The device and operation of the steering rack "Volkswagen Polo" sedan, the main malfunctions and do-it-yourself repairs

Content

Proper steering is the key to a safe ride in any car, including the Volkswagen Polo sedan. Steering rack failure is the cause of many traffic accidents (accidents), so automakers pay a lot of attention to the reliability of this unit. Volkswagen Polo, developed by the German concern VAG, is produced in Russia, on the territory of the Kaluga Automobile Plant. The car enjoys well-deserved popularity among Russian motorists.

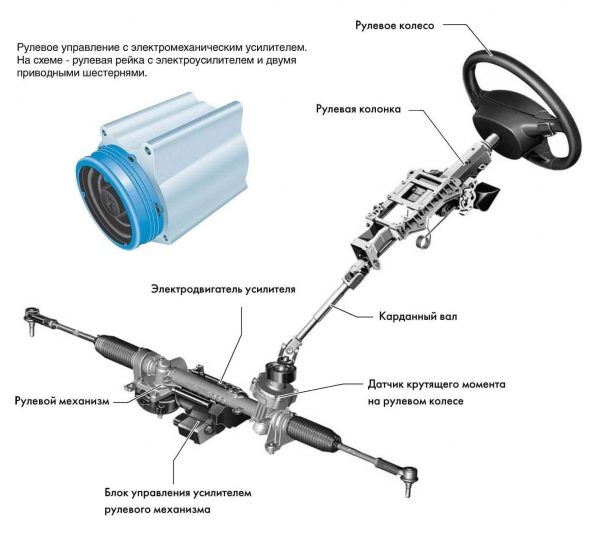

How the steering is arranged and works in the Volkswagen Polo sedan

The main unit of the system that controls the car is a rail that regulates the rotation of the front wheels. It is located on the subframe, in the area of \uXNUMXb\uXNUMXbthe front axle suspension. The end part of the steering shaft of the column, on which the steering wheel is mounted, goes into the salon. The steering column also includes: an ignition switch and a lever handle that adjusts its position relative to the driver. The column is closed by a casing located below the dashboard in the cabin.

The structure of the node that controls the car includes the following main components:

- steering column with steering wheel;

- cardan shaft through which the column is connected to the rail;

- steering rack that controls the rotation of the wheels;

- electric amplifier with control unit.

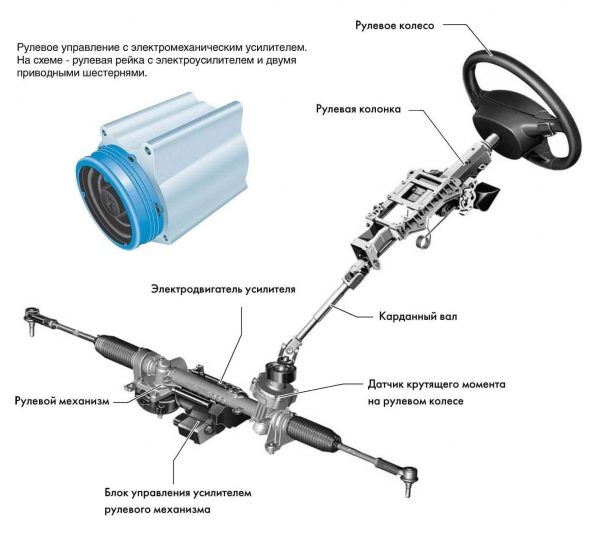

The steering column transmits the rotating force from the driver's steering wheel to the intermediate shaft, with universal joints at the ends. This part of the control system consists of the following parts:

- Upper and lower cardan shafts.

- intermediate shaft.

- Bracket that secures the steering column to the body.

- The handle of the lever that controls the position of the steering column.

- Egnition lock.

- The shaft to which the steering wheel is attached.

- Electric motor with gearbox.

- Electric power steering control unit (ECU).

An electric motor with a gearbox creates additional torque for the shaft to which the steering wheel is attached. The electronic control unit analyzes the speed of the car, the angle of the steering wheel, as well as information from the torque sensor developed on the steering wheel. Depending on this data, the ECU decides to turn on the electric motor, making it easier for the driver to work. The structure of the steering column includes energy-absorbing elements that increase the passive safety of the driver. There is also an anti-theft device that blocks the steering shaft.

