The device and adjustment of the carburetor OZONE VAZ 2107

Content

- Ozone carburetor design and working principle

- Adjustment and maintenance

- Carburetor adjustment Ozone 2107

- The design of the carburetor "Ozone"

- The principle of operation of carburetors "Ozone"

- Video - Do-it-yourself Ozone carburetor adjustment

- How to adjust the VAZ 2107 carburetor yourself

- Carburetor device VAZ 2107 (diagram)

- Setting up the carburetor VAZ 2107

- Checking the condition of the strainer

- Setting up a VAZ 2107 carburetor - float chamber

- Launcher setup

- Idling setting on the VAZ 2107

For a long time, an ozone carburetor was installed on domestic cars.

Fuel supply systems of this type were produced in three versions:

- Bubble;

- Needle;

- floating mechanism.

The first two types are practically no longer used, their production has been discontinued. On cars of brands 2107, 2105, an ozone carburetor was installed, the device of which was widely used. The modification replaced the Italian invention "Weber". At the Volga Automobile Plant, the ozone carburetor received modifications, due to which they received an increase in power, more stable operation. The DAAZ OZONE carburetor, of which it is a predecessor, is more technologically advanced and was installed on cars of different families.

Ozone carburetor design and working principle

Cars of the VAZ family, equipped with ozonator carburetors, had more advantages over their predecessors. The difference was in a more durable case, in which the internal elements of the system were installed, in order to eliminate the effects of temperature effects, mechanical shocks.

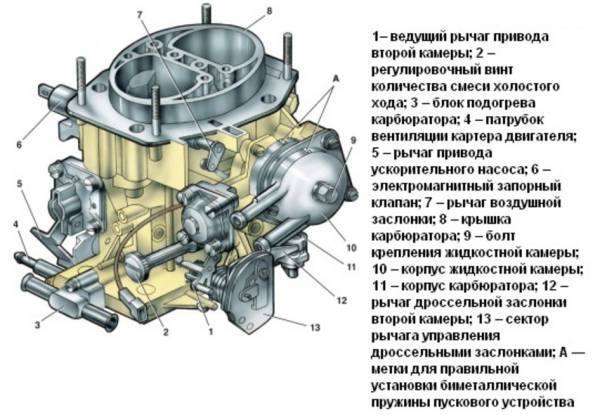

Carburetor DAAZ "OZON" (view from the side of the throttle actuator): 1 - throttle body; 2 - carburetor body; 3 - pneumatic actuator of the throttle valve of the second chamber; 4 - carburetor cover; 5 - air damper; 6 - boot device; 7 - control lever three-lever air shock absorber; 8 - telescopic rod; 9 - a lever that limits the opening of the throttle valve of the second chamber; 10 - return spring; 11 - pneumatic drive rod.

- Two main fuel accounting systems;

- Balanced float chamber;

- Idling solenoid valve, inter-chamber interaction systems;

- The air damper in the first chamber is actuated by a transmission cable;

- The pneumatic valve for opening the second chamber allows it to work only after certain engine loads;

- The accelerator pump allows you to supply a rich mixture when you press the accelerator pedal hard.

Cars use an ozone carburetor, the device of which allows the car to be operated in difficult conditions. Repair, adjustment of the ozone 2107 carburetor allows you to adjust the quality and quantity of fuel, and larger nozzles contribute to working with lower quality fuel.

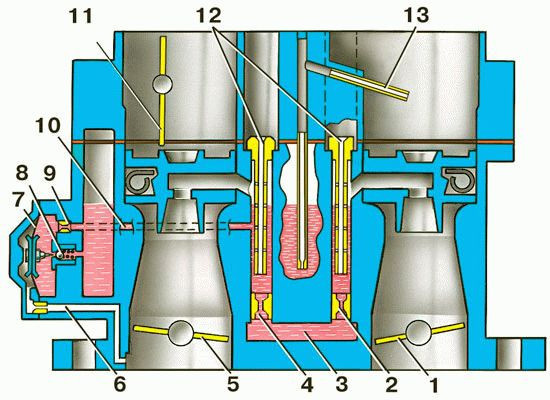

Scheme of power modes of the econostat and carburetor economizer: 1 - throttle valve of the second chamber; 2 - main fuel jet of the second chamber; 3 — fuel jet econostat with a tube; 4 - main fuel jet of the first chamber; 5 - throttle valve of the first chamber; 6 - vacuum supply channel; 7 - economizer diaphragm; 8 - ball valve; 9 - economizer fuel jet; fuel channel 10; 11 - air damper; 12 - main air jets; 13 - injection tube of the econostat.

