Cracking and grinding noise on cold start

Content

- Why does a crack appear on a cold internal combustion engine

- Causes of cod in a car on a cold

- Common cod problems on popular cars

- Answers to frequently asked questions

- Why does the internal combustion engine crackle when cold at the first start, when everything is fine again?

- What is cracking under the hood of the internal combustion engine if the timing chain is not stretched?

- Why does the internal combustion engine crackle when cold when starting from autorun?

- Engine rattle after oil change?

A loud rattle or crackle under the hood when cold is usually a sign of a problem in the engine itself. motor or attachment, including incorrectly set valve clearances, worn timing belt, alternator and pump bearings. The sound that disappears after warming up usually indicates that the breakdown is in the early stages and can still be eliminated with minimal investment.

You can learn how to find out why a crackling sound is heard when starting the internal combustion engine on a cold one and how to fix the problem, see this article.

Why does a crack appear on a cold internal combustion engine

During the downtime of the internal combustion engine, oil flows into the crankcase, and thermal gaps in the interfaces of parts at low temperatures are outside the standard values. In the first seconds after starting, the engine experiences increased loads, so usually a crack in the internal combustion engine appears on a cold one.

A common culprit for sounds is the parts of the gas distribution mechanism drive:

Checking the timing chain for tension

- stretched timing chain;

- worn gears of crankshaft pulleys and camshafts;

- chain tensioner or damper;

- timing belt tensioner;

- faulty hydraulic lifters, incorrectly selected washers and other parts for adjusting valve clearances;

- the camshaft makes a crackling sound on a cold one after starting the internal combustion engine in the presence of development in its beds;

- camshaft pulley with a faulty control mechanism in engines with variable valve timing (VVT, VTEC, VVT-I, Valvetronic, VANOS and other similar systems).

Attached equipment parts can also be a source of crackling and rattle in the cold:

Worn alternator bearing

- worn or unlubricated alternator bearings;

- damaged power steering pump and air conditioning compressor;

- cooling pump bearing;

- starter bendix with critical wear;

- the exhaust manifold protection, which resonates with the vibration of the motor, can make crackling and metallic clicks on a cold one.

In the internal combustion engine itself, the problem lies less often, but with high mileage, untimely and poor-quality service, the following can crack in the cold:

Worn main bearings

- piston skirts knocking on the cylinders due to increased clearances;

- piston pins - for the same reason;

- worn main bearings.

In addition to the internal combustion engine, the transmission sometimes becomes a source of cold crackling:

- a clutch driven disk in which the damper springs have sagged or there is wear in their windows;

- worn gearbox input shaft bearings;

- gear bearings on the secondary shaft of the gearbox;

- insufficient oil pressure in the gearbox.

Even if the crackling is heard only when starting the internal combustion engine on a cold one, and after warming up it goes away, you need to make sure that there are no malfunctions. Otherwise, the wear of parts will progress until the incorrectly functioning unit is not will fail. The instructions and tables below will help you diagnose.

Causes of cod in a car on a cold

You can determine the source of crackling under the hood to a cold one by the nature of the sound, its location, and the conditions under which it manifests itself. The table below will help you figure out what is cracking, or distinguish chain crackling when cold from valve clatter, bendix noise, and other problems.

Causes of cod under the hood on a cold internal combustion engine

| Equipment group | Failed node | Causes of cod | What to produce | Aftermath |

|---|---|---|---|---|

| Gas distribution mechanism | Phase shifters | Dirty or worn retainer as part of the timing gear | Inspect the timing gear with the adjusting mechanism. In the presence of dirt and deposits - clean, rinse. In the event of a breakdown, repair or replace the entire part | The timing is disrupted, fuel consumption increases, dynamics disappears, and the risk of overheating and coking increases. With a complete failure of the phase shifter, damage to the timing belt, its breakage, the meeting of valves with pistons. |

| Valve lifters | Clogged or worn hydraulic lifters | Inspect hydraulic lifters, their oil channels. Clean the oil supply channels in the cylinder head | If the hydraulic lifters crack when cold or the valve clearances are incorrectly adjusted, the wear of the camshaft cams and pushers is accelerated. | |

| Valve clearance adjuster | The gap increases naturally as the engine runs. | Adjust the thermal clearances of the valves using nuts, washers or "cups" for this | ||

| Timing chain or gears | The chain, stretched from wear, dangles, hits the walls of the block. Due to a fuzzy hit on the teeth of the pulleys, noise also appears. | Replace timing chain and/or gears | If you ignore the crackling of the chain when it is cold, it will continue to wear out and stretch, “eating up” the gear teeth. An open circuit may damage the pistons and valves. | |

