Variable speed drive

Content

A CVT gearbox (or CVT) is a device that transmits rotational forces (torque) from the engine to the wheels, lowering or increasing the wheel speed (gear ratio) at the same engine speed. A distinctive property of the variator is that you can change gears in three ways:

- manually;

- automatically;

- according to the original program.

The CVT gearbox is continuously variable, that is, it does not switch from one gear to another in steps, but simply systematically changes the gear ratio up or down. This principle of operation ensures productive use of the power of the power unit, improves dynamic characteristics and extends the service life of the mechanism (the experience of the Favorit Motors Group of Companies service center confirms this)

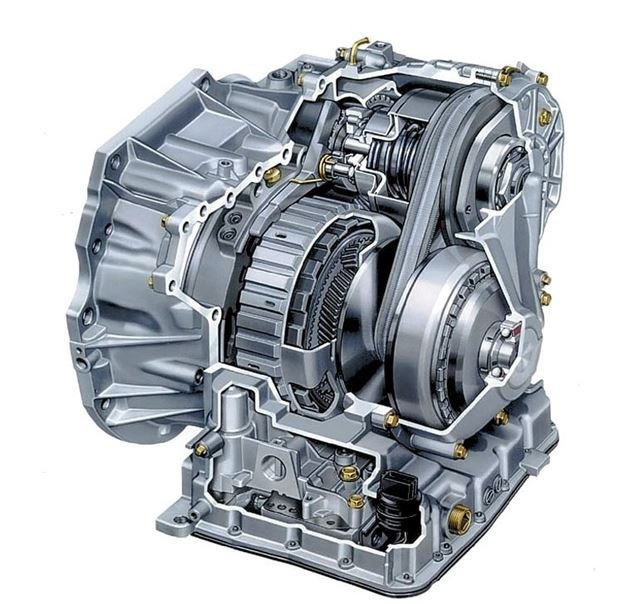

The variator box is a fairly simple device, it consists of the following elements:

- a device for asynchronizing the engine and gearbox (for starting off);

- directly the variator itself;

- a device for providing reverse (usually a gearbox);

- electronic control unit;

- hydraulic pump.

On vehicles of the latest generation, two types of variators are widely used - V-belt and toroid.

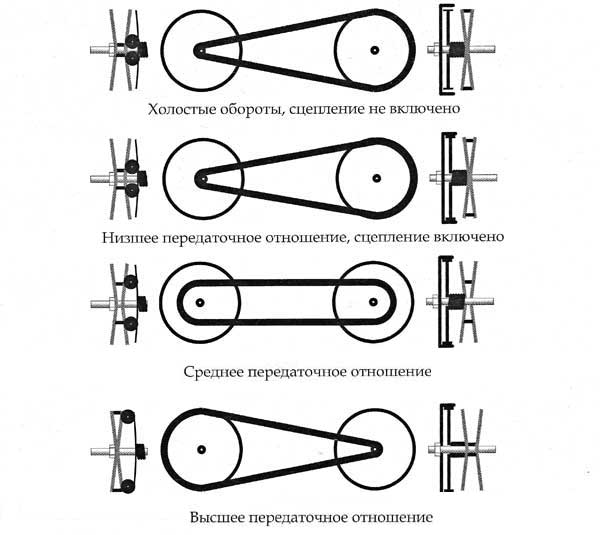

Features of the operation of V-belt CVT boxes

The V-belt CVT box is a pair of pulleys connected by a V-belt made of high-strength rubber or metal. Each pulley is formed by two specially shaped discs that can move and change the diameter of the pulley during movement, ensuring the belt moves with more or less friction.

The V-belt variator cannot independently provide reverse (reverse driving), since the belt can only rotate in one direction. To do this, the V-belt variator box is equipped with a gear device. The gearbox ensures the distribution of forces in such a way that movement in the "back" direction becomes possible. And the electronic control module synchronizes the diameter of the pulleys in accordance with the operation of the power unit.

