Trambler: device and principle of operation

A distributor, or an ignition distributor breaker, is an important element of a gasoline internal combustion engine. It is thanks to the distributor that an electrical impulse is supplied to each of the spark plugs, which is why it is discharged and the fuel-air mixture in the combustion chamber of each piston is ignited.

The design of this device has remained virtually unchanged since its invention in 1912 by the American inventor and successful entrepreneur Charles Kettering. In particular, Kettering was the founder of the well-known company Delco, he owns 186 patents related to the electric contact ignition system.

Let's try to understand the device and the principle of operation of the ignition distributor breaker.

Устройство

We will not describe in detail each washer and spring, since there is an article on our website Vodi.su in which the breaker device is disclosed quite accessible.

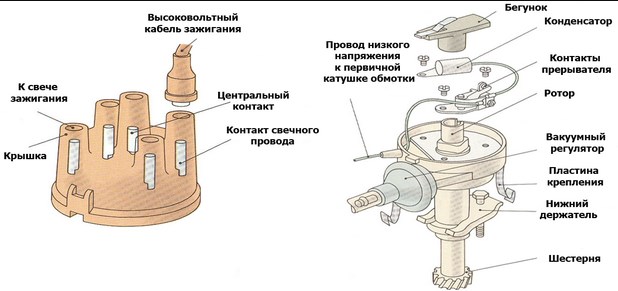

The main elements are:

- distributor drive (rotor) - a splined roller that engages with a camshaft gear or a special promshaft (depending on the engine design);

- ignition coil with double winding;

- interrupter - inside it there is a cam clutch, a group of contacts, a centrifugal clutch;

- distributor - slider (it is attached to the clutch drive shaft and rotates with it), distributor cover (high-voltage wires go from it to each of the candles).

Also an integral element of the distributor is a vacuum ignition timing regulator. The circuit includes a capacitor, the main task of which is to take on part of the charge, thus protecting the group of contacts from rapid melting under the influence of high voltage.

In addition, depending on the type of distributor, in the lower part, structurally connected with the drive roller, an octane corrector is installed, which corrects the rotation speed for a certain type of gasoline - the octane number. In older versions, it must be adjusted manually. What is the octane number, we also told on our website Vodi.su.

Principle of operation

The principle of operation is quite simple.

When you turn the key in the ignition, an electrical circuit is completed and voltage from the battery is supplied to the starter. The starter bendix engages with the crankshaft flywheel crown, respectively, the movement from the crankshaft is transmitted to the drive gear of the ignition distributor shaft.

In this case, a circuit closes on the primary winding of the coil and a low-voltage current occurs. The breaker contacts open and high voltage current accumulates in the secondary circuit of the coil. Then this current is supplied to the cover of the distributor - in its lower part there is a graphite contact - a coal or a brush.

The runner is constantly in contact with this central electrode and, rotating, transfers part of the voltage alternately to each of the contacts associated with a specific spark plug. That is, the voltage induced in the ignition coil is equally distributed among all four spark plugs.

The vacuum regulator is connected by a tube to the intake manifold - throttle space. Accordingly, it reacts to a change in the intensity of the air mixture supply to the engine and changes the ignition timing. This is necessary so that the spark is supplied to the cylinder not at the moment when the piston is at top dead center, but slightly ahead of it. Detonation will occur exactly at the moment the fuel-air mixture is injected into the combustion chamber, and its energy will push the piston down.

The centrifugal regulator, which is located in the housing, responds to changes in the speed of rotation of the crankshaft. Its task is also to change the ignition timing so that the fuel is used as efficiently as possible.

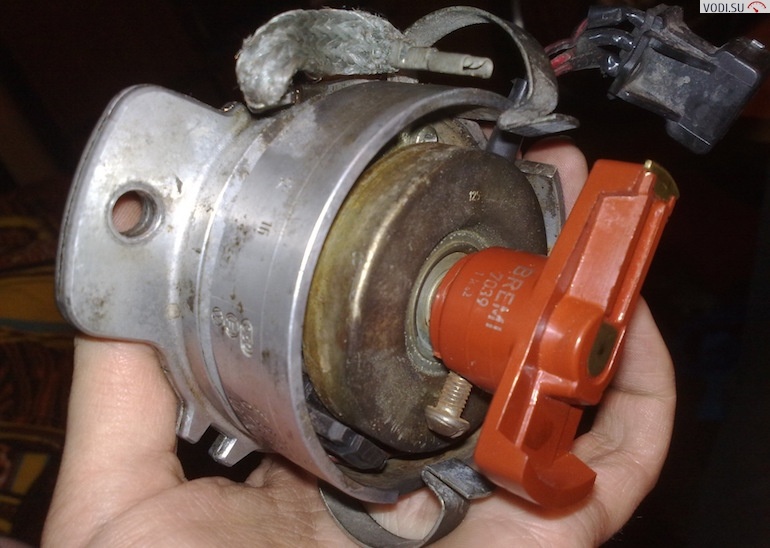

It should be noted that this type of distributor with a mechanical distributor is installed mainly on vehicles with carburetor-type engines. It is clear that if there are any rotating parts, they wear out. In injection engines or even more modern carburetor engines, instead of a mechanical runner, a Hall sensor is used, thanks to which the distribution is carried out by changing the intensity of the magnetic field (see the Hall effect). This system is more efficient and takes up less space under the hood.

If we talk about the most modern cars with an injector and distributed injection, then an electronic ignition system is used there, it is also called contactless. The change in engine operating modes is monitored by various sensors - oxygen, crankshaft - from which signals are sent to the electronic control unit, and commands are already sent from it to the ignition system switches.

Loading…