Types of car suspensions

Content

The suspension of a vehicle is called the combination of several parts, which are designed to act as a connecting element between the car body structure and the roadway. The suspension is included in the chassis and regulates the following works:

- connects the wheels or axles to the frame structure or body (depending on what is considered the supporting structure on a given car model);

- transfers energy to the supporting structure, which appears when the wheels come into contact with the roadway;

- organizes the desired character of the movement of the wheels and gives additional softness to the car.

The main suspension parameters include: track, wheelbase and ground clearance (or ground clearance). The track is the length between the two axes of the points of contact of the tires with the road surface. The wheelbase is a characteristic of the distance between the axles of the wheels located in front and behind. And clearance is a value that is determined by the length between the road and the part of the car closest to the roadway. Depending on these three indicators, the smoothness / rigidity of the course, the maneuverability and controllability of the vehicle are determined.

General suspension device

For all types of suspensions, the following elements are common:

- mechanisms for ensuring the elasticity of the position of the supporting structure relative to the road;

- nodes that distribute the directions of the force coming from the road;

- elements that dampen blows coming from the road;

- details for stabilization of transverse course stability;

- fastening elements.

At the same time, the mechanisms for ensuring elasticity are a kind of gasket between the car body and the existing defects on the road. It is these mechanisms that are the very first to meet all road defects and transfer them to the body:

- spring elements that can contain working fluid both in a constant cycle and in a variable one. In the very center of the spring there is a bump stop made of plastic material, which is designed to smooth out and reduce all vibrations coming from the road;

- springs are a combination of several elastic strips of metal, which are intercepted by a hook and are characterized by different lengths. Due to the elasticity of the metal strips and their different sizes, the unevenness of the roadway is also smoothed out;

- torsion bars look like a small tube of metal, with internal rods in it. The rod elements function on the principle of twisting and unwinding, since the torsion bars are twisted along their center line at the time of their installation;

- Pneumatics and hydraulics, used in some suspension elements, allow you to go through road bumps as softly as possible by guiding the body up and down. The element, based on a pneumatic or hydropneumatic principle of operation, is a fully sealed cylinder that is inflated with a compressed liquid or air and controls the stiffness during control.

The nodes that distribute the directions of the impact coming from the road serve several tasks. Firstly, there is a more reliable fixation of the suspension units to the body, secondly, the process of transferring the energy force to the passenger compartment is softened and, thirdly, the necessary position of the drive wheels relative to the axes of movement is ensured. The spreading elements include double levers as well as transverse and longitudinal mounting lever components.

The element for dampening the force of road shocks (shock absorber) counteracts the shocks and vibrations coming from the road. Externally, the shock absorber looks like a smooth metal tube with welded parts for fastening. The functionality of the extinguishing element is ensured through the use of hydraulic force, that is, under the action of irregularities, the working fluid passes through the valve from one cavity to another.

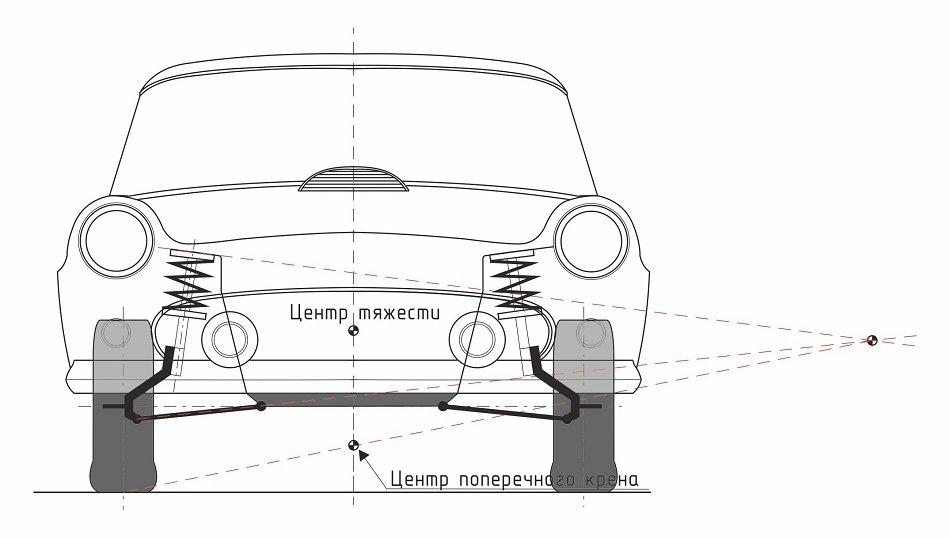

Details for stabilizing the transverse stability of the car are a bar and supports for attaching to a part of the body. These parts connect the levers of opposite wheels. Due to this, they increase the stability of the vehicle and smooth out the roll when cornering.

Fastener elements include both bolted connections, and spherical and plastic ones. For example, high-pressure silent blocks are pressed into the levers and bolted to the body or frame. And the ball joint is a hinge that is fixed to the levers with one part, and the other is in contact with the support of the wheel mechanism.

Existing suspension types

Depending on the differences in design, suspension systems are divided into two large types - dependent and independent suspensions. Each of these types is characterized by its own advantages and disadvantages, but one cannot say that one type is preferable to another.

Dependent suspensions

Differ in simple structure and functionality. The principle of operation is based on a very rigid connection of opposite wheel mechanisms, that is, the movement of one wheel will invariably cause the rotation of the other.

This is the most "ancient" type of suspension mechanism, which modern cars inherited from the first horse-drawn carriages. However, this did not prevent the dependent suspension from being constantly improved, so today they are considered as common as the newer, independent ones.

