Types of coupling connections

Content

A coupling is a special device (vehicle element) that connects the ends of the shafts and the moving parts located on them. The essence of such a connection is to transfer mechanical energy without losing its magnitude. At the same time, depending on the purpose and design, the couplings can also connect two shafts that are located in close proximity to each other.

The role of coupling joints in the operation of a car can hardly be overestimated: they are designed to remove high loads from mechanisms, adjust the course of the shafts, ensure the separation and connection of the shafts during operation, etc.

Coupling classification

The most popular types of couplings in the automotive industry are standardized today, however, there are a number of devices that will be made according to individual measurements for each particular brand of car. In view of the main purpose of the clutch (transmission of torque without changing its value), there are several main types of device:

- according to the principle of controllability - unmanaged (permanent, static) and self-managed (automatic);

- by groups and differing functions in the car - rigid (these include sleeve, flange and longitudinally coiled couplings);

- to adjust the angle of connection between two coaxial shafts, articulated couplings are used (their main types are gear and chain);

- according to the possibilities of compensating loads when driving (using a star mechanism, sleeve-finger and elements with a shell);

- by the nature of the connection / separation of two shafts (cam, cam-disk, friction and centrifugal);

- fully automatic, that is, controlled regardless of the actions of the driver (overrunning, centrifugal and safety);

- on the use of dynamic forces (electromagnetic and simply magnetic).

Description of each item

For a more detailed consideration of the functions and structure of each of the coupling connections, the following description is offered.

Unmanaged

They are characterized by their static position and simple design. It is possible to carry out various settings and adjustments in their work only in a specialized car service with a complete stop of the engine.

The blind coupling is a completely static and clearly fixed connection between the shafts. The installation of this type of coupling requires particularly precise centering, since if at least one small mistake is made, the operation of the shafts will be disrupted or impossible in principle.

The sleeve type of couplings is considered the simplest of all types of blind couplings. This element is made up of a bushing equipped with pins. The use of sleeve couplings has fully justified itself on vehicles whose operation does not imply heavy loads (urban-type sedans). Traditionally, blind sleeve couplings are installed on shafts with a small diameter - no more than 70 mm.

The flange coupling is considered today one of the most common connecting elements in cars of all types. It consists of two equal-sized coupling halves, which are bolted to each other.

This type of coupling is designed to connect two shafts with a cross section of 200 mm. Due to their small size and simplified design, flange couplings allow them to be used on both budget cars and luxury cars.

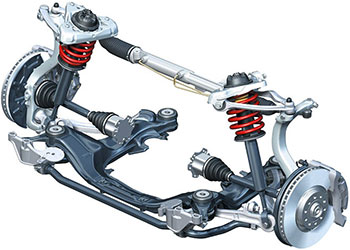

The compensating version of the couplings (rigid coupling) is designed to align all types of shaft accommodation. Whatever axis the shaft moves along, all the shortcomings of the installation or driving of the vehicle will be smoothed out. Due to the work of compensating clutches, the load is reduced both on the shafts themselves and on the axial bearings, which ensures a long service life of the mechanisms and the vehicle as a whole.

The main disadvantage in the operation of this type of clutch is that there is no element that would mitigate road shocks.

The cam-disc clutch has the following structure: it contains two half-couplings and one connecting disk, which is located between them. Carrying out its work, the disk moves along the holes cut in the coupling halves and thereby makes adjustments to the operation of the coaxial shafts. Of course, disc friction will be accompanied by rapid wear. Therefore, scheduled lubrication of the coupling surfaces and a gentle, non-aggressive driving style are required. In addition, to extend the service life of the Cam-disc clutches are made today from the most wear-resistant steel alloys.

The structure of the gear coupling is determined by two coupling halves, which have special teeth on their surface. In addition, the coupling halves are additionally equipped with a clip with internal teeth. Thus, the gear coupling can transmit torque to several working teeth at once, which also ensures a higher load carrying capacity. Due to its structure, this coupling has very small dimensions, which makes it in demand in cars of all types.

Elements for gear couplings are made of steels saturated with carbon. Before installation, the elements must undergo heat treatment.

Compensating elastic couplings, unlike compensating rigid couplings, not only correct the alignment of the shafts, but also reduce the load force that appears when shifting gears.