A special role in the operation of the system is played by the computer. It not only determines the direction and amount of force to be added to the steering torque, but also reports errors in the operation of the entire steering system. As soon as a malfunction is detected, the control unit remembers its code and turns off the electric power steering. A fault message appears on the dashboard informing the driver.

The choice of a classic steering rack is due to the fact that the automaker VAG uses a McPherson-type suspension for the front-wheel drive of the car. The mechanism is simple, has a minimum number of parts. This causes a relatively small weight of the rail. The steering mechanism consists of the following main components:

- Traction tip of the left wheel.

- The rod that controls the left wheel.

- Anthers protecting from dirt.

- Drive shaft with worm gear.

- A housing that acts as a crankcase.

- The rod that controls the right wheel.

- Traction tip of the right wheel.

The device works as follows: a rack-and-pinion located inside the body (5) has fixed rods at the ends that control the wheels (2, 6). The rotation from the steering column is transmitted through the drive worm shaft (4). Carrying out translational movement from the rotation of the worm gear, the rail moves the rods along its axis - to the left or right. At the ends of the rods, there are traction lugs (1, 7) that interact through ball joints with the steering knuckles of the McPherson front suspension. To prevent dust and dirt from entering the mechanism, the rods are covered with corrugated anthers (3). The steering rack housing (5) is attached to the front suspension cross member.

The steering unit is designed for the entire period of operation of the Volkswagen Polo sedan. In the event of a malfunction or poor technical condition that does not meet safety requirements, its main components can be repaired or replaced.

Video: device and operation of a classic steering rack

Main steering malfunctions and their symptoms

Over time, any mechanism wears out. Steering is no exception. The degree of wear is affected by the condition of the road surface in the region where the vehicle is operated. For some cars, problems appear after the first 10 thousand kilometers of travel. Others reach, without any problems in management, up to 100 thousand km. Below is a list of common Volkswagen Polo sedan malfunctions and their symptoms:

- Tight steering. May be caused by uneven front tire pressure or by a faulty electric power steering. Jamming of the hinges on the traction lugs also makes it difficult to turn the wheels. The ball joints of the front suspension can also wedge. A common malfunction is jamming of the bearing of the drive shaft of the steering rack. If the tie rod boots are damaged, the ingress of moisture leads to corrosion of the metal, resulting in heavy movement of the rack, as well as wear of the fixing sleeve.

- Steering wheel turns freely. If the wheels do not turn, the steering is faulty. The wear of the gears of the rack and the worm of the drive shaft requires additional adjustment, using an adjusting bolt, or replacement of worn parts. Wear on the hinges on the traction lugs can also be a cause.

- Steering wheel play is too high. This indicates wear on the steering parts. There may be play in the cardan joints of the intermediate shaft. It is also necessary to check the hinges of the traction lugs for wear. The ball pin nuts can be loosened at the junction of the rack with the steering rods. There is a possibility of wear of the worm of the rack drive shaft and the toothed surface of the pinion shaft as a result of prolonged operation or lack of the proper amount of lubrication.

- Extraneous sounds from the steering column while driving. They appear when turning the wheels or driving on a problematic road surface. The main reason is premature wear of the bushing that fixes the gear shaft in the housing on the side of the right wheel. There may be a large gap between the stop and the pinion shaft. The gap is removed with an adjusting bolt. If this does not help, worn parts are replaced with new ones.

Video: Steering Malfunction Diagnosis

Watch this video on YouTube

Can the steering rack be repaired?

In most cases, the steering rack can not be replaced, as it can be repaired. It should be noted that official dealers do not repair rails. Parts for them are not supplied separately, so dealers change this assembly completely. In practice, it turns out that the bearing included in the design of the drive shaft can be replaced. Buy a bearing with the same size.

