Internal combustion engine device - video, diagrams, pictures

The internal combustion engine is one of those inventions that radically turned our lives around - people were able to transfer from horse-drawn carts to fast and powerful cars.

The first internal combustion engines had low power, and the efficiency did not even reach ten percent, but tireless inventors - Lenoir, Otto, Daimler, Maybach, Diesel, Benz and many others - brought something new, thanks to which the names of many are immortalized in the names of famous automotive companies.

Internal combustion engines have come a long way of development from smoky and often broken primitive engines to ultra-modern biturbo engines, but the principle of their operation remains the same - the heat of combustion of the fuel is converted into mechanical energy.

The name "internal combustion engine" is used because the fuel burns in the middle of the engine, and not outside, as in external combustion engines - steam turbines and steam engines.

Thanks to this, internal combustion engines received many positive characteristics:

- they have become much lighter and more economical;

- it became possible to get rid of additional units for transferring the energy of combustion of fuel or steam to the working parts of the engine;

- fuel for internal combustion engines has specified parameters and allows you to get much more energy that can be converted into useful work.

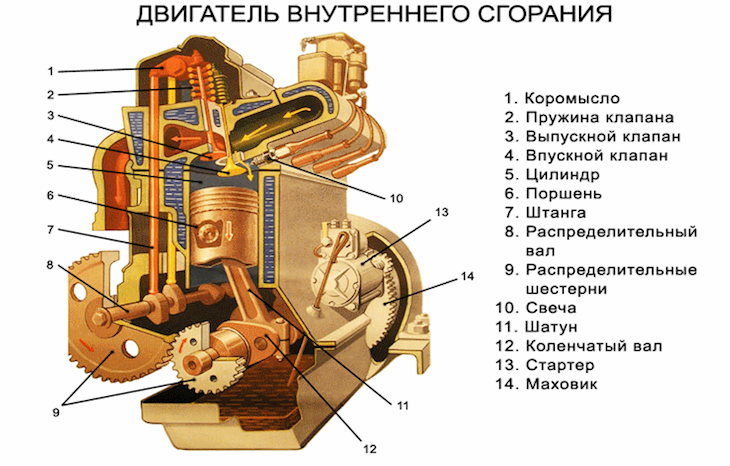

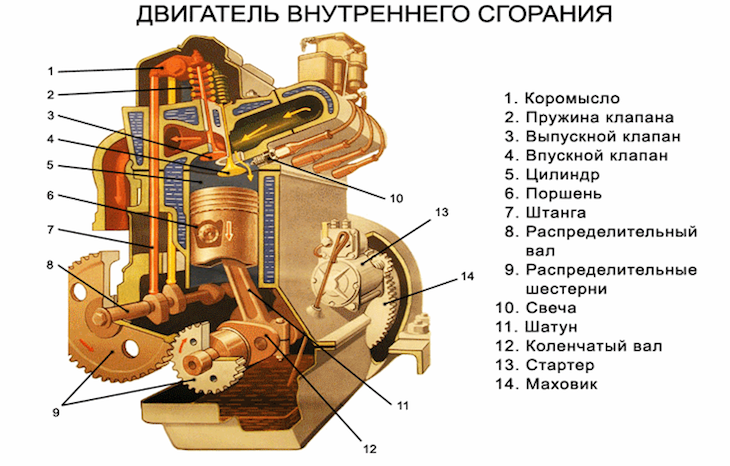

ICE device

Regardless of what fuel the engine is running on - gasoline, diesel, propane-butane or eco-fuel based on vegetable oils - the main active element is the piston, which is located inside the cylinder. The piston looks like an inverted metal glass (a comparison with a whiskey glass is more suitable - with a flat thick bottom and straight walls), and the cylinder looks like a small piece of pipe inside which the piston goes.

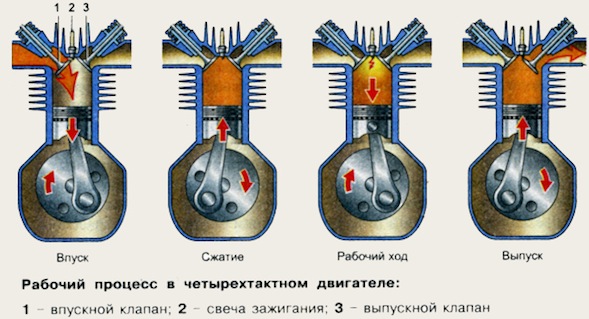

In the upper flat part of the piston there is a combustion chamber - a round recess, it is into it that the air-fuel mixture enters and detonates here, setting the piston in motion. This movement is transmitted to the crankshaft using connecting rods. The upper part of the connecting rods is attached to the piston with the help of a piston pin, which is inserted into two holes on the sides of the piston, and the lower part is attached to the connecting rod journal of the crankshaft.