The sleeve-and-pin coupling is made up of two coupling halves, which are connected by fingers. Tips made of plastic materials are put on the ends of the fingers in order to reduce the load force and soften it. At the same time, the thickness of the tips themselves (or bushings) is relatively small, and therefore the springing effect is also not great.

These coupling devices are widely used in complexes of electric propulsion units.

The use of a clutch with snake springs implies the transmission of a large torque. Structurally, these are two coupling halves, which are equipped with teeth of a unique shape. Between the coupling halves are springs in the form of a snake. In this case, the clutch is mounted in a cup, which, firstly, saves the working place of each of the springs and, secondly, performs the function of supplying lubricant to the elements of the mechanism.

The clutch is more expensive to manufacture, but its long-lasting performance makes this type of mechanism suitable for premium cars.

Managed

The main difference from uncontrolled ones is that it is possible to close and open coaxial shafts without stopping the operation of the propulsion unit. Because of this, controlled types of couplings require extremely careful approach to their installation and alignment of the shaft arrangements.

The cam clutch consists of two half-couplings that are in contact with each other with special protrusions - cams. The principle of operation of such couplings is that, when turned on, one half-coupling with its protrusions rigidly enters the cavities of the other. Thus, a reliable connection between them is achieved.

The operation of the cam clutch is accompanied by increased noise and even shock, which is why it is customary to use synchronizers in the design. Due to the susceptibility to rapid wear, the coupling halves themselves and their cams are made of durable steels, and then fire-hardened.

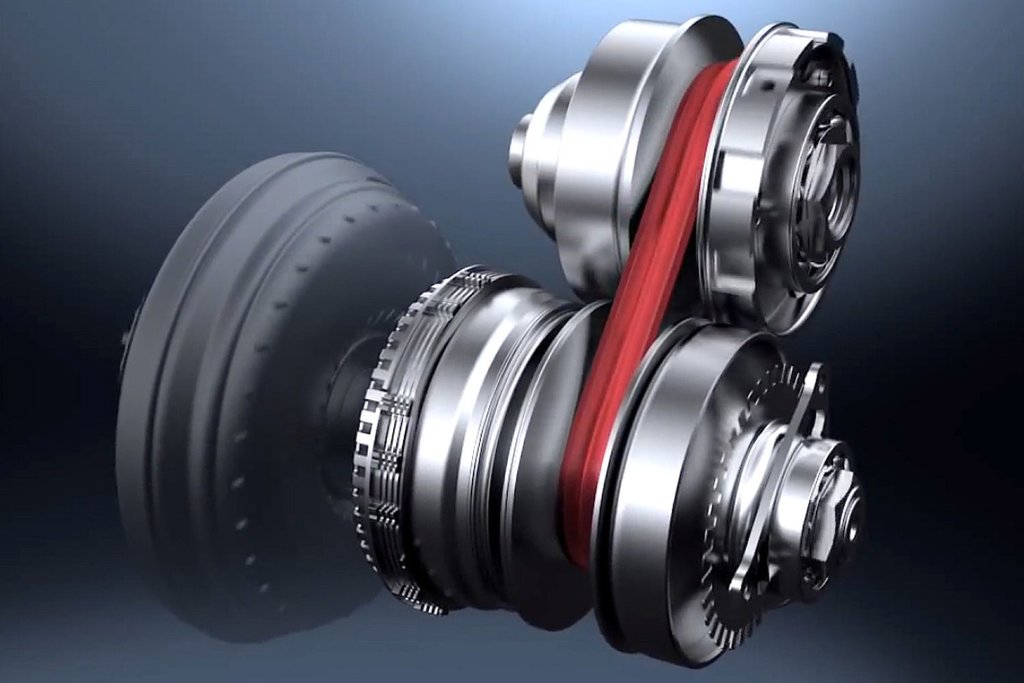

Friction couplings work on the principle of torque transmission due to the force arising from friction between the surfaces of the elements. At the very beginning of the working activity, slippage occurs between the coupling halves, that is, a smooth switching on of the device is ensured. Friction in friction clutches is achieved by contact of several pairs of disks, which are located between two equal-sized half-couplings.

self-managed

This is a type of automatic coupling that performs several tasks in a machine at once. First, it limits the magnitude of the loads. Secondly, it transfers the load only in a strictly specified direction. Thirdly, they turn on or off at a certain speed.