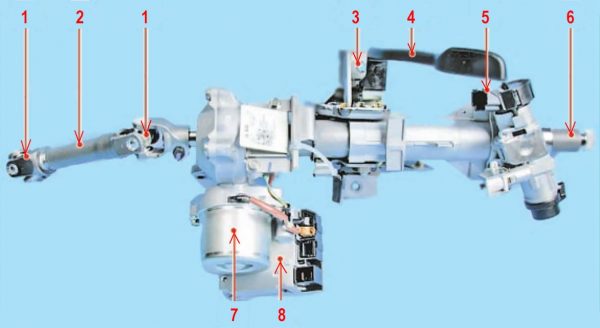

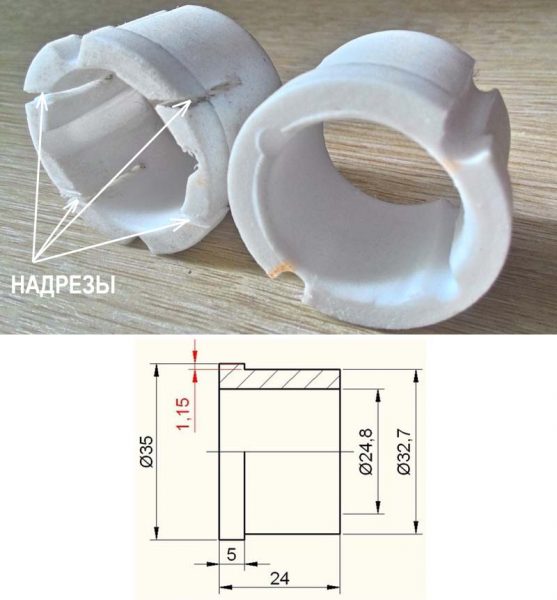

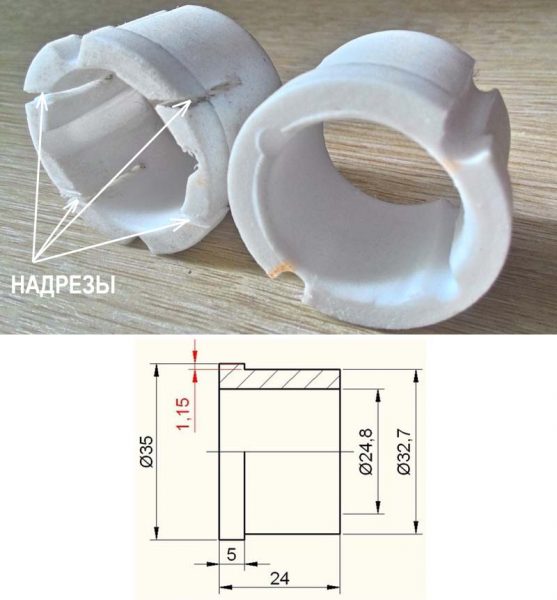

The sleeve fixing the pinion shaft can be ordered. It is made from PTFE. If the gear shaft is corroded, this part can be sanded with sandpaper. Such an operation must be done, since the rusty shaft "eats" the fixing sleeve, made of a softer material.

Self-repair of the steering rack

If there is a garage with a viewing hole, a flyover or a lift, you can troubleshoot the steering rack with your own hands. The knock and play of the gear shaft is eliminated by installing a new bushing, the dimensions of which are presented above. This is one of the most common steering problems in the Volkswagen Polo sedan. To carry out such a repair, it is necessary to grind the sleeve and make cuts in it (see figure).

For dismantling and repair work, you will need a tool:

- wrenches in sizes 13, 16 and 18, with socket heads of the same sizes;

- hexagon size 6 and dodecahedron M10;

- keys for 19 and 21, as well as heads for 14 and 32;

- self-made head for 36 (see figure below);

- removable device for hinges;

- grease for the rail - you need to choose one that does not liquefy at high temperatures;

- a hammer;

- rags.

The work is carried out in the following order:

- The car is installed on the inspection pit.

- The plastic casing of the steering column is removed and the carpet is turned away.

You need to unscrew the plastic nut that fixes the carpet

You need to unscrew the plastic nut that fixes the carpet - The cardan intermediate shaft is separated from the rack drive shaft.

In order to unscrew the bolt, you need a key for 13 or M10 dodecahedron

In order to unscrew the bolt, you need a key for 13 or M10 dodecahedron The car is hung on both sides in order to remove the front wheels. To do this, stops are installed under the body.

The wheels are removed so that the steering rack can be pulled out.

The wheels are removed so that the steering rack can be pulled out.- Steering rod ends are disconnected from the steering knuckles.

For dismantling, use a socket head 18

For dismantling, use a socket head 18 - The exhaust pipe of the muffler is disconnected from the manifold in order not to damage the muffler corrugation when disconnecting the subframe from the body.