| Chain or belt tensioner | Relaxation of the chain due to wear out of the tensioner. On belt motors, the tensioner bearing itself is noisy. | Replace tensioner, adjust chain or belt tension | ||

| Fuel system | Nozzles | Nozzle parts wear | If the knock appears only on a cold one, and the internal combustion engine works stably, the consumption has not increased - you can drive. If there are additional symptoms of poor-quality spray, the nozzles must be replaced. | Worn injectors pour fuel, its consumption increases, dynamics worsens, there is a risk of coking of the internal combustion engine due to operation on a rich mixture. |

| Clogging of the fuel return channel leads to fuel overflow and its more severe combustion. | Clean and flush nozzles | The wear of the internal combustion engine accelerates due to increased loads. | ||

| Control equipment | The injectors are overflowing fuel due to a failure of the injection pump. | Adjust or replace faulty components. | ||

| Connecting rod-piston group | Pistons, pins or connecting rod bearings | Wear due to overheating, scuffing, lack of lubrication | Requires a comprehensive overhaul of the internal combustion engine, possibly a major | If the internal combustion engine is not repaired in time, it will fail, it may jam on the go. |

| Design features | Use a quality oil that meets the manufacturer's specifications. It is advisable to fill in less viscous in winter (for example, 5W30 or 0W30) | No obvious consequences | ||

| Attachment | Starter Bendix or Flywheel Crown | The starter bendix is dirty or stuck. Flywheel teeth knocked down | Remove the starter, inspect the condition of the bendix and the flywheel crown. If there is contamination, clean and lubricate; if worn, replace the part. | If the starter works with a bang on a cold one, with further wear, the bendix will not engage well, and the crown may break. The machine cannot be started. |

| Compressor clutch | Clutch due to wear, solenoid malfunctions, does not provide fixed engagement, slips | Replace clutch | If the noise is not eliminated in time, the air conditioning compressor will fail, the air conditioning system will not work. Attachment drive belt may be broken. | |

| Air conditioning compressor | Generation in bearings or in the reciprocating mechanism of the compressor | Repair or replace the compressor. | ||

| Generator or power steering pump | Bearing wear | Replace the alternator or power steering pump bearings, or the assembly. | If you do not eliminate the crackling sound of the generator when it is cold, the unit may jam and the attachment belt may break. The power steering pump will begin to leak and may completely fail. | |

| Трансмиссия | Clutch disc | From loads, damper springs, seats on the disc hub wear out. | The dismantling of the gearbox is required to inspect the clutch disc, clutch release. A defective node needs to be replaced with a new one. | With a complete failure, the clutch of the gearbox with the engine will disappear, the car will not be able to move under its own power. |

| Gearbox bearings | In the course of development, the gaps between the friction surfaces grow, and the oil thickens when the car is idle | Need troubleshooting of the gearbox with the diagnosis of bearing wear | The gearbox wears out, jamming of its parts is possible. As the problems progress, it is accompanied by a constant knock and howl, the flight of individual gears is possible, their poor inclusion. |

On some vehicles, a crackling, knocking or ringing sound in cold weather can be caused by the thermal protection of the exhaust manifold. As it heats up, it expands a little, stops touching the pipes and the sound disappears. The problem does not threaten with dangerous consequences, but in order to get rid of the sound, you can slightly bend the shield.

How to determine where the crack comes from on a cold start

Electronic stethoscope ADD350D

It is not only the character that matters, but also the place where extraneous sounds spread. In order to identify the source of the problem, you first need to determine where is the crack coming from when starting the internal combustion engine on a cold one, opening the hood and listening to the operation of the internal combustion engine and attachments. A tool that will help localize the source of the cod will be a stethoscope.

Recommendations for finding where the cold start crackle comes from

- Cracking from under the valve cover with a frequency above the crankshaft speed, and disappearing a few seconds after a cold start, indicates problems in the phase regulator. Sometimes the internal combustion engine may stall on the first attempt to start, but starts normally on the second. The problem needs to be solved, but it is not critical, since the phase regulator is maintained in the working position by oil pressure on the running engine.

- A dull metallic clatter from under the valve cover is usually a sign that hydraulic lifters or incorrectly adjusted valves crack when warmed up. In this case, you can continue to move, but you should not postpone repairs for a long time.

- Metallic clatter on the intake side may indicate worn fuel injectors or a malfunctioning fuel pump. Most often, diesel injectors crack, as they work under higher pressure there. A failed injector doses fuel incorrectly, which worsens the operation of the engine and accelerates its wear, so it is advisable to fix the problem as soon as possible.