The main advantage of dependent suspension is the guarantee that the parameters of the wheel movement will not change even when passing through the tightest corner. Opposite wheels will always be parallel to each other. In addition, on off-road or very rough roads, the wheelset will forcibly remain in the most favorable and safe position for the car - strictly perpendicular to the surface of the canvas.

However, drivers often experience some discomfort from driving cars with a dependent type of suspension. For example, when hitting an obstacle (hill, pit, rut), due to the continuity of the movement of a pair of wheels, the car can deviate from the tilt of the axle. In addition, the specific arrangement of the mechanisms does not allow expanding the usable space in the trunk, in some cases a higher position of the propulsion unit is also required, which directly affects the shift in the center of gravity of the car.

Because of this, dependent suspension is now commonly used on trucks, passenger buses, and off-road vehicles. In passenger cars, this type of suspension is quite rare, as it does not give the driver increased handling and comfort. However, on front-wheel drive passenger vehicles, it is possible to install some varieties of this type without losing functionality and convenience.

Dependent type includes several types:

- elements located on the spring structure of the cross section;

- elements located on the springs of the longitudinal section;

- assemblies having guiding lever components;

- suspension with drawbar or tube;

- view of "De Dion";

- torsion-lever.

Independent suspensions

Structurally, this is a more complex mechanism that allows a pair of wheels to rotate independently of each other. As a result, the use of an independent type of suspension guarantees a good ride.

Wheels independent of each other can move along different trajectories and at different speeds. This gives both ease of use and the ability to overcome road obstacles with maximum comfort. At the same time, some types of independent suspensions have become especially widespread today due to their budget and manufacturability (for example, the MacPherson type and the Multi-link suspension).

The main principle of operation of independent suspension systems is the use of staggering (moving) elements in wheel mechanisms. Therefore, when passing obstacles, each wheel will behave differently, which will provide the driver and his passengers with a smoother ride. Again, this advantage for a number of motorists can also become a disadvantage: when entering a turn, the wheels do not become parallel, which requires a reduction in the speed limit on each dangerous section of the road. In addition, due to uneven wear, various defects in operation may be observed in the future. Therefore, independent suspensions more often than dependent ones need high-quality diagnostics and replacement, these services are carried out in the technical centers of FAVORIT MOTORS Group, whose employees have the necessary qualifications.

The main application of independent suspension systems is in the equipment of rear-wheel drive cars.

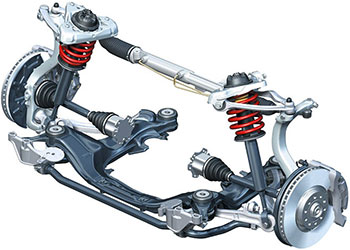

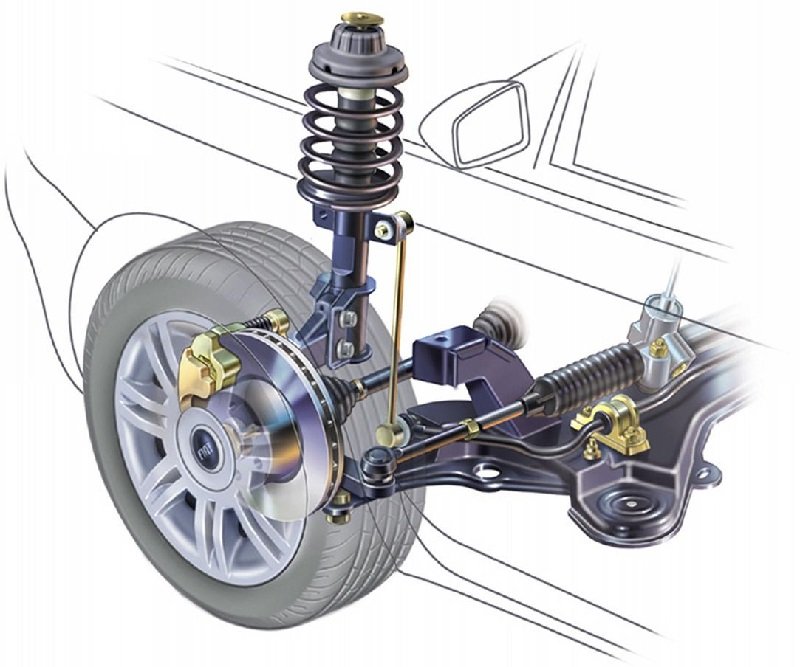

The independent type includes several types:

- with 2 axle shafts having a "swinging" nature of work;

- elements that are located on the longitudinal semiaxes;

- spring;

- torsion;

- Dubonne type;

- arrangement on double levers of longitudinal section;

- location on oblique levers;

- arrangement on double levers of cross section;

- spring;

- multi-link;

- MacPherson type;

- candle.

The principle of operation of suspensions

Regardless of the design features and type, the suspension operation scheme is based on the conversion of energy received from the roadway. That is, when a car wheel receives a blow that occurs when hitting a stone, a bulge or falling into a hole, the kinetic force of this blow is immediately transferred to the elastic suspension element (spring).

Further, the impact force is smoothed (softened) by the distribution work of the shock absorber. Thus, the power received from the wheel is supplied to the body in a much reduced form. It is from this that the smoothness of the ride will depend.

Regardless of the type of suspension system used on the car, the car owner must pay special attention to the suspension elements. In the event of a hardening of the machine and the appearance of suspicious knocks in the area of the shock absorbers, you should immediately contact the professionals, since only timely repairs can save money on the future overhaul of the entire suspension system. The services provided by Favorit Motors Group of Companies are characterized by an optimal price-quality ratio, and therefore are considered affordable for all car enthusiasts of the capital.