The first internal combustion engines had only one piston, but this was enough to develop a power of several tens of horsepower.

Nowadays, engines with a single piston are also used, for example, starting engines for tractors, which act as a starter. However, 2, 3, 4, 6 and 8-cylinder engines are most common, although engines with 16 cylinders or more are available.

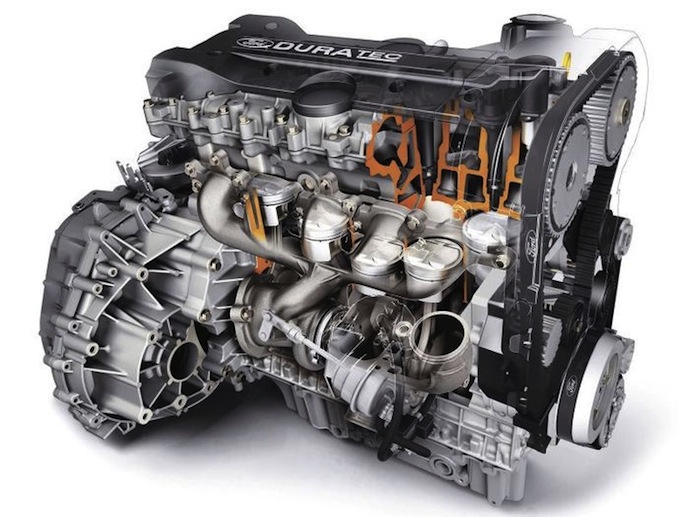

Pistons and cylinders are located in the cylinder block. From how the cylinders are located in relation to each other and to other elements of the engine, several types of internal combustion engines are distinguished:

- in-line - cylinders are arranged in one row;

- V-shaped - the cylinders are located opposite each other at an angle, in the section they resemble the letter “V”;

- U-shaped - two interconnected in-line engines;

- X-shaped - internal combustion engines with twin V-shaped blocks;

- boxer - the angle between the cylinder blocks is 180 degrees;

- W-shaped 12-cylinder - three or four rows of cylinders installed in the shape of the letter “W”;

- radial engines - used in aviation, the pistons are located in radial beams around the crankshaft.

An important element of the engine is the crankshaft, to which the reciprocating motion of the piston is transmitted, the crankshaft converts it into rotation.

When the engine speed is displayed on the tachometer, this is exactly the number of crankshaft rotations per minute, that is, it rotates at a speed of 2000 rpm even at the lowest speeds. On the one hand, the crankshaft is connected to the flywheel, from which rotation is fed through the clutch to the gearbox, on the other hand, the crankshaft pulley is connected to the generator and gas distribution mechanism through a belt drive. In more modern cars, the crankshaft pulley is also connected to the air conditioning and power steering pulleys.

Fuel is supplied to the engine through a carburetor or injector. Carburetor internal combustion engines are already becoming obsolete due to design imperfections. In such internal combustion engines, there is a continuous flow of gasoline through the carburetor, then the fuel is mixed in the intake manifold and fed into the combustion chambers of the pistons, where it detonates under the action of an ignition spark.

In direct injection engines, fuel is mixed with air in the cylinder block, where a spark is supplied from the spark plug.

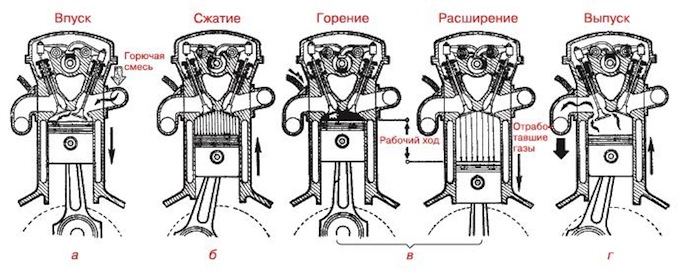

The gas distribution mechanism is responsible for the coordinated operation of the valve system. The intake valves ensure the timely flow of the air-fuel mixture, and the exhaust valves are responsible for the removal of combustion products. As we wrote earlier, such a system is used in four-stroke engines, while in two-stroke engines there is no need for valves.

This video shows how an internal combustion engine works, what functions it performs and how it does it.

Four-stroke internal combustion engine device

Loading…