- Rhythmic crackling or ringing, synchronous with the operation of the internal combustion engine, coming from the timing side, indicates the absence of chain tension, its wear or breakage of the tensioner / damper. If the chain breaks or jumps over several links, the pistons may meet the valves. A non-critical problem is only if the crack appears briefly in frost, and disappears as it warms up. In severe frost (below -15 ℃), even a fully functional circuit can make noise after a cold start.

- On motors with a timing belt drive, the tensioner bearing becomes the source of noise. To check it, you need to remove the timing belt cover, check its tension, and also loosen the tension and twist the roller by hand. If the bearing is jammed or destroyed, the belt may jump and break. As a result, the machine will be immobilized, on some engines a broken timing belt will lead to mutual contact and damage to the pistons and valves.

- When the sound comes from the depth of the motor, there is a loss of power, a deterioration in the dynamics of the car, the problem may be related to pistons or connecting rods (rings, fingers, liners). It is not recommended to operate a car, as the internal combustion engine can jam at any time. An exception is some models (for example, a VAZ with a lightweight piston), for which such a sound in frost is acceptable.

- Crack and rattle from the side of the starter, heard only at startup at the moment the key is turned or the “Start” button is pressed, indicate wedging or wear of the starter bendix, or the development of a crown. If possible, you can try to start the car without using a starter (on a slope, from a tow, etc.). On a car with a transverse internal combustion engine, where access to the starter is not difficult, you can immediately remove it in order to inspect the bendix and crown teeth. In motion, this problem does not threaten anything, but any start-up can be dangerous by breaking off the crown or further destroying the teeth. When the internal combustion engine crackles when starting from auto start, the problem may also be in the starter, the bendix of which does not immediately return to the neutral position, or in a worn flywheel ring.

- If the crackling on the cold appears only when the clutch is depressed to facilitate the start, it indicates the wear of the release bearing. It is necessary to eliminate the defect as soon as possible, since in case of destruction it will not be possible to turn on the transmission. You can get to the nearest repair place by trying to use the clutch pedal less.

- If the crackling and clatter, on the contrary, is absent when the clutch is depressed, but appears when it is released, the problem is in the gearbox or in the clutch disc. This may be the wear of the damper springs and their seats, lack of oil in the gearbox or its low pressure, wear of the input shaft bearings or gears on the secondary. As long as the problem does not manifest itself when hot, the car is serviceable. If the noise persists even after warming up, trips should be avoided.

- You can determine that the sound is coming from the generator by removing the belt from it. The source of the crackling is usually worn shaft bearings that have washed out the grease.

- If the air conditioning compressor connected by the clutch crackles, then there will be no sound when the climate system is turned off. With the air conditioner turned off, the machine can be operated without the risk of serious consequences. A compressor without a clutch can also crackle with the air conditioner turned off.

- A quiet and even crackle of the power steering pump when cold can be normal for some cars, especially in cold weather. An alarming sign is the appearance of bursts of clicks or crackling, grinding when the engine is warm.

Clogged fuel injectors

Diagnosis of baseline noise in the internal combustion engine using a mechanical stethoscope: video

Development of the starter crown

Cracked damper spring on clutch disc

Since the parts are arranged quite closely under the hood and inside the motor, the cause of the crackling when starting a cold internal combustion engine cannot always be determined by ear. To accurately localize the source, it is necessary to consistently diagnose all systems.

In some cases, crackling and rhythmic clicks may be normal at extremely low temperatures (-20 ℃ and below). This is due to the fact that in the first seconds after the start, the parts work with a lack of lubrication. As soon as the pressure in the system rises to operating values, the oil begins to warm up, and the thermal gaps return to normal - they go away.

Common cod problems on popular cars

Some vehicles are more likely to have a cold start rattle than others. In some cases, an unpleasant sound indicates problems, and sometimes it is a design feature that does not affect operation. The table will help determine why a crack appears after a cold start, how dangerous it is and how to deal with it.