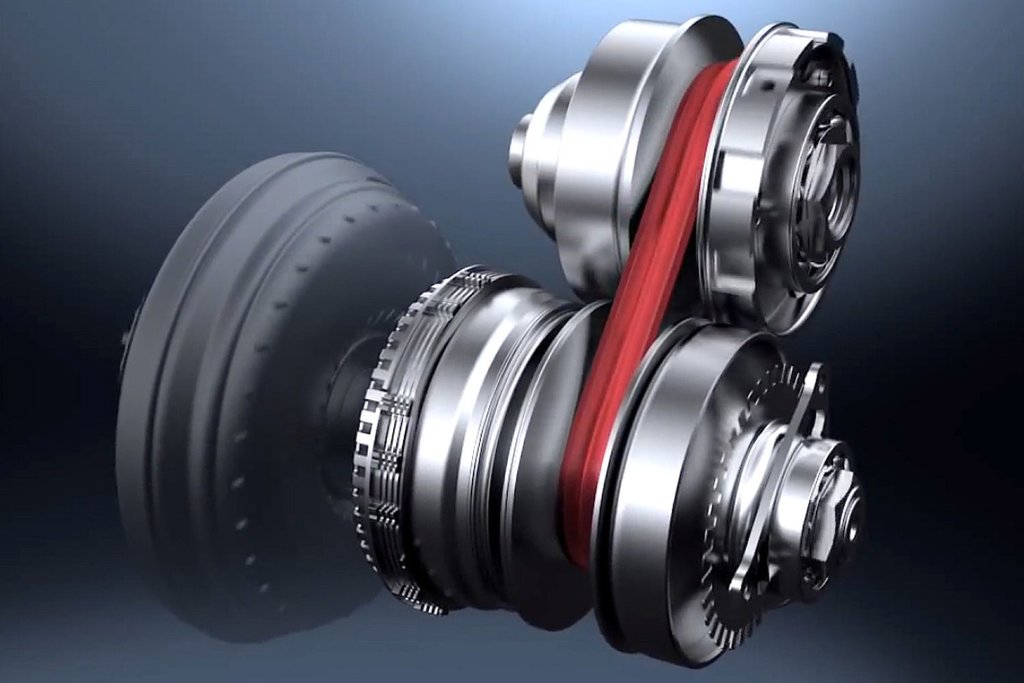

Features of the operation of toroidal CVT boxes

Toroidal variator structurally consists of two shafts having a toroidal shape. The shafts are coaxial with respect to each other, and rollers are clamped between them. During the operation of the box, the increase / decrease in the gear ratio occurs due to the movement of the rollers themselves, which change position due to the movement of the shafts. The torque is transmitted due to the frictional force that occurs between the surfaces of the shafts and rollers.

However, toroidal CVT gearboxes are relatively rarely used in modern automotive industry, since they do not have the same reliability as more modern V-belts.

Electronic control functions

To control the CVT, the car is equipped with an electronic system. The system allows you to perform several tasks:

- increase / decrease in the gear ratio in accordance with the mode of operation of the power unit;

- regulation of the clutch operation (in the role of which the torque converter usually acts);

- organization of the gearbox functionality (for reversing).

The driver controls the CVT by means of a lever (selector). The essence of the control is about the same as on cars with an automatic transmission: you just need to select a function (driving forward, driving backward, parking, manual control, etc.).

Recommendations for the operation of variators

Specialists of Favorit Motors Group of Companies note that CVT gearboxes are not suitable for freight transport due to increased loads on the engine. However, the scope of their application on passenger cars has a bright future, since the continuously variable transmission is as simple and convenient as possible for drivers.

At the same time, there are no specific tips for owners of vehicles with CVT. The car feels good both on city roads and off-road, because the decrease / increase in speed is as smooth as possible.

However, as with any type of transmission, two factors will affect the life of the variator: driving style and timely replacement of the working fluid. At the same time, it is necessary to emphasize the uniqueness of the variator maintenance: if the car is operated only in urban conditions, then an oil change is not required. When driving off-road, with trailers or on the highway at high speed, manufacturers advise changing the oil after 70-80 thousand kilometers.

Owners of cars with CVT (V-belt version) are aware that the belt needs to be replaced after 120 thousand kilometers. Even if there are no visible defects during the operation of the car, you should carefully consider this procedure, since neglecting to replace the belt can cause damage to the box.

Advantages of the variator over other types of transmissions

The CVT is considered today the most "advanced" type of transmission. There are a number of reasons for this:

- smooth shifting of the gear ratio provides better dynamics when starting off or accelerating;

- economy of fuel consumption;

- the most even and smooth ride;

- no slowdowns even during long climbs;

- undemanding maintenance (the design is quite simple, has less weight than, for example, a classic automatic transmission).

Today, an increasing number of automakers are introducing CVTs into vehicles. For example, the Ford plant has its own developments in this area, so a new generation of cars is produced with a branded Ecotronic or Durashift CVT.

The specificity of the operation of the CVT is also that when changing the gear ratio, the sound of the engine does not change, which is not typical for other types of transmissions. However, some manufacturers in the latest types of CVTs have begun to use the effect of an increase in engine noise in accordance with an increase in vehicle speed. After all, most motorists are accustomed to changing the sound of the engine with increasing power.

Each car owner chooses a car based on personal preferences, needs and financial capabilities. Vehicles with CVT are characterized by reliability and increased wear resistance, but new technologies are quite expensive. You can quickly choose a car according to your wishes and possibilities if you choose the right car dealership. Favorit Motors Group of Companies offers a wide range of models from different manufacturers at affordable prices.

Only certified car services can undertake diagnostics, repair and adjustment of the variator. At the disposal of the specialists of the Favorit Motors technical center there is all the necessary diagnostic and repair equipment, which allows you to quickly and in a short time eliminate malfunctions of the variator of any modification.

Experienced masters of Favorit Motors will perform high-quality diagnostics of the variator, establish the causes of the malfunction and eliminate it. And, in addition, they will advise on the correct operation of the CVT gearbox. The repair process is agreed with the client, and the cost of repair and restoration services is announced after the diagnosis.