A frequently used type of self-controlled clutch is considered to be a safety clutch. It is included in the work at the moment when the loads begin to exceed some value set by the manufacturer of the machine.

Centrifugal type clutches are installed on vehicles for soft start capabilities. This allows the propulsion unit to develop maximum speed faster.

But overrunning clutches, on the contrary, transfer torque only in one given direction. This allows you to increase the speed of the car and optimize the performance of its systems.

The main types of couplings used today

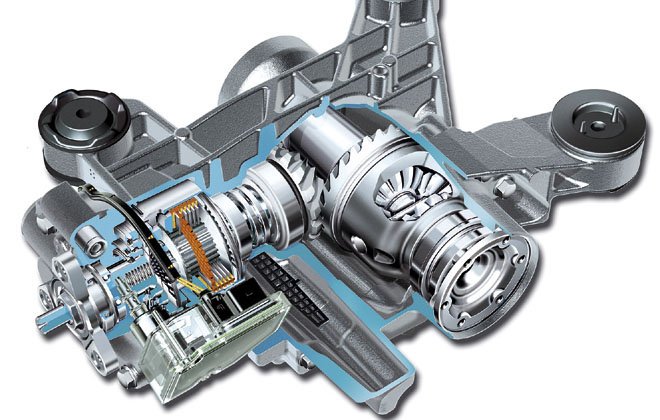

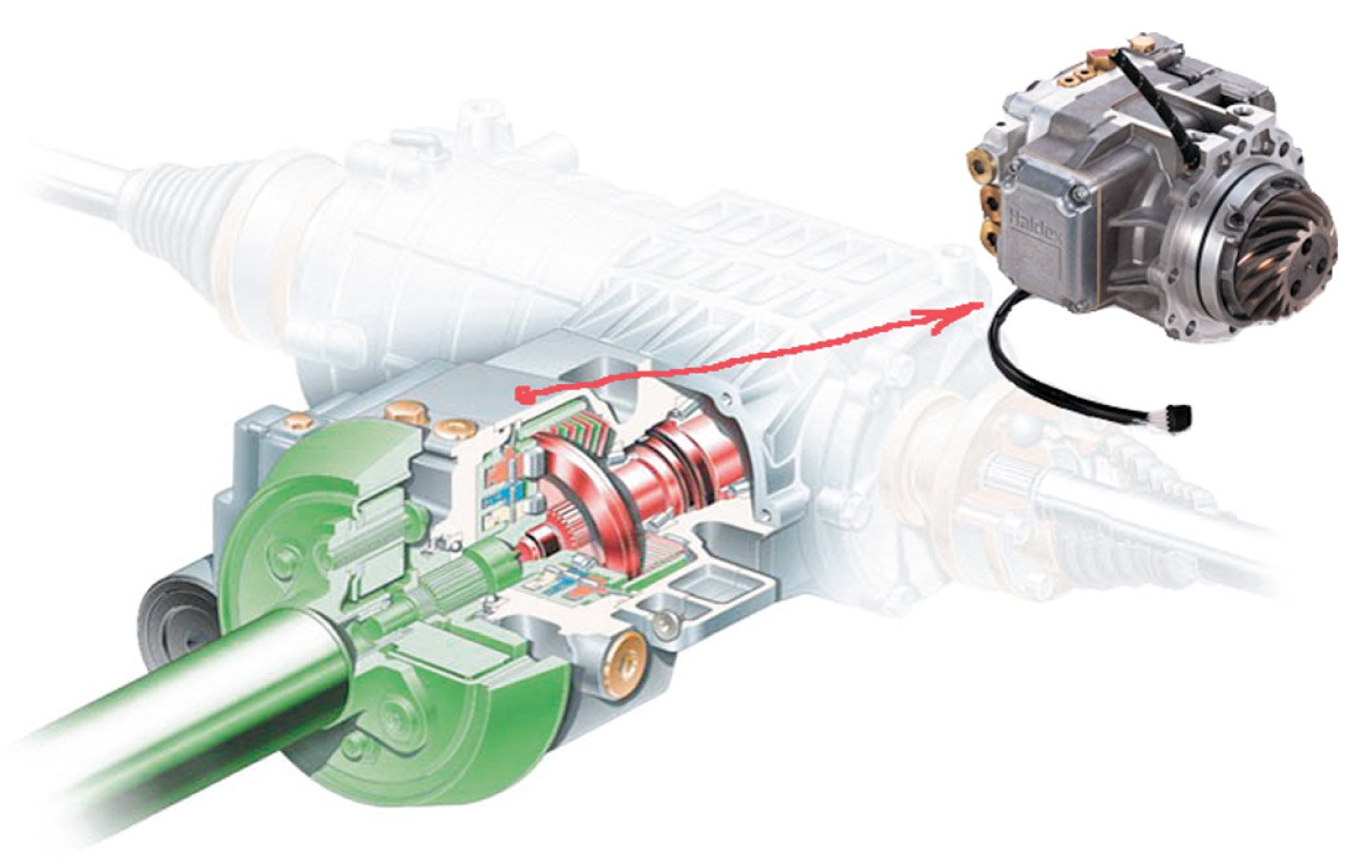

The Haldex coupling is quite popular in the automotive market. The first generation of this clutch for all-wheel drive vehicles was released back in 1998. The clutch was blocked only on the front drive axle at the time of wheel slip. It was for this reason that Haldex received a lot of negative reviews at that time, since the work of this clutch did not allow you to gently control the car during drifts or slips.

Since 2002, an improved second-generation Haldex model has been released, since 2004 - the third, since 2007 - the fourth, and since 2012 the last, fifth generation has been released. To date, the Haldex coupling