Popular car models that are characterized by cracking during cold start.

| Car model | Why is it bursting | How normal/dangerous is this? | What to produce |

|---|---|---|---|

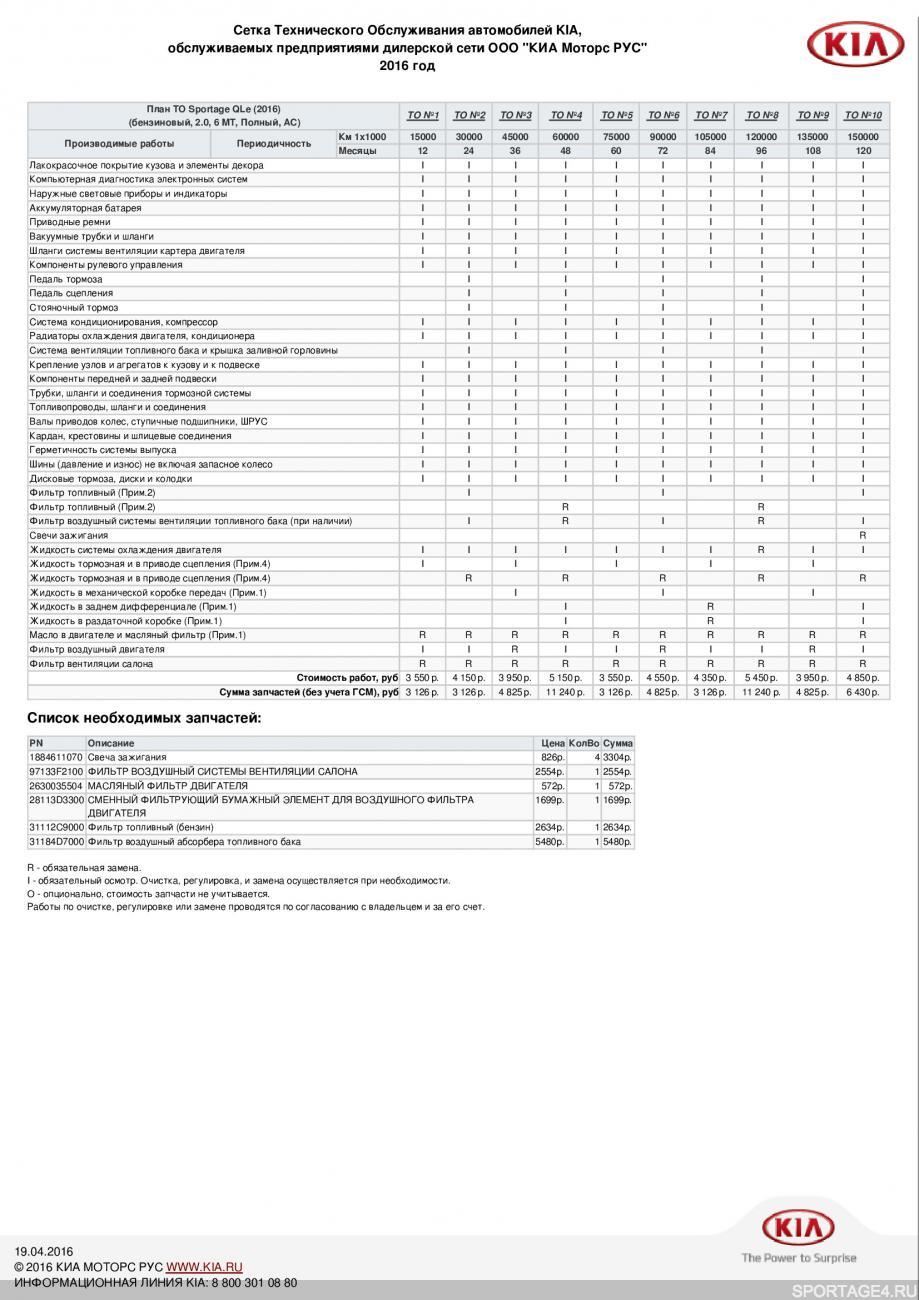

| Kia Sportage 3, Optima 3, Magentis 2, Cerate 2, Hyundai Sonata 5, 6, ix35 with G4KD engine | The cause of knocks and cod in the cold are seizures in the cylinders. Often their culprit is particles of a collapsing collector, which are sucked into the combustion chambers. | The problem is common and indicates that the motor is failing. There is a small risk of engine jamming, but judging by the reviews, some drivers drive tens of thousands of kilometers with knocks. | To eliminate the problem - a major overhaul (liner, replacement of pistons, etc.) of the engine and replacement (or removal) of the catalyst. If the problem does not bother you much and only appears when it is cold, you can drive, checking the oil level more often and adding it if necessary. |

| Kia Sportage, Hyundai ix35, Creta and other related models with manual transmission | Crack appears on the cold at elevated (warm-up) speed. It comes from the gearbox side, disappears when the clutch is depressed. The sound appears due to design flaws in the gearbox (presumably input shaft bearings) and low oil levels. | The deficiency does not progress, therefore it does not pose a threat. | Adding oil to the gearbox can help eliminate or muffle the sound. |