The OZONE carburetor design is designed to get the most out of your car. The principle of operation is based on a number of systems, each of which is interconnected, is important in the system. OZONE carburetor whose device consists of the most important parts:

- The float chamber is additionally filled with fuel through a needle valve, previously filtered through a special mesh;

- Gasoline enters the working chambers through jets connecting the float chamber. Mixing of fuel takes place in emulsion wells with air suction through air nozzles.

- Inactive channels are blocked by a solenoid valve;

- To operate the vehicle in XX mode, fuel enters through the jets into the compartments of the first chamber, where it enters the fuel line;

- The enrichment of the mixture is carried out by the economizer, which is included in the work at maximum loads;

- The design of the accelerator pump is made in the form of a ball, it works due to its own weight when gasoline flows through the valve.

Adjustment and maintenance

For the stable operation of all systems, there is a maintenance schedule that must be followed. Before adjusting the ozone carburetor on cars of the 2107 brand, it is necessary to identify the faulty assembly, flush, disassemble the repairable assemblies is not necessary. It is not difficult to flush the system at home, it is important to follow the sequence of actions.

- Repair and tuning of the ozone 2107 carburetor begins with its disassembly, turning off all supply systems. It is necessary to disconnect the throttle actuator, coolant supply and fuel hose.

- Clean and wash the VAZ carburetor, modifications with ozone from the outside, inspect for mechanical damage.

- Clean the strainer and starter with low pressure compressed air.

- The flotation system is cleared of soot and visible deposits. It is important to understand that the old scale will be difficult to clean, and it can also get into the jet holes and disrupt the system.

- Flush and adjust trigger, air jets, XX system.

- We set up the carburetor components, assemble and install the device before adjustment, which is subsequently tuned to a warm engine.

Tuning and tuning are carried out according to a given sequence with screws, according to the desired fuel consumption, the dynamic characteristics of the car. The technical condition is fully consistent with driving performance, comfort when driving a car.

Carburetor adjustment Ozone 2107

The functional purpose of the carburetor in general and the Ozone model installed on the VAZ of the seventh model, in particular, is the preparation of a combustible mixture (air plus automotive fuel) and its metered supply to the combustion chamber of the engine cylinders power supply unit. Regulation of the amount of automotive fuel injected into the air flow is a rather important function that determines the optimal operating modes of the automotive engine and its long overhaul and operational periods.

The design of the carburetor "Ozone"

The Ozone carburetor, the device of which will be discussed below, is a factory option for equipping cars of the Volga Automobile Plant of the seventh model. Designed in 1979, this carburetor model is based on a Weber product developed by Italian automakers. However, in comparison with it, Ozone has significantly improved such important performance indicators as efficiency and minimization of the level of toxicity of gases emitted into the atmosphere.

So, the Ozone emulsion carburetor is a two-chamber product, characterized by the following design features:

The presence of two main dosing systems.

Excellent balance of the float chamber (pos.2).

Equip the second chamber with an economizer (enrichment device).

The presence of inter-chamber transitional systems and an autonomous idle system with a solenoid valve.

Provision of the air damper of the first chamber with a mechanical control system with a cable drive.

Equip the first chamber with an accelerator pump (pos.13) with a sprayer.

The presence of a gas removal device.

Equip the product with a pneumatic actuator (pos.39) of the damper (throttle) of the second chamber.

Equipment with a device that opens the damper at the time of starting the engine, having a diaphragm.

The presence of an accessory that determines the choice of vacuum that occurs in the process of controlling the ignition timing controller.