For dismantling are used: dodecahedron M10 and head 16

For dismantling are used: dodecahedron M10 and head 16 - Two bolts securing the steering rack to the subframe are unscrewed, as well as 4 bolts in two directions, securing the subframe to the body.

For dismantling, heads for 13, 16 and 18 are used

For dismantling, heads for 13, 16 and 18 are used - After detaching, the subframe will lower slightly. The rack is removed from the side of the right wheel. After extraction, you need to support the subframe with some kind of stop so that the silent blocks of the levers are not loaded.

The emphasis rests on the floor of the inspection hole

The emphasis rests on the floor of the inspection hole - The casing is removed, covering the drive shaft of the rack with a worm gear.

Remove the duster carefully, it is tight

Remove the duster carefully, it is tight - A disposable fixing collar is removed from the anther covering the left linkage hinge. The steering rod is disconnected from the pinion shaft.

Boot diameter 52 mm

Boot diameter 52 mm - The rack drive shaft turns counterclockwise until it stops. In this case, the pinion shaft should move to the extreme right position, sinking as much as possible into the housing on the left side. Marks are applied to the shaft, fixing nut and housing.

If you do not remove the left tie rod, the position of the marks will be different, so reassembly is also carried out with the left tie rod removed

If you do not remove the left tie rod, the position of the marks will be different, so reassembly is also carried out with the left tie rod removed - The fixing nut is unscrewed, the drive shaft is removed from the housing.

The fixing nut is unscrewed by a head on 36

The fixing nut is unscrewed by a head on 36The head for removing the shaft must be made independently or ordered by the master. In this case, it should be remembered that the diameter of the drive shaft is 18 mm (the head must pass through it), and the outer diameter of the head must not exceed 52 mm (it must pass freely into the housing hole). In the upper part of the head, cuts must be made in order to use the gas wrench to unscrew.

The fixing nut is removed very tightly, so you need good cuts for a gas wrench and a lever

The fixing nut is removed very tightly, so you need good cuts for a gas wrench and a lever - Marks are placed on the adjusting bolt to return it to its original position during assembly. The bolt is unscrewed and the pinion shaft is removed from the housing. Immediately after this, it is better to insert the drive shaft into the housing. This is done so that during further movement of the housing, the needle bearing that fixes the lower part of the shaft does not crumble.

In order to remove the gear shaft, it is enough to unscrew the bolt by 2 turns

In order to remove the gear shaft, it is enough to unscrew the bolt by 2 turns - From the side of the right thrust, you can see the retaining ring that fixes the spent bushing located immediately behind it.

To remove the bushing, you must first remove the retaining ring

To remove the bushing, you must first remove the retaining ringTo extract the retaining ring, a bar is taken, bent and sharpened at one end. It is knocked out by tapping on the bar from the side of the left thrust.

So that the ring does not warp, it must be carefully shifted around the entire circumference by moving the bar

So that the ring does not warp, it must be carefully shifted around the entire circumference by moving the bar - Following the retaining ring, the old bushing is removed. A new bushing and retaining ring are pressed in its place.

- A small chamfer is removed from the left side of the gear shaft so that it can go into the new bushing without problems.

The chamfer can be removed with a file and sanded with fine emery

The chamfer can be removed with a file and sanded with fine emery - The pinion shaft is carefully inserted into the bushing. If it does not work by screwing by hand, you can use a hammer, tapping it on the shaft through a wooden block.

Before inserting the shaft, the new bushing must be coated with grease.

Before inserting the shaft, the new bushing must be coated with grease. - All parts are generously lubricated and assembled in reverse order.

After everything is assembled, you need to check the steering wheel for ease of rotation and return to its original position. Then you need to go to the service station and make a wheel alignment adjustment so that the car does not pull to the side on the road and the tires on the wheels do not wear out prematurely.

Video: replacing the bushing in the steering rack "Volkswagen Polo" sedan

Watch this video on YouTube

Video: useful tips that will come in handy when replacing the bushing in the Volkswagen Polo sedan steering rack

Watch this video on YouTube

As you can see, you can even repair the steering rack in the garage. True, for this you need to have certain locksmith skills and the appropriate tool. As practice shows, new bushings allow you to drive another 60-70 thousand kilometers with good steering. Knock on bumps in the road disappears, there is no backlash. Many motorists note that the car behaves on the road like a new one.