| Volkswagen Polo sedan | On the VW Polo sedan, hydraulic valve lifters knock on the cold | Slightly increased camshaft wear | Change oil. If the hydraulic lifters knock for a long time (more than 1–2 minutes after the start), or the sound appears hot, change the HA |

| Pistons knock due to natural wear | The wear of the internal combustion engine is accelerating, but it is impossible to say for sure by how much. Numerous reviews indicate the normal operation of the internal combustion engine even after 50-100 thousand km after the appearance of knocks on the cold. | Use quality oil. Monitor the level and top up when necessary. You can install modernized pistons (with an extended skirt), but after 10–30 thousand km the knocking may return. | |

| Subaru Forester | The knock is emitted by the protection of the exhaust pipes of the manifold. | The sound disappears as it warms up and does not always appear, it does not threaten with dangerous consequences. | If it happens constantly, slightly bend the protection, if it happens occasionally, you can ignore it. |

| Lada Grant | On 8-valve engines, the camshaft knocks on the washers due to large thermal gaps | Since the gaps are increased on a cold engine, camshaft clatter is the norm. If the sound does not disappear even when warming up, the gaps are broken. | Measure clearances and adjust valves |

| Pistons rumble on those equipped with engines with a lightweight piston Lada Granta. | If the sound appears only in frost and lasts no more than 2 minutes, this is acceptable. | For prevention, you need to use high-quality oil, observing the replacement intervals, in order to slow down the wear of pistons, rings and cylinders. | |

| Hyundai Solaris | On Hyundai Solaris, the crackling of the generator in the cold appears due to wear on the tensioner pulley of the attachment drive belt. | The roller may fail, due to which the belt will wear out rapidly and slip. | Replace the attachment belt tensioner. |

| Ford Focus | On a Ford Focus with a 1,6 engine, hydraulic lifters make a knock on a cold one. | After downtime, in cold weather, a knock is acceptable for an internal combustion engine with a mileage of more than 100 thousand km. | If the problem also appears when it’s hot, diagnose hydraulic compensators or valve clearances. Change faulty compensators or select pusher cups to match the size. If the knocking occurs only during the first few minutes in the cold, you don’t have to worry, the knocking is not dangerous, but it is advisable to use high-quality oil. |

| On motors without hydraulic lifters, the camshaft can knock on the valve lifters, piston pins, the camshaft itself in the beds. The reason is natural production. | |||

| Toyota Corolla | On Toyota Corolla (and other models of the company), a crackling sound at startup appears due to the VVT-I (phase shifter) running for the first few seconds with a lack of lubrication. | If crackling appears only in frosts below -10, then there is no problem, the sound is acceptable. If it appears in warmer weather, you need to diagnose the motor. | Carry out diagnostics and troubleshooting of the phase regulator, if necessary, replace it. |

| Toyota ICE 3S-FE, 4S-FE | Loose timing belt | On 3S-FE and 4S-FE, the valve does not bend when the timing belt breaks, so in this case the car will simply stop driving. | Check the condition of the timing roller, tension the belt with the correct torque. |

| Peugeot 308 | On the Peugeot 308, a crack or knock on a cold appears due to the attachment belt and its tension roller | usually, nothing dangerous. If there is a beating of the tension roller or one of the pulleys, the wear of the belt is accelerated. | Check attachment belt tension, check pulleys for runout. |

Answers to frequently asked questions

Why does the internal combustion engine crackle when cold at the first start, when everything is fine again?

Cracking at the first cold start is due to the fact that the oil drains into the crankcase and the nodes in the upper part of the internal combustion engine experience a lack of lubrication at first. As soon as the oil pump pumps up oil, the nodes go to normal operation and there will be no more noise when starting again.

What is cracking under the hood of the internal combustion engine if the timing chain is not stretched?

If the timing drive mechanism is in order, the following can crack under the hood:

- starter;

- hydraulic compensators;

- unadjusted valves;

- phase regulator;

- attachments: generator, power steering pump, air conditioning compressor, etc.

Why does the internal combustion engine crackle when cold when starting from autorun?

When starting from auto start, the clutch remains engaged, so the starter has to rotate the gearbox shafts, which increases the load. Most often, the problem is associated with contamination and / or wear of the bendix, the starter ring on the flywheel.

Engine rattle after oil change?

If the engine began to crackle when cold after changing the oil, most likely it was incorrectly selected or its level was too low. If the replacement interval is exceeded for a long time, delamination of contaminants and clogging of the oil channels of the phase shifter and hydraulic compensators is possible.