The structural elements of the Ozone carburetor are enclosed in a durable metal casing, which is distinguished by an increased level of strength, which minimizes the effects of deformation effects, temperature fluctuations and mechanical damage.

The solid diameter of the fuel jets ensures stable operation of the product even when using low-quality fuel and in difficult operating conditions. One of the main design flaws of the Ozone carburetor is the lack of an economizer in power modes, which leads to poor dynamic performance and low efficiency.

The principle of operation of carburetors "Ozone"

The principle of operation of a carburetor manufactured by the Dimitrovgrad Automobile Plant (DAAZ) can be described as follows:

The fuel supply device provides its supply (fuel) through the filter mesh and the needle valve that determines the filling level of the float chamber.

The first and second chambers are filled with fuel from the float chamber through the main fuel jets. In wells and emulsion pipes, gasoline is mixed with air from the respective pumps. The prepared fuel mixture (emulsion) enters the diffusers through nozzles.

After starting the power unit, the “idle” channel is blocked by a shut-off solenoid valve.

In the "idling" mode, gasoline is taken from the first chamber and then fed through a nozzle connected to an electromagnetic lock. In the process of fuel passing through the "idling" jet and the compartments of the transition system of the 1st chamber, gasoline is mixed with air. Then the combustible mixture enters the pipe.

At the moment of partial opening of the throttle valves, the air-fuel mixture enters the chambers (through the openings of the transition system).

Passing through the economizer, the fuel mixture enters the atomizer from the float chamber. In full power mode, the device enriches the emulsion.

The ball valve of the accelerator pump opens at the moment of filling with the fuel mixture. The valve closes (by its own weight) when the fuel supply is cut off.

Video - Do-it-yourself Ozone carburetor adjustment

Work on adjusting the Ozone carburetor is carried out not only in case of its (carburetor) malfunction, but also in the case of repair measures involving the replacement of some elements of this assembly. Let us consider in more detail the list of settings that are a mandatory continuation of the repair and restoration work.

Replacing the rod with a diaphragm or a damper (throttle) actuator of the second chamber requires adjustment of the pneumatic actuator.

After replacing the elements of the boot device, it is configured.

The reasons for setting the "idle" system, along with violations of the power unit, prepare the car for a technical inspection.

Replacing a float or needle valve requires adjusting the fuel level in the chamber (float).

How to adjust the VAZ 2107 carburetor yourself

The VAZ 2107 car is one of the most common representatives of the domestic "classics". Although these sedans are no longer in production, they are heavily used by a large number of motorists. Setting up a VAZ 2107 carburetor is one of the most pressing issues for every owner of such a car.

It is worth noting that membrane, float and bubbler needle carburetors are used in cars. In our article we will talk about how to adjust the float carburetor VAZ 2107 from the manufacturer "OZON".

Carburetor device VAZ 2107 (diagram)

Firstly, I would like to emphasize that individual versions of carburetors can differ significantly from each other, as they are used only on certain cars. In our case, the situation looks like this:

- DAAZ version 2107-1107010 is used exclusively on VAZ 2105-2107 models.

- The DAAZ 2107-1107010-10 version is installed on VAZ 2103 and VAZ 2106 engines with an ignition distributor that do not have a vacuum corrector.

- DAAZ version 2107-1107010-20 is used exclusively in engines of the latest VAZ 2103 and VAZ 2106 models.

The device of the VAZ 2107 carburetor looks like this:

- flotation chamber;

- autonomous idle system;

- dosing system;

- two-chamber transitional system;

- idle shutoff valve;

- throttle valve;

- separation of crankcase gases;

- economist

You simply do not need more detailed information, since it is not useful for tuning the VAZ 2107 carburetor. The carburetor of this car includes the following devices that provide and also distribute the combustible mixture:

- Support for starting and warming up the engine.

- Econostat system.

- Support for a stable level of gasoline.

- Accelerating pump.

- Engine idle support.

- The main dosing chamber, in which the fuel and air jet, emulsion tube, VTS sprayer, well and diffuser are located.