can be installed both on the front axle and on the rear. Driving a car has become much more convenient due to both the design features of the clutch and innovative improvements such as a constantly running pump or clutch controlled by hydraulics or electricity.

Couplings of this type are actively used on Volkswagen cars.

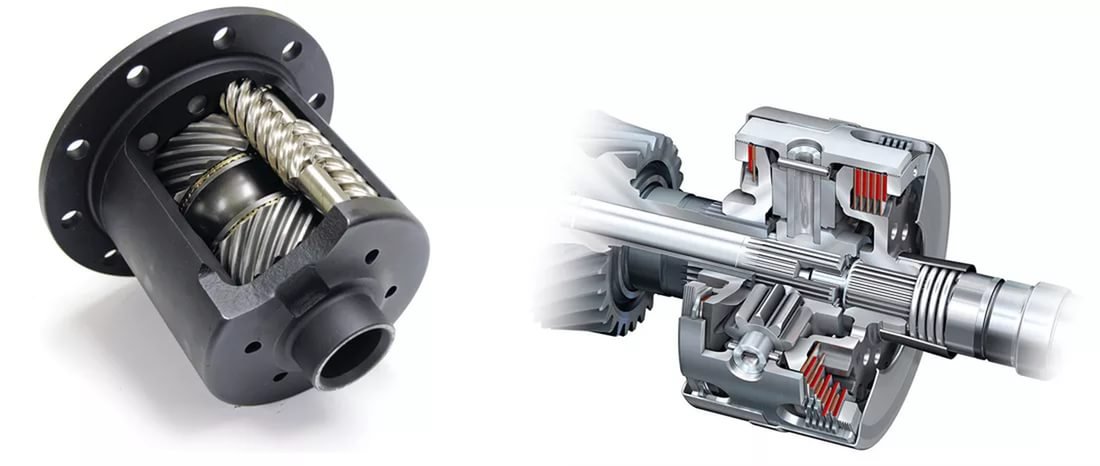

However, Torsen clutches are considered more common (installed on Skoda, Volvo, Kia and others). This clutch was developed by American engineers specifically for limited slip differential devices. Torsen's way of working is very simple: it does not equalize the torque supply to the slipping wheels, but simply redirects mechanical energy to the wheel that has more reliable grip on the road surface.

The advantage of differential devices with Torsen clutch is their low cost and instant response to any changes in the operation of the wheels while driving. The coupling has been repeatedly refined, and today it can be considered the most popular in modern automotive industry.

Maintaining clutches

Like any other unit or mechanism of a vehicle, coupling devices need quality maintenance. Specialists of Favorit Motors Group of Companies will correct the operation of couplings of any type or replace any of their components.