage received. Minor damage, such as slight deformation of the work surface, can be repaired by re-sanding or lapping the straight edge. |

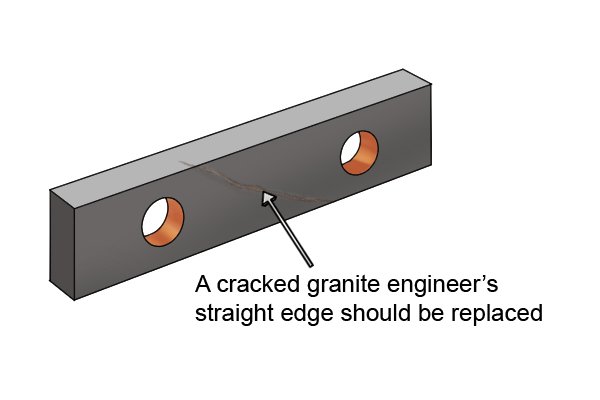

| This must be done by an accredited laboratory to maintain and certify the accuracy of the straightedge. More severe damage such as dents in the worktop, bent rulers, or cracked granite rulers will most likely require replacement of the ruler with a new one. |

How long does an engineering line last? | |

| With proper care and maintenance with regular calibration, an engineering ruler will last for many years. |