Before cleaning the VAZ 2107 carburetor and its subsequent adjustment, it must be clearly understood that it is not necessary to disassemble the elements that normally perform their functions. In particular, you must be very careful with the dosing system.

Setting up the carburetor VAZ 2107

Carburetor adjustment is carried out in the following sequence:

- First, rinse and clean the outside of the carburetor elements.

- Next, you need to check all the elements for visible defects.

- It is also very important to remove various contaminants from the filter.

- Then flush the float chamber.

- Be sure to clean the air jets.

- At the end, the floating chamber of the VAZ 2107 carburetor is regulated, as well as the starting mechanism and idling.

We want to emphasize that for this type of work it is not necessary to disassemble the carburetor. In addition, you need to understand that all elements have a self-cleaning function, and dust and dirt do not get inside.

It is recommended to check the strainer every 60 thousand kilometers traveled. It is located near the entrance to the flotation cell.

Checking the condition of the strainer

It is necessary to fill the float chamber with fuel by pumping. This will close the check valve, after which you will need to slide the top of the filter, disassemble the valve and clean it with solvent. For best results, it is also recommended to use compressed air to purge the valve.

This is interesting: Changing the oil in the Lada Vesta engine

If you decide to adjust the VAZ 2107 carburetor due to the fact that the engine has become unstable, we recommend that you first check the strainer. Problems often stem from fuel delivery problems, which can be caused by a clogged filter.

Do not use a cloth to clean the bottom of the float chamber. This will cause fibers to form on the bottom, which will clog the carburetor jets. For cleaning, a rubber bulb is used, as well as compressed air.

A pear is also used to check the tightness of the lock needle, since the pressure resulting from squeezing this object with the help of hands approximately corresponds to the pressure of the gasoline pump. When installing the carburetor cover, it is necessary to check whether the floats are installed upwards. Significant pressure will be felt during installation. At this point, you should listen to the VAZ 2107 carburetor, since air leaks are unacceptable. If you notice minimal leakage, you will have to replace the valve body as well as the needle.

Setting up a VAZ 2107 carburetor - float chamber

To adjust the float chamber, follow these steps:

- Check the position of the float and make sure its mounting bracket is not skewed (if the shape has changed, the bracket needs to be leveled). This is very important, because otherwise the carburetor float will not be able to sink properly into the chamber.

- Closed needle valve adjustment. Open the float chamber cover and move it aside. Then you need to carefully pull the tab on the bracket. It is necessary to ensure that there is a distance of 6-7 mm between the cover gasket and the float. After immersion, it should be between 1 and 2 mm. If the distance is noticeably greater, you need to change the needle.

- With the needle valve open, there should be approximately 15 millimeters between the needle and the float.

It is also not necessary to remove the carburetor from the engine to perform these steps.

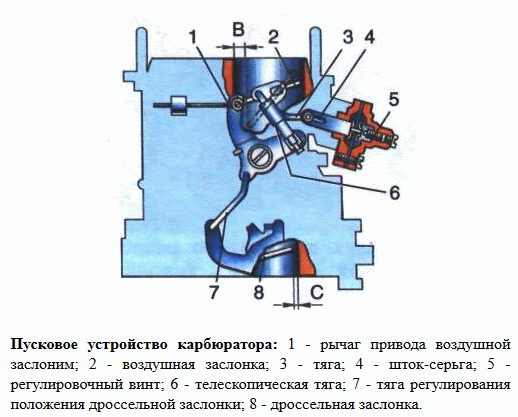

Launcher setup

To adjust the starting system of the VAZ 2107 carburetor, it is necessary to disassemble the air filter, start the engine and remove the choke. The air damper should open by about a third, and the speed level should be in the range of 3,2-3,6 thousand rpm.

After that, the air shock absorber was lowered and the speed was set to 300 less than the nominal one.

Idling setting on the VAZ 2107

Idling adjustment is made after the machine has warmed up. With the help of the quality screw, it is necessary to set the maximum speed, and the quantity screw does not need to be turned.

Then, using the quantity screw, it is necessary to achieve a speed level setting of 100 rpm more than required. After that, we start the engine and adjust the speed with the quality